Plastic Bottle Labeling Machine: The Complete Buying Guide in 2024

Do you know plastic bottle labeling machine is increasingly employed because of their fast speed, extreme precision, and easy-to-use functionalities?

Plastic bottle labeling machine has attained a market size of more than 2.7 billion dollars in 2021. Industries need this state-of-the-art solution for their products because it boosts the overall shelf value of products. Its convenience and cost-saving benefits have also made this machine an all-time favorite of various brands.

Having a plastic bottle labeling machine automates your production and also results in high-quality labeling and increased throughput. Read through this comprehensive guide to discover all the useful characteristics of this handy machine.

1.What Is A Plastic Bottle Labeling Machine?

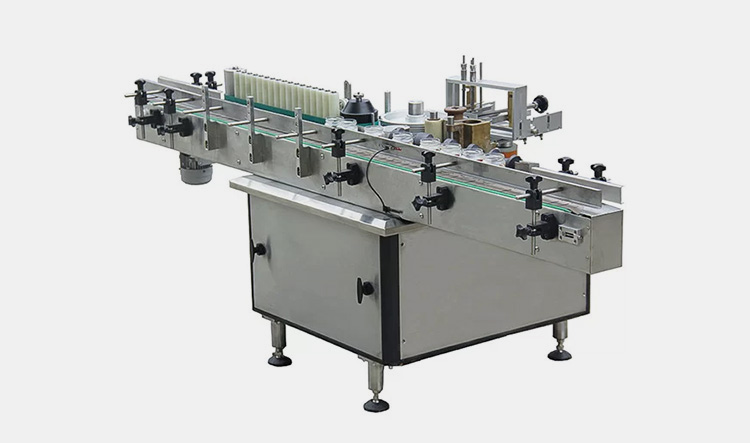

A plastic bottle labeling machine is a multipurpose piece of equipment that sticks or pastes labels over the surface of plastic bottles. This machine has a label applicator, conveyors, and sensors to guide the precise application of labels. Sometimes, it also has a glue applicator that spreads glue over the label back.

It is an important machine in product identification and brand promotion. Today, this machine has gained unique significance in the security field because it pastes tamper-evident and tracible labels.

2.What Advantages Does A Plastic Bottle Labeling Machine Bring To Production?

Plastic bottle labeling machine offers a handy solution that sticks value-added labels and provides maximum brand awareness. Adoption and implementation of this machine have plenty of advantages for productions like:

Automation

Picture Courtesy: CNC Vina

This machine offers automation to businesses because it can carry out labeling at high speeds. With advanced hardware and software components, it labels thousands of plastic bottles per hour. This leads to more products in the market generating high revenues.

Flexibility

Evolving and transformative industrial sectors require equipment that can meet ever-changing packaging needs. Plastic bottle labeling machine has acquired a special place in fulfilling these demands. This machine handles different shapes, sizes, and material labels because it is easily customized to meet the latest labeling requirements.

Brand Awareness

Labeling aids brands in creating their unique personal identity as labels are usually first to captivate customers. Hence, a plastic bottle labeling machine is best for businesses in establishing their exclusive brand profile as it sticks -creatively designed labels for maximum brand advertising.

Precision

Picture Courtesy: HERMA

Badly labeled plastic bottles are poorly received by customers and usually lead to product recalls. However, plastic bottle labeling machine is known for its highly accurate labeling. It typically pastes wrinkle-free and tear-free labels with perfect placement.

Product Tracing

Today, plastic bottle labeling machine is vital in product tracing. It applies barcodes, QR codes, and RFID tags over products to ascertain product quality and safety. These labels often minimize product counterfeiting and aid in product tracking during shipment.

3.In what type of industries is a plastic bottle labeling machine utilized?

With the evolution in packaging, next-generation labeling has attained footing in every industry. Hence, plastic bottle labeling machine has found their use in every industry where products are packaged in bottles.

Diverse applications of this machine are discussed below:

Food and Beverage Industry

Product identification has immense value in the food and beverage industry. Customers want to know what is the product they are buying. Therefore, manufacturers routinely employ a plastic bottle labeling machine for its neat and striking labeling over sauce, dressing, condiment, water, milk, cream, etc. in the food and beverage industry.

Cosmetic Industry

In the cosmetic industry, a diverse range of labels is used to give cosmetic products a sleek, captivating, and elegant look. Plastic bottle labeling machine is popular in the cosmetic industry because it processes labels with all material types and shape. Plastic bottles holding foundations, lipgloss, eyeliners, blushes, and other cosmetic products are labeled by this machine.

Personal Care Industry

It is another consumer-based industry where plastic bottle labeling machine has found its application. This machine is well-received by personal care brands because of its stylish and attractive packaging. It typically labels plastic bottles of soaps, shampoos, face masks, deodorants, gels, etc.

House-Hold Industry

For labeling detergents, dishwashing liquids, bleaches, cleaners, furniture polishes, paints, and insect repellents, a plastic bottle labeling machine is employed in the household industry. By pasting labels, this machine informs users about the expiry date, ingredients, usage, and safety instructions related to the product.

Health-Care Industry

Plastic bottle labeling machine is of prime significance in the healthcare, pharmaceutical, and nutraceutical industry. It not only communicates to consumers about the ingredients and benefits of products but also acquired a strong reputation in this industry due to its tamper-evident and anticounterfeiting labels

Automotive Industry

Different fluids such as coolants, engine oils, battery chemicals, lubricants, varnishes, glues, etc. are stored in plastic bottles. Plastic bottle labeling machine is routinely employed in the automotive industry to give automotive bottles a professional and lustrous look and to enlighten users about the safe handling of automotive liquids.

4.How does a plastic bottle labeling machine work?

A plastic bottle labeling machine is an automated unit that works in perfect harmony for precise labeling. The exact working of this equipment varies with different types of plastic bottle labeling machines. But for your information, a typical work principle of this machine is discussed below:

| Label Roll Feeding and Unwinding

Before the start of the labeling process, at first bulk label roll is loaded on the label holder by the operator. Then label unwinding plate is rotated and the label is passed over the rollers to the label dispensing unit. |

Picture Courtesy: Sheapak |

| Plastic Bottle Infeed

Plastic bottles are placed on the moving conveyors at precise intervals for accurate labeling by a plastic bottle unscrambling machine or manually. |

|

| Label Dispensing and Pasting

When the plastic bottle reaches the labeling unit, a sensor detects its proximity to the labeling head. The labels are cut from the roll using dies and are stuck over the plastic bottles by the labeling head. Other equipment types have glue applicators that apply glue to plastic bottles and then paste labels over them. After labeling, label presses, rollers, and brushes remove crinkles, folds, and creases from labels. |

Picture Courtesy: HERMA |

| Plastic Bottle Unloading

After testing the label quality, plastic bottles that pass quality tests are removed from the labeling unit and transported to the plastic bottle collection unit or other machines down the line by the conveyor systems. |

Picture Courtesy: iBottling |

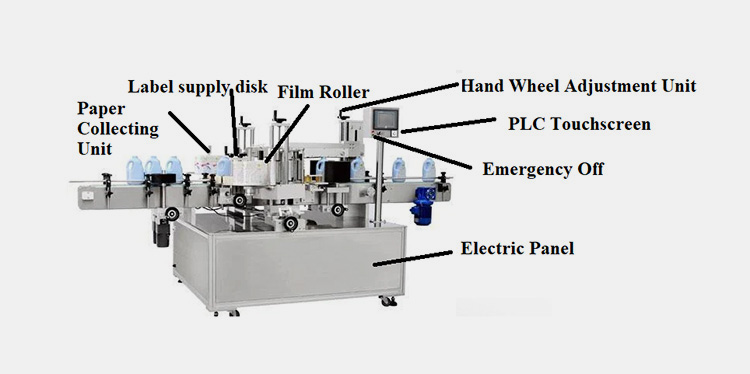

5.What are the different components of a plastic bottle labeling machine?

Plastic bottle labeling machine consists of advanced labeling units- performing specific label handling and dispensing functions. Below are some details of important components present in this machine.

Hand Wheel Adjusting Unit

It is the part that aids workers in physically fine-tuning label settings like label alignment, placement, and tension. It has a hand wheel that is rotated to make accurate adjustments in labeling operation and is linked with the label application unit.

Paper Collecting Unit

It is the component that receives back liners after they are peeled off the labels. This spool rotates and rolls liners around itself. This prevents the messiness and paper build-up on the machine.

Label Supply Disk

It is a label unwinding system that rotates to release label film from the roll. The label film is placed on the label roll holder. As the label supply disk spins, the label film is gradually unwound from the roll.

Touch Screen

It is a smart and intuitive component of a plastic bottle labeling machine that aids in the automatic modification of labeling parameters. Data recipes are also stored in its processor that allows quick format change with one swipe of a finger.

Film Rollers

They are responsible for keeping the film under proper tension and also stopping the film from spillage and slacking. Film tension also helps in accurate label placement.

Conveyors

For the transportation of plastic bottles from one unit to another conveyors are employed in the plastic bottle labeling machine. They are formed by drive belts, rollers, or chains and are powered by motors that assist in the synchronized movement of conveyors.

Emergency Light

It is the safety component present in several plastic bottle labeling machines. Its function is to light in case of component failure or accidents. Emergency light grabs the immediate attention of operators and allows them to take necessary safety protocols.

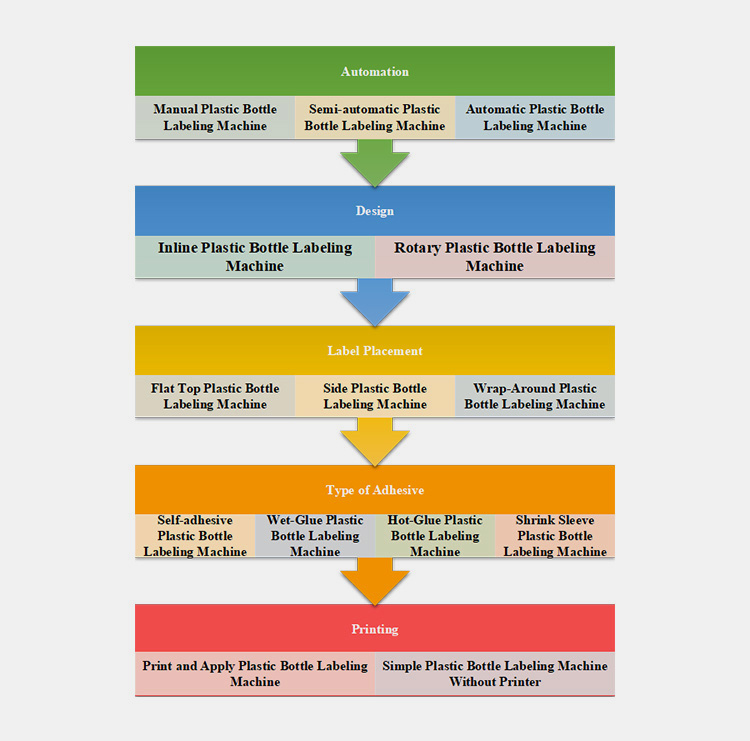

6.How does a plastic bottle labeling machine categorize?

A plastic bottle labeling machine is an adaptable piece of equipment that handles and places labels in different orientations and positions over plastic bottles. For these diverse applications, various kinds of plastic bottle labeling machines exist in the market.

Major classes of this machine are penned below:

Categorization on Automation

Manual Plastic Bottle Labeling Machine

It is the first form of plastic bottle labeling machine and is known for its simple design and ease of use. It is a portable machine that is ideal for a home-based labeling business where a small number of plastic bottles are processed daily. Handwheels and rotating levers are present in this machine for plastic bottle labeling by hand.

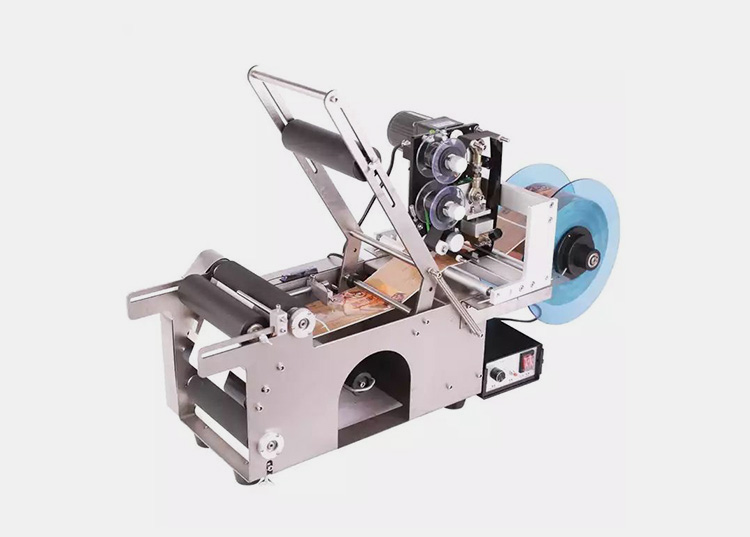

Semi-automatic Plastic Bottle Labeling Machine

This machine is a benchtop model and performs automatic plastic bottle labeling. However, workers load and unload plastic bottles by hand in this equipment. Workers start the labeling process by pressing the bottom pedal, button, or other level control. This machine is suited for medium-scale businesses where thousands of plastic bottles are labeled by hour.

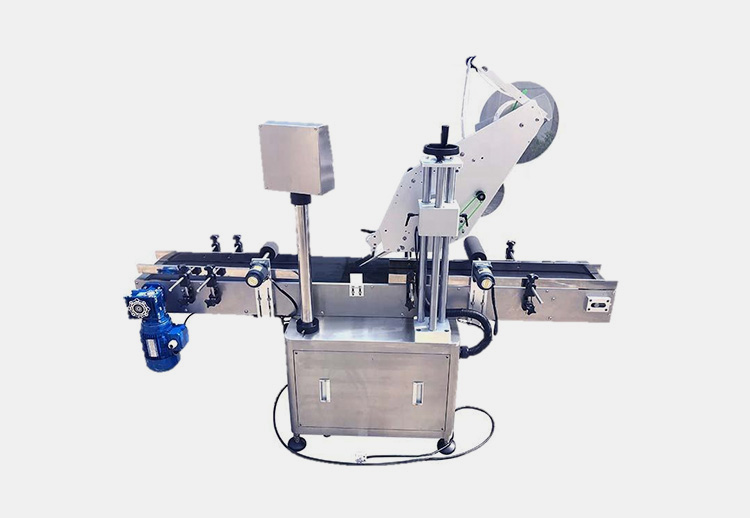

Automatic Plastic Bottle Labeling Machine

It is the latest form of plastic bottle labeling machine that completely executes every labeling step by itself. State-of-the-art gadgets and controls are responsible for precise label placement and orientation. The HMI touch screen in this machine allows easy and quick change of settings while alarms and sensors aid in monitoring the safety status of a machine.

Categorization on Design

Inline Plastic Bottle Labeling Machine

This plastic bottle labeling machine has a straight-line design in which plastic bottles travel to the labeling head one at a time. Hence, the productivity of this machine is lower than its rotary counterpart. However, this machine has a small number of parts thus maintaining and integrating this machine is undemanding.

Rotary Plastic Bottle Labeling Machine

Picture Courtesy: Quadrel

In a rotary plastic bottle labeling machine, a star-wheel or turntable is present that gives this machine its circular configuration. Multiple plastic bottles are labeled simultaneously using rotary wheels. These bottles are held by clamps and the star-wheel rotates to correctly align bottles to the label applicator. This machine offers more production capacity.

Categorization on Label Placement

Flat Top Plastic Bottle Labeling Machine

This machine pastes a single strip of label over the flat surface such as the top lid or caps of the plastic bottles. This is done to avert product tampering. It is also used for sticking barcodes, RFID, and tracing numbers over the flat side of plastic bottle caps.

Side Plastic Bottle Labeling Machine

The function of this machine is to stick labels over the sides or arcs of plastic bottles. This machine labels one to two panels of plastic bottles usually at the front or back side. It is used for improving product display and information. This machine offers flexibility as it can handle a variety of label shapes and materials.

Wrap-Around Plastic Bottle Labeling Machine

Picture Courtesy: NeuraLabel

This machine pastes labels by rotating them over the plastic bottle surface. This machine has simpler operation than pick-and-place equipment and offers an identical product display to a shrink-labeling machine. It is typically employed for labeling the circumference of a round plastic bottle but can be used for labeling other container shapes with few modifications.

Categorization of Type of Adhesive

Self-adhesive Plastic Bottle Labeling Machine

This machine is the most widely used type of plastic bottle labeling machine as it can meet the fast-evolving labeling needs of industries. It applies a broad range of labels varying in their designs, colors, and textures. It does not require glue for labeling thus resulting in mess-free labeling. This machine is lucrative solution than a shrink-labeling machine.

Wet-Glue Plastic Bottle Labeling Machine

Picture Courtesy: china automatic lab

This machine applies liquid glue to labels before pasting them. The glue is liquid at room temperature. It is known for its use in the beverage industry since it sticks complex shape ornate labels over rigid plastic beverage bottles. More than one label is applied by this equipment to complex-shaped plastic bottles.

Hot-Glue Plastic Bottle Labeling Machine

The glue that is solid at room temperature is first melted by heat in this machine. Then this glue is applied to plastic bottles for adhesivity by glue dispensing nozzles. This machine is ideally used for wrap-around labeling over round as well as square-shaped plastic bottles.

Shrink Sleeve Plastic Bottle Labeling Machine

It is the most modern type of plastic bottle labeling machine and is becoming extremely popular in industries due to its full-body labeling. This machine puts thermoplastic over plastic bottles which after passing through a heat tunnel, this thermoplastic shrinks to fit the contours of plastic bottles. It is a more expensive option than other plastic bottle labeling machines but makes for its utmost brand advertisement.

Categorization on Printing

Print and Apply Plastic Bottle Labeling Machine

Picture Courtesy: ALTech UK

As this machine has built-in high-definition printers, so, it is employed for printing variable information like tracking numbers, batch numbers, addresses, etc over plastic bottles. This machine supports custom labeling and has a higher processing time than a simple plastic bottle labeling machine

Simple Plastic Bottle Labeling Machine Without Printer

Picture Courtesy:Herma

This machine does not have a printer so instead uses pre-printed labels. It pastes informative and decorative labels that are pre-designed by designers. It has minimal parts thus providing ease of maintenance. Moreover, this machine labels more plastic bottles in a short span.

7.What Is A Plastic Bottle Labeling Machine Production Line?

Several machines are present in the plastic bottle labeling machine production line, that contribute to high-quality packaging. These machines systematize packaging by executing specific tasks. The order of these instruments is:

|

Plastic Bottle Unscrambler

This machine has a hopper in which plastic bottles are loaded in random order. The bottle collecting systems receive bottles from the hopper and align them in standing position, one after the other with suitable gaps for filling and other packaging processes. |

|

Counting and Filling Machine

With a light beam, photoelectric sensors, vision systems, and a vibratory chute, the counting and filling machine accurately counts and fills tablets, pills, beads, capsules, pearls, confectionaries, and gummies in plastic bottles. |

|

Desiccant Inserter

In humid environments, hygroscopic and sensitive chemical products absorb moisture consequently losing their quality. A desiccant inserter is a machine that puts small desiccant packs inside the plastic bottle to prevent the soaking of water vapors. |

|

Automatic Capping Machine

This machine uses torque or force to tightly place caps over the plastic bottles. Twisting forces securely attach caps to decrease product contamination and leakage. Grippers hold the plastic bottles in place while capping heads in this machine exert uniform torque for twisting caps. |

|

Induction Sealing Machine

For fully sealing plastic bottles, an induction sealing machine uses electromagnetic current or heat for melting foil or liner. These materials are typically found on the inner surface of caps. The melted material sticks to the opening of plastic bottles to create hermetic and airtight seals that prevent product spillage. |

|

Plastic Bottle Labeling Machine

Industry utilized this machine for gluing plastic or paper labels over plastic bottles. This machine applies labels to oval, square, round, cylindrical, and pump plastic bottles. HMI controller, labeling head, sensors, and conveyors execute the labeling process. |

8.What Is The Difference Between Vertical And Horizontal Plastic Bottle Labeling Machines?

Vertical and horizontal plastic bottle labeling machines have principal function labeling. However, their labeling orientation and labeling process are vastly different from each other. These differences are discussed in detail below:

| Vertical Plastic Bottle Labeling Machine | Horizontal Plastic Bottle Labeling Machine |

|

|

| In this machine, labels are pasted in the vertical direction over the plastic bottle. It labels plastic bottles parallel to their length and is employed for labeling the sides of plastic bottles or wrapping around their vertical circumference. | This machine sticks labels in the horizontal direction. If labeling of plastic bottles perpendicular to their length is required then a horizontal plastic bottle labeling machine is the best bet. It labels plastic bottles at the top or bottom side. |

| It is highly recommended for labeling round or cylindrical plastic bottles. | It is ideal for processing square, flat, or rectangular plastic bottles. |

| Labels are pasted over the circumference of plastic bottles as they rotate in a vertical labeling machine. | Labels are typically glued to the flat side of plastic bottles as they move through the labeling unit. |

| It mostly applies product information labels that improve product shelf appearance. | It usually applies barcodes, QR codes, and other tracible labels over plastic bottles. |

| Plastic bottles move on the conveyor in a standing tall position in this machine. | Plastic bottles are loaded in a horizontal lying down position on the conveyors. |

9.What other products a plastic bottle labeling machine can process?

A plastic bottle labeling machine is a flexible automation that is also used for labeling other packaging containers besides plastic bottles. These product containers include:

Glass Bottles

Different industries use glass bottle packaging to give their products a classy and elegant look. Plastic bottle labeling machine labels glass bottles with premium quality labels. This machine is specifically designed for plastic bottles and can process glass bottles with just a change of a few labeling parameters.

Jars

As the dimensions and geometries of plastic and glass jars are identical to plastic bottles, so, the plastic bottle labeling machine easily accommodates jar packaging. In the food industry, this machine pastes labels over jars of honey, jams, dressings, etc.

Cans

This machine is frequently used in the beverage industry for labeling soft drinks, juices, and other beverage cans. The shrink plastic bottle labeling machine is adjusted to shrink sleeve label beverage cans with high-quality images and logo designs.

10.What are the frequent issues in a plastic bottle labeling machine?

Common problems in a plastic bottle labeling machine severely impact the performance of production and cost manufacturers a lot of money. But these problems are easily resolved by following some guidelines.

| Cause | Solution | Picture |

| Skewed Labels | ||

| Labels are not designed according to the curvature of plastic bottles. Former have minute tapering that can lead to label skewness. | It is best to design labels with little curves so that they are matched with bottle shapes. |

Picture Courtesy: Cognex |

| Flagging of Labels | ||

| Sometimes, the size of labels is too big as than circumference of plastic bottles | It is best to design labels leaving 1/8-1/4 inches of space around the sides of plastic bottles to accommodate minute imperfection in labels. |

Picture Courtesy: The Label Printers |

| Wrinkles in Labels | ||

| Uneven application of labels causes wrinkling. Dirt or dust also causes wrinkling in labels. Sudden temperature change is also the reason for wrinkling. | Ensure even and uniform application of labels. Clean the surface of the plastic bottle before label pasting. Prevent sudden temperature change during labeling. |

Picture Courtesy: CTM Labeling |

| Labels are not Gluing to Plastic Bottles | ||

| Adhesives are not compatible with the surface of plastic bottles and cause label non-stickiness. Temperature change causes brittlely and tackiness of adhesives leading to poor gluing. | Use adhesives that are completely compatible with the characteristics of plastic bottles. Minimize temperature changes to ensure high-quality labeling. |

Picture Courtesy: CNET |

| Adhesive Accumulation on Plastic Bottles or Labels | ||

| A high amount of glue could result in the buildup on plastic bottles as well as labels. Labels slip while their application causes adhesive accumulation. The use of freshly printed labels could also lead to adhesive accumulation. Presence of glue on hopper prongs. | Adjust the amount of glue by calibrating the glue applicator. Adjust equipment to ensure proper label tension. Use aged labels for pasting. Fully clean hopper prongs before labeling. |

Picture Courtesy: Productos Colcar |

11.What Are Some Common Maintenance Guidelines For A Plastic Bottle Labeling Machine?

Regular maintenance of a plastic bottle labeling machine is directly proportional to its long operational life. Therefore, it is suggested that manufacturers should encourage their operators to perform daily schedule maintenance.

Some common maintenance guidelines are given below that you might find useful.

| Daily Maintenance | Clean the plastic bottle labeling machine daily to get rid of sticky residue, dust, or label buildup.

Check for failure in any component. Lubricate all moving components to prevent defects due to friction. Align the labeling parts and other components for smooth labeling. Tighten all nuts, bolts, screws, and other moving joints. |

| Weekly Maintenance | Thoroughly inspect and calibrate sensors to ensure their proper working order.

Inspect label roll and other labeling components for damage and if necessary replace them. |

| Monthly Maintenance | Carefully examine every part of the electric cabinet for wear and tear to prevent electric incidents. Also check for old and defective switches, cables, wires, etc.

Check the air pipes of the pneumatic system and ensure that air pressure is at a specific threshold as mentioned in the manufacturer manual. |

| Yearly Maintenance | Perform a detailed and full examination of a machine under the supervision of a skilled technician.

Replace old parts. If the latest updates of machine software are available then update it. |

12.How To Choose A Plastic Bottle Labeling Machine That Is Suitable For Your Production?

The selection of a plastic bottle labeling machine is a critical decision that can bring about an excellent match between the equipment and your production. However, poor planning before purchase results in bad choices that could cause serious loss of money.

Some important points that must be considered while selecting are:

Determine Your Production Needs

Picture Courtesy: STM Pack

Plastic bottle labeling machine with high labeling capacity typically has a higher price. Selecting a higher processing machine while your labeling requirement is low often results in a waste of money. Thus, having an idea about your production needs and volumes will justify your budget without going overboard.

Label and Bottle Characteristics

Each plastic bottle labeling machine handles specific types of labels and bottles. Therefore, it is essential to determine what type of label and plastic bottle you will process. Purchased machine with poor compatibility with label and bottle properties leads to a change in equipment or label and plastic bottle.

User-Friendly Technology

When it comes to labeling every second matters and easy-to-use technology saves a lot of time. So, opt for a plastic bottle labeling machine that is designed with easy-to-use controls and gadgets because hard-to-use controls often create confusion consequently lowering labeling quality.

Ease of Setup and Format Change

Consider buying a plastic bottle labeling machine that is easily installed to minimize the extra expense needed for hiring professional technicians to set up your machine. Moreover, choose equipment that has quick changeover as lengthy changeover often slows down production. But a plastic bottle labeling machine with rapid changeovers can drastically boost your production efficiency.

Warranty and After-Sale Support

Since equipment could unexpectedly experience failure, therefore, it is recommended to always go for a manufacturer that provides a high warranty period and subpar aftersales support. Ongoing customer support saves you from lengthy downtimes and expensive repairs because the manufacturer of equipment is always ready to lend you support.

Conclusion

Due to the high demands of consumers for labeled products, plastic bottle labeling machine has acquired traction in the modern industrial world. Its automation, flexibility, brand promotion, and high-speed label make this machine the first choice of manufacturers when it comes to labeling. If you are interested in buying this machine, visit our “Allpack” website for pricing details. We offer superior-quality solutions that are seamlessly added to productions to generate the best-quality labeling.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide