Pill Presser Machine: The Complete Buying Guide In 2024

Are you looking for a pill presser machine? Are you interested in investing in pill presser machine? Do you feel difficulty in finding the best type of pill presser machine for your production setup? So, this is the right platform where you will get detail information regarding a pill presser machine, its operation and the types of pill presser machine available globally.

Mid Speed Double Sided Pill Presser Machine - Picture Courtesy: United Pharmatek

This buying guide will give you complete assistance and guidance regarding it and will help in resolving your queries. Read the complete blog to take the most of it.

1. What Is A Pill Presser Machine?

Pill Presser Machine - Picture Courtesy: Shanghai Pharmaceuticals Co. Ltd.

A pill presser machine or a tablet presser machine is generally a modified automated way of compressing granules or powders into uniformly shaped structures with defined weight. Pill presser machines according to their usage are important for both small and large-scale industries and are widely used in the pharmaceutical, food, cosmetic, chemical, and agricultural industries.

2.What Are The Applications Of A Pill Presser Machine?

Pill presser machines are widely used in pharmaceutical industries but they also somehow have other applications including

Pharmaceutical Industry

Medicine Pills - Picture Courtesy: iStock

Pill presser machines are extensively applied in pharmaceutical industries where various types and sizes of pills and tablets are manufactured. A variety of medicines, vitamin supplements, oral medications, etc. are easily formed using a pill presser machine. The most important advantage of using a pill presser machine is that it maintains the dosage of drugs and forms uniform-sized pills throughout the process.

Food Industry

Chocolate In A Pill - Picture Courtesy: Bloomberg

Other than the pharmaceutical industry, pill presser machines are also used in food industries for the production of flavored and eatable pills. Pills with chocolate, supplements and other nutrients that are mostly consumed by children are produced using a pill presser machine.

Cosmetic And Chemical Industry

Cosmetics Pills And Capsules - Picture Courtesy: Freepik

Various types of chemicals and cosmetic supplements are available in the form of pills and tablets. They can either be used for personal protection or research purposes. These chemical and cosmetic pills are uniformly produced using both manual and automated pill presser machines.

Agricultural Industry

Pesticides, insecticides, and other important products that are used for the growth of an agricultural farm are mostly available in pills and tablets compressed by a pill presser machine. This not only compact the size of the packaging but also gives an attractive look to it that can impress the customer.

3.What Benefits Can We Get From A Pill Presser Machine?

Some of the advantages that can be taken from a pill presser machine are

Precision

Drug Products - Picture Courtesy: Verywell Health

Pills are directly associated with human life and with increases in any of the active pharmaceutical ingredient it can directly affect the individual. In this regard the most important benefit a pill presser machine offers are that it precisely and accurately fills the pill with standard dosage. Each of the pills shows uniformity and appears to be of similar shape and size.

Easy To Operate

Pill Presser - Picture Courtesy: CBC

A pill presser machine is much easier to operate and does not requires and prior expertise. It can simply be operated by reading its operational manual and having a basic training from the manufacturer.

Extended Shelf Life

Pill Expiry Dates- Picture Courtesy: Dr Fox

Pills formed by a pill presser machine are highly resistive against the environmental conditions including moisture and humidity. This increases the sensitivity of these pills and extends their consumption shelf life.

Customization

Pill Press Dies

One of the unique advantages a pill presser machine offers is that it contains option for customization according to the size and shape of pills. The manufacturer can easily replace the mold and die to the required desired shape. No new machine is required for different type of pills.

Quality Products

Quality Vitamins And Supplements - Picture Courtesy: Healthline

Pills that are taken out of a pill presser machine are of high-quality standards and shows greater uniformity in each of the product. Each of the required dimensions is monitored and controlled according to the quality control processes to produce best products out of it.

4.What Is The Working Principle Of A Pill Presser Machine?

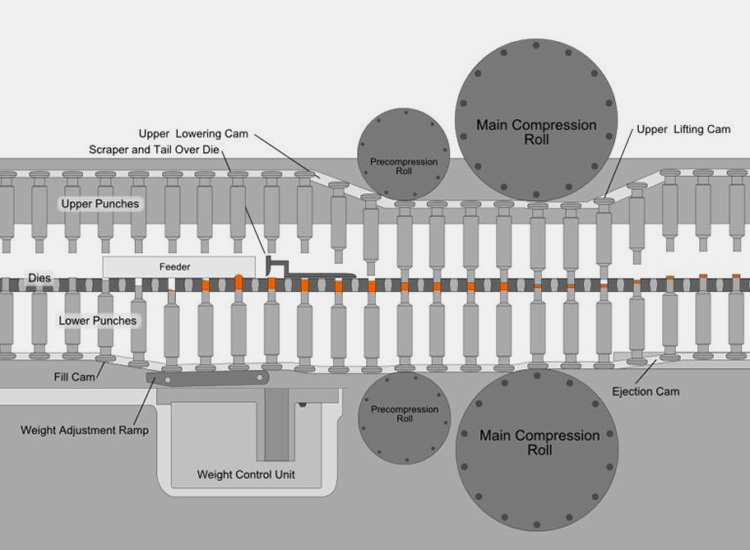

Working And Principle Of Pill Presser Machine - Picture Courtesy: Pharma Guideline

The operating procedure of a pill presser machine is done in a simpler way and follows following important steps

Initially, the powdered or granular raw material is inserted into the feeding hopper of a pill presser machine, and from here the filling lines take this material to the die cavity.

In the second step, when the material reaches the die cavity specific amount of material settles in the cavity of the die to form standard pills or tablets

Once the material gets settled down, the compressor rollers start their operation and compress the material so that all the sides of the die cavity are filled properly.

After compressing, both the upper and lower punches controlled by a turret move in both horizontal and vertical directions to form a pill. This movement continuously presses the pills so that their size gets uniform.

Finally, the lower punch pushes the pill and ejects it out from the system so that it can be packed in the further procedures.

5.What Are The Main Components Of A Pill Presser Machine?

Components Of A Pill Presser Machine

Hopper

A hopper is present at the top of a pill presser machine and is the area in which the raw material in terms of powder or granules is inserted. From here the material flows towards the feeding mechanism in a highly precise and controlled manner.

Rotary Table

The rotary table is the place which contains the die cavity and continuously rotates for large number of pills compressing and ejecting.

Adjusting Handle

The adjusting handle of a pill presser machine involves adjusting of both die cavity size and material compressing pressure. Speed of the production is also controlled through these adjusting handles.

Discharge Port

Once the pills are completely manufactured these are ejected out of the system through these discharge ports or discharge chute. From here the pills are carried for packaging and labeling processes.

Die

Die Of A Pill Presser Machine - Picture Courtesy: LFA Tablet Presses

Die or die molds are the most important part in a pill presser machine. Different sizes of pills are formed using different types of die cavities. A pill presser machine can be customized by just changing these dies so that other type of pills can be produced.

Punches

Tablet Compression Tooling- Picture Courtesy: VORTEX

Both lower and upper punches of a pill presser machine are associated with the die cavity and are used to define the shape of a pill. These punches are responsible to compress the pill according to the size and shape of die so that no cavity or empty space remains during ejecting process.

Electrical Operational Appliances

A pill presser machine includes operational panel, danger or emergency button, electrical appliance box and power plug that are used to control the machines operation and processes. These are present on the body of a pill presser machine.

6.What Are The Types Of Pill Presser Machine Available Globally?

According to the number of dies there are three types of a pill presser machine. These are

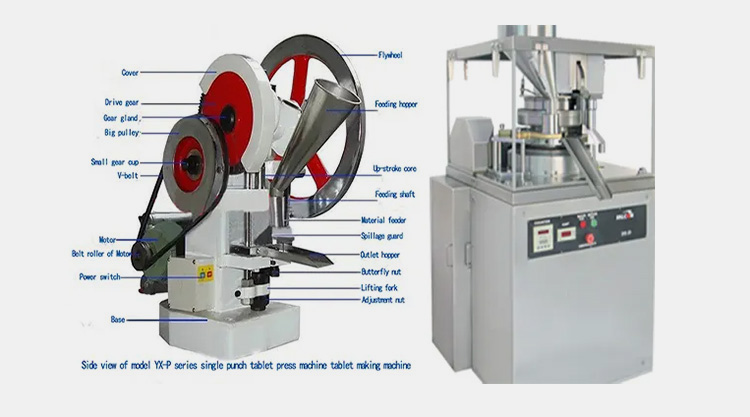

Single Station Pill Presser Machine

Single Station Pill Press - Picture Courtesy: CapPlus Technologies

A single station pill presser machine is one of the simplest one for pressing of pills and tablets. It has a single die cavity and a pair of upper and lower punches in it. It is mostly used in small scale industries but is available in both manual and automated modes of operation.

Working Of A Single Station Pill Presser Machine

Initially the powdered or granule raw material is inserted either via hopper or manually into the die cavity of a single station pill presser machine.

The punches are then forced together for doing the compressing step.

Finally, the formed pill is ejected out of the system manually and the die is cleaned before each of the step to avoid any deformation.

Multi Station Pill Presser Machine

Multi-Layer Pill Press Machine - Picture Courtesy: PTK-GB

For large scale industries where production capacity is in thousands, multi station pill presser machine is used due to its accurate and high productivity results. The machine has more than one filling station in it. Each of the pill formation station has its own die cavity and pair of upper and lower punches. Number of pills can be formed in a second of time.

Working Of A Multi Station Pill Presser Machine

In the first step the powdered or granule raw material is filled into the hopper present at the top of a multi station pill presser machine.

The material automatically travels through the filling mechanism and then enters the die cavity of machine.

Each of the die is filled with raw material their respective punches are then forced together for doing the compressing step.

Finally, the formed pills are ejected out of the system through the discharge port or discharged chute.

The machine automatically cleans all the residual and inserts it back to the feeding mechanism to avoid spillage and wastage.

Rotary Pill Presser Machine

Pill Press Rotary Press Machine - Picture Courtesy: Sino Pharmaceutical

A rotary pill presser machine is just like a multi station pill presser machine. The only difference is that it has a rotating turret in it that has multiple sets of punches and their respective dies. The continuous rotation allows formation of pills and tablets and their ejection.

Working Of A Rotary Pill Presser Machine

Firstly, the powdered or granule raw material is filled into the hopper present at the top of a rotary pill presser machine.

The material automatically travels through the filling mechanism and then enters the die cavity of machine.

Each of the die continuously rotates around a turret and is filled with raw material. The punches are then forced together to compress the raw material and formation of pills.

Once the pills are formed, they are taken out of the system through the discharge port or discharged chute.

The machine automatically cleans all the residual and inserts it back to the feeding mechanism to avoid spillage and wastage.

7.What Is The Difference Between Traditional Pill Pressing Method And A Pill Presser Machine?

Pill Presser Machines - Picture Courtesy: Pharmaeducation

Some of the differences between a traditional pill presser method and pill presser machines are

Operation

Traditionally the powder or granule is inserted into the pill pressing machine and then pressed with manual force to form a pill.

Whereas, a pill presser machine involves complete automated processes from feeding of material to die cavity to its compression and then finally ejection.

Productivity

Small or house industry used the traditional method of pill pressing as it produce just hundreds of pills in hours.

Thousands of pills can be produced in a second of time without any deformation or destruction using a pill presser machine.

Efficiency

Pills with defects and no uniformity are produced from a pill presser machine. Reverse process is mostly carried out due to inaccuracy in forming process.

Pill presser machines are highly accurate and efficient in their process that different sizes and shapes of pills can easily be produced in a single machine.

8.What Are The Auxiliary Machines Associated With A Pill Presser Machine?

Pill presser machine involves auxiliary machines to complete the forming and packaging of pills in an efficient manner. These machines are

Pulverizing Machine

High-Speed Pulverizing Machine

In the pill formation process, a pulverizing machine is the one from which the process starts. A high-speed pulverizing or grinding machine is capable of crushing granules that are hard in nature. This gives fine particles as a result of grinding that can easily be carried to pressing process.

Vibro Sifter

Vibrating Sifter

A vibro sifter or a vibrational sifter works on the principle of vibration and used to remove all the left large sized granules and also separates them from the system.

Wet Granulator

High-Speed Wet Mixing Granulator

Once uniform size granule raw material is obtained, it is passed through wet granulators which can mix the material in a homogenous manner. Large sized particles are eliminated from the process using a wet granulator or grinding machine.

Roll Compactor

Roller Compactor - Picture Courtesy: Pharmaceutical Networking

Roller compactors are used to press the material so that they can be compact in desired shape. Regular movement of material on rollers produce an internal pressure within the machine and makes the material to flow in a synchronized manner

Fluid Bed Dryer

Fluid Bed Processor – Picture Courtesy: Senieer

Medicines in form of pills are highly sensitive in nature. Any content of moisture or humidity can change the entire nature of pills. A fluid bed dryer is used to remove all the moisture present in the raw material to preserve it and to make it useable for a longer period.

Pharmaceutical Mixer

High Efficiency Pharmaceutical Mixer

Pills that have multiple types of chemical compositions in it are usually mixed in a mixer or blender so that each of the material gets uniformly distributes according to the composition of pills required. These mixers or blender are found in the initially and foremost stage of pills formation.

Tablet Deduster

Tablet Deduster

Once the pills are pressed in the pill presser machine they are then passed through a tablet deduster where the extra material, dust or particles are completely removed from the surface of a pill. The machine is highly precise that is send fine pills from further coating and packaging purpose.

Pill Coating Machine

Semi-Automatic Pill Coating Presser - Picture Courtesy: Shanghai Pharmaceuticals

Pills and tablets that have coating on their outer most layer uses pill coating machine for its application. This coating gives a thin layer of protein, sugar or other material to protect it from environmental conditions.

Pill Counting Machine

Tablet Counting Machine

Before the packaging process, tablet counting machines are present to verify the packaging of total numbers of pills so that no over or under packaging can be performed. This makes the packaging to be done according to standards and to make it look pleasant to the customer.

Blister Packing Machine

Blister Packing Machine - Picture Courtesy: Hualian Pharmaceutical Machinery

For final packaging of the counted pills, blister pack machines are used that packs them in plastic and aluminum foils to protect their nature and extend their shelf life. Packaging also gives them a pleasant look that attracts the customers.

Cartoning Machine

Cartoning Machine - Picture Courtesy: SED Pharma

The blistered pills are finally packed together using a cartoning machine in large boxes to make it easy in transportation around the globe.

9.How Pill Presser Machine Cope Up With Different Sizes Of Pills And Tablets?

Dies And Punches - Picture Courtesy: Shamdew

The most important benefit of a pill presser machine is that it can easily cope up with different sizes of pills and tablets and does not requires an additional machine for it. This is in a way that a single pill presser machine has wide options to insert and adjust punches and dies of different sizes in it. Irrespective of their shapes, one can directly equipped the machine with these dies and their respective punches.

The tools and dies are changed in a short time and does not creates any machine down time. Also, the rotating turret in a rotary pill presser machine allows the insertion of different types of die set at same time. Each of the step can be keenly monitored and checked to maintain the quality and accuracy.

Conclusion

Finally, concluding the discussion on a note that you would now be completely familiar with what is a “Pill Presser Machine” and how it can be beneficial for any processing line. All pack provides variety of pill presser machines to its customers globally for food, pharmaceutical, agricultural and chemical industries. If you still feel any query related to a pill presser machine, you can directly contact us 24/7. Our representatives are always available for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide