Multi-lane Liquid Packaging Machine: The Complete Buying Guide In 2024

Starting from morning shower to light brunch and night skincare, liquids are essential parts of our lives in form of shampoo, ketchup, lotion, and much more. Seems relatable? Well, it must be! That's why both consumers and manufacturers are in struggle to make the availability of these liquids possible every time. The former looks for handy way, while as, the latter is striving to provide these materials in best attainable way while reducing packaging cost.

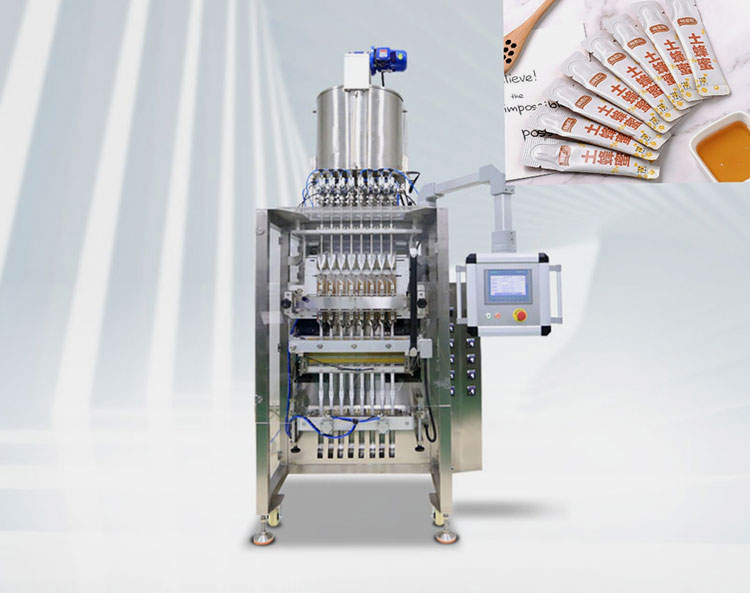

To meet this end, Multi-lane Liquid Packaging Machine is brought into the field. This equipment is a manifestation of sophisticated technology where production efficiency, packaging precision, and automation level is at optimal condition. So, be prepared to discover further about the operating procedure, types, and applications of a Multi-lane Liquid Packaging Machine in this comprehensive buying guide!

1.What Is Multi-lane Liquid Packaging Machine?

Allpack- APK 8-480 Multilane stick packing machine for liquid

Multi-lane liquid packaging machine is an advanced equipment tailored with innovative features to pack various types of free flowing and viscous liquids into beautifully formed sachets and stick packs. The machine can create number of packages in a single run due to its distinctive feature of being multi-lane.

Similarly, it carries out the task of liquid packaging by weighing the product, creating separate packages, filling precise measured volume of material into these packages and undergoing these packages through stringent sealing. In this way, the machine has attained fully automatic capability where all steps are accomplished efficiently in a safe hygienic environment.

2.Write Down The Eclectic Advantages Of A Multi-lane Liquid Packaging Machine?

In this age, where the use of machine in our lives is inevitable, it is also very important that the concerned machine must be able to meet the established targets of user. Hence, to help you whether a multi-lane liquid packaging machine possess the qualities which you require, we have explained some of its notable features:

High Protection & Efficiency

Bulk sachets of honey- Picture Courtesy: Behance

As a multi-lane liquid packaging machine comes in fully automatic technology, it can produce large number of packages in a single minute. Along with that, its enclosed structure and corrosion resistant stainless-steel body together keep the material protected against external environment and extend its shelf life.

Human Friendly

Multi-lane liquid packaging machine is quite human friendly in a way that it provides the operator with an easy-to-use touch screen penal through which machine can be operated. Moreover, it has simple maintenance and operation requirement which are easily understood by a layman.

Adaptability

Various stick packs- Picture Courtesy: iecopacking.com

The most prominent attribute of a multi-lane liquid packaging machine is that it supports great variations in terms of packaging formats such as stick packs and sachets with 3, 4, or back sealing. Not only that, but the same machine can be used for creating vibrant design sealing and cutting over packages by mere changing the parts and setting of machine.

Consistency

Consistently packed 3 side sealed stick packs- Picture Courtesy: chengyipacking.com

The machine is able to deliver perfectly finished packages with extremely consistent quality that every package is containing same amount of liquid and the size and shape of packages are also similar. Therefore, you can get the desired targets without any weighing or packaging fault.

Reduce Waste

Honey spilling from sachet- Picture Courtesy: homeypax.com

Manually handling liquid packaging can cost you more as human errors often lead to product and packaging material waste. However, this fear has no place when using a multi-lane liquid packaging machine. Instead, the machine works intelligently to reduce waste by bringing in use its multiple sensors, stringent sealing, and accurate filling specifications.

Wide Application

Application of multi-lane liquid packaging machine- Picture Courtesy: khmesindo.com

Last but not least, a multi-lane liquid packaging machine can be employed to process and pack all types of liquids encompasses think, thick, and lumpy liquids. Therefore, it can be used in food, cosmetic, chemical, and medical industries.

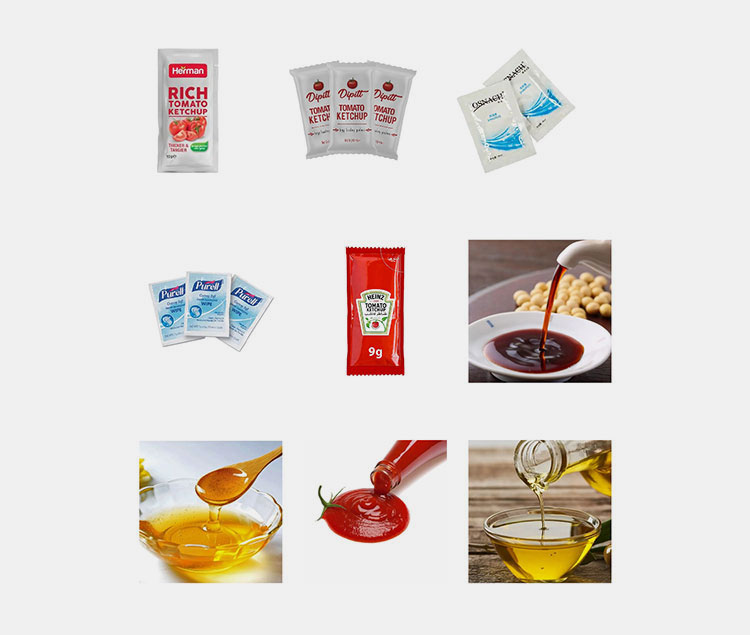

3.Enumerate The Materials Which Can Be Packed By A Multi-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine can process different types of liquids such as free-flowing liquids, viscous liquids, and lumpy liquids etc. These are explained below in detail:

Free-flowing Liquids

Various fruit juices- Picture Courtesy: creativemarket.com

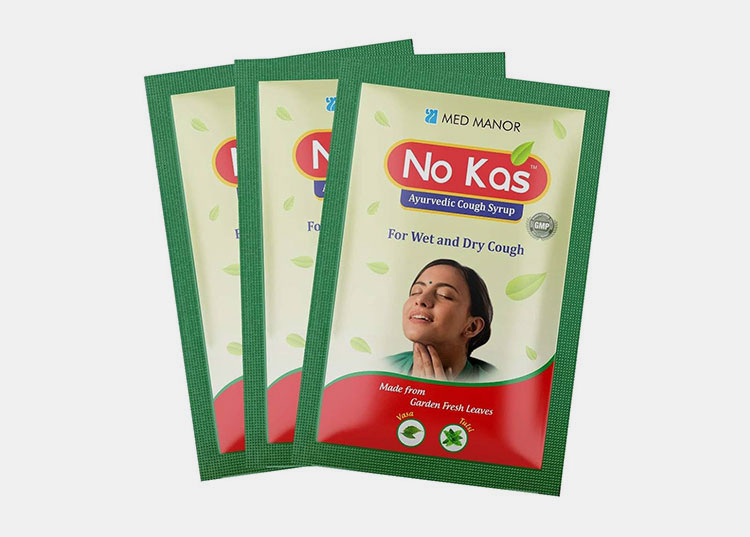

Free-flowing liquids refer to liquids which flow easily and quickly without showing any kind of resistance to flow. Such type of liquids are often packed in small size sachets or stick packs for convenient handling especially during traveling. The common examples of free-flowing liquids include water, juices, milk, soy sauce, vinegar, and cough syrup etc.

Viscous Liquids

Viscous honey presentation idea

Another type of liquids which can be processed by using a multi-lane liquid packaging machine are viscous liquids. These liquids are extremely viscous in their nature and characterized by their high resistance to flow. Most of the liquids which we use in our daily life belong to this category including shampoo, honey, lotion, pastes, gel, ketchup, mayonnaise, and dyes etc.

Lumpy Liquids

Strawberry compote- Picture Courtesy: cookwithmanali.com

The last category of liquids encompasses lumpy liquids. As the name indicates, such liquids are uneven and often contain small chunks. Jam, ketchup, and fruit compote are the common examples of lumpy liquids. So, they are best suitable to be packed in single serving sachets or stick packs with the help of a multi-lane liquid packaging machine.

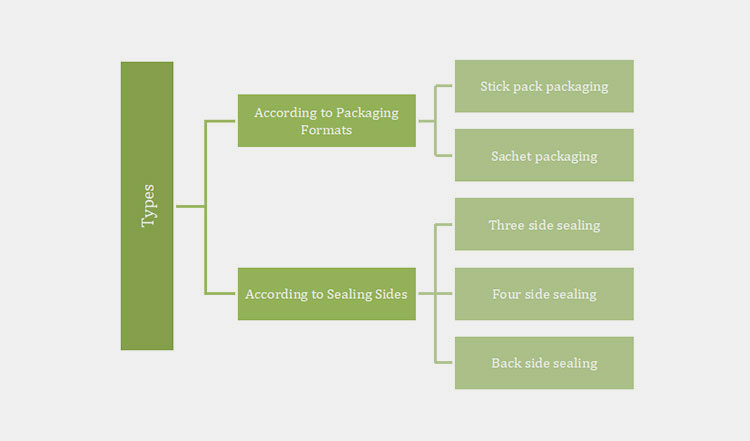

4.What Packaging Formats Are Offered By A Multi-lane Liquid Packaging Machine?

You will be amazed when introduced to the wide variety of packaging formats offered by a multi-lane liquid packaging machine in terms of shape, sealing, and cutting. So, let's discover these all!

Stick Packs

Various liquid stick packs- Picture Courtesy: Dieline

Stick packs are long narrow tubular shape packages. They can be formed by using a multi-lane liquid packaging machine. Products like ointment, jellies, and beverages can be ideally served in stick packs via this machine.

Sachets

Cough syrup sachets

Sachet is the most favored flexible packaging format supported by a multi-lane liquid packaging machine. It has often square or rectangular shape. Sachets can hold single serving liquids such as ketchup, cough syrup, shampoo, and lotion etc.

3 Side Sealing

3 side sealed liquid sachets- Picture Courtesy: chengyipavling.com

3 side sealing depict beautiful appearance of sachets. These sachets are made from single film layer and are sealed from three sides and one side is left to provide additional space for product holding.

4 Side Sealing

4 side seal liquid sachets- Picture Courtesy: wordpress.com

Liquids requiring high protection are often delivered in 4 side sealing because in this format, the package is sealed from all its four sides. So, you can have 4 side sealing packaging by this resilient machine.

Back Side Sealing

Back side stick packs- Picture Courtesy: all-bloom.com

The machine is able to support back side sealing for various types of liquid stick packs and sachets. In this form of sealing, unlike 3 side or 4 side sealing, a single vertical sealing is created at the back of the package along with two obligatory horizontal seals on top and bottom.

Flat Cut

Ketchup sachets with flat cutting- Picture Courtesy: chengyipacling.com

A multi-lane liquid packaging machine can perfectly add a flat cut to any kind of plastic, aluminum, or laminated stick packs during packaging. It is often preferred for products which need extra care in handling such as medicines and certain types of beauty care products.

Zigzag Cut

Pickle sachets with zigzag cutting- Picture Courtesy: flipkart.com

Zigzag cut is known for its eye-catching appearance, that's why, most of the food, cosmetic, and beverage industries used to opt for zigzag cutting for their goods packaging.

Easy Tear Cut

Easy tear cut liquid sachet

The machine can also incorporate an easy tear cut into the top of your sachet. It is straight in line, therefore, by pulling it in directed position will easily open the pack.

Connected Packs

Various connected sachets of shampoo- Picture Courtesy: mundocaoba.com

Continuous packs refer to the individual finished packages connected to each other through a layer of perforation. This makes them continuous and easy carrying while providing a convenient way for their separation through perforation. Hence, while using a multi-lane liquid packaging machine, you can have continuous liquid packages by simply switching to continuous mode.

5.Explain The Working Principles Of A Multi-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine can be brought into operation by following few easy steps which are explained below:

Feeding & Setting

The working process of multi-lane liquid packaging machine starts with operator feeding the machine with sufficient volume of liquid and film roll. After this step has been taken, it is crucial to reset the machine and fix all the essential parameters regarding machine functioning comprising filling dosage, sealing temperature, cutting pressure, and coding data etc.

Unwinding & Forming

Stick Pack forming- Picture Courtesy: samfull.net

Now, the machine is ready to be started. Once powered on, it will initiate pulling film fixed in frame via rollers and pulleys. The same rollers will guide the direction of film and will take it to the bag forming station where the actual process of bag formation takes place. It is important to note here, that bag formation format entirely depends upon the type of machine being used such as 3 side sealing, 4 side sealing, or center sealing machine etc.

Weighing & Filling

Liquid filling into packages- Picture Courtesy: samfull.net

This phase cover the weighing and filling of liquid. During bag formation, the machine is engaged in measuring of liquid through weighing system. Similarly, when the required amount of liquid dosage is precisely measured, it is filled into respective bags and pushed ahead for sealing.

Sealing & Cutting

Stick Pack sealing & cutting- Picture Courtesy: samfull.net

The filled bags get tightly sealed during this phase via heated horizontal sealing jaws that meet on the top side of the bags. Now, these bags are sealed and then either separated apart through cutting or they are left connected by mere leaving perforation between pair of bags.

Discharging

Stick packs discharging- Picture Courtesy: samfull.net

Finally, all the finished bags are ready for discharging. The conveyor belt takes these bags and drop into a collection container or conveyed to the adjoined machine for secondary packaging.

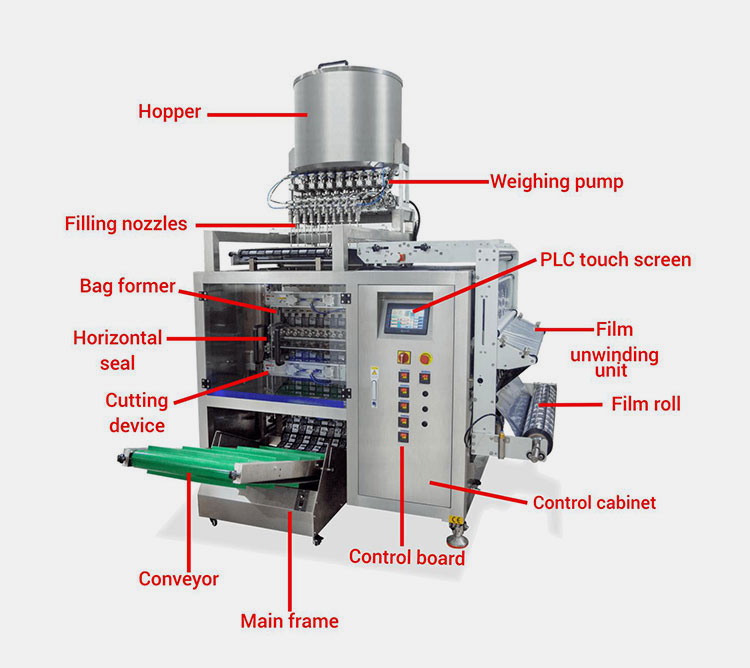

6.Describe The Structure Of A Multi-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine is composed of the following components:

Structure of Four Side Sealing Multi Row Liquid Packaging Machine- Picture Courtesy: khmesindo.com

Hopper

Hopper is a large storage tank placed on the top of the machine. It is supplied with large volume of liquid, so, that the machine will function smoothly and process the material by taking it from hopper and passing it through different phases.

Weighing Pump

Weighing pump is situated directly under the hopper. It is the core component of a multi-lane liquid packaging machine through which material is measured.

Filling Nozzles

Filling nozzles are long narrow tubes attached to the hopper on top side, while as, to the formed bags on the bottom. These filling heads deliver the accurately weighed liquids from hopper into the packages.

Bag Former

Bag former is another crucial part of a multi-lane liquid packaging machine. It is a device responsible for forming bags from flat film. The shape of bag former changes according to the type of machine such as three side sealing machines has a conical bag former on left or right side, while as, four side seal packaging machine has conical structure in mid front.

Horizontal Seal

Horizontal seal is a long sealing bar which seals the top of each finished package, similarly, the bottom of packages is made automatically.

Cutting Device

Cutting device is also known as cutting knife or blades. What matters here is the role and function of cutting device which it performs to split the finished packages from continuous film.

Conveyor

There is a discharge conveyor attached to a multi-lane liquid packaging machine through which packed sachets and stick packs are discharged out of the machine.

Main Frame

Main frame refers to the overall structure of a multi-lane liquid packaging machine which is make up of stainless steel. It helps the other parts of machine remain integrated. There is an enclosed window for clear and protected observation of the ongoing process.

Control Board

Another notable component of a multi-lane liquid packaging machine is control board. It consists of several knobs for controlling the working of machine such as power button, emergency stop, and temperature adjustment knob etc.

Control Cabinet

A heavy-duty machinery fixed into the machine is often termed as control cabinet or electric enclosure. Inside this cabinet, there is a web of wires and electrical components which enable the machine to function properly. The purpose of combining these wires and devices in a place is to keep the machine safe from spontaneous breakdown.

Film Roll

Film roll is a stock of film that is supplied to the machine. It is fitted into the frame which collectively known as film supply system.

Film Unwinding Unit

Film unwinding unit consists of several rolling shafts or film pulleys which carry out the task of unwinding film from roll and supply it to the bag forming station for creating individual bags.

PLC Touch Screen

Programmable logic controller touch screen is a type of computer device over which multiple types of information regarding machine is displayed. User simply contact with this set of information and alter it as per the production and packaging requirements.

7.What Are The Types Of A Multi-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine has different types, and you can have it in various forms with unique features and specifications. But for this, it is essential to know what these types are! These include:

Multi-lane Liquid Stick Packaging Machine

High Capacity Liquid Stick Pack Multi-lane Packing Machine- Picture Courtesy: samfull.net

Multi-lane liquid stick packaging machine is an equipment designed to pack liquids in stick packs. The machine has wonderful mechanism for creating different styles of stick packs with beautiful sealing and cutting designs. You can have the utmost precision and efficiency level by using the machine. The average production output of the machine is finishing up to 250 bags in a minute.

Structure

The structure of machine is robust and heavy-duty with multiple bag forming and finishing units. It can be distinguished from multi-lane liquid sachet packaging machine due to its narrow units for bag forming.

Packaging Format

Various stick packs- Picture Courtesy: chengyipacking.com

The machine support stick packs formation which are characterized by their long narrow shapes. It can be used for packing beverages, jellies, and ointment etc., in stick packs.

Multi-lane Liquid Sachet Packaging Machine

High Production Liquid Sachet Multilane Packing Machine- Picture Courtesy: samfull.net

Multi-lane liquid sachet packaging machine is another type of machine peculiarly brought into the field to provide you with amazing sachet packaging. It can be also integrated with other machines such as carton packing machine and mending line for secondary packaging of liquids. Depending upon the specifications, the machine is available in 4-12 lanes.

Structure

The machine is an assembly of various tools and equipment encompassing electric control system, film supplying unit, material feeding hopper, bag forming, filling, sealing, and cutting mechanism etc.

Packaging Format

Pickle sachets- Picture Courtesy: flipkart.com

Multi-lane liquid sachet packaging machine is capable of producing 3 side, 4 side, or back side flat sachets of square or rectangular shape depending on the machine specifications. Therefore, it can be employed in food industries, cosmetic industry, and medical industry for delivering seasonings, shampoo, and syrup etc.

Multi-lane 3 Side Sealing Liquid Packaging Machine

Multi row three side sealing liquid packaging machine- Picture Courtesy: chengyipacking.com

This sophisticated machine is designed to meet the manufacturers' needs regarding 3 side sealing packaging. It creates bags with two horizontal seal of top and bottom followed by a single horizontal seal. The machine uses single film layer for packaging.

Structure

It is made up of food grade quality stainless steel. Its conical bag forming unit to side define its unique structure. Other parts are similar to those of other machines such as film unwinding, liquid measuring, filling, and sealing etc.

Working Principles

The working process is simple, starting from unfurling single film layer, it forms the bags by one-fold of single film. After this, a bottom and longitudinal seal is added into film and then bags are filled with liquid. At the end, filled bags are sealed from top and ejected out of machine through conveyor.

Multi-lane 4 Side Sealing Liquid Packaging Machine

Multi row four side sealing liquid packaging machine- Picture Courtesy: chengyipacking.com

Multi-lane 4 side sealing liquid packaging machine is applicable for packing liquids with various nature into 4 side sealed packages. It perfectly forms 4 side sealing bags for the enhancement of liquids. Therefore, the product laying inside remains intact from all sorts of environmental elements.

Structure

The machine is composed of several parts and those which accounts for its differentiation from other machines include the distinctive bag forming system which uses double layer of film instead of turning single film.

Working Principles

The machine start functioning by unwinding the film from roll and dividing it into multiple layers for bag forming through cutting. Similarly, these film layers are kept parallel to each other where bottom and horizontal seals are introduced to the films. Afterwards, the measured liquid is poured into bags and bags are sealed from top. The blades then separate the finished bags for discharging.

Back Side Sealing Liquid Packaging Machine

Another type of multi-lane liquid packaging machine is back side sealing liquid packaging machine. This equipment is specialized in forming and processing bags with back or center sealing. Most of the industries processing edible liquids and medicated supplements are delivered in such type of bags.

Structure

It is an assembly of several parts among which the core one is its conical bag forming units which mark distinction between back sealing machine from that of 3 side and 4 side multi-lane liquid packaging machine.

Working Principles

It performs the function by pulling film from roll and expanding it around the bag forming units. Similarly, these bags are sealed from horizontal lower side and longitudinal side on the center. After the filling gets done, bags are closed from top and mobilized from the machine through conveyor belt.

8.Differentiate Between A Multi-lane Liquid Packaging Machine And Multi-Lane Powder Packaging Machine?

Multi-lane liquid packaging machine and multi-lane powder packaging machine are used as obligatory machines for the primary packaging of powders and liquids, and both are flexible packaging machines. However, both are totally different from each other in several aspects which are explained below:

| No | Factors | Multi-lane Liquid Packaging Machine | Multi-lane Powder Packaging Machine |

| 1 | Definition | Multi-lane liquid packaging machine is used to pack liquids in flexible packages such as stick packs or sachets. | On the other hand, multi-lane powder packaging machine is employed to deal with powder packaging task. |

| 2 | Material processed | Free-flowing, viscous and lumpy liquids. | Fine and adhesive powders. |

| 3 | Filling system | Piston filling system and gravity filling system. | Auger screw filling system along with vibration system. |

| 4 | Application | Large scale industries associated with liquid manufacturing such as beverage industry, seasoning industry, and daily care industry. | Large scale industries involved in making powders such as cosmetic industry, condiments industry, and pharmaceutical industry etc. |

| 5 | Picture |

Four Side Sealing Multi Row Liquid Packaging Machine- Picture Courtesy: khmesindo.com |

Allpack- APK 4-480 Multilane stick packing machine for powder |

9.Differentiate Between A Multi-lane Liquid Packaging Machine And Single-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine and single-lane liquid packaging machine are two equipment made for the same purpose of packing liquids, yet both differ from each other in many ways. Let's know what these are!

| No | Factors | Multi-lane Liquid Packaging Machine | Single-lane Liquid Packaging Machine |

| 1 | Definition | Multi-lane liquid packaging machine is innovative machine made for processing liquids in extraordinary efficient way. | Single-lane liquid packaging machine is an equipment employed to pack liquids with low pace. |

| 2 | Structure | The structure of machine is robust and complicated with so many components and heavy-duty machinery. | It has comparatively precise structure with small footprint and easily portable body. |

| 3 | Process | It has a complex process where multiple bags are processed simultaneously. | It follows a simple working procedure by only processing a single bag at a time. |

| 4 | Number of lanes | Multiple lanes for bag forming, filling, sealing, and cutting. | Single lane for bag forming, filling, sealing, and cutting. |

| 5 | Production output | 100- 540 bags in a minute. | 30- 60 bags per minute. |

| 6 | Application | Large and extra-large production facilities. | Small to medium size industries. |

| 7 | Picture |

High Production Liquid Sachet Multilane Packing Machine- Picture Courtesy: samfull.net |

Single Lane Liquid Packing Machine For Sachet & Stick Pack- Picture Courtesy: samfull.net |

10.What Are The Applications Of A Multi-lane Liquid Packaging Machine?

Multi-lane liquid packaging machine has wide applications due to its adaptability and flexibility to process myriad of liquids. These applications are highlighted below:

Seasoning Industry

Various sauces sachets- Picture Courtesy: flipkart.com

The very first industry where the use of a multi-lane liquid packaging machine is indeed a seasoning industry where the machine is admired for its advanced automation level. No matter is it ketchup, mayonnaise, chilli sauce, pickle, or soy sauce, this machine will always be a perfect choice to meet your growing needs regarding vibrant seasoning packaging.

Beverage Industry

Fruit tea stick packs- Picture Courtesy: prettytasty.com

Beverages are also popularly delivered in small sachets and stick packs for kids. Therefore, a multi-lane liquid packaging machine is used to undertake this function. So, you can pack both the free-flowing nectar as well as processed thick juices by using this machine.

Confectionery Industry

Jam presentation idea

When talking about the uses of a multi-lane liquid packaging machine, how can confectionery industry be left? Well, chocolate, jam, and jellies are some of the popular liquids which are packed in sachets and stick packs to provide consumers with unique way of enjoying their favorite sweets.

Medical Industry

Liquid collagen sachet packaging- Picture Courtesy: qvcuk.com

How can medical industry be left behind in the race when all other sectors are making the best use of a multi-lane liquid packaging machine? Of course it can't be! Therefore, it will not be incorrect to say that this machine is gaining momentum in the medical field. Cough syrup, ointment, and protein liquid are some of the common examples in this way.

Beauty Care Industry

Beauty cream- Picture Courtesy: fiverr.com

Another sector which we have in our lives is beauty care industry or cosmetic industry. Here too, the relevance of multi-lane liquid packaging machine is present due to its efforts to pack liquids like shampoo, lotion, dyes, and hand washing gel etc.

11.How To Conduct A Leakage Test For A Multi-lane Liquid Packaging Machine?

No matter how small the leak is, it will cause harm to your product as well as your reputation and product loss. Therefore, it is significant to conduct a proper leakage test for the finished bags processed by a multi-lane liquid packaging machine to make sure that the machine is effective and errorless in its performance and especially in achieving tight sealing. This test is known as vacuum leak test.

Vacuum leak tester- Picture Courtesy: pacorr.com

In vacuum leak test, a packed sachet is placed in an empty chamber for checking leaks. After its placement, all connections of air to chamber are closed and the machine start evacuating air from the chamber. At this point, if the air inside the chamber remain constant with no change found in pressure, it means the package is free from leaks.

However, in contrast, if the air pressure inside the chamber start decreasing, then it indicates the possible leakage of bags. The size of leak will then be determined by the pressure loss over time as noted by the machine.

12.What Is The Cleaning And Maintenance Requirements Of A Multi-lane Liquid Packaging Machine?

Cleaning and maintaining a multi-lane liquid packaging machine is crucial for its proper functioning and longevity. Here are some general guidelines that will surely help you in this way:

Operators maintaining machine- Picture Courtesy: mengsolutions.com.au

Regular Cleaning: Clean the machine daily or as per the manufacturer's recommendations to prevent the buildup of residue.

Use a mild cleaning solution recommended by the manufacturer to clean surfaces and remove any product

Use a soft cloth or brush to wipe down the machine components. Avoid using abrasive materials that could scratch or damage the surfaces.

Pay special attention to areas where product particulates tendto accumulate, such as sealing bars and conveyors. Remove any buildup carefully to ensure smooth operation.

Scheduled Maintenance: Follow a maintenance schedule provided by the manufacturer. This include lubricating moving parts, inspecting seals and gaskets, and replacing worn-out components.

Always unplug the machine before performing any maintenance or cleaning to avoid accidents.

Regularly inspect seals and gaskets for signs of wear or damage. Replace them if necessary to maintain the integrity of the packaging process.

Periodically check electrical connections to ensure they are secure and free from corrosion.

13.What Are The Considerations For Selecting The Best Multi-lane Liquid Packaging Machine?

Having a right multi-lane liquid packaging machine is significant for becoming a successful business owner. However, for getting right machine you need to consider some factors which will ultimately leads you to make a sound purchase. What these factors are is a question we have answered below:

Filling System

Liquids with different viscosities

As we have discussed in question no 3 of this article that liquids are of many nature such as free-flowing, viscous, and lumpy liquids. So, it is very necessary that your multi-lane liquid packaging machine must have the right type of filling system which can be easily done if you know the nature of your material. The filling systems can be piston filling or gravity filling system etc.

Machine Specifications

Another crucial thing to look for is the specifications of a multi-lane liquid packaging machine. It includes checking the dimensions of machine, its features for supporting various designs in terms of sealing, cutting, and bag formation, and most importantly its adaptability to support different types of packaging formats.

Quality

Quality assurance- Picture Courtesy: Outsource Accelerator

Buying a machine means incorporating in your production line a determiner who will control or shape your business. That's why, it is inevitable to be sure of the quality of your machine. It is simple to confirm, you just need to examine the construction material of material along with its durability and hygiene. These all facets you will know in the form of machine's adherence to certain quality standards such a as GMP, FDA, and ISO etc.

Warranty & Customer Support

Warranty policy icon- Picture Courtesy: security360.pk

It is for sure, that every entrepreneur need assurance when purchasing a multi-lane liquid packaging machine is. So, what if look to the most admired policy which is warranty policy. Similarly, after-sale service and customer care are other significant factors which must be available to the buyer when dealing with any sort of problem.

Conclusion

In a nutshell, multi-lane liquid packaging machine is a high-speed equipment applicable to different liquids produced in any industry. Its high quality sturdy build up is what's count for its advanced protection and which the machine ensures during operation. Not only that, but it is a life time solution that allows you to alter or modify its structure to suit eclectic needs regarding sealing and cutting and connect it to other machines. If benefits are numerous and option is feasible then what are you waiting for? Just click on the given link and become Allpack's valuable customer!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide