Medical Powder Sachet Packing Machine: The Complete Buying Guide In 2024

Various medical dosage formulations are available in powder and granules, that you administer orally. You take it with water or milk for best working. In the same way, the manufacturing companies implement similar rules to dispense the medical powder sachet in a safe manner. For that reason, a medical powder sachet packing machine is worthwhile.

You will be surprised to know that this machine is ideal for picking a pre-determined amount of medical powder and dropping it into the sachet. Ideally, every associated company must hook up with this machine; if you’re not sure, please read the detailed information in this blog.

1.Can You Describe a Medical Powder Sachet Packing Machine?

Medical Powder Sachet Packing Machine

Patients always need a simple and convenient method of medicine packing and nevertheless, it must be safe and reliable.

For that purpose, a medical powder sachet packing machine is significantly utilized all around the world to keep it easier way for patients' medication packing hence they can avail of accurate medication on time.

A medical powder sachet packing machine is user-friendly equipment that is primarily used to dispense powders and seals them all around 3 sides or 4 sides to make it tamper evident to its consumer.

Moreover, you can achieve a single unit dosage that helps in instant usages for various applications. This can form a single-use sachet that allows a small quantity of medicines for a single setting.

2.How a Medical Powder Sachet Packing Machine is Useful in the Industry?

Medical Powder Sachet Packing- Picture Courtesy: Health Nuts Australia

A medical powder sachet packing machine is versatile equipment that finds its large applications among the world’s demanding manufacturing companies. Some of the major industries that get benefits from this machine include:

Medicinal Industry

Application of medical powder sachet packing machine- Picture Courtesy: Callagan Campus

Correct, safe, and accurate dosing is always the first priority of the medicinal industry. Your medical powder sachet promises you potent and hygienic content inside whenever you open it. Moreover, you always find powders in dried and freshened formulations.

This is all because of the medical powder sachet packing machine that ensures single-use medical powder in the correct dosage and prevents degradation from physical factors. This includes digestive system treatment sachet (Risek), anti-diarrheal powder (ORS), urinary bladder strengthening drugs (Cran-Max), and other related products.

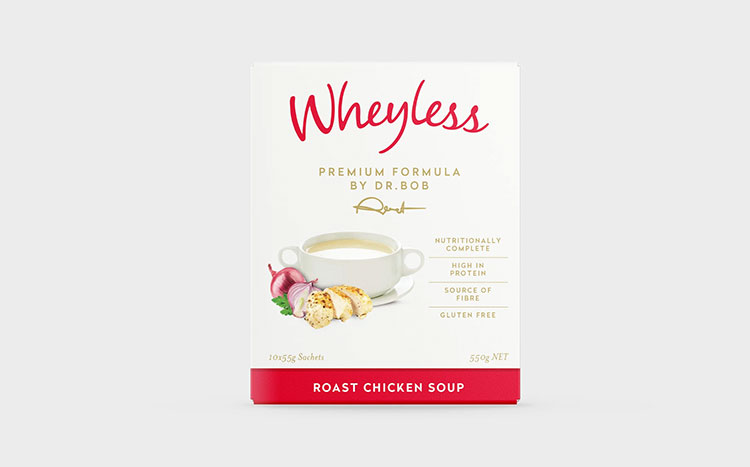

Food Industry

Food Industry- Picture Courtesy: Wheyless Australia

This is the second most demanding manufacturing field which is highly close to the medicinal industry. Because food industry equipment must be compliant to international quality standards to ensure the prepared and packed product is safe to its end-users.

A medical powder sachet packing machine is made up of food-grade materials that avoid the progression of contamination in food products. It ensures you to dispense a safe and convenient product in a sachet, such as spices, condiments, flavors, dried herbs, milk powder, coffee powders, baking soda, and much more.

Cosmetic Industry

Cosmetic Industry- Picture Courtesy: Intu Wellness

To be very frank, in the cosmetic industry aesthetics matters a lot. Your product potency is equally important as its packaging. A medical powder sachet packing machine offering you accurate single-unit packets with a beautiful presentation in a travel-size sachet.

This includes face scrub powder, manicure, and pedicure items, cleaners, dusting powder, bleaching powder, hair dyes, in tiny sachet.

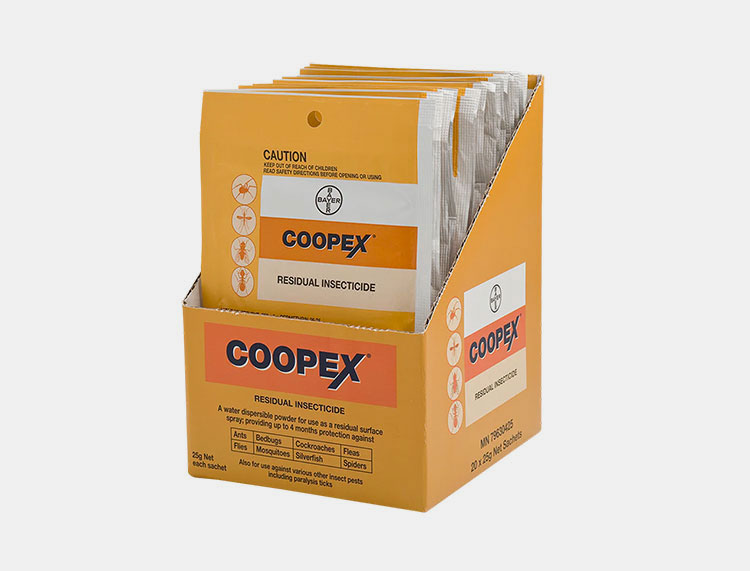

Chemical Industry

Chemical Industry

Safety and leakage-proof packaging is very important in the chemical industry. Products like bleaching agents, acidic and alkaline powders, pH granules, neutral salts, etc are required to be packed accurately in each unit sachet with the help of a medical powder sachet packing machine to improve user and environment safety.

Agricultural Industry

Agriculture Industry- Picture Courtesy: Parrot Supplies Australia

This is an important field of packing that brings flawless packaging by using a medical powder sachet packing machine for the delivery of products such as seeds, supplements, pesticides, and fertilizer packets efficiently.

Beverage Industry

Beverage Industry- Picture Courtesy: Food 21

This is super a demanding industry that is mainly related to the manufacturing and packing of products such as brew, coffee, energy drinks, soda, boosters, flavors milk powders, etc ., which is mostly done by utilizing a medical powder sachet packing machine.

Herbal Industry

Herbal Industry- Picture Courtesy: Natural Health Organic

The herbal industry never loses its importance due to its greater benefits and low side effects. Various herbal powders are still popular among people and are often packed in small single-unit sachets by using a medical powder sachet packing machine.

3.What benefits does a medical powder sachet packing machine offer to you?

A medical powder sachet packing machine is a super innovation that is hooked to a bunch of benefits in the packaging industry, for example:

Convenience

Greater Packaging Convenience

A highly convenient mode of packing that helps the patient to cut off the requirement of dosage adjustment and picking the concentration by using a manual procedure.

This machine offers a versatile sachet that allows patients to pick, open, and administer them in a safe manner.

No-More Errors

Errore Free Packing- Picture Courtesy: Eagle Clinicals

This is PLC controlled machine that carefully dispenses products into each created sachet ensuring accurate medication inside the sachet that directly reduces the likelihood of over-dosing or under-dosing among patients.

Peace of Mind

Peace of mind with medical powder sachet packing machine- Picture Courtesy: Bioflex

All manufacturers who have set up a medical powder sachet packing machine in their facility are confident as they are assured that their company is offering the right medication powder sachet to suppliers with promising output.

Flexible Production Capacity

Flexible Throughput- Picture Courtesy: Purition

In a busy work life, managing high production demand from a single machine is always challenging; a medical powder sachet packing is a tailoring dosage solution that is capable of dealing large production line with flawless working principles.

Flexible Packing Options

Flexible Packing Options – Picture Courtesy: Meagher Pharmacy

The machine is ideal to offer various styles, designs, sealing, and related options to its customers. This is how a medical powder sachet packing machine receives commands from the PLC unit and implements them mechanically to provide you perfectly crafted sachet according to your needs.

4.How does a Medical Powder Sachet Packing Machine work?

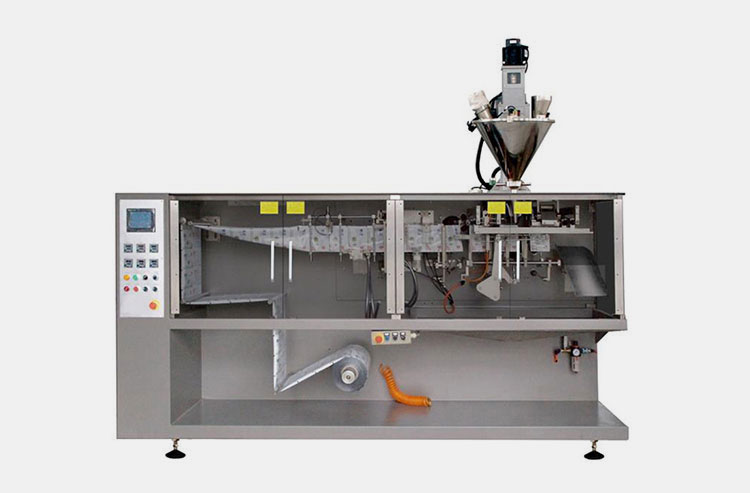

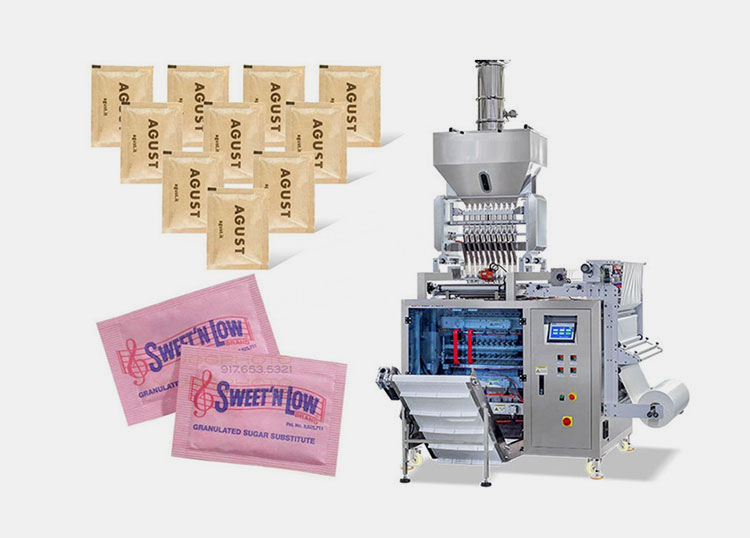

Allpack Medical Powder Sachet Packing Machie

A medical powder sachet packing machine is a greatly engineered equipment that is specifically designed to bring safe dispensing of medical powders in a sachet via an easy and flexible mode of working.

This machine working is a combination of electrical and mechanical involvement that produces an amazing result in the end. Let’s see the major working steps of the medical powder sachet packing machine:

Loading

A very first step where you are subjected to load the medical powder into the hopper of the machine; this part also serves as a reservoir that keeps medicines safe and potent throughout the procedure. Also, set the film roll over the unwind or unwind roller of the machine and adjust the film.

Sachet Formation

You can now in-feed the protocol in the machine using a PLC unit and start the process by clicking the option. The sachet formation is involved in the following steps:

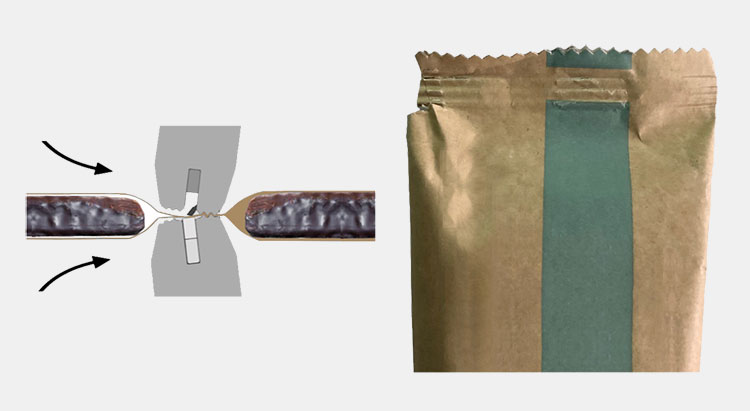

Unwinding & Sealing

Soon after sending the command, the film roll unwinds slowly and wraps around the forming tube of the machine. This simultaneously creates a sachet that is sealed horizontally and vertically leaving one end open for the dispensing of medical powder inside.

Weighing

The hopper allows the concentration of medical powder into the formed sachet accurately as ordered by the machine. In the case of medical powder, an auger filler is responsible for the filling job.

Final Sealing

It is almost the final step of the work; a top seal is done by the machine which ultimately forms an air-tight sachet packet.

Cutting

Once a sachet is formed, a set of cutting knives punch at the edges and separate the sachet. The sealing and cutting steps are rapidly done as both units are very close to each other.

Outputting

The discharge of the medical powder sachet packing machine allows the final and finished sachet from the machine which is ready for other packaging steps.

5.What are the types of Medical Powder Sachet Packing Machine?

You will be surprised to know that a medical powder sachet packing machine is not only a single category of equipment rather it shows a broad classification. The main types are based on functionality, design, automation, and others. We have simplified the basic types of medical powder sachet packing machines below:

Automatic Medical Powder Sachet Packing Machine

Automatic Medical Powder Sachet Packing Machine- Picture Courtesy: Foshan

This machine's work is entirely based on automatic functionality. This is suitable equipment for bringing high packaging output; therefore, it is mainly observed in larger companies. If you see it's working, there’s no human intervention or long-standing required throughout the procedure. Yes, you should adjust the film and set the command in the machine while this equipment is capable of carrying the entire production line in a flawless manner.

Large Size Medical Powder Sachet Packing Machine

Large Size Medical Powder Sachet Packing Machine- Picture Courtesy: Propac

This is the giant addition in the packaging world which has displayed a larger structure and is helpful in integrating units belonging to greater production capacities.

Single-lane Medical Powder Sachet Packing Machine

Single-lane Medical Powder Sachet Packing Machine- Picture Courtesy:Honor Pack

The entire work plan and design of the single-lane medical powder sachet packing machine is similar to the standard machine except it has demonstrated a single lane for the formation, filling, sealing, and cutting protocol.

Multi-lane Medical Powder Sachet Packing Machine

Multi-lane Medical Powder Sachet Packing Machine- Picture Courtesy: Packing Machine

This is a modern and advanced technology where the machine is presented with a multi-lane operation that is able to bring formation, filling, sealing, and cutting of sachets in one go. Due to this feature, it is mainly used in bringing high productivity and in limited time.

Horizontal Medical Powder Sachet Packing Machine

Allpack Horizontal Medical Powder Sachet Packing Machine

This machine is a large addition to the packaging world and ensures the formation and filling of sachet following a horizontal working principle. As compared to vertical machines, this type of machine requires a large installation space and more investment, though it is mainly considered to add when you look for more or high production capacity. this machine is indeed ideal as it offers you unlimited benefits related to sachet types, speed, ease of operation, various formats, etc.,

6.What Products Can be Filled by Medical Powder Sachet Packing Machine?

A medical powder sachet packing machine is created to deal broad range of products ensuring that the machine is capable of meeting them effectively. The machine is excellent for handling certain types of products easily including:

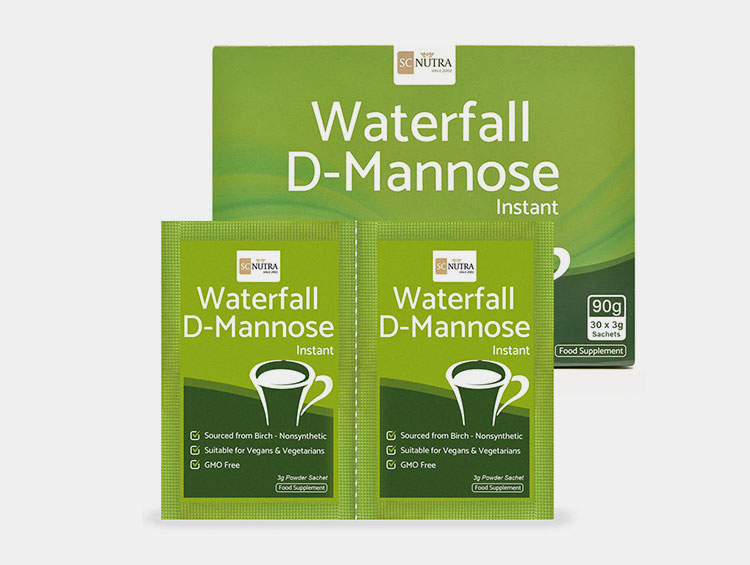

Powder

Powder- Picture Courtesy: Nutra Organic

Whether antibiotics, topical powders, pharmaceutical powders, nutritional powders, or infant formula, a medical powder sachet packing machine is ideal for packing mess-free products.

Granules

Granules- Picture Courtesy: Chemistware Australia

Apart from powders, granules are also easy to fill by the medical powder sachet packing machine into each sachet to make a perfect product packet. For example, pellets, uniform granules, and random granules.

Free- Flowing Formulation

Free- Flowing Formulation

Products like seeds, herbs, or spices with smooth surface or textures can also be filled into sachet by using a medical powder sachet packing machine.

7.What are the parts of a Medical Powder Sachet Packing Machine?

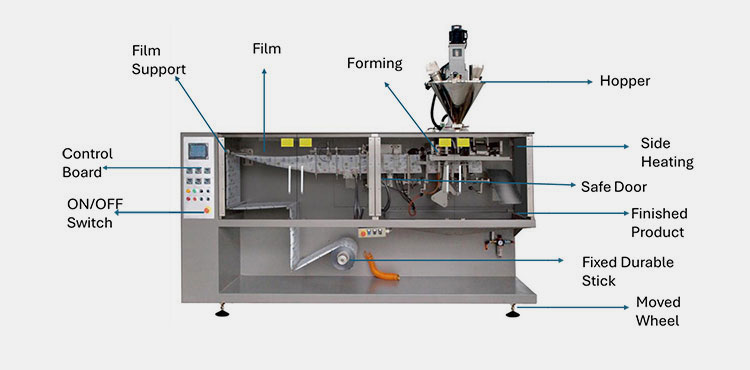

Allpack Medical Powder Sachet Packing Machine

A medical powder sachet packing machine is composed of the following illustrated parts that play a significant role in the formation, filling, and sealing of the sachet each time. The explanation of each unit is described below:

| Part | Description |

| Fixed Durable Stick | This part is also known as a dancer's arm which allows the holding of the film roll. This unit itself is a stationary part that moves gently to unwind the film roll during the sachet packing procedure. |

| Film | This is not exactly the part of the machine but yes, you can call it an essential component of the sachet packing process which is commonly available in different materials such as aluminum, plastic, and others. |

| Film Support | There are some associated channels equipped in the machine that allow support to the film. |

| Hopper | A tank that is meant to hold the filling medical powder inside. Hopper can be loaded manually or by using a loader that fills it automatically. It stores and delivers the products for filling during the process. |

| Filling Machine | A filler is used to ensure the correct and accurate dispensing of the medical powder into each sachet respectively. There are various types of fillers that is commonly based on the type of material or product to be filled. For example, auger filler is used for powders and volumetric filler for granules. |

| Forming | This is an important component of the machine that allows a suitable shape for the sachet. This is a narrow tube shape element that supports the film to create a correct shape and make it ready for sealing. |

| Side Heating | Side heating elements seal the edges of the sachet, creating a secure seal to prevent leakage and contamination. |

| Control Board | This is the special part of the machine where you can put important key parameters into the machine. It includes the temperature you require, the speed of sachet formation, how much amount of medical powder is inside each sachet, and so on. |

| On/Off Switch | You can start the machine by using the ON button and shut down the machine by pressing the OFF button. |

| Clamp Bag Switch | For securing a film, a clamp bag switch is present that facilitates a proper holding of the film during the filling and packing procedure.

The clamp bag switch is a safety feature that ensures the film is properly secured and held in place during the packaging process. |

| Safe Door | This unit is helpful in offering direct access to the machine. In some cases, the film, or sachet is trapped, safe door allows easy troubleshooting. Moreover, for cleaning and maintenance of the machine, it serves as a gateway for an operator. |

| Finished Product | This unit allows the final product to be released from the machine. |

| Moved Wheel | You can move the machine easily and fix it in the laboratory or production unit with the help of wheels. |

8.Why do you need to take care of your Medical Powder Sachet Packing Machine?

Medical Powder Sachet Packing Machine- Picture Courtesy: Propac

One of the prime reasons to take care of medical powder sachet machine is to attain a high level of hygiene and cleanliness. However, it includes ‘cross-contamination’ that has to be strictly avoided when dealing with medical products.

For that reason, clean your machine after every use and prior to starting the procedure to avoid the piling of debris or dust inside the packaging units.

There are always some simple techniques that you must use to ensure that your machine is ready to pack every type of medication.

It is very important to clean and maintain your machine on a regular basis. Disassembles the inner parts of the machine, opens the hopper, and cleans it. Moreover, using compressed air can help to eliminate dust or leftover particles inside. Also, you can clean the machine by using micro-fiber clothing. However, it is not suggested to use ethanol for its cleaning this is because powder may stick, and ethanol particle evaporates.

9.What are the problems and troubleshooting related to a Medical Powder Sachet Packing Machine?

A medical powder sachet packing machine is a reliable and promising tool. However, there are main technical issues that might arise at any time. You should know how to deal with them. We have listed the following problems and their solutions for you.

Hot Air Emissions in the Sachet Film

Hot Air Emissions in the Sachet Film

This is well known to you that a medical powder sachet packing machine creates a sachet from heat sealers that may be responsible for the emission of heated radiation which can ultimately cause problems as it can affect the sachet and the material inside.

Solution

To solve this problem, you can regulate the heat or lower the temperature of the processing system to control the heat emission. Moreover, calibrate the machine on a regular basis.

Atomization of Sachet Film

Atomization of Sachet Film

An unwanted state of the sachet formation and filling process which is accompanied by blurry or mist formation around the surface of the sachet can affect the products and the quality of the packing.

Solution

This is caused by the disruptive internal setting of the machine. Re-adjust the machine, and run the test. Make sure, the machine is not generating extra heat. Regular cleaning and maintenance can reduce the occurrence.

Jamming of the Film

Jamming of the Film

The film roll becomes blocked and does not move which can ultimately interrupt the entire procedure.

Solution

To solve the problem, open the linked components and release the jammed strip of the film. Moreover, you must lubricate the units regularly to prevent such incidents. Always keep your system in calibrated mode so that such technical faults can be avoided further.

Wrinkled or torn film

Wrinkling- Picture Courtesy: Greener Corp

This is a very common problem in the medical powder sachet packing where a sachet film is wrinkled or broken which can reject the whole sample and lead to product wastage and time.

Solution

This problem can be caused by various factors such as wrong or extra film tension, high temperature of the sealers, as well as greater speed or very poor kind of film materials.

For that, you must use regulated temperatures, modulated speed, controlled film tension, and a good quality film for the sachet. Use clean cutting blades and sealers must be cleaned. Calibrate the film alignment parts to control wrinkling or twisting of the sachet film.

10.What are the basic factors to know when buying a Medical Powder Sachet Packing Machine?

Medical Powder Sachet Packing Machine- Picture Courtesy: Lenis Machine

There are several important factors to take into account when buying a medical powder sachet packing machine for your production area. Let's look at them:

What Are You Packaging?

Is your medical powder useful for topical applications? Are you packing sachet for internal or oral applications? It is essential to know about your products and their stability.

How Do You Want Production Capacity?

What production capacity each hour or each day you are looking for? You must know your production goals in your mind before investing in machinery.

Consider a medical powder sachet packing machine that can be capable of delivering throughput as you expect. There are various kinds of machines available perfect for your dreams such as semi-automatic machines for moderate productivity and automatic packing machines for high size capacity.

What’s Your Available Space?

Too large a machine for a compact facility is not a wise decision. In the same way, you must know the measurement of floor space where the machine can easily be installed and the operator can move around without hassle.

Conclusion

Nevertheless, packaging is a significant element for attaining a good quality medical powder. This is what a medical powder sachet packing machine offers to its customers- a reliable solution to help manufacturers of medicines and food products across the globe. With high expertise and knowledge, Allpack offers a comprehensive solution to you with an excellent series of packing machines. For more information and guidance please visit our website & message our Advisory Team.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide