Lip Gloss Tube Filler: A Complete Buying Guide in 2024

Consumers prefer shiny lustrous lip gloss that enhances their beauty. Lip gloss is packaged in a variety of containers but tubes are the biggest of all packaging for lip gloss. To fill accurately and hygienically lip gloss in tubes, lip gloss tube filler is a widely popular machine. This machine delicately handles lip gloss and is high-performance equipment.

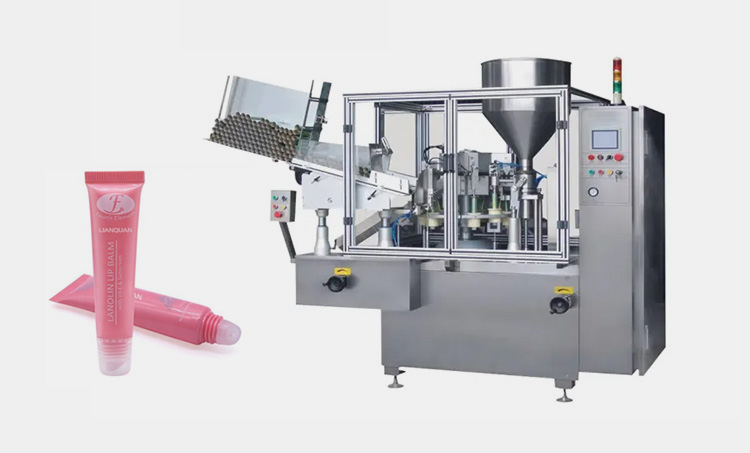

Lip Gloss Tube- Picture Courtesy: Lancome

It processes batches of variable sizes which is a major challenge in the cosmetic industry. Want to invest in or upgrade a lip gloss tube filler then carefully read this information-packed blog to learn the handy features, structure, and benefits of this machine.

1.What is a Lip Gloss Tube Filler?

Lip Gloss Tube Filler

Lip gloss tube filler is a compact unit that is used for filling viscous lip gloss in different styled tubes. This machine is designed with filling nozzles that dispense the right amount of lip gloss in tubes. It prepares lip gloss for shipment and distribution.

Lip gloss tube filler has a central place in the cosmetic industry. A handy tooling in this equipment properly orients tubes for lip gloss filling. Moreover, it is also equipped with capping systems that hermetically seal the lip gloss tubes to avoid content spillage and leakage. It automates the lip gloss packaging and is easily adapted to different kinds of tubes.

2.What are the Important Benefits of Using Lip Gloss Tube Filler?

Lip gloss tube filler is an important machine that is crucial in filling lip gloss and provides a competitive edge to brands due to its quick dispensing. Some of the significant benefits of this equipment are:

Hygienic Fill

Lip Gloss Tubes- Picture Courtesy: Makeup Muddle

Hygiene is an important pillar of the cosmetic industry. If cosmetic products, especially lip gloss are cross-contaminated or have microbial or dust presence, they will be poorly received by consumers and could cause health problems. Hence, lip gloss tube filler loads lip gloss using hygienic protocols and thus has a sterile filling.

No Lip Gloss Wastage

No Lip Gloss Wastage- Picture Courtesy: Shoes & Glitter

This machine is an efficient and accurate equipment, having consistency in every tube fill. It precisely loads the preprogrammed amount in the lip gloss tube, resulting in zero error in lip gloss fill. In this way, it prevents the wastage of lip gloss.

Versatility

Versatility of Lip Gloss Tube Filler

Lip gloss tube filler is an extremely flexible and versatile machine that is comprised of quick tooling and is easily altered to different-sized tubes. Moreover, it can easily process different types of lip gloss material whether shiny, matte, or metallic. It can also feed two different lip glosses in the same tube.

Short Processing Time

Short Processing Time of Lip Gloss Tube Filler- Picture Courtesy: bzmachinery

With increasing market saturation, brands require machines that can process large batches in a short duration for an increasing number of products in the market. Therefore, lip gloss tube filler is well-liked by many brands in the cosmetic industry as it can greatly reduce processing time by quickly filling lip gloss tubes.

Satisfy Increasing Demands

Higher Processing Demands by Lip Gloss Tube Filler- Picture Courtesy: NEWECO

Expanding businesses face different hurdles in coping with increasing demands. But with automatic lip gloss tube filler, this issue is easily resolved. This machine is upscaled easily by adding more filling nozzles thus can fill a higher number of orders and can fulfil the ever-expanding demands of consumers for lip gloss.

3.Where is Lip Gloss Tube Filler Used in Industries?

Lip gloss tube filler is a high-speed machine that has technologically advanced components for automating production lines. Thus, it is readily employed by many industries, for instance:

Cosmetic Industry

Lip Gloss Tube Filler in Cosmetic Industry- Picture Courtesy: Hilotherm

Lip gloss is an important component of the aesthetic industry, consequently, lip gloss tube filler is a need of the cosmetic industry. It precisely loads and dispenses the correct quantity of lip gloss in tubes with or without applicators. It is also used in the packaging of face masks, essential oils, gels, cosmetic jellies, dyes, blushes, foundations, and many more in the cosmetic industry.

Personal Care Industry

Lip Gloss Tube Filler in Personal Care Industry- Picture Courtesy: Accent Amenities

Lip gloss tube filler is used in the personal care industry for packing different free-flowing and viscous personal care liquids like shampoos, soaps, body wash, conditioners, hair colours, lotions, moisturizers, and sunscreen in different-sized tubes.

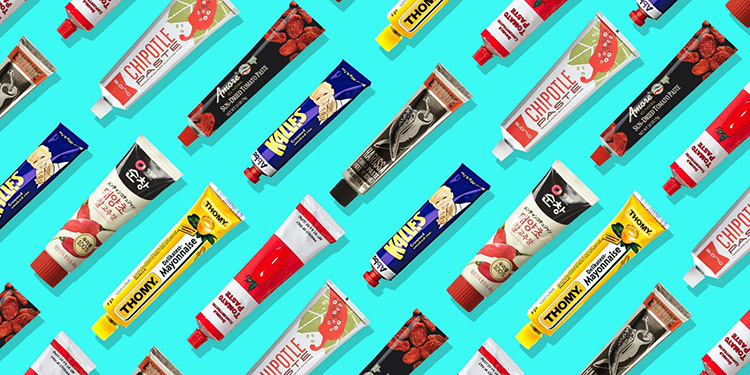

Food Industry

Lip Gloss Tube Filler in Food Industry- Picture Courtesy: New York Magazine

Today, various kinds of food products such as pastes, condiments, jams, honey, cream, ketchup, and peanut butter are available in tube packaging. Filling these tubes in the food industry is only possible because of the lip gloss tube filler. It efficiently fills food products in leak-proof tubes that have minimal chance of spilling. Moreover, it prevents contamination of foodstuff while product filling.

Pharmaceutical and Nutraceutical Industry

Lip Gloss Tube Filler in the Pharmaceutical and Nutraceutical Industry

Pharmaceutical and nutraceutical industry use lip gloss tube filler because of its fill reliability. Creams, ointments, dermal supplements, burn salves, etc are filled in tubes with lip gloss tube filler.

Chemical Industry

Lip Gloss Tube Filler in Chemical Industry- Picture Courtesy: Long Thames

In the chemical industry, this machine is employed for dispensing different expensive and precious chemicals, such as fertilizers, grease, adhesives, grouts, sealants, solvents, cleaning agents, lubricants, coolants, oils, and degreasers, and other chemicals are loaded inside the sturdy tubes by the lip gloss tube filler.

Stationery Industry

Lip Gloss Tube Filler in Stationery Industry

Yes, lip gloss tube filler is an essential part of stationery packaging lines. It feeds the correct volume of liquid stationary products, for instance, paints, glitter, glues, highlighters, and inks in the tube. It can process both laminate and plastic stationary tubes.

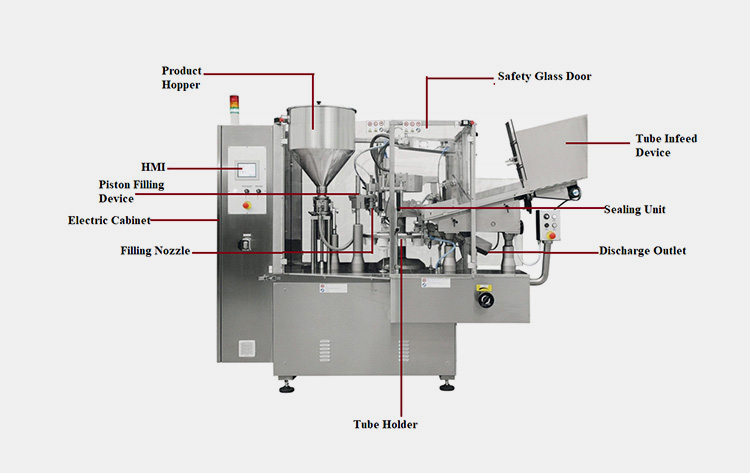

4.What are the Essential Components of Lip Gloss Tube Filler?

Lip gloss tube filler is comprised of different mechanical, electrical, and motorized components that act at the right time to fill lip gloss in the tubes. A list of important components is penned below for your information.

Parts of Lip Gloss Tube Filler

| Product Hopper | It is like a funnel device that typically stores huge loads of lip gloss for dispensing. In these hoppers, lip gloss is manually loaded by the operator or by the infeed tanks. |

| HMI | An intuitive and intelligent touch screen that provides ease of customizing the lip gloss filling process. Different options for filling parameters are displayed on the screen and are easily selected by swap of fingers. Prestored data recipes are also saved on the touch screen which aids in quick changeovers. |

| Piston Filling Device | It is a cylindrical device that moves up and down to exert pressure on the lip gloss and assists in the flow of product from the hopper into the filling unit. |

| Electric Cabinet | It is a robust electric powerhouse of the machine in which different switches, relays, and breakers are present. These electric switches control different parts of the lip gloss tube filler and provide them with energy for running. |

| Filling Nozzle | It is an elongated tubular device that has a central place in the lip gloss dispensing. It extends to the bottom of the lip gloss tube and smoothly fills the tube with lip gloss without creating a spill mess. |

| Tube Holder | This is the part of the lip gloss tube filler that properly holds the tube during different working stages. It does not allow the tubes to tilt over and spatter products. |

| Discharge Outlet | It is a chute-like opening from which completely packaged lip gloss tubes are discharged from the equipment. The discharge outlet usually drops tubes into a collection bin. |

| Sealing Unit | This part of the lip gloss tube filler hermetically seals the tubes using heated bars in different patterns and shapes such as curves, rounds, etc. The opening of the tube is closed using sealing devices. |

| Tube Infeed Device | A bulk number of empty tubes are placed inside the tube infeed device. This unit dispenses tubes one by one to the working station of lip gloss tube filler. |

| Safety Glass Door | It is a glass panel that separates the lip gloss tube filling and sealing section from the operator; however, due to transparent glass, operators can visually see the progress of the filling operation. This helps to prevent contamination of the products while also protecting operators from chemical fumes and dust. |

5.How Does Lip Gloss Tube Filler Work?

Different steps are executed with perfect diligence to have a uniform and consistent filling of lip gloss. The working steps of lip gloss tube filler are detailed below:

Lip Gloss and Empty Tubes Loading

Lip Gloss and Empty Tubes Loading- Picture Courtesy: Comadis Tube Filling Machine

Usually before the initiation of lip gloss filling, the materials for filling- lip gloss and tubes- are stored inside the machine. A large quantity of lip gloss is loaded in the hopper by the pumps while huge quantities of empty tubes are placed in the infeed device. The tubes are also placed on the conveyors after an interval by the operator.

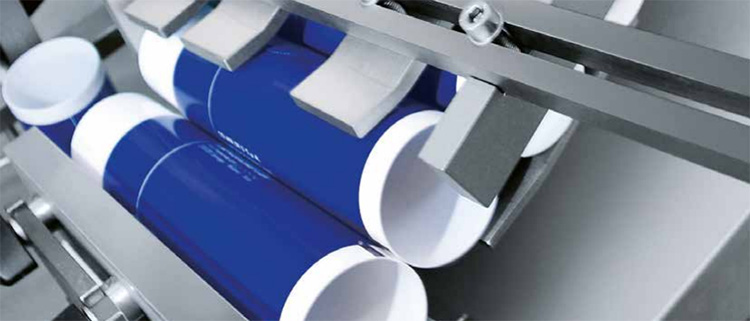

Tube Orientation

Tube Orientation- Picture Courtesy: Npackmachine.com

At the start of the operation, the empty tubes are moved from the infeed device to the lip gloss tube filler turn table and are vertically oriented by scanning their print mark. This step is necessary for mess-free filling.

Lip Gloss Filling

Lip Gloss Filling- Picture Courtesy: Comadis

After tube orientation, the next step is lip gloss filling inside the tubes. The product from the hopper is moved via pipes, pumps, and pistons to the filling nozzle. Lip gloss from the nozzle gradually trickles into the tubes. Sensors detect the precise amount of lip gloss while loading which aids in achieving accuracy in filling.

Lip Gloss Tube Sealing

Lip Gloss Tube Sealing- Picture Courtesy: Jornen Machinery

In the next step, the ends of lip gloss tubes are heated by hot air for sealing while the outer part of the tube is cooled down by the cold-water circulation to avoid product damage. High pressure exerted by the sealing jaws seals the end of lip gloss tubes.

Tube Trim and Ejection

Tube Trim and Ejection- Picture Courtesy: delitepharmamachine

Next uneven edges are refined using cutting knives that trim edges to give a smooth and elegant look and feel of the lip gloss tubes. After trimming, the packaged tubes are removed from the worktable into the tube chute and ultimately, lip gloss tubes are stored in the collection unit.

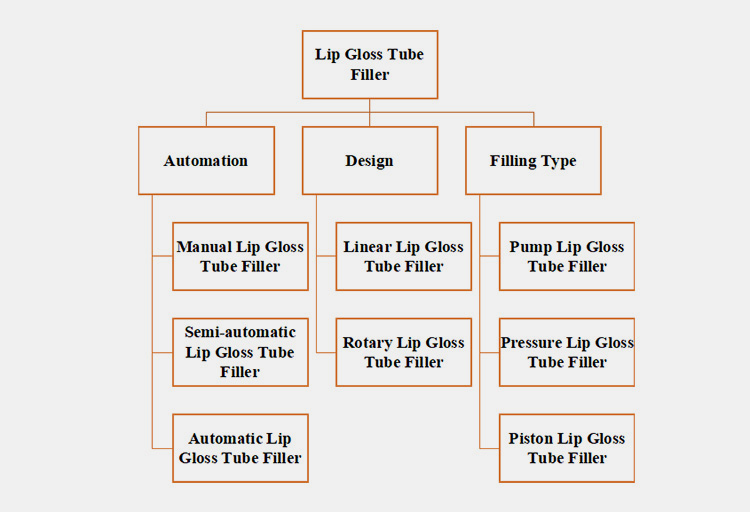

6.What are Different Kinds of Lip Gloss Tube Filler?

The technological revolution has led to the manufacturing of a wide range of lip gloss tube fillers, consequently, there exists diversity in this machine. For simplicity, this device is classified into the following types.

Classification Based on Automation

There are three types of lip gloss tube fillers when categorized depending upon the level of automation.

Manual Lip Gloss Tube Filler

Manual Lip Gloss Tube Filler

It is one of the earliest forms of lip gloss tube filler. It is an easily movable unit that is fitted on the top of a desktop or benchtop. Typically, operators have to place tubes one by one under the filling nozzle of the machine and gears or levers are rotated to fill the lip gloss tubes. It is an inexpensive machine employed in small businesses. However, this equipment is labour-intensive and has minimal accuracy.

Semi-automatic Lip Gloss Tube Filler

Semi-automatic Lip Gloss Tube Filler- Picture Courtesy: PENGLAI Packing

It is a medium-sized unit but has a compact construction. It has one to two filling nozzles, resulting in much higher lip gloss tube filling than its manual counterpart. It is equipped with automatic controls that provide a high percentage of accuracy in the fill. However, this machine is burdensome for the operators as they have to manually load or unload the tubes.

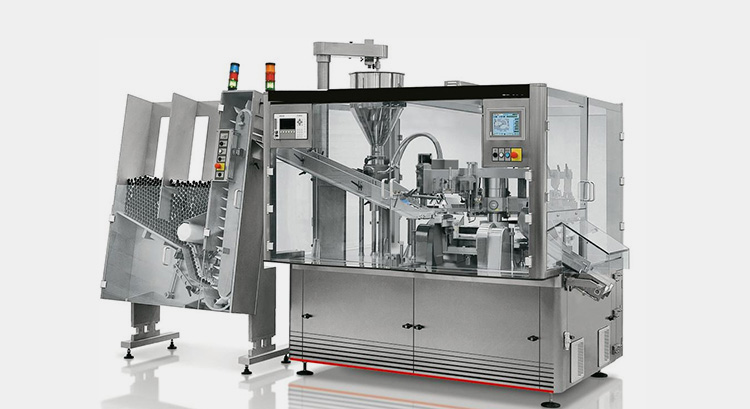

Automatic Lip Gloss Tube Filler

Automatic Lip Gloss Tube Filler

It is a fully autonomous unit available in much larger sizes, thus needing more room for installation. However, this machine speeds up lip gloss tube filling, therefore, it is the preferred choice of large-scale production plants because it can process more volume of lip gloss tube. It performs every step independently, thus saving labour expenses. Moreover, it has advanced sensors and weight-checking systems that provide a higher level of precision in lip gloss filling.

Classification Based on Design

Depending upon the design of the lip gloss tube filler, it is classified into two kinds.

Linear Lip Gloss Tube Filler

Linear Lip Gloss Tube Filler- Picture Courtesy: Wuxi Yingrun Machinery Technology Co., Ltd

As the name suggests, the design configuration of this machine is typically a straight line. Linear lip gloss tube filler is equipped with a long conveyor on which tubes are placed. Usually, tube grippers are used for holding the tubes for filling. This machine has fairly low processing speed and a smaller number of tubes are filled at the time. This is because the transport of tubes stops during tube fill. However, this unit is easily maintained and cleaned requiring less effort on the operators’ part.

Rotary Lip Gloss Tube Filler

Rotary Lip Gloss Tube Filler- Picture Courtesy: NEWECO

This machine has a circular kind of construction because of the rotary star wheel. This wheel has various stations that aid in quick filling, sealing, and, trimming of the lip gloss tubes. Multiple tubes are processed during one machine turn therefore; this equipment has a significantly larger processing speed than linear lip gloss tube filler.

Classification Based on Filling Type

There are three types of lip gloss tube fillers when classified based on filling type.

Pump Lip Gloss Tube Filler

Pump Tube Filler- Picture Courtesy: IMA Srl

This machine has a pump system for dispensing lip gloss in the tubes. there are different kinds of pumps, for instance, cavity pumps and flow metering pumps. This machine can easily handle lip gloss with higher viscosities. This machine has a higher consistent accuracy and is widely employed for filling lip gloss.

Pressure Lip Gloss Tube Filler

Pressure Lip Gloss Tube Filler- Picture Courtesy: Adelphi Group of Companies

It is a positive displacement pressure lip gloss tube filler. It exerts a high-pressure force on the thick and viscous lip gloss that has poor fluidity. This machine is a volumetric filling equipment that loads a precise quantity of lip gloss using springs as well as pumps. However, it is less commonly used in industries because it consumes more energy, resulting in huge utility bills.

Piston Lip Gloss Tube Filler

Piston Lip Gloss Tube Filler- Picture Courtesy: Rhino-Pak

In this type of lip gloss tube filler, the filling device is the piston cylinder. It is also offered with valves that are closed when filling is not taking place. The piston movement in the cylinder applies the force of the lip gloss that moves into the cylinder and ultimately into the tube via the filling nozzle. The stroke adjustment of pistons aids in lip gloss fill in this machine.

7.What Tube Sizes are Processed by Lip Gloss Tube Filler?

Sizes of Lip Gloss Tubes

A lip gloss tube filler can process a huge range of tubes by just changing of tube holder. The small-sized tube requires a small tube holder while large-sized tubes are contained in large-diameter tube holders. The largest-sized tube processed by the lip gloss tube filler is about 15 ml while the smallest-sized lip gloss tube filled by this machine is 3 ml or less. Tube sizes processed by lip gloss tube filler are:

| Tube Size (ml) | Height (mm) |

| 3 | 50 |

| 4 | 55 |

| 5 | 63 |

| 8 | 69 |

| 9 | 75 |

| 10 | 82 |

| 12 | 90 |

| 15 | 95 |

8.What are Tube Formats Filled by Lip Gloss Tube Filler?

Every cosmetic brand customises its tip gloss tube according to its brand identity, therefore different styled lip gloss tube formats are seen on retail shelves. Some popular tube formats filled by lip gloss tube filler are:

Cylindrical Lip Gloss Tubes

Cylindrical Lip Gloss Tubes

It is cylindrical with a round base and usually comes with a brush or lobe. It is one of the widely available formats for lip gloss. Thinner slimmer cylindrical lip gloss tubes are easier to carry around in handbags while travelling.

Squeeze Lip Gloss Tube

Squeeze Lip Gloss Tube

This is a classical option of filling tip gloss and it has a lobe at the top for application of the lip gloss. It has a low price and is light in weight. Different kinds of caps are used for sealing such tubes after use.

Square Lip Gloss Tube

Square Lip Gloss Tube

It is a rectangular or square-shaped lip gloss tube that has a wide diameter. It is a popular option for lip gloss packaging and gives products a luxurious look and feel. It is heavier than other lip gloss tube formats and consists of a lip wand for use.

9.How To Maintain Lip Gloss Tube Filler?

Maintenance of Lip Gloss Tube- Picture Courtesy: PolarSeal

For operating lip gloss tube filler to maximum period, it should be constantly maintained and cleaned. This regular maintenance also increases equipment safety. Here are some common tips for maintaining a lip gloss tube filler.

| Daily Maintenance | To prevent contamination of the lip gloss the equipment should be wiped and cleaned.

Fix any loose nuts and screws. Check the levelling of heating bars. Clean filling nozzle to remove solidified lip gloss. Inspect the grounding of the machine. Check the working status of sealing and trimming devices. Properly check the temperature of the cold-water circulation device. |

| Weekly Maintenance | Check cables and wires and tighten any loose wiring.

Check for leakage in the air pressure valve. Examine the lubricating liquid in the oil box and if required, fill it up. |

| Monthly Maintenance | Examine chain link and gear system.

Lubricate the working joints of the turn table. Substitute the old seal ring in the inner piston cylinder with a new one. |

| Bi-Yearly Maintenance | Thoroughly check the working status of switches and fuses in the electric board and if defective then replace them.

Secure motor connections. |

| Yearly Maintenance | Replace the damaged gear bearings.

Check the working orders of pumps, drives, motors, and water circulation systems and replace them if needed. Fill the fresh lubricating oil in the motor. |

10.How Can You Troubleshoot Lip Gloss Tube Filler?

Lip gloss tube filler is an efficient machine having a long running life but sometimes unexpected issues arise in this equipment which could cause downtimes. However, here are some tips to troubleshoot these unanticipated problems.

| Cause | Remedy | Image |

| Lip Gloss Does Not Discharging | ||

| Filling pipes are clogged because of debris and leftover products and are not properly cleaned.

The sealing ring located on the inner piston is damaged |

Properly clean the piston tube to remove the solidified products.

Replace the defective sealing ring. |

Lip Gloss Does Not Discharging- Picture Courtesy: cms.making.com |

| Poor Accuracy in Fill Volume | ||

| The filling pressure is not correct. There is a leakage in the air pressure valve. The Diaphragm valve is defective. | Fix the pressure valve. Replace the air pressure valve if there is leakage. Get a new diaphragm valve. |

Poor Fill Accuracy- Picture Courtesy: tubefillingmachine.net |

| Defective Lip Gloss Tube Seal | ||

| Blowing air volume is low and there is high suction force. The temperature of sealing elements is less. The tube walls are dirty and unclean causing poor sealing. The heating belt is not at the right level. | Calibrate the air metering unit to adjust the volume of blown air. Adjust the heating temperature of the sealing element. Thoroughly wash and dry the tubes before operation. Adjust the level of the heating belt. |

Poor Lip Gloss Seal- Picture Courtesy: tubefillingmachine.net |

| Lip Gloss Tubes Have Sharp Corner | ||

| There is an error in the positioning of the heating element and it is not levelled with the tubes. The sealing temperature is not accurate | The heating element should be at the right level with the tubes and it should have vertical positioning in the centre of the turn turntable. Adjust the amount of cooled water circulation to lower the sealing temperature. |

Lip Gloss Tubes Have Sharp Corner- Picture Courtesy: Msmakeupoem.com |

| Uneven Side Seals of Lip Gloss Tubes | ||

| Untightened cooling ring. The levelling of the heating bar is not right. | Properly tighten the cooling ring and if still loose, replace it. The heating bar should be aligned in the middle of the rotary unit. |

Uneven Side Seals of Lip Gloss Tubes - Picture Courtesy: Tefani Beauti |

11.What are the Guidelines for Choosing the Ideal Lip Gloss Tube Filler?

Lip gloss tube filler is a hefty purchase that runs smoothly for many years, generating substantial profit every year. Hence, much thought should be put into finding a perfect machine, well-aligned with the production needs. Here are some tips for getting an ideal lip gloss tube filler.

Access Your Needs

Production Needs of Businesses- Picture Courtesy: BellaRx Inc.

First, and foremost calculate your processing needs that is how many lip gloss tubes will you fill per hour. How many orders do you need to process every day? It will give you a rough idea about the level of automation. If your processing needs are higher, then it is best to look for an automatic lip gloss tube filler.

Get an Idea about Power Consumption

Power Consumption

Buying the ideal lip gloss tube filler is not only about price but it is also important to make inquiries about the energy consumption of your machine. Every industry is supplied with a precalculated amount of power by the government and if the equipment on your list runs on more power then you have to make special power arrangements for your business which is quite time-consuming.

Tube Handling

Cosmetic brands are constantly updating their lip gloss tube packaging. Therefore, it is crucial to select a lip gloss tube filler that can handle not only four present tube designs but also your future tube styles. Always check the tube holder in the equipment to see whether it can hold your current and future tube style.

Decide on Tube Material

Lip Gloss Tube Material

Today, plastic, aluminium, and laminate tubes are quite in rage for lip gloss. Brands are using material fabrication to introduce new materials for cosmetic tubes. Make sure the machine you are purchasing is the right fit for your lip gloss tube materials because otherwise, it will result in an investment with no return.

Go with a Reputable Brand

Reputable Brand

The brand of lip gloss tube filler is extremely important as good brands are competent and are reputed for manufacturing excellent-quality machines. Quality is a measure of operational life and the accuracy of the machine. Thus, do some homework and internet surfing for positive customer reviews regarding brands before going out for purchase.

Conclusion

Lip gloss tube filler is a significant machine in the cosmetic industry that fulfils the demands of consumers for on-the-go lip colour. This machine is well-liked by the brands because it fills higher numbers of tubes in a short time. Furthermore, this is a go-to solution because of its versatility and precision. If you require buying such equipment for your business, look no further because you are at the right place. We Allpack is home to top-quality cosmetic machinery and provides customized equipment at discounted rates.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide