Labeling Machine for Bottles: The Complete Buying Guide in 2024

Did you know that labeling machine for bottles can do much more than presenting information about formulation?

Today’s labeling machine helps in enhancing appealing presentations about your product, brands, packaging information, and visual aesthetics. So, a manufacturing and packaging company must consider ongoing and upcoming trends to skyrocket the competitive market. In this article, you will be a potential innovative labeling machine for bottles and how it can make your work easy in such an advanced technology. With so many available machines, deciding which is the best solution is of course difficult. So, we have outlined this article to help you select an effective and productive machine.

1.What should you know about Labeling machine for Bottles?

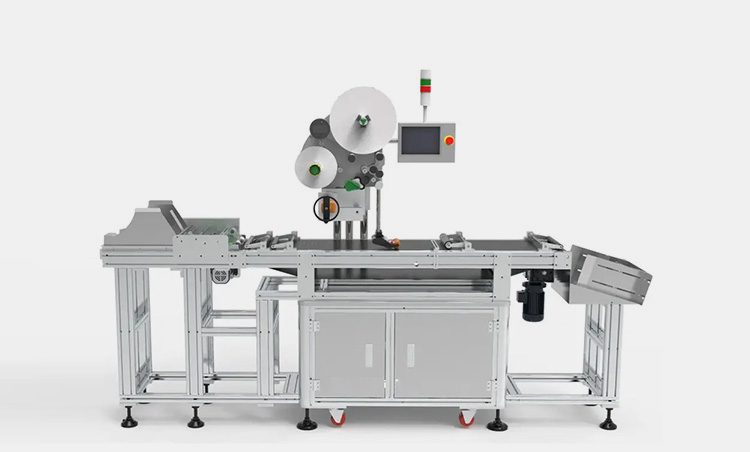

Labeling Machine For Bottles

A labeling machine for bottles is particularly constructed to label the packaging products effectively. This machine is useful to run any business that deals with large or bulk quantities of bottles.

You must be aware that dealing with bottles especially labeling them is an extremely difficult task whether done manually or by the machine. By means of labeling machine for bottles, it has been improved and enhanced the overall productivity of any production line.

2.How a labeling machine for bottles is beneficial?

We now know what a labeling machine is, so you might have definitely got a glimpse of how important it could be for industries to own this machine.

Enhanced Throughput and Work efficiency

Application of pressure-sensitive labels can be tedious work if done manually, instead work done by labeling machine for bottles would not only increase production capacity but also increase the speed at which the labels are being applied as many as per second.

Reduce Labor cost!

The use of the labeling machine for bottles cuts down on labor costs as there is less human intervention required to operate this machine except for loading the labels. This brings greater chances of earning a profit, as you won’t require hiring extra staff for this work and could redirect your workforce for greater value tasks such as quality control and supply chain management.

Accuracy

It is important to note that the placement of labels on your bottles must be precise and accurate, for this the labeling machine for bottles appropriately adheres to the label by positioning it where it is supposed to be placed. Unlike manual labeling, where there are chances of labels getting peeled off or not applied on the correct position, these risks are eliminated by using this machine as it assures tolerance precision up to +/- 0.3 mm.

Safety In Handling

Picture courtesy: Accraply

To ensure the safe and healthy working of your staff, labeling machine for bottles provides sensor-activated applicators and a conveyor belt system for the label application process and transferring of bottles. The process of label application can be the cause of musculoskeletal disorders and might be the reason for injuries.

3.What are the industrial applications of labeling machine for bottles?

Automotive Industry

The automotive industry uses labeling machine for bottles intended for outstanding depiction of graphics which helps them in building brand image, and for applying labels that states the purpose of fluid, its method of use, and safety warnings. It can be applied to plastic and metal bottles of different shapes and sizes.

Beverages Industry

From attracting customers with a cool design to portraying the quality of your product, whether it is mineral water, soft drinks, or alcoholic beverages, a labeling machine for bottles can handle all types of bottles for placing labels. It is necessary that the label must be resistant to spoilage due to any fluid or wear off due to scratches.

Chemicals Industry

Aware of its hazardous possibilities, the chemical industry uses bottle labeling machines in order to clearly mention all the constituents, safety and precautionary statements, and the direction for the intended use.

Food Industry

Picture courtesy: Delicious

An assorted range of food products like spices and condiments, confectionery, jams, sauces, and other edible items require catchy and effective labeling for their consumable items. For this purpose, they use a bottle labeling machine which assists the manufacturer in providing all details about the product such as their ingredients, date of manufacturing and expiry, etc. A bottle labeling machine used in the food industry can handle a variety of glass, plastic, and metal bottles.

Cosmetics Industry

Picture courtesy: Avon Care

Promising enough according to its packaging, the cosmetics industry requires competent and good visualizing labeling designs to deliver its products. A labeling machine for bottles comes in handy to fulfill this requirement as it can handle various shapes and sizes of bottles used for the filling of different beauty products.

Household Products

A labeling machine for bottles can be utilized for effective labeling of household products like floor and toilet cleaners, detergents, pest control sprays, hand wash, stain removers etc. These bottles are labeled with a good marketing strategy to depict their purpose of use.

Pharmaceutical Industry

The pharmaceutical industry uses the bottle labeling machine for safe and reliable placement of labels that state medicinal constituents, storage condition, direction for use date of manufacturing, and expiry date. Bottles for liquid and solid dosage forms of medicine are labeled with precision.

Nutraceutical Industry

This industry uses a labeling machine for bottles to efficiently put adhesive labels on their nutritional supplements such as multivitamins, dietary supplements, supplements for skin and hair health, supplements for different deficiencies, etc. Labels applied represent the nutritional requirements for different age groups and mention various minerals that they contain.

4.How does a labeling machine for bottles work?

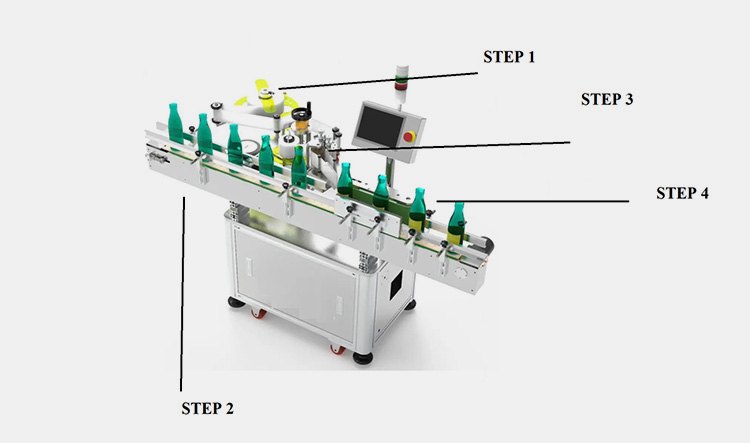

The working steps of labeling machine for bottles

The labeling machine for bottles works in a pretty straightforward way. The discussed below are following steps:

STEP 1

The first step involves feeding of roll over the feeding supplier and unwinding of label material from it. This can be achieved by manually handling an operator to ensure that fixation is done for supplying a steady roll.

STEP 2

The second step is receiving bottles for labeling purposes. The bottles are fed into the unit with the help of a conveyor which is presented for easy transportation of material prior to and after labeling.

STEP 3

This is the main step where bottles are subjected to a labeling unit for dispensing the label. The unit is equipped with a sensor that detects the bottles and places the label at the assigned measurement for an exact position as recommended by the manufacturer.

This step is divided into two steps; first, the application second is the presser. The applications of label can be done either pressure-sensitive or wrap method using hot -melt glue or cold or self-adhesion method; furthermore, applied horizontally or vertically. The presser are rollers that firmly press the applied labeled to avoid wrinkle, bubble or folding and ensure evenly application.

STEP 4

This step is divided into two sections, if labels are not corrected; the bottles are sent to the rejection unit. Similarly, the corrected labeled bottles are sent to the next machine via a conveyor to complete the packaging process.

5.What are the parts of the labeling machine for bottles?

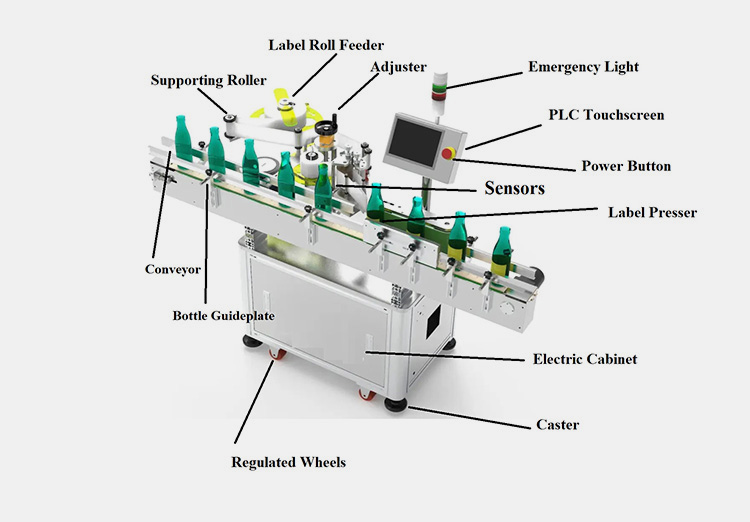

The major parts of the labeling machine for bottles are described below:

The common parts of the labeling machine for bottles

Label Roll Feeder

Every machine has start-up step. For labeling, this is the section where the operator has to fix and adjust the label roll to ensure the supply of labeling material is steady and smooth during operation.

Adjuster

This unit ensures proper regulation of labeling on the bottles. By use of an adjuster, you can finely correct the position of the label and alignment of bottles by adjusting the label roller.

Supporting Roller

When the label roll is fixed and adjusted; it is further supported by rollers that helps in fixation for smooth and uniform application of labels so wrinkles, bubbles, or folding can be prevented.

Emergency Light

This is used for safety purposes and is brightened during emergency scenarios to alert the operator for immediate action and keep the environment safe.

PLC Touchscreen

A touchscreen interface that controls via clicking keys available on the screen with a single touch. It allows users to add settings, troubleshoot, find alerts, diagnostic issues, etc.,

Power Button

This button is mostly situated adjacent to the PLC touchscreen that is simply used to activate the machine. Once you’re done with working; the final switching off can be attained by the same power switch.

Sensor

This is a prime section of the labeling machine for bottles that detects the presence of bottles and allows the machine to press the label in the right position as fed in the setting of the machine.

Conveyor

This is used for the steady transportation of bottles for labeling purposes. The conveyor is also used to integrate machines with other equipment.

Label Presser

The unit is meant for fixing labels once applied by the applicator. The presser exerts pressure on each fixed label to prevent the development of bubbles, wrinkles, or folding.

Bottle Guide plate

This unit helps in the alignment and stabilizing of bottles during transportation for labeling and leaving the machine. The prime purpose of this unit is to upright the bottles for uniform application of the labels.

Electric Cabinet

All electrical wiring, relays, switches, plugs, and circuit boards are housed in an electric cabinet.

Caster Wheels

The unit is helpful in providing support, relocation, and easy movement to the machine.

6.What are Types of Labeling Machine for Bottles?

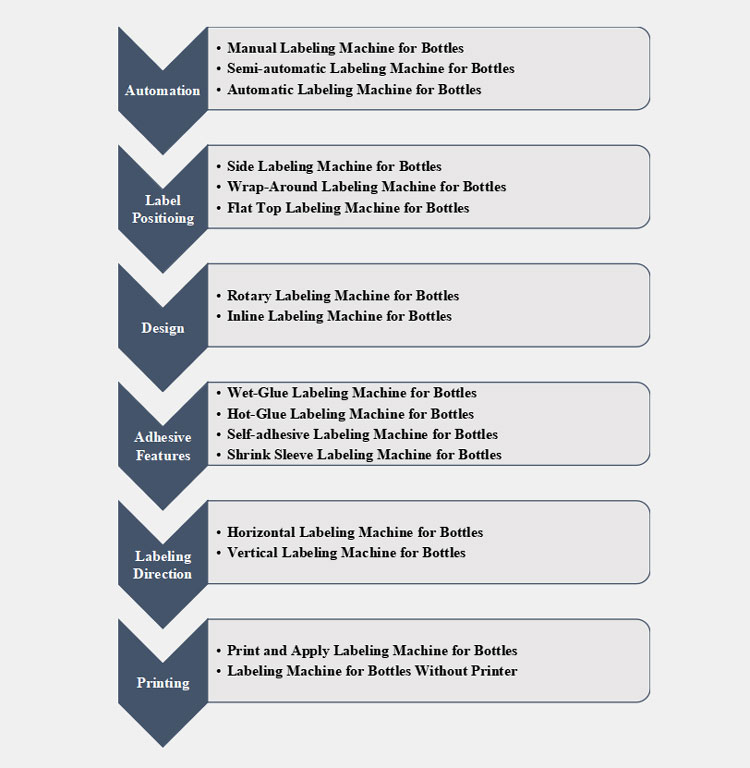

As packaging machinery is continuously evolving, every day different model of labeling machine for bottles is introduced. This equipment is classified depending on design, labeling direction, level of automation, etc.

A detailed overview of types of labeling machine for bottles is penned below to aid in your selection.

Classification Based on Automation

| Machine | Overview |

| Manual Labeling Machine for Bottles

|

It is the most straightforward type of labeling machine for bottles. For small home-based businesses where productivity is low, this machine is suitable since it is fairly expensive and can stick labels on a few bottles. It has handwheels or levels for manual label application. |

| Semi-automatic Labeling Machine for Bottles

|

This machine has a compact construction and is capable of labeling bottles independently. However, users manually load bottles on the conveyors. It has a higher accuracy rate than a manual labeling machine for bottles. Moreover, it has a higher labeling capacity and can label up to a thousand bottles per hour. |

| Automatic Labeling Machine for Bottles

|

It is the most advanced form of labeling machine for bottles when categorized on the level of automation. It has higher labeling speed and is typically employed in mass-scale labeling production to automate labeling. It is equipped with state-of-the-art gadgets, sensors, and alarm systems that not only provide high precision in labeling but are also essential for safety purposes. |

Classification Based on Label Positioning

| Machine | Overview |

| Side Labeling Machine for Bottles

|

For labeling one side or two sides of bottles, a side labeling machine is used. This equipment labels the front or back panel of the bottles. It works well with round, oval, flat, or square bottles. It is often employed for increasing the visual appeal of labeling since it offers wrinkle-free and crease-free labeling. However, it provides a limited area for information display. |

| Wrap-around Labeling Machine for Bottles

Picture Courtesy: ALLMA.NET |

It is one of the widely used machines for labeling of bottles. This machine wraps the complete circumference of bottles with labels. However, it is ideal for labeling round or cylindrical bottles. This equipment glues labels by rotating them on the exterior of bottles. This machine can process glass, plastic, as well as, metal bottles. |

| Top Labeling Machine for Bottles

Picture Courtesy: vkpak |

This machine sticks labels at the top side of bottles to minimize the tampering risk. It processes bottles of any shape and size and is very helpful in resolving security problems |

Classification Based on Design

| Machine | Overview |

| Rotary Labeling Machine for Bottles

Picture Courtesy: vkpak |

This machine is equipped with turrets or turntables that tightly hold bottles at the bottom using a bottle holder. This holder rotates at 360° for ideal label placement. Furthermore, this machine operates at high speed due to its simultaneous labeling of multiple bottles. |

| Inline Labeling Machine for Bottles

|

This machine has a straight-line configuration and labels one bottle at a time. It is more suited to simple productions where low labeling capacity is required. But it has minimal parts and can be easily upgraded. |

Classification Based on Adhesive Features

| Machine | Overview |

| Wet-Glue Labeling Machine for Bottles

|

It mainly processes decorative and embossed paper labels and applies liquid glue to bottles. It has a glue applicator that spreads glue over label strips and the label press sticks them over the bottles. It is mostly employed in the beverage industry. |

| Hot-Glue Labeling Machine for Bottles

|

In this machine, first glue or adhesive is heated before application. The melted glue is best for applying wrap-around labels over bottles. This machine has glue dispensing nozzles that spread precise amounts of glue to labels. This prevents glue buildup on labeling components. |

| Self-Adhesive Labeling Machine for Bottles

|

This machine does not need any adhesive instead it fixes pre-glue labels over bottles. It simply peels off the back paper from label strips and then applies the sticky part of labels over bottles. Its biggest advantage is- gluing complex-shaped labels over products. |

| Shrink Sleeve Labeling Machine for Bottles

|

This machine puts plastic sleeves over the moving bottles. Then, bottles go inside the heat tunnel for melting and shrinking sleeves so that they tightly fit bottles. This machine is employed for increasing aesthetic value and branding of products. |

Classification Based on Labeling Direction

| Machine | Overview |

| Horizontal Labeling Machine for Bottles

|

In this machine, labels are usually applied over bottles while they are lolling on their side. It works best for bottles with unstable bases that cannot stand right like round bottom bottles |

| Vertical Labeling Machine for Bottles

|

Partial or complete labels are stuck over the bottle while they are standing upright. This machine is ideal for labeling bottles with flat bases or slightly tapered bottles like square or rectangular bottles. |

Classification Based on Printing

| Machine | Overview |

| Print and Apply Labeling Machine for Bottles

Picture Courtesy: NJM Packaging |

For printing real-time changing product information such as barcode, tracing numbers, batch numbers, etc. Print and apply labeling machine for bottles is employed. This machine has high-definition printers for printing graphics to build a unique brand image. |

| Labeling Machine for Bottles Without Printers

|

This machine is simple without any advanced printers. It simply uses preprinted stickers or add-ons for labeling. It has a high processing speed as it does not involve a printing process. |

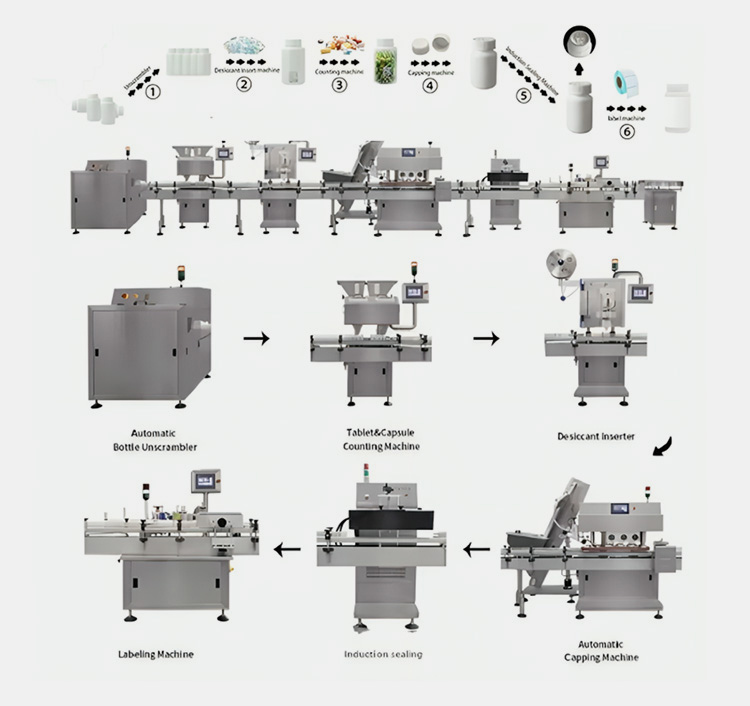

7.What is the production line of labeling machine for bottles?

Automatic Bottle Unscrambler

Often bottle unscrambling machine aligns bottles at precise positions on the production line conveyors. This machine receives bottles in random order from the hopper and uses mechanical systems for placing bottles in standing positions on conveyors to speed up bottle packaging.

Counting and Filling Machine

In health care, pharmaceutical, nutraceutical, food, and cosmetic industries, this device is utilized for counting and filling capsules, pills, confectionaries, pearls, and other related products with a high precision rate. This machine consists of advanced camera vision systems and sensors that detect the precise number of products, passing through vibratory or rotary disks and then load them into bottles

Desiccant Inserter

A desiccant is placed into bottles by a desiccant inserter machine to prevent moisture absorbance by hygroscopic and sensitive products in humid and damp environments. This equipment cuts individual packets using a cutting knife and inserts them into bottles.

Automatic Bottle Capping Machine

Caps are tightly affixed on the bottle mouths by this equipment. It comes in handy in averting spillage and leaking risks. Pick-off systems present in these machines randomly select caps from the hopper and place them on bottles. Capping heads and rotary disks present in the bottle capping machine rotate caps using torque and firmly seal bottles.

Induction Sealing Machine

This machine securely seals the bottles with foils or liners. It ensures product integrity and prevents tampering. An induction sealing machine is also important in maintaining product quality, especially its freshness and taste. Usually, liners present inside the caps are bonded to the mouth of bottles by the application of electromagnetic current or heat. This melts foil that is then stuck onto bottle mouths.

Bottle Labeling Machine

In product recognition and identification, the bottle labeling machine has a central place. This machine uses a labeling head, label press, and glue applicator for sticking labels on the circumference, front side, back panel, top, or bottom of bottles.

8.Is the labeling machine for bottles suitable for other packaging types?

Owing to the huge industrial sectors that are covered by labeling machine for bottles, it can be seen by other packaging types that are processed for application of labels. For example:

Jars

Jars made up of glass or plastic containing various products like sauces, jams, nutritional supplements, medicines, chemicals, etc can be labeled using a labeling machine for bottles.

Vials

This type of packaging material is used usually for pharmaceutical liquid medicines, cosmetic serums and also some chemicals. Vials are small cylindrical shaped glass bottles which can be labeled using this machine.

Ampoules

Picture Courtesy: Science Photo Library

Ampoules are sealed small glass packaging types that can be labeled using a labeling machine for bottles. These are used to hold pharmaceutical liquid medicines and cosmetic serums, which require extreme care while placing labels. The label on it usually mentions drug name, expiry and batch code.

Cans

Cans are cylindrically shaped, oval-shaped, or round packaging material that holds different beverages like soft drinks and juices, alcoholic drinks, food items, etc. They are made of metal, plastic, and glass, and can be labeled using this machine.

Containers

Large and small sized containers such as gallons of different shapes like oval, round, cylindrical which are used to hold household products, chemicals, water, milk, and cosmetic products, etc. may be labeled using this machine. They are usually of plastic, glass, and metal packaging material.

9.What Are Common Problems with Labelling Machine For Bottles?

According to our expertise, we have noticed so common problems with labeling machine for bottles and many clients do contact us for that. Therefore, we are mentioning them to help you out as well.

Labels Curling

Picture Courtesy:Reddit

This is another condition that occurs when labels are applied on the surface of the bottle.

This can be caused by due to uneven application of adhesive, and label separation. To solve this problem, calibrate the machine. Use new adhesive and notice its application must be evenly done by the machine. Thirdly, assess the die-strike of the labeled roll.

Tearing and Breaking of Label

Picture Courtesy: bluelabelpackaging

Tearing is a common problem that occurs when using a label machine for bottles that interrupt the workflow of a production line.

This condition can be sorted out by calibrating the machine. Correct the movement of bottles to avoid dragging the bottles.

Peeling of Labeled Bottles

Picture Courtesy: Eco Organic Garden

Peeling occurs in labeled products during the procedure. This can occur when working conditions are facing high temperatures and humidity. To solve this problem. First, reuse the adhesive because in case of old glue application can affect the process therefore new products should be used.

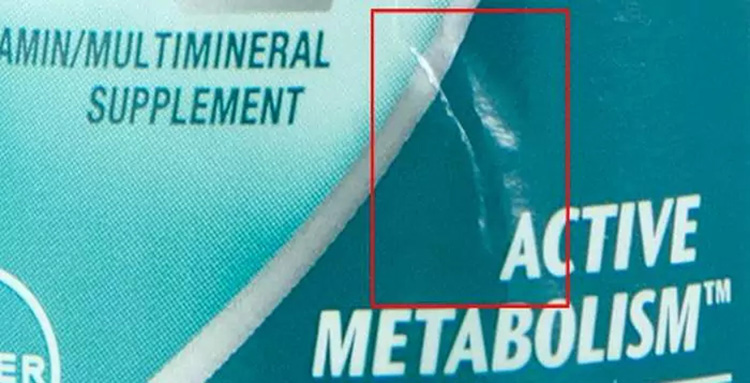

Wrinkling and Folding

Picture Courtesy: Resource Labeling Group

Wrinkling is the condition where labels are presented with folding and gaps inside.

This occurred due to incorrect usage of adhesive. Moreover, due to the irregular shape of bottles labels cannot adhere properly to the surface of the bottles that is resulting in wrinkling.

To solve this problem, correct the pressure or label tension. Calibrate the rollers, and supporters to allow smooth movement and re-adjust the presser that ensure each applied label is pressed with the required tension to avoid ridges.

10.How to Clean and maintain labeling machine for bottles?

A correctly maintained labeling machine for bottles is the key to getting long long-lasting machine, making you capable of attaining a great return on investment. Ignoring this factor can lead to failing the equipment. Discussed below points are helpful to learn exactly how to clean and maintain.

The Wiping of Applicator Head

If you want to label evenly and clearly, you need to clean the head before and after running each process. For that, use a dry cloth and shape sponge stick that can carefully erase and gently erase the debris or dust.

Cleaning of Sensors

Be sure to view sensors, as it is sensitive part and perform a significant role therefore remove dust or debris accumulated on them by gently wiping off the sticky material for optimal operation.

Never Ignore the Rollers

If the label is still left or remains around the roller it can interrupt the adjustment for further operation. It is imperative to clear the rollers and clear the unwanted remanent.

Replacing Old with New

If you notice something in worn-out condition; please replace it with a new one to sustain the work efficiency of the equipment. For example; plugs, nuts and bolts, circuits, etc.

Using Lubricants!

The moveable parts such as conveyors, rollers, feeders, pressers, and others must be applied with lubricants for efficient and noise-free workability.

Get rid of the dirt & dust!

By application of highly compressed air blowers efficiently clears minute particles of dust and dirt.

11.What should be considered when purchasing labeling machine for bottles?

When purchasing a labeling machine for bottles, it is primarily important to consider essential factors that will help you select the right machine that exactly matches your business needs.

Understand Your Labeling Needs!

Not every labeling machine for bottles can perform labeling with various shapes such as for round bottles, the labeling machine for bottles would be different for example wrap-around. If you have selected a flat top or other type it won’t be suitable for the wrap-around labeling procedure. Moreover, assess your capacity goals, designs, and production capacity.

Set Your Budget

Considering budget and selecting machines are directly proportional to each other. The variation in prices always affects therefore buyers must be a little bit flexible for the perfect solution. Plus, for a smaller budget, there are semi-automatic machines available in the market that can fulfill and begin your procedure as a start-up.

Consider Machine’s Features

Whether machine can integrate with other equipment? What should be the installation space requirements? What are the product’s dimensions? How frequent maintenance and cleaning schedules should be conducted? etc. Ensure the machine is easy to handle, clean, and maintain, and must comply with your required specifications.

Conclusion

Indeed, purchasing and adding machines to your production line is a complex task that must be taken into high consideration, with ALLPACK, it doesn’t have to be. We know every need of labeling with superb machines to attain a consistent output. With pride, ALLPACK offers bespoke customer services that are helpful for your business. Please contact us to get what you are looking for; we’re here to schedule free consultations and offer buying guidelines and various available options for your business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours