Inline Label Applicator: The Complete Buying Guide in 2024

Do you know that container labels are important for not only product communication but also for product presentation? The machine important for labeling purposes is- an inline label applicator. The need for labeling is increasing in this modern era and with it, demand for an inline label applicator is also increasing.

The inline label applicator is dominating labeling market because of its contribution to product identification and product information. It also keeps the product relevant and prevents risks of counterfeiting, fraud, product tampering and many more.

In this blog, you will learn what kind of innovative potential an inline label applicator brings to products. How does it automate and streamline production? So, let’s get started.

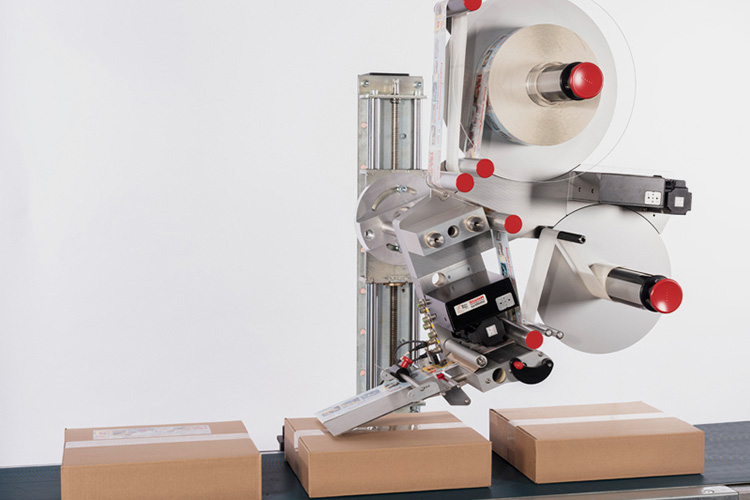

1.What is Meant by Inline Label Applicator?

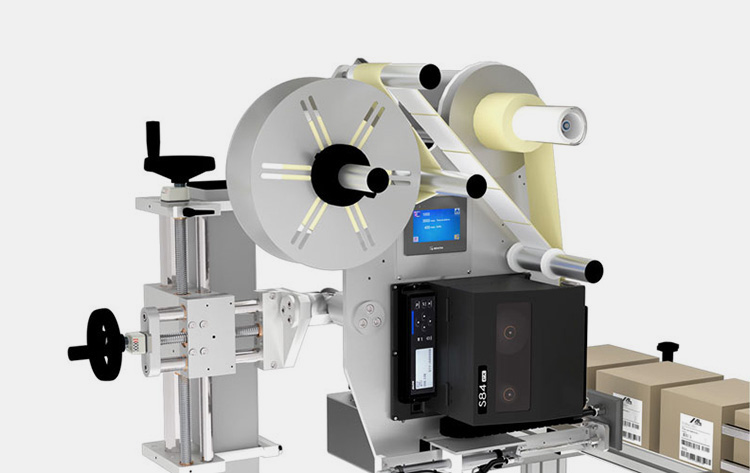

Allpack Inline Label Applicator

An inline label applicator has a straight-line construction, usually in the shape of letters L, U, and Z. This machine is a start-of-the-art equipment that places labels on the sides of the container.

It can be configured to stick labels at the top side, bottom side, front panel, back panel, and corners of the containers. It sticks transit labels, point-of-sale, decorative, informative, and display labels on the containers

Sometimes, this machine is customized for placing labels entirely around the whole middle side of the bottles and jars. It also places temper-evident and tracking labels on the container for safety and security purposes

2.How Inline Label Applicator is Useful for Productions?

Inline label application is a quick and efficient machine that generates a heavy return on investment by its swift production. Here is a list of benefits with which inline label applicator proves its usefulness to businesses.

High Efficiency

High Efficiency with Inline Label Applicator- Picture Courtesy: bb-automation

Businesses add machines for their increased output rate and this feature is a fundamental component of the inline label applicator machine. With its automated systems, it increasingly achieves high speeds. It labels more containers in less time. This is a failsafe way to boost the throughput of the production.

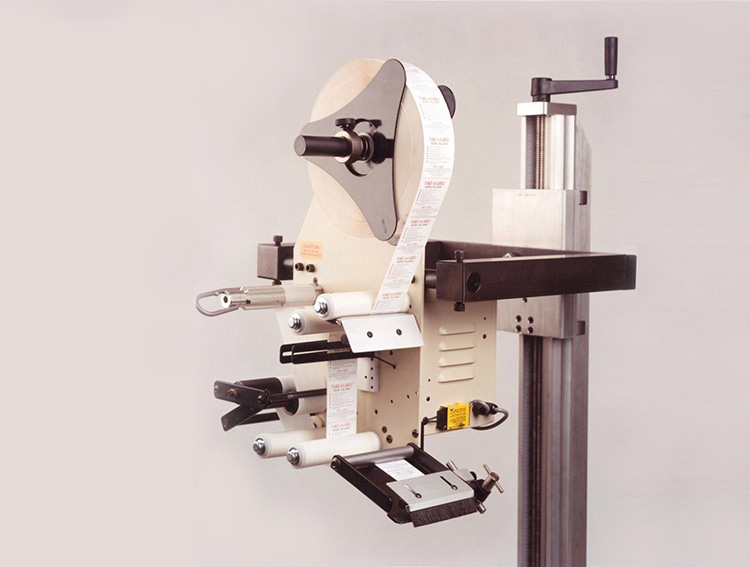

Automation

Automation with Inline Label Applicator- Picture Courtesy: EPI Labeling

Manual labeling is filled with a long list of problems like shortage of labour, increased demand for label products and lengthy production delays. Therefore, automation in the inline label applicator is high in demand. It boosts the output rate while requiring little to no human involvement. Furthermore, it also cuts down labour wages which saves operational expenses.

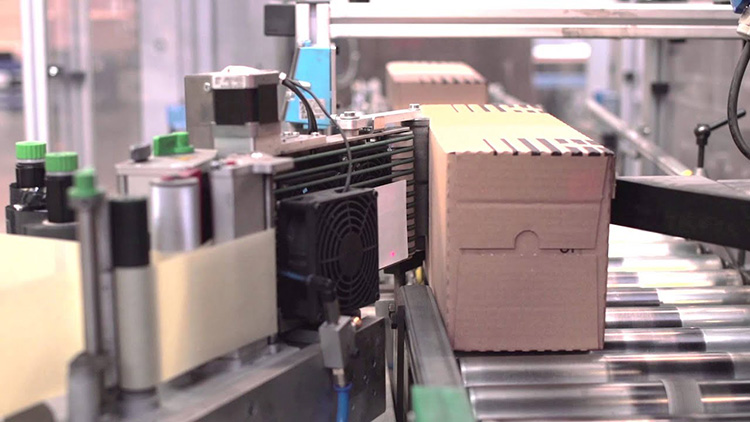

Labeling Precision

Labeling Precision by Inline Label Applicator- Picture Courtesy: Weber Marking Systems

The inline label applicator has a highly sensitive sensor and computerized controls that aid it in accomplishing labeling precision. Due to its accurate labeling, it has an edge over hand labeling. An inline label applicator is preferred in large productions, as it does not have labeling orientation and adhesivity errors that are possible with manual labeling.

Labeling Flexibility

Product Flexibility by Inline Label Applicator- Picture Courtesy: Dieline

Its quick change of parts opens up more possibilities for labeling differing in their shapes, sizes, and orientations. Furthermore. With its easy configuration changes, it can process a wide variety of label materials.

Safety and Security

Safety and Security by Inline Label Applicator

Inline label applicator has a significant role in the safety and security of the products. It applies tamper-proof that shows signs of tampering if the product has authorized access. This prevents fraudulent and theft activities. It also sticks tracking labels by which product shipment can be tracked anywhere in the world.

Product Information

Product Information by Inline Label Applicator- Picture Courtesy: Experts Label

With labeling containers, an inline label applicator is essential for product communication and information. Detail-conscious individuals demand thoroughly labeled products and hence; the inline label applicator plays a role in communicating details about usage instructions, expiry date, ingredients, nutrition, etc., to customers.

3.In What Industries Inline Label Applicator Is Used?

With its quick pace and optimal labeling results, inline label applicator is used in different industries such as:

Food Industries

Use of Inline Label Applicator in Food Industry- Picture Courtesy: Dieline

An inline label applicator is important in the food industry for the safety of food products. By labeling, brands communicate storage and handling details to the users. It is used to label every foodstuff like dairy, vegetables, meat, pulses, grains, fruits, bakery items, confectioneries, snacks, sauces, dressings, and many more.

Beverage Industry

Use of Inline Label Applicator in Beverage Industry- Picture Courtesy: Beverage Label

Inline label applicator is utilized in the beverage industry because of its higher throughput and mess-free labeling. It labels juices, essential oils, cooking oils, mineral waters, milk, energy drinks, alcoholic beverages, and soft drinks, to name a few in the beverage industry.

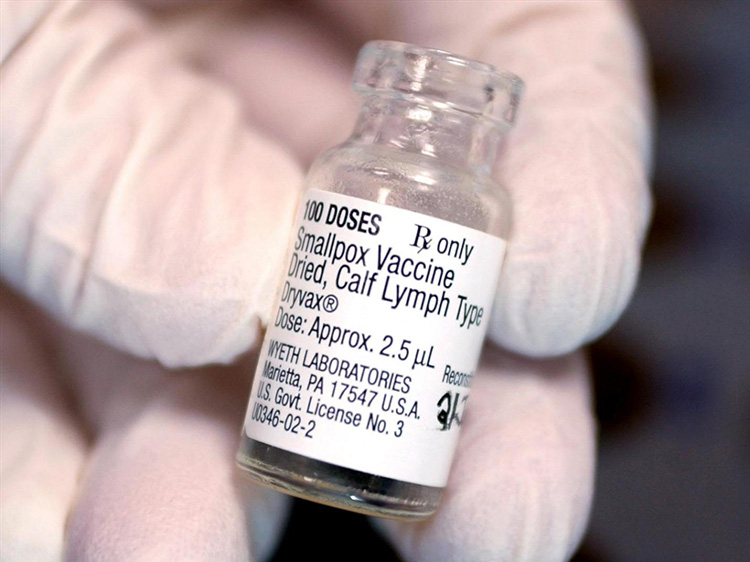

Pharmaceutical Industry

Use of Inline Label Applicator in Pharmaceutical Industry

Product information is a strict regulation imposed by the FDA and other drug regulatory authorities in the pharmaceutical sector. Therefore, pharma brands employ this machine to label bottles, vials, ampoules, syringes, pouches, and sachets in the pharmaceutical industry.

Nutraceutical Industry

Use of Inline Label Applicator in Nutraceutical Industry

Inline label applicator has an important role in the nutraceutical industry for labeling of nutraceutical bottles and pouches. It labels vitamin and mineral supplements, energy boosters, hormones, dietary fibres, and probiotics.

Cosmetic Industry

Use of Inline Label Applicator in Cosmetics Industry- Picture Courtesy: Rebsons Label

Inline label applicator is utilized for branding purposes in the cosmetic industry. It enhances the product appeal of cosmetic products by sticking striking and stylish labels on the cosmetic products, for instance, bottles, pouches, and jars of gels, dyes, creams, fragrances, foundations, etc.

Chemical Industrial

Use of Inline Label Applicator in Chemical Industry- Picture Courtesy: Computype

Chemical products are dangerous for the health and safety of users, hence; they must be labelled correctly. To communicate the hazards of chemicals, an inline label applicator is utilized in the chemical industry to label acids, alkalis, salts, bleaches, toilet cleaners, sanitisers, disinfectants, detergents, chlorine, etc.

Personal Care Industry

Use of Inline Label Applicator in Personal Care Industry

Inline label applicator has a prime value in the personal care industry for brand promotion and product appeal. Personal care brands add personalized labels on their container to attract and inform their clients. So, this machine is utilized in the personal care industry to label shampoo, sanitary products, soaps, body mists, shaving gels, and deodorants, to name a few.

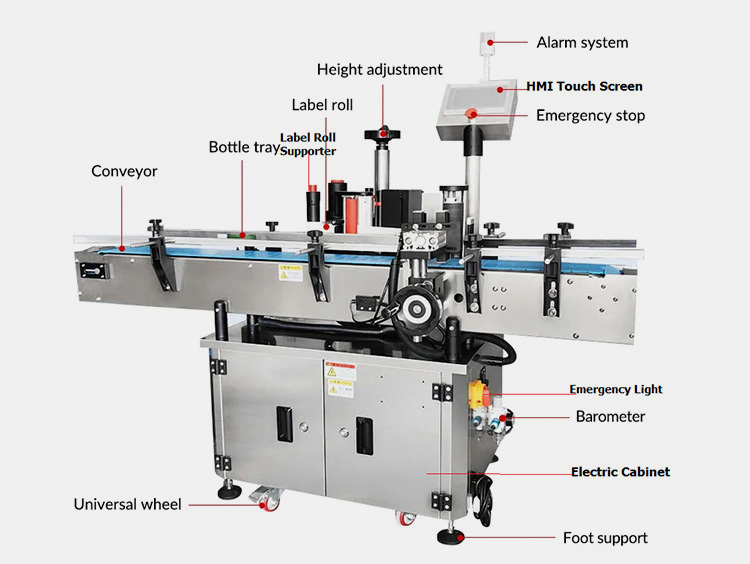

4.What are the Main Parts of Inline Label Applicator?

The inline label applicator consists of advanced labeling components that work in harmony for precise and effective labeling. Here is a list of a few important components:

Parts of Inline Label Applicator

| Conveyor | It consists of drive belts, rollers, or chains that support the container during their transport. It is meant for moving the containers between different stations of the inline label applicator. |

| Label Roll | It is the unwinding disk on which labeling film is housed. This roller rotates for the unfurling of the labeling film. |

| Label Roll Supporter | They support the labeling film while labels are glued to the containers. It ensures error-free dispensing of labels. |

| Bottle Tray | This component is present in most of the models of inline label applicators for supporting and stabilizing bottles when they are travelling on the conveyor. |

| Alarm System | It is an alarm system that plays an important in the safety of the inline label applicator. It lights up and sounds an alarm to swiftly halt the machine if there is a misalignment of labels, jamming of the machine or any other issue in the equipment. |

| Emergency Light | It is a safety component present in most of the inline label applicators and lightens up to grab the instant attention of the operator for quick intervention and to avoid accidents. |

| Barometer | The barometer is a device used for gauging the air pressure in the equipment. It ensures consistent air pressure and smooth labeling performance. |

| Electric Cabinet | It is an enclosed unit present in the inline label application for housing wires, cables, circuit breakers, switches, etc. It is essential in providing power to different components of the machine. |

| Foot Support | It is a support system that bears the entire weight of the machine and keeps it aligned and balanced. |

| Universal wheel | The universal wheels are present in the equipment for ease of portability and movement. |

| Height Adjustment Lever | It is present on the upper side of the inline label applicator and consists of wheels that are rotated to adjust the level of the label applicator according to the size of the container. It aids in perfect label alignment on the container. |

| HMI touch Screen | A smart touch screen is a technologically advanced setup, present in the inline label applicator using which the operator can easily program the labeling operation. Moreover, it is employed in viewing the throughput of the operation and diagnosis of the machine. |

| Emergency Stop Button | It is a red-coloured knob and is prominently visible on the HMI control panel. This is pressed to quickly stop the machine in case of fire or electric accidents. |

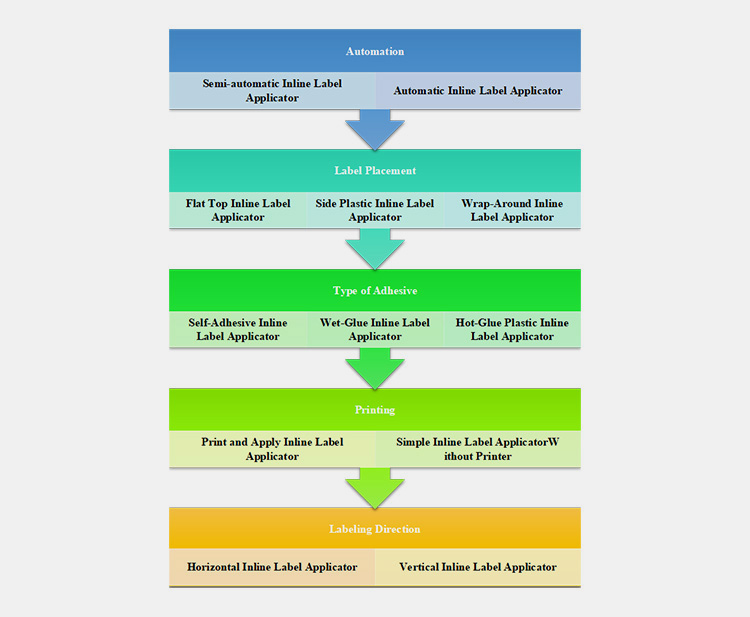

5.What Types of Inline Label Applicators Exist in the Market?

There are various makes and models of the inline label applicator differing based on label orientation, adhesive type, labeling direction, and type of container. The detailed classification of this machine is penned below for your understanding.

According to Automation

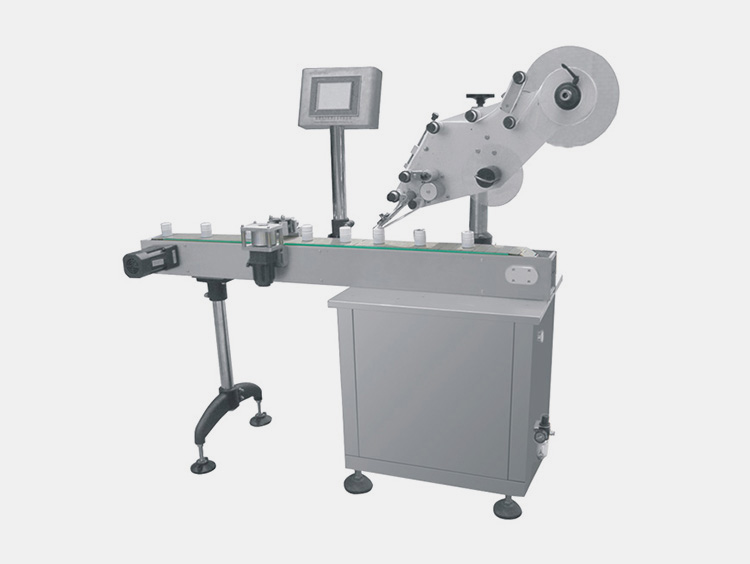

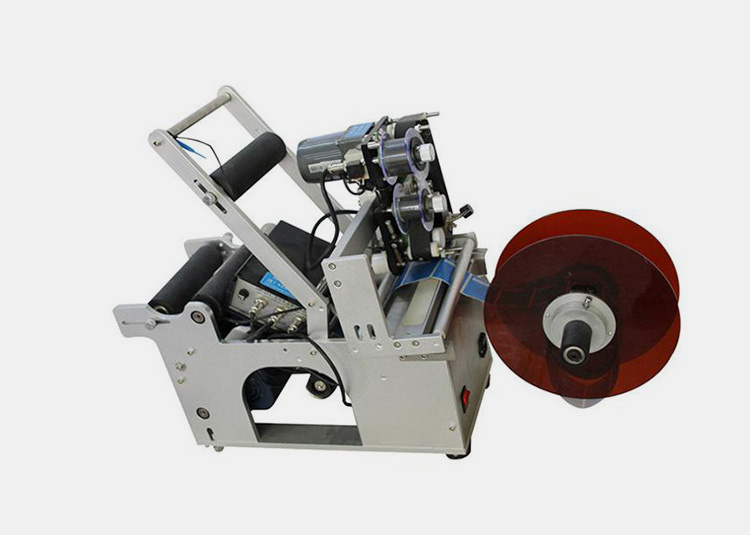

Semi-automatic Inline Label Applicator

Allpack Semi-automatic Inline Label Applicator

It is a small tabletop machine best for businesses with space and budget constraints. It has low labeling productivity but comes at affordable prices. Operators manually have to load and unload containers on this machine but labeling itself is carried out by the machine itself.

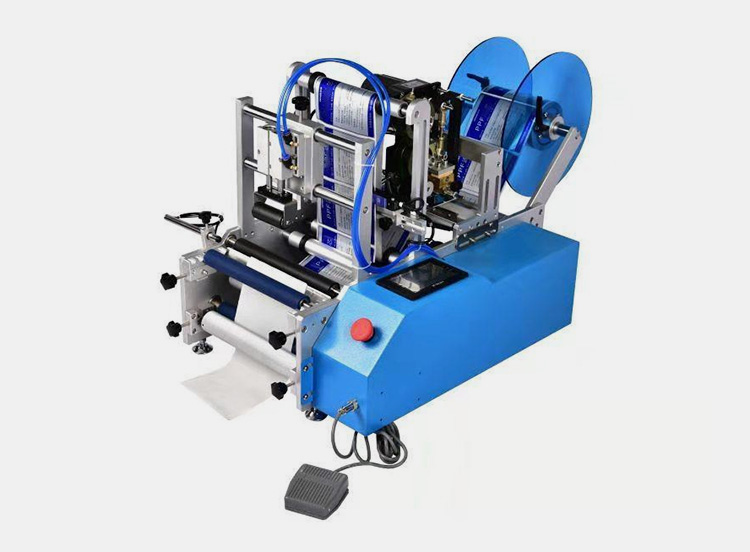

Automatic Inline Label Applicator

Allpack Automatic Inline Label Applicator

It is a fast and completely autonomous system in which all process from labeling to unloading is performed by the machine itself. It is best for productions that process bulk batches of labeled containers. It is equipped with sensors, rollers, and label unwinding disk for smooth and efficient label application.

According to Label Placement

Flat Top Inline Label Applicator

Allpack Top Inline Label Applicator

As the name suggests, this machine is employed for labeling the top corner of the container. It applies labels to the flat sides of boxes and pouches. Printers can be added to this system for printing information for instance, safety instructions, expiry dates, lot numbers, bar codes, and shipping guidelines. It glues labels without air bubbles and wrinkling papers.

Side Plastic Inline Label Applicator

Allpack Side Plastic Inline Label Applicator

It is also termed as front and back panel inline label applicators. It labels the front and back seams of the packaging container. It is a versatile piece of equipment that easily processes rectangular, square, round, and, oval objects. It typically sticks pre-glued add-ons and stickers to create strong adhesivity with the container.

Wrap-Around Inline Label Applicator

Wrap-Around Inline Label Applicator- Picture Courtesy: HERMA

This type of inline label applicator works best with round or cylindrical objects. It completely covers the central area of such a container by wrapping labels around its entire circumference. It rotates the packaging containers for sticking labels.

According to the Type of Adhesive

Self-adhesive Inline Label Applicator

Allpack Self-adhesive Inline Label Applicator

It is also called pressure pressure-sensitive inline label applicator. It applies ready-to-use labels by simply peeling off the back paper. It sticks the label using high pressure and does not require hot water or heat for labeling functions, saving utility bills.

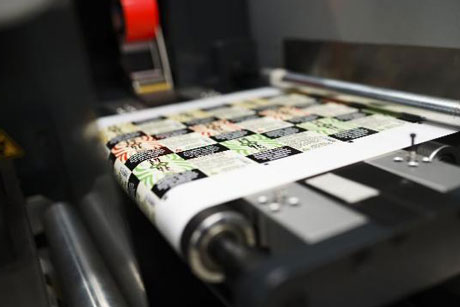

Wet-Glue Inline Label Applicator

Allpack Inline Label Applicator

It has significant value in the packaging industry as it sticks the labels at room temperature. It applies liquefied glue at the exterior of containers for sticking labels. It is mostly used for rigid containers made of plastic, glass or tin.

Hot-Glue Inline Label Applicator

Allpack Hot-Glue Inline Label Applicator

As the name suggests, this machine uses hot glue for label application. The glue is solid at room temperature, is melted by the heating elements, and then is applied to the labels. This type of inline label applicator works best for wrap-around labeling.

According to Printing

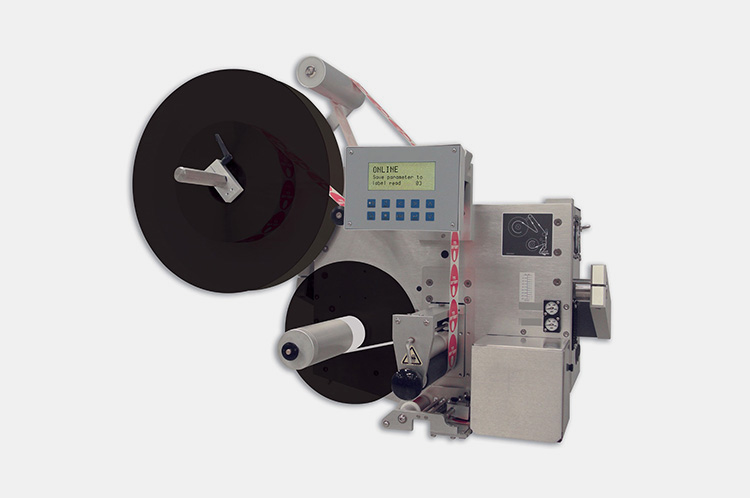

Print and Apply Inline Label Applicator

Print and Apply Inline Label Applicator- Picture Courtesy: Quaderal Labeling Systems

This type of inline label applicator comes with printers like thermal transfer printers or inkjet printers that print high-definition stickers for labeling purposes. This machine typically prints product information like barcodes, batch numbers, and expiry dates.

Simple Inline Label Applicator Without Printer

Allpack Simple Inline Label Applicator Without Printer

This machine does not have a built-in printer and instead uses pre-printed labels or stickers for labeling objects. This type of machine can be tailored to label diverse style labels for branding purposes.

According to Labeling Direction

Horizontal Inline Label Applicator

Allpack Horizontal Inline Label Applicator

This machine labels the packaging objects when they are lying on the conveyor. It is difficult to label objects with unstable bases; hence, the horizontal inline label applicator labels these containers horizontally.

Vertical Inline Label Applicator

Allpack Vertical Inline Label Applicator

It is an ideal machine when labeling is required in the vertical orientation of containers like tubes, and ampoules that have more elongated areas with a stable base. This machine is useful for accurate and smooth vertical labeling. It applies labels when containers are standing in a tall position on the conveyors.

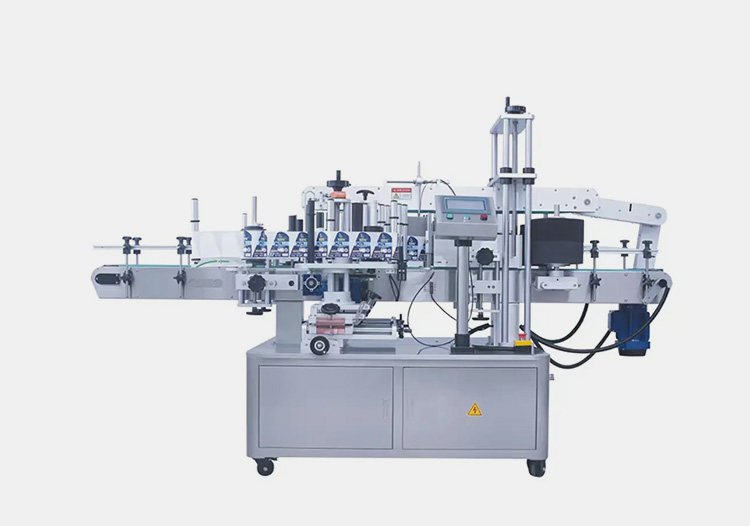

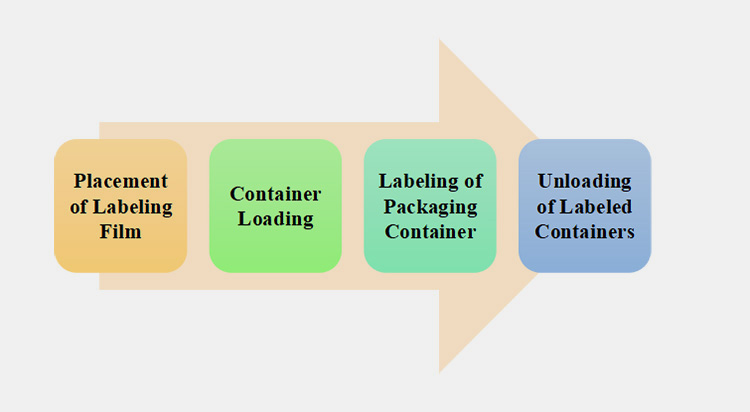

6.What are the Working Steps of Inline Label Applicator?

The working steps of an inline label applicator generally depend upon the type of inline label applicator. However, here are some general steps that are carried out in every inline label applicator.

Placement of Labeling Film

Loading of Labeling Film- Picture Courtesy: Label & Labeling

At first, the huge roll of labeling film is inserted on the holder and is passed over the supporting rollers to maintain film tension. This is essential in smooth labeling operation and averts the spillage of film.

Container Loading

Container Loading- Picture Courtesy: Accurate Industrial

In the next step, the conveyor height is adjusted to accommodate container height, this allows smooth container entrance. Next, the bottle unscrambling machine or operator puts the containers in the correct orientation on the moving conveyors. A photosensor detects the positioning of the container and keeps a fixed interval between packaging objects.

Labeling of Packaging Container

Label Packaging Container- Picture Courtesy: www.altech-uk.com

Once the containers are detected under the labeling station by the photosensor, the labeling process starts. The label applicators align labels at the correct orientation onto the exterior of labeling objects. Next, the label press component smoothly presses labels onto the container to avoid air bubbles and create a strong bond between labels and containers.

Unloading of Labeled Containers

Unloading of Labeled Containers- Picture Courtesy: Werfring

Finally, labelled containers leave the inline label applicator and travel down the line for further subsequent packaging.

7.What Label Materials are Processed by Inline Label Applicator?

Versatile label materials create a strong aesthetic presence; hence, brands customize label materials according to their needs. A few of these labeled materials processed by inline label applicator are:

| Paper

It is one of the most common label materials and this material can be coated, textured or embossed. It is compatible with almost every applicator and is best for flat and curved containers. |

Paper Labels- Picture Courtesy: Cute Paper Inks |

| Plastic Labels

It is another most frequently used label material and different forms of plastic labeling films like PP, PE, PET, and PVC have their specific benefits. It is mostly used with all container types like flat, round, or complex designs. |

Plastic Labels- Picture Courtesy: Claws Printers |

| Fluorescent or Holographic Foil

It is a brightly coloured or colour-changing foil that adds to the product's aesthetic appeal. It engages customers with its bright colours and colour-shifting patterns. It is used for branding, anti-tampering and anti-counterfeiting purposes. |

Fluorescent or Holographic Foil Labels- Picture Courtesy: Sticker it |

| Metalized Films

These are composed of aluminium and laminated foils. It is applied using special heat and pressure label applicators. These are more costly than plastic and paper labels. |

Metalized Films Labels- Picture Courtesy: FastLabels |

| Thermal Transfer Labels

These labels are covered using heat-sensitive materials and are transferred to containers using heat. It is commonly used in barcoding and product shipping. |

Thermal Transfer Labels- Picture Courtesy: LabTAG |

| Clear Labels

These labels are made of clear PP and PE materials and showcase underneath products while communicating product information. |

Clear Labels- Picture Courtesy: Resource Label Groups |

8.What is the Difference between an Inline Label Applicator and a Rotary Label Applicator?

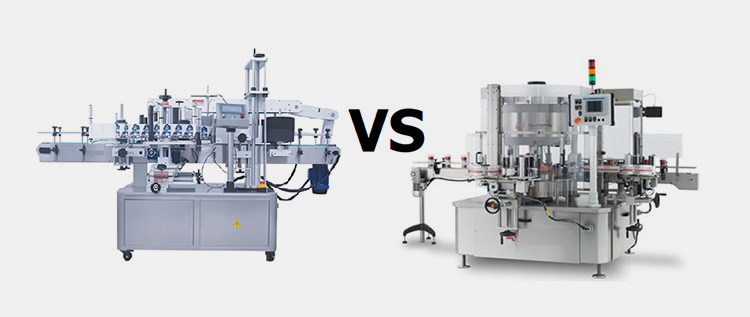

Difference between an Inline Label Applicator and a Rotary Label Applicator

Inline label applicator and rotary label applicator are both labeling machines but there is a major difference in design configuration between them. A breakdown of their differences is given below:

| Features | Inline Label Applicator | Rotary Label Applicator |

| Design | This machine has a straight-line configuration marked by a long conveyor. | This machine has a circular configuration due to the rotary starwheel or carousel. |

| Product Handling | Products remain on the conveyor in this machine for labeling. | After the conveyor, the containers go to the starwheel for labeling. |

| Labeling | The containers move to labeling station for labeling. | Each station on the starwheel holds the container and the label is stuck to the container. |

| Speed | The speed of the inline label applicator is lower than the rotary label applicator. | It is faster than an inline label applicator. |

| Container Type | It is versatile and can process bottles, jars, boxes, and pouches. | It has limited processivity and is suited to bottles and vials. |

| Operation | It is easy to operate an inline label applicator. | It requires special training skills for operating. |

| Cost | It is less expensive. | It requires higher purchase investment. |

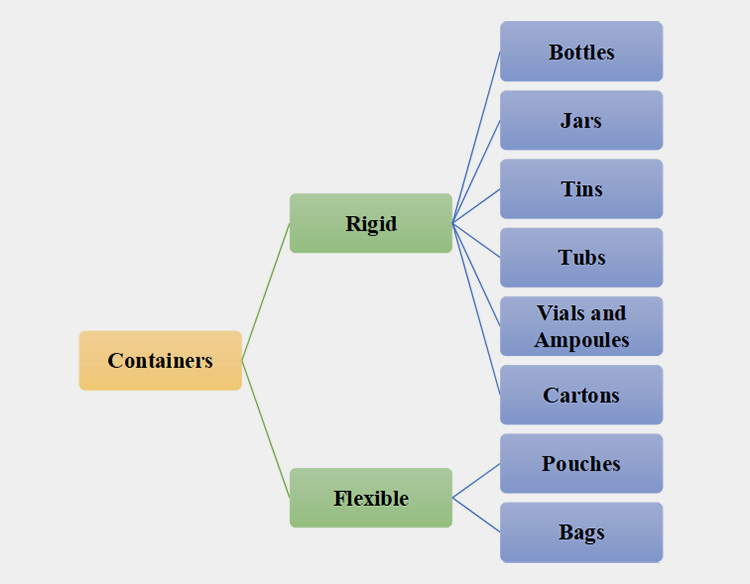

9.What Container Types are Labeled by Inline Label Applicator?

Inline label applicator processes multipurpose containers differing in their materials, shapes, sizes, and label orientation. Some common container types labeled by inline label applicator are:

Rigid Containers

Examples of rigid containers processed by inline label applicator are given below:

Bottles

Labeled Bottles- Picture Courtesy: 48HoursPrint

An inline label applicator can easily process bottles with curved or complex contours. It can handle bottles made with glass and rigid plastics such as bottles of jams, honey, sauces, pharma, etc.

Jars

Labeled Jars- Picture Courtesy: Uniquely Primitive

Jars with cylindrical, square, hexagon, and other shapes are labeled by the inline label applicator. Examples include cosmetic and candle jars.

Tins

Labeled Tins- Picture Courtesy: Trend Hunter

Metal tins, for instance, food and beverages having cylindrical, rectangular or round geometries are branded by an inline label applicator.

Tubs

Labeled Tubs- Picture Courtesy: Go Dairy Free

Inline label applicator sticks labels on plastic tubs having flat surfaces. They include dairy and personal care tubs.

Vials and Ampoules

Labeled Vials- Picture Courtesy: yourErie.com

The pharmaceutical industry uses an inline label applicator for hygienically labeling infusion vials and ampoules.

Cartons

Labeled Cartons- Picture Courtesy: Consolidated Label

Rectangular cartons and square boxes for transit and secondary packaging are labeled by an inline label applicator.

Flexible

This machine also labels flexible containers such as:

Pouches

Labeled Jars- Picture Courtesy: Wizard Labels

Inline label applicator labels pouches like standup, gussets, flat bottom, and Doypack in far wide industries.

Bags

Labeled Bags- Picture Courtesy: Online Labels

This machine also applies paper and plastic labels on gift and grocery bags.

10.What Type of Applicator System Are in Inline Label Applicator?

There are various types of application systems in the inline label applicator for adhering and sticking labels. A particular type of applicator system is used in the specific model of inline label applicator. These applicator systems are discussed one by one below:

Air Pressure Applicator

Air Pressure Applicator- Picture Courtesy: Pacific Labeling

This applicator system uses air pressure to stick labels onto the surface of the container. Compressed air is blown onto the labels for their application. This system works at faster rates and is configured to handle any shape and size container. However, it has low precision.

Tamp Applicator

Tamp Applicator- Picture Courtesy: Cleveland Equipment

This system uses a pneumatic or motorized label presser that delivers a tamping force for affixing the label onto the exterior of the container. The tamping applicator system has extreme label positioning accuracy and it is ideal for labeling delicate products with nonuniform surfaces.

Tamp-Blow Applicator

Tamp-Blow Applicator- Picture Courtesy: Weber Packaging Solutions

It combines the features of both tamp and air pressure applicator systems, resulting in high speed and accurate labeling. It is used for objects with complex contours but comes at a higher price.

Rotary Disk Applicator

Rotary Disk Applicator- Picture Courtesy: HERMA Labeling Machines

This applicator system uses a rotary wheel to transfer labels on products as they move on the conveyor. It is used for wrap-around labeling on cylindrical objects and works at a higher speed.

Roll-on Applicator

Rollon Applicator- Picture Courtesy: Accurate Labelling

This applicator has a spring roller that smoothly sticks labels to the containers. It is ideal for the wrap-around labeling of delicate objects.

Vacuum Applicator

Vacuum Applicator- Picture Courtesy: cab Produkttechnik GmbH

The vacuum label applicator consists of a vacuum pad that grips and sticks labels onto the packaging objects. It is best for fragile labels and allows more label positioning control. It is slower than other label applicators.

11.How to Troubleshoot Inline Label Applicator?

Unanticipated issues in the inline applicator cause production delays, and loss of profits. They are troublesome for manufacturers. But with simple skill and training these downtimes can be avoided. Some tips and tricks for an inline label applicator are detailed below:

| Reason | Solution | Image |

| Tearing of Labels | ||

| Inadequate film tension.

Sharp corners in the sticker labels Accumulation of dust and contamination of label press |

Maintain adequate film tension.

Ascertain that there are no sharp edges in labels Clean and wipe label press |

Tearing of Labels- Picture Courtesy: Cognex |

| Misalignment of Labels on Containers | ||

| Incorrect lining of the applicator with the container.

Rough container surface. Incompatibility of container and label material. Old or defective applicator system. |

Check and realign the applicator.

Replace container. Use label material that is compatible with the container. Replace old and defective label applicators. |

Misalignment of Labels on Containers- Picture Courtesy: PesPro - WordPress.com |

| Peeling off of Labels | ||

| Inadequate quantity of adhesive.

Incorrect bonding of label with the container. Dust or debris on container or label. Poor storage settings for labels. |

Use an adequate adhesive amount.

Improve the bonding between the container and label using pressure or drying. Clean both labels and containers. Store label films in the right temperature and humidity settings. |

Peeling off of Labels- Picture Courtesy: Wizard Label |

| Jamming of Labels in the Machine | ||

| Poor label loading

A buildup of static charges Glue deposit on the machine. Defect in the applicator. |

Fix the label feed tension

Use anti-static equipment Clean thoroughly the labeling glue before the operation. Repair the defective applicator. |

Jamming of Labels in the Machine- Picture Courtesy: Blue Label Packaging |

| Label Do not Come Out of Labeling Head | ||

| Tightly gripped labels by labeling head.

Poor alignment of labeling head. |

Open up labeling head and reload the label feed.

Realign labeling head. |

Label Do not Come Out of Labeling Head- Picture Courtesy: DirectIndustry |

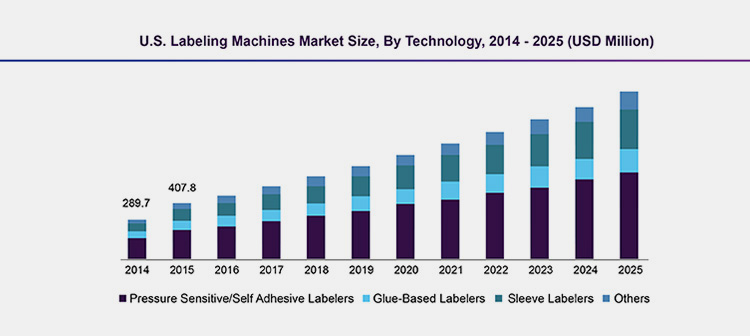

12.What are the Future Trends of an Inline Label Applicator?

Future Trends of an Inline Label Applicator- Picture Courtesy: Grand View Research

The market of the inline label applicator is quickly expanding because of the demand for detailed labelled products. It is estimated around US$ 5.7 billion in 2018 and will grow with a CAGR of 7.0% during the years 2019-2025. It is forecasted that it will accumulate a revenue of US$ 9.22 billion in 2018.

Brands are continuously innovating their inline label applicator. With the growing demands of artificial intelligence, augmented reality and robotics in different fields, these technologies are also been integrated into inline label applicators to speed up productivity and also to train operators. With the IoT and remote connectivity, users can view operational protocols and maintain this machine on the screens of their cellphones and laptops.

It is predicted that the upcoming inline label applicator will apply technologically advanced labels like FID (Radio-Frequency Identification) and NFC (Near Field Communication) on containers for interactive and verification purposes. Modern inline label applicator will be in line with eco-friendly efforts by using recyclable and green labels.

Conclusion

For enhanced aesthetic appeal, product information, anti-tempering, and tracking jobs, brands add the inline label applicator. It is a straightforward device and compact device with candid working. With its precise labeling and increased productivity, it generates hefty revenue for businesses. Are you confused about the selection of an inline label applicator? Click on our main Allpack webpage to purchase exceptional quality labeling machines at discounted rates.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide