Induction Heat Sealing Machine: The Complete Buying Guide In 2024

Have you ever been to the delighted experience of spreading pleasant fragrance around, suddenly after you opened the sealed bottle? If Yes! You must have desired to repeat the process. It is pertinent to mention here, that this experience is the result of using an advance induction heat sealing machine which is excellent in its performance.

An induction heat sealing machine is the proven technology specialized in giving hermetic sealing to range of containers holding eclectic products. It is thus giving the businesses an opportunity to grow their popularity by satisfying customers through provision of safe and trustable packaging in form of induction heat sealing. Are you also wandering for an induction heat sealing machine to achieve the same purpose? Definitely, your search has been found as you are on right track to fulfill your aim. Just be ready to know how you can make the best use of this machine by absorbing this comprehensive guide which holds in it the answers to all confusion!

1.What Is An Induction Heat Sealing Machine?

Aipak Induction Heat heat Sealing Machine

Induction heat sealing machine refers to the sealing device featured with electromagnetic principle to innovate the sealing of bottles, jars and containers by non-contact heating. This exceptional quality machine transforms the electrical energy into heat energy during operation and resultantly sticks the aluminum foil to the neck of bottle creating hermetic sealing. By doing so, the bottle’s inside content is fully protected from temperature, humidity and dirt.

In this way, induction heat sealing machine is efficiently responsible for the entire process of generating heat as well as cooling machine against heat. Together these attributes helps in temper proof sealing, increase production and safe packaging. Therefore, manufacturers from diverse sectors prefer using different types of induction heat sealing machines as per their requirements.

2.Explain The Uses Of An Induction Heat Sealing Machine?

When it comes to discuss the uses of an induction heat sealing machine, there are ample areas where this machine is perfectly applicable. Some of these are highlighted below:

Pharmaceutical Industry

Picture Courtesy: Joreshtech

Pharmaceutical industry is responsible for regulating safe packaging of medicines and supplements in all its forms such as tablets, capsules, syrups and nutraceuticals. Hence, an induction heat sealing machine is contributing to meet this end by ensuring full proof sealing in an environment safe from bacteria, dirt and pollution.

Edible Oil Industry

Picture Courtesy: thankdesign.com

Edible oil industry is one of the leading industries in food sector. Its consumption is found obligatory in almost all the countries of the world. Therefore, every manufacturer is striving to sustain their individual identity by providing excellent packaging in form of induction heat sealing which is done by this machine.

Confectionary Industry

Picture Courtesy: a to zebra celebrations.blogpost.com

Confectioneries are rich in sugar and often contain liquids which make them attractive for ants and other insects. To preserve their quality and keep them away from the approach of external elements, most of the industries are now taking help of an induction heat sealing machine.

Dairy Industry

Picture Courtesy: packaging of the world

Dairy sector is vast enough that its significance can be found by examining our daily life necessities fulfilled by using these products including milk, yogurt, butter and cheese etc. All these products are processed by an induction heat sealing machine due to which their shelf life is extended and quality is protected.

Beverage Industry

Picture Courtesy: packaging of the world.com

Like other essentials, beverages are also susceptible to be downgraded in quality as a result of leakage. Hence, to counter this challenge most of the industries pass their bottles and containers of wine, juices and soft drinks by an induction heat sealing machine.

Cosmetic Industry

Picture Courtesy: Luxor

Products such as lotion, cream, foundation and gel etc., come under the field of cosmetic industry. Therefore, to retain their fragrance, essence and humidity level up to the mark, induction heat sealing machine is the first ever choice of manufacturers.

3.What Are The Benefits Of Using An Induction Heat Sealing Machine?

An induction heat sealing machine is well known for its advantages in several ways. Some of these perks are enumerated below:

Prevent Leakage

Picture Courtesy: DuPont Teijin Films

This machine is the best solution for its creation of effective and air-tight sealing which reduces the chances of product leakage to zero percent. Moreover, the sealing form a strong barrier to withstand moderate to high pressure during transportation.

Increase Shelf life

Picture Courtesy: Famous foods

By forming the protection layer between product and external environment, this machine extends the shelf life of the content as well as the conservation of aroma and taste.

Product Safety

Picture Courtesy: SKS Bottle & Packaging, Inc.

Sealing products by induction heat sealing machine can better retain its quality and keep it safe from contamination.

Eco-friendly

Picture Courtesy: en.porte.coffee

This machine is entirely based upon generating electromagnetic energy which mean consuming less energy than other sealing machines like conduction sealing. Moreover, it does not affect the surrounding environment by creating thermal pollution.

Enhance Productivity

Picture Courtesy: Joreshtech

Induction heat sealing machine is introduced as an alternative to other methods of sealing in order to reduce the time and energy wasted on sealing. Hence, this machine is proficient in sealing up to 120 bottles in a minute.

Customer Satisfaction

Picture Courtesy: the kitchen.com

As a result of market competition, people get confused to choose the right products. For this reason, they always go for one which is adorably packed with originality at its peak. Therefore, using induction heat sealing machine can grow customer satisfaction who would be able to distinguish between quality products on the basis of sealed or unsealed items.

4.Do You Know The Working Principles Of An Induction Heat Sealing Machine?

The working principles of an induction heat sealing machine are somehow technical; however, machine in itself is easy to operate. Below description will be helpful in this regard:

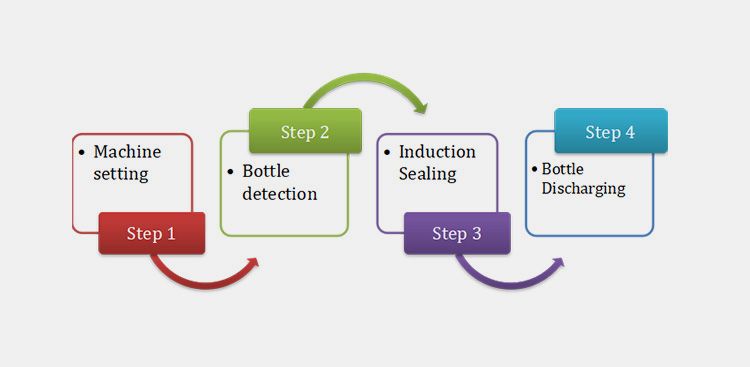

Step 1

Picture Courtesy: Joreshtech

The working of machine begins with operator setting the basic functional parameters of machine. These include adjusting the height of induction heat sealing station, fixing the speed of conveyor belt and the level of temperature caused by an electromagnetic field.

Step 2

Now, when the basic parameters are fixed, machine is ready to start the process. When capped bottles start mobilization towards the induction heat sealing station, the sensor detects the presence of bottles and send message to machine.

Step 3

Picture Courtesy: Enercon

At this point, the machine started transmitting heat through integrated electromagnetic coils. When the bottle passes through sealing head, the heat seal under cap starts to soften and eventually stick to mouth of the bottle. This result in the formation of impermeable and tamper-proof sealing.

Step 4

Picture Courtesy: Technopack

Finally, the hermetically sealed bottles move towards the discharge outlet with the help of conveyor belt.

5.Which Type Of Bottles And Caps are Supported By An Induction Heat Sealing Machine?

An induction heat sealing machine is capable of processing wide variety of bottles as well as caps. They are shown below with description:

PET Bottles

Picture Courtesy: Sunday Morning Foods

Polyethylene therephthalate is transparent plastic commonly used for packaging of beverages, edible oil and carbonated drinks. These bottles are cost-effective, highly chemical resistant and moisture proof, however, they are not good to combat high temperature.

HDPE Bottles

Picture Courtesy: Wayfair.com

HDPE is short for high density polyethylene which is most economical and highly moisture proof plastic used for bottles. It is rigid in texture and is almost opaque with showing little color if loaded with dark products.

LDPE Bottles

Picture Courtesy: migros.com.tr

These bottles are made with low density polyethylene which means that they are extremely flexible making them more feasible to be squeezed and used for shampoo, lotion and sauces etc.

Glass Bottles

Picture Courtesy: travel.mdpr.jp

Glass bottles are impermeable and nonporous due to which they have strong protection against bacteria and chemical reactions. Therefore, glass bottles containing food items, medicines and cosmetic creams are sealed by an induction heat sealing machine to trap the fragrance and flavor of goods inside bottles.

Plastic Caps

Picture Courtesy: SKS Bottle & Packaging, Inc.

Plastic Caps are resilient due to which forming shapes, writing or designs become easy. They prevent damage by resisting breakage and assist in stringent safety of products by being induction sealed.

Aluminum Caps

Picture Courtesy: SKS Bottle & Packaging, Inc.

Aluminum caps are good at anti rust function and ensure product protection from all kinds of acids, solvents and chemicals etc. An Induction heat sealing machine has excellent strength to form hermetic seals in aluminum caps.

6.Which Components Make The Structure Of An Induction Heat Sealing Machine?

Picture Courtesy: KWT Machine Systems

The structure of an induction heat sealing machine varies from one type of machine to another. However, few components are common to all which are described below:

Power Supply Unit

It is the power house of an induction heat sealing machine which is responsible to provide the required energy to machine. For instance, by using this unit, user set the commands for operation and thereby the machine executes these commands.

Foil Indicator

It is an essential component of the machine which is responsible to detect the presence of foil liner inside caps, and aware the user if the cap lacks foil or containers double foil.

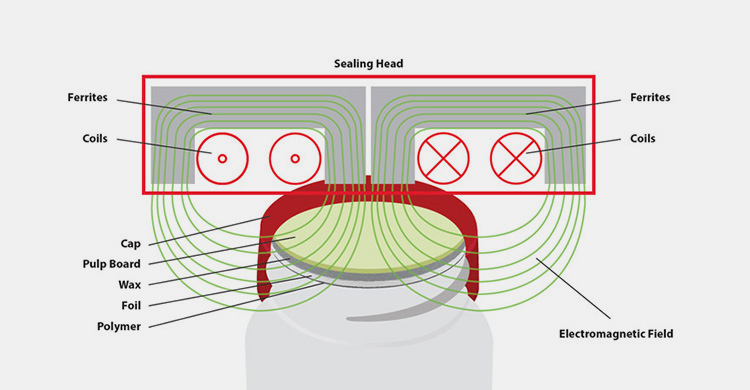

Sealing Head

Sealing head is the core part of machine which actually performs the sealing of bottles. It consists of ferrites and induction coils. These coils have electromagnetic system which produces heat during sealing process.

Conveyor

Conveyor is a stainless steel device with rolling shafts or rubber belt over it. The main task of conveyor is to facilitate the movement of bottles and containers during operation. Semi-automatic and handheld induction heat sealing machines do not have conveyor.

Cooling System

Cooling system is used to dissipate the heat produced during heat sealing process. It mainly consists of two types; air cooling system and water cooling system. In air cooling system, a fan or air blower is used for disappearing heat, while as, in water cooling system, water chiller is utilized to cool down the machine temperature.

Electric Cabinet

This part of machine is containing all the electrical components such as wires and knobs to prevent the machine from electric shocks.

7.Enlist The Types Of An Induction Heat Sealing Machine?

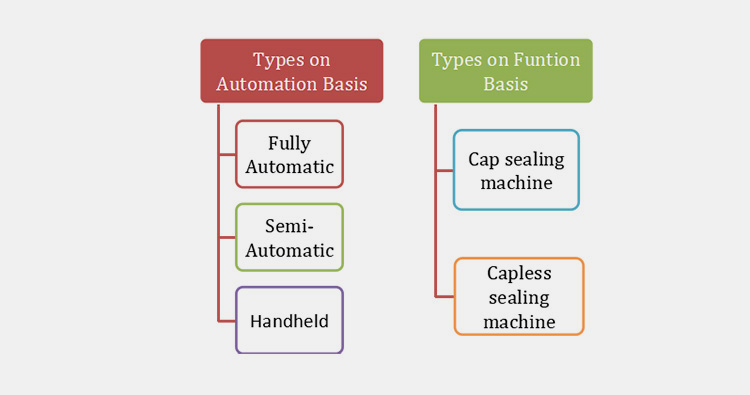

An induction heat sealing machine can be divided into following types:

On The Basis of Automation

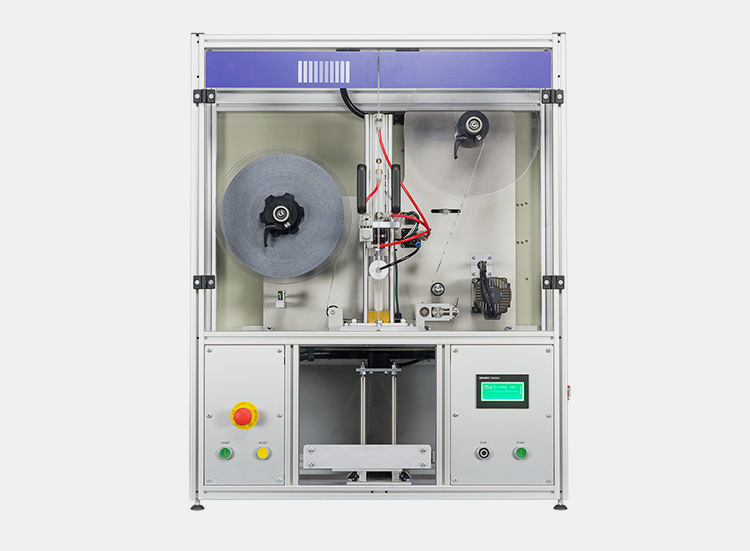

Fully Automatic Induction Heat Sealing Machine

Picture Courtesy: KWT Machine Systems

Fully automatic heat sealing machine is featured with intelligent inspection system, controlling unit, cooling system and high operational memory storage. It undertakes the process automatically and ensure forming air-tight sealing by generating uniform heat via induction sealing head. Apart from this, the machine is able to be attached directly with other machines in a production line. Hence, huge manufacturing firms opt for this machine.

Semi-Automatic Induction Heat Sealing Machine

Picture Courtesy: Joreshtech

Semi-automatic induction heat sealing machine is small sized precise machine employed for batch production and laboratory use. It implies user to load the bottles in machine and then run these bottles automatically. This compact machine is suitable to be used as table-top machine. While semi-automatic in processing it constitutes all the features of detection, cooling system and digital system for setting. Therefore, this advance technology machine is the best solution for start-up business.

Handheld Induction Heat Sealing Machine

Picture Courtesy: Joreshtech

It is the most flexible type of induction heat sealing machine with convenient portability and handling system. It is composed of incredible small footprint, digital display and an induction device attached to the main machine through electric wire. The machine does not need any cooling system during processing thus consume less energy. While performing the task of induction sealing, this machine is able to induction seal by following a timer, indicate missing foil count the number of foils present in each bottle. It is suitable for small batch packaging, laboratories or home based businesses and shops etc.

On The Basis of Function

Induction Heat Cap Sealing Machine

Allpack Induction Heat Sealing Machine

As manifested by the name, this machine is created to seal the bottles having plastic or metal caps over them. When capped bottles with attached aluminum foils are passed by the tunnel, heat is generated by the electromagnetic energy via induction coils towards bottles, where the aluminum foils of under caps get attached to the bottles' necks. Similarly, these bottles are discharged by conveyor and the process continues. Products such as liquids or chemicals which have high risk of getting affected by temperature or get leaked due to external pressure, are packed in capped bottles for which this machine is ideally perfect.

CaplessInduction Heat Sealing Machine

Picture Courtesy: Relco

This innovative machine is most reliable in a way that it can be used for bottles with no caps over them. Its unique structure with inclusion of pressure belts for holding seals over caps is designed to facilitate the secure and undamaged sealing of bottles. During the process, bottles are transferred through conveyor. After reaching to sealing station, series of induction coils while taking aluminum foil adopt downward movement and apply the foils over bottles which swiftly get stuck to the bottles' necks. The machine is desirable for solid food, medicines and cosmetics.

8.Highlight The Main Differences Between Induction Heat Sealing Machine And Other Types Of Sealing Machines?

Along with induction heat sealing machine, there are other machines which perform the same function of sealing, however, they are different from one another. These differences can be understood by the table below:

| No | Factors | Induction Heat Sealing Machine | Conduction Sealing Machine | Heat Sealing Machine |

| 1 | Definition | Induction heat sealing machine is designed to seal capped and capless bottles via electromagnetic heat energy | Conduction sealing machine is employed to seal the capless bottles through heated plate | Heat sealing machine is used for sealing plastic bags, pouches and films through hot bar sealing or impulse dealing |

| 2 | Sealing Method | Non-contact | Contact based | Contact based |

| 3 | Heat Source | Electromagnetic energy generates heat through induction coil | Electric power produces heat to hard metal plate | Heat produced by machine is spread through metal bars |

| 4 | Speed | Swift in producing heat | Slow in producing heat due to time taken by plate for warmth | It is fast in spreading heat and thus perform sealing quickly |

| 5 | Material Used | Aluminum linear | Aluminum linear | Hard to soft plastic film |

| 6 | Picture |  |

|

|

9.Which Type Of Induction Wads Can Be Processed By Induction Heat Sealing Machine?

Picture Courtesy: Kaufmancontainer.com

There are mainly two types of induction wads which are used in bottles, jars or containers for sealing purposes. These are described below in detail:

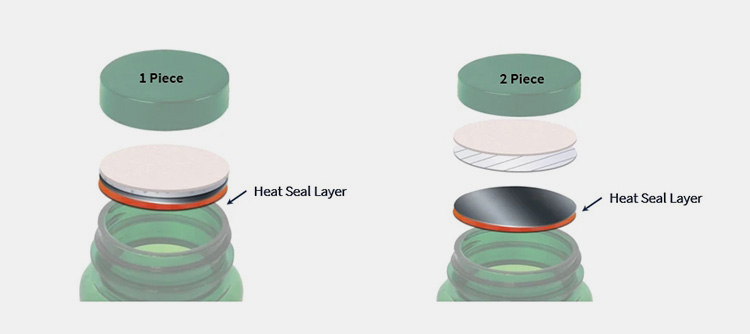

One Piece Induction Wad

One piece induction wad is composed of foaming material, aluminum foil and a sealing material upward down the bottle cap. This type of induction wads are meant for sealing only once which means when the cap will be removed from bottle its purpose of protecting products will be ended. Therefore, goods like food products, cosmetics and beverages are often found with caps having one piece liners.

Two Piece Induction Wad

On the other hand, two piece induction wads are more durable in a way that they can be used for resealing. For instance, bottles with two piece induction wad if opened for consumption, the one piece will be removed while the other remains on the cap for resealing. Hence, products which are sterile and needs extra protection till the end of existence like chemicals, medicines and spirit are induction sealed with two piece induction wads.

10.What Is The Preventive Maintenance Of An Induction Heat Sealing Machine?

Picture Courtesy: BT Equipment

If you want your induction heat sealing machine to let your business grow consistently, you must have to take some measures for its preventive maintenance. In this way, underlying points are crucial:

Regular Cleaning: It is necessary to clean the machine on regular basis for fast running. For this, you can use tidy soft cloth to clean front panel of the supply power unit, never use solvent as it can harm the plastic display, and remove the spillage immediately. In addition, the filters, air blower and sealing coils must be cleaned through vacuum cleaner or compressed air.

Lubrication: Another step required for preventive maintenance is to lubricate the jack screw, conveyor shafts and movable wheels for fancy running of machine.

Cooling Machine: Cooling system is the inevitable part of induction heat sealing machine which cannot be overlooked. Hence, the air blower of water chiller must be checked in case they stop working. It will help to prevent the machine from excessive heat and damage.

Parts Replacing: In case, the pressure belts, electric wires, knobs or sensor are damaged or worn out, make sure to replace them with new parts.

11.Give Remedies To Cure The Possible Pitfalls Occur While Using An Induction Heat Sealing Machine?

What if you face the issues such as bad sealing, damaged foil or inadequate heating during process? The solutions are simple! Just consider the table below:

| No | Pitfalls | Causes | Remedies | Pictures |

| 1 | Burned aluminum linear | Either the conveyor speed is too slow or power is excessive | To generate required heat, djust the speed of conveyor as well as power |

By-yespacks.in |

| 2 | Inconsistent bottle sealing | It happens when bottles are incorrectly torqued or the seating of bottle is uneven | Make sure all the bottles are well torqued and the surface is even |

By-technopack |

| 3 | No sealing | Sealing head is located too high | Adjust the height of sealing head. |

By-technopack |

| 4 | The seal is too difficult to remove | It occurs due to insufficient power or high coil set | Increase the power supply by checking. Also, alter the sealing head height |

By-the sun |

12.What Are The Auxiliary Devices Needed For An Induction Heat Sealing Machine?

There are several other machines which if you add into your production line along with induction heat sealing machine can enhance the level of efficiency in your manufacturing. These include the following:

Bottle Unscrambler

Aipak Bottle Unscrambler

This advance machine is made with super quality features to aid the production facility by feeding rightly positioned bottles and containers onto production line.

Liquid Filling Machine

As the name suggests, liquid filling machine has been introduced in the packaging field to precisely fill the liquids with vary nature in separate bottles, jars and containers. In this way, the liquid filled bottles processed by this machine are sent to induction heat sealing machine for stringent sealing.

Tablet Counting Machine

AllpackTablet Counting Machine

Tablet counting machine is single machine with dual functions of tablet counting and filling into containers. It can count numerous products ranging from medicines to food items and daily chemicals etc. Therefore, it can be included into the production line of induction heat sealing machine.

Labeling Machine

Picture Courtesy: Paima Packaging

This machine is employed to label the empty or loaded containers with single or multiple labels.

Capping Machine

Allpack Bottle Capping Machine

Like other machines, bottle capping machine is one of the essential tools of packaging. Its function is to cap the loaded bottles accurately by taking aluminum foiled caps from hopper and tightly screwing them over bottles' mouth.

Shrink Wrapping Machine

Picture Courtesy: Allpack

Shrink wrapping machine is the ultimate solution to seal bulk containers and bottles together by wrapping them in a plastic film which is then shrunk with the help of heat. These shrink-wrapped goods are easy to handle, mobilize and their integrity remains the same during transit.

13.Which Factors Should Be Considered To Get The Best Induction Heat Sealing Machine?

In order to get the best induction heat sealing machine, you should be vigilant to consider some of the important factors which are highlighted below:

Type of Packaging

Picture Courtesy: Technopack

It is important to look at your packaging style which you are following in your industry. For instance, if you are processing capped bottles you will need machine which is able to carry the function. On the other hand, capless induction heat sealing machine is right for capless bottles.

Production Volume

What is the size of your production? Does it follow batch production or continuous? If you are running small factory it is better to choose a precise, less expensive and compact machine like semi-automatic, while as, your may go for fully automatic machine in case the production volume is giant.

Cooling Ways

Picture Courtesy: Kingpng

You have to determine which type of cooling system you will need for your induction heat sealing machine. Since, water cooling system is often adopted for containers holding liquid content and air cooling system for bottles with solid objects. It will help you to go for suitable option.

Customization

Picture Courtesy: cocoislandmart.com

Another factor to look for is the degree of customization of machine. Therefore, preferring a flexible induction heat sealing machine can help you seal the bottles and containers of different sizes and shapes.

Conclusion

To wrap up, induction heat sealing machine is an excellent machine with the ability to seal capped and uncapped bottles via non-contact heat and thus prolong their shelf life. This unique method of sealing make it unique and advance from other machines. Hence, industries with high demand for quality packaging machines are always ready to bring it into use. Similarly, if you are also planning to make a purchase, be sure to consider Allpack which has astonishing induction heat sealing machines as per your need. Feel free to ask further information through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide