How To Make Hard Gummy Bears?

Gummy Bears have been the most sought after treat by children and grownups. However the ones that are responsible for making it, needs to perfectly speculate it’s recipe to ensure considerable texture and flavor of the gummies. Oftentimes this question might have popped up in your mind that how to give this jiggly gummies the right hardness or how to prevent these gummy bears from melting?

Well, this is probably the magical secret! But don’t worry we will pen down our best formula and what could be done for achieving rigidity to your gummies.

Without further ado , let’s read the article and find out.

1.What Are Hard Gummy Bears?

Hard Gummy Bears- Picture Courtesy: Medical Product Outsourcing

Gummy bears are identified by their general squishy and easily chewable texture, however unlike the usual softness some gummies are hard and require effort for mastication. Hard gummy bears are due to the ratio of certain mixing ingredients along with the type of ingredients used and it also depends on the amount of time it is given for drying.

Gummies that are tougher to bite means you can slowly engulf burst of flavors and suck its juiciness before finally chewing on it. The hardness of the gummy candy can also be attributed if it is left out in the air for too long, or if moisture escapes out of it and they turn dry.

2.What Ingredients Can Make Hard Gummy Bears?

Ingredients of Hard Gummy Bears- Picture courtesy: Lolli and pops

For controlling the texture of how your gummy looks, it is essential to take consideration of how different ingredients can be used to make a hard gummy bear.

The prime ingredient being gelatin which can determine the elasticity of gummies depending on how it is added and in what ratio it is combined with other ingredients. It is important that you take notes of these points prior to making a hard gummy candy.

The more gelatin you add in your recipe the more firm and solid your gummies will result.

Blooming factor for gummies is necessary to keep in notice as far as skipping the grittiness and maintaining the solid structure of your gummy bear is concerned, as too much water might also weaken the hardness texture.

The ratio of water and gelatin and sugar syrup must be such that it is checked and monitored to give firmness to a gummy.

If pectin is added at high temperature such as 240°F it may turn into a hard candy format.

If you will add citric acid or any fruit flavors such that they help to retain moisture, your gummies will be softer . Skip this ingredient to make a gummy bear hard and add such fruit flavors which do not retain moisture such as pineapple, papaya, kiwi etc.

Playing with different ingredients can be a really tricky step because that would involve your whole batch of gummies getting affected. Usually coconut oil or any type of wax such as beeswax or carnauba wax is also added that gives a finished coating to the gummies.

3.How To Make Hard Gummy Bears at Home?

To make your gummies harder at home, there are a few general steps you will be required to follow to get results.

Picture courtesy: The Spruce Eats

When you add gelatin or pectin to water, simply ensure that it’s concentration is higher than the presence of water and sugar syrup. This will make elastic collagen bonds develop greatly so that gummy gets firmer texture.

Picture courtesy: Chewable Structures

Allow 5-10 minutes time for gelling agent to bloom. This is when you’re going to keep stirring the mixture slowly.

After combining, mixing and cooking of other ingredients let it stay aside for few minutes until upper layer of mixture is covered with foam so that the foam may be scooped off. Ensure that the temperature you cook your gummy mixture at is above 240°F so that the desired hardness is achieved.

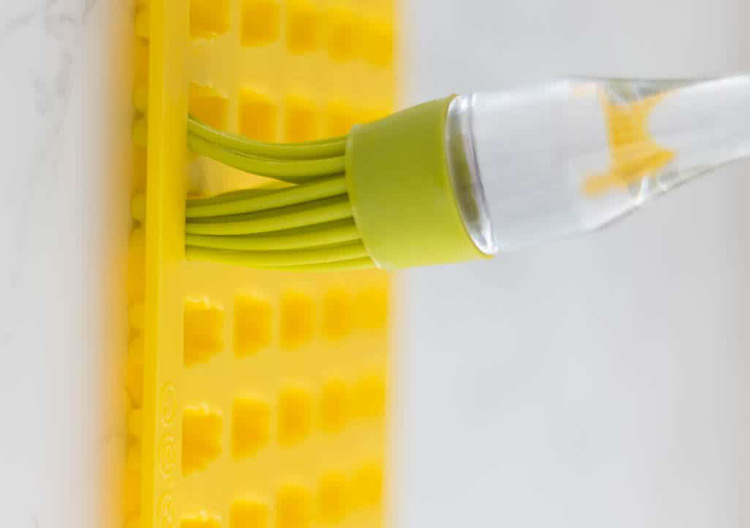

The mold cavities are sprayed with oil or coated with any type of wax usually carnauba or beeswax, which allows them to be easily removed without getting stickier.

Picture courtesy: The Soccer Mom Blog

At least half hour will be required for setting of gummies before it is moved to cooling unit . The refrigeration process will be further needing half hour time to ensure gummies are chilled.

Finally, remove the gummies from refrigerator and make them stand on a flat surface to give them maximum exposure to air. This will require two days time. After which you will make the gummies lie down again on the same flat surface ensuring maximal surface area to air ratio which will make the gummies more chewier and firmer.

4.How To Make Hard Gummy Bears at Industry?

Step Involved in Making Hard gummy bears

The process of making hard gummy bears commercially at a confectionery industry can be massive requiring gummy making machine and quite a few days time for overall manufacturing to be completed. The basic steps involve cooking and mixing, cooling, coating and drying to be carried out.

Step 1: Preparing Raw Ingredients

To start your procedure without preparation can be troublesome. So, first of all, make a list of requirements. Weigh the raw-ingredients begin with the second step now.

Step 2: Dissolving and Cooking

Unlock the dissolving and cooking unit and pour each ingredient into neat and cleaned unit one by one. Add water and initiate the agitation and cooking. This unit is double jacketed that would help you in sustaining the temperature throughout the operation. The required temperature where all material dissolves and forms a syrup is 108-110°C. You can also observe little boiling bubbles in a thick gummy slurry. Yes, this is what you look for. The entire process is hardly occurred in 15 to 20 minutes and a thick evenly dispersed syrup is prepared. It is usually stored in 60 to 70 °C under gentle agitation to maintain the formulation.

STEP 3: Small Scale Gummy Deposition

The molten gummy bears formulation is poured into the depositing hopper either manually or using a transferred pump. At this stage, you need to set the mold or depositing mold onto the depositing conveyor. Now push the handle to fill the gummy syrup into each cavity of the depositing mold respectively. Once the mold is filled, you can manually remove the tray and put the next one. By this way, you can run small to medium batches hourly.

STEP 4: Cooling

Now your gummy bears are almost ready, the only thing left is, acquiring a correct shape. This is attained when you place gummy depositing mold inside the cooling tunnel.

STEP 5: Polishing

This step is somewhat optional; though it is essential to enhance the appearance of gummy bears as it gives a shiny and smooth look to gummy bears. The de-mould gummies are now subjected to coating machine where spray of sugar and oil is applied to the bed of gummies revolving inside the coater.

STEP 6: Drying

Now gummies are subjected to the drying area where room temperature and drying fans help to eliminate extra moisture present in the gummies and making them desirable for the packaging and marketing.

Hard and sweet gummy candies- Picture courtesy: Step away from carb

When it comes to considering the hardness of gummy bears, from the start of cooking and mixing process , it takes about 30 minutes to 3 hours depending upon the size of batch used for making of hard gummy bears.

Then comes the cooling stage which must be given at least half hour to 24 hours, allowing the gummies to set and harden. This depends on the type of gelling agent being used, for example gelatin takes longer to set and form than pectin. Once dried and they are brought out of molds, further 2-3 days time is given to allow maximum air exposure and further drying. As much the gummies will be exposed to air and kept out in the environment, that will account for hardness and firmness of gummy texture.

5.Why Do Gummies Turn Hard?

Hard Gummy Bears

If you ponder upon the procedure by which how the gummies are made, you will know that it’s the key ingredients where the secret actually lies. Now it doesn’t solely depend on those ingredients but also some other factors like manufacturing process and quality control parameters matter too. As you read above gummies are not only purposefully made hard, but they might also turn rigid due to some of the below reasons:

Because of ingredients: The carefully picked selection of start off formula agents such as any gelling agent whether it is animal based or plant based like gelatin or agar agar, their ratio of mixing with sugar syrup and starch consistency develops the texture of your gummy. It can be made hard or soft using various ratios of these products.

About cooking strategy: The way gummies are formulated while cooking process and then been allowed to cool and dry directly affects how well this candy mixture will settle down in their molds. It depends on the time given and method for drying that will give firm shape to the gummies.

Storage conditions: It of course affects the setting of gummies as for example if you let your gummies kept exposed quite too long with air , moisture or heat they will lose their water content and turn out to be harder in texture.

Weather conditions: Temperature and level of humidity will also have an impact on how your gummy bears are. High temperature and humidity level can make them lose their moisture and turn hard or possibly even melt.

Shelf Life: Along with time and as the expiration date nears, gummy bears might lose their originality and change their squishy usual form to hard ones.

Manufacturing problems: Any mishandling or inconsistency in ingredients mixing or procedure technique can result in gummy bears turning hard.

6.Are Hard Gummy Bears Called Stale?

Picture courtesy: 27F Chilean Way

Any product is said to be stale when it passes beyond its best before date or is stored improperly and results in that product being either totally unable to be eaten or lose their quality of taste.

Likewise, gummy bears can turn stale too. A hard gummy bear is probably called stale as mostly it happens unnecessarily, like when the packet of your gummies rests open in air for unwanted longer duration of time, or it is placed somewhere in high moisture area and heat, etc.

Gummy Bears if turned moldy or dry and grainy, then that means your candies have expired and now you better throw them off instead of rescuing them.

7.What Are the Properties of A Hard Gummy?

Hard Gummy Bears

Making a hard gummy bears along with necessarily managing it’s physical and chemical properties is a must to know before manufacturing of such gummies. The hardness of these gummies can be described as gelling strength and chewiness can be shown by tackiness level while observing and analyzing the texture of hard gummy.

For a gummy candy to be hard, following properties must be achieved in a gummy mixture:

- Use of an acid treated gelatin with higher strength blooming of about 250 or more, can assure greater chewability and hardness of a gummy that seems physically similar to chewing on a gum.

- Compounding sugar syrup and starch with different dextrose equivalent (DE) values makes excellent chewing and gelling feature.

- Adjustment of gummy mixture’s pH to acidic range of 3.2- 3.4 for acid treated gelatin.

- The moisture level of the hard gummy mixture should be around 13-17% as it is closely linked with hardness texture.

- The hardness of the gummy can also be affected by it’s size so it is necessary to ensure filling gummy mixture into molds, having average thickness of 5.5-8.5mm.

- The temperature scale while filling of mold for achieving hard gummy should be 30-100°C and during the drying process, the temperature should be at 40°C or lower to get desired moisture level as mentioned above.

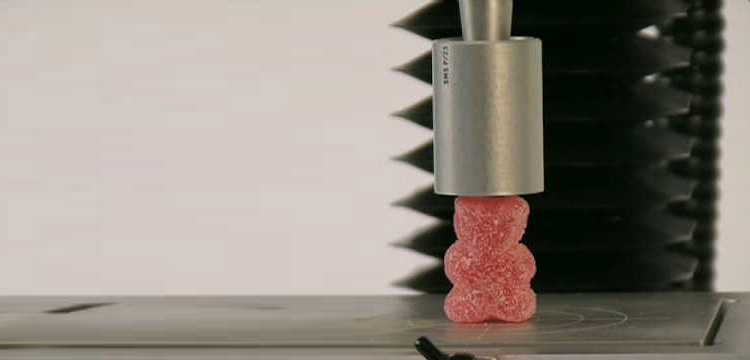

8.How Can Hardness of Gummy Be Tested?

Picture courtesy: Texture Analysis

In order to evaluate and monitor gummy hardness to ensure accuracy and prevent batch variation in gummy sizes, gummy candy hardness can be checked using a compression test.

This test is similar to checking a gummy’s hardness by pressing it between your thumb and forefinger. A large ball probe senses textural evaluation using a hardness scale range for monitoring upper and lower tolerance values of gummy hardness.

9.How to Harden Soft Gummy Bears?

Hard Gummy Bears- Picture courtesy: Nut and Candy

In case your gummies have turned out to be too soft or they’re unlike the way you wanted it to be tougher in consistency you need to first make sure you have got your gelatin to water ratio alright. It also depends on the ratio of sugar syrup or sorbitol you’ve added to starch. Less starch and more sorbitol mean harder gummy.

You can also place your gummies in refrigerator or freezer for about half hour or more as we just discussed above in order to harden them.

10.How To Prevent Hard Gummy Bears from melting?

Hard Gummy Bears- Picture courtesy: Kitchen Alchemy

Hard gummy bears may be prone to melting if the formulating ingredients are not properly measured and some of them are inaccurate in ratios than other. This can happen if you’ve added too little gelatin or pectin or if you’ve added too much of citric acid or water.

To prevent these gummies from melting make sure you store them properly in room temperature, in an airtight container if the weather is not too hot and humid. If its hot enough outside you must place your gummies in refrigerator or at a cool place away from heat and sunlight. Gummies can also be prevented from melting if you coat them with cornstarch or sugar, which also helps prolong it’s shelf life and doesn’t let them from sticking. Ensuring that the gummies are allowed to set and dry for a longer period of time can also help them from melting. Usually at commercial scale, manufacturers apply a coating of carnauba wax in slight amount to make them last for longer.

11.What To do if Gummy Bears are not Hardening?

Various consistency of gummy candies

You already have read that inconsistency in ingredients ratio and mixing might result in gummies being melted easily or not hardening at all. Now what can be done if gummy bears are not setting properly even though you tried to figure it out? Let us help you.

Make sure that any excess amount of water from blooming is removed when you’re letting the gelatin to set. This could be because either you’ve added very little amount of gelatin or added too much water.

It can be fixed by immersing them in ethanol and drying, and later coating it with citric acid before you go for sugar coating your gummies.

Monitor and control the temperature while you’re cooking and mix your gummy formula so that undercooking or overcooking doesn’t takes place.

Give them a period of at least 72 hours to dry in room temperature, letting enough air exposure to gummies. Remember to lay down the gummies out of the mold on drying trays so that good drying is ensured from all surface sides.

12.What Are Different Types of Hard Gummy Bears Available?

Markets have brought forward diversity of colorful and fruity , hard but chewy gummy candies which can be bought in various shapes and sizes.

Let’s look at some of these below:

Oval Shaped Hard Crunchy Shell Gummy

Oval hard gummies

These rainbow colored gummy candies are oval in shape, having outside hard crunchy shell of candy which is filled with fruity burst of juice inside released slowly when you chew on it.

Round Cluster Crunchy Gummy

Round cluster hard gummies- Picture courtesy: Lolly kingdom

Small bite sized gummy cluster candies are hard to chew and crunchy, having tangy flavor and when you chew it has sweet gummy texture and flavor from inside.

Kohakutou Crystal Gummy

Kohakutou- Picture courtesy: Sugar Geek

They are japanese origin , vibrant colored , crystal like gummies which are hard in texture but delicious in taste. Kohakutou gummy candies are very sweet and chewy from inside made from agar agar as a gelling agent.

Berry Gummy Bears

Berry hard gummies- Picture courtesy: Sugar Free

Berry gummies can be found in exciting blueberry and strawberry flavored , hard crunchy flavor and texture . They are equally enjoyed by kids and adults due to their delightful taste.

Bottle Shaped Hard Gummy

Bottle shaped hard gummy

This belongs to the famous gummy which has cola flavored bottle shaped hard gummies.

Assorted Gummy

Picture courtesy: Boston

The hard gummy assortment of exciting and amazing flavors include, yoghurt, lemon, strawberry hard and crispy sugar shell gummies and jellybeans which are crunchier on the outside.

Customized Shapes Hard Gummy

Customized hard gummy candies

Japanese invented, hard textured but soft for chewing gummy eatables are also there in customized shapes . These can be ordered or made available for any of your occasions. Shapes like heart, flower, rectangle, cube, diamond and many more can be made.

Crispy Crunchy Gummy Bears

Crunchy hard gummy bears- Picture courtesy: Candy Warehouse

This type of gummy bear candy has colorful sprinkles coated on the hard and crunchy textured gummies. They come in exciting flavors and are delicious to eat. When you chew on it , it’s inside is of fruity flavored jelly.

Crunchy Worm Shape Gummy

Candy coated hard gummy- Picture courtesy: Brand Eating

Candy coated, crunchy crawling worms shaped gummy are popular amongst children and adults as they’re appealing in taste of dual flavors as well as sour and tangy to feel.

Gumdrops Shaped Crunchy Gummy Bears

Picture courtesy: Blain Farm

Gumdrops Shaped gummy are hard coated with colorful sprinkles of candy and are very sweet in taste. When you bite it, it releases a quick gush of fruity flavors due to soft center filled gummy inside.

Crunchy Rope Shape Gummy

Crunchy rope hard gummy

Coated with sprinkles of sugar in multicolored crunchy texture, this rope shaped gummy is a long sweet jelly with a bit of fruity and sour taste.

13.Are Hard Gummy Bears Available as Vitamin Supplements?

Hard gummy bear multi-vitamins-Picture courtesy: Pen field

Yes. Hard gummy can be made into multivitamin supplements as well. The famous brand Flintstones has these nutritional supplements available in the form of hard and chewy gummy. These are good for your dental health along with providing essential nutrients.

Conclusion

The hard gummy bears are also similar way to make gummy bears by simply altering few components in its formulation. We hope you’ve found this article really interesting to know important facts about ‘how to make hard gummy bears’. If you’re looking for more information or planning to buy excellent equipment required in the hard gummy bears production, then Allpack is here to listen to you. Just send us a message to contact our experts and find new opportunity to avail free consultation and guidance right now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide