Hot Sauce Bottling Machine: The Complete Buying Guide In 2024

Globally the use of hot sauces has increased exponentially due to increasing in world’s population. But it has always been a concerned that how the productivity of hot sauces can be increased.

Hot sauce bottling machine is one of the finest solution for filling and sealing of hot sauce bottles in an efficient manner. For selection of right type of hot sauce bottling machine we Allpack are providing you this complete buying guide. Read it completely and take the most of it!

1. What Is A Hot Sauce Bottling Machine?

For providing ease in sauce filling processes, hot sauce bottling machine is one of the remarkable advancement in technology. Different types of hot sauces can easily be filled using a hot sauce bottling machine.

The machine is use to fill, seal and pack hot sauces in different shapes of bottles. An automatic processing remains in the machine which increases productivity and product quality. Hot sauce bottling machines are mostly used in food industries with high efficiency and presentable outcomes.

2. What Are The Types Of Sauces Production By A Hot Sauce Bottling Machine?

In the world where varieties of hot sauces are now prepared, hot sauce bottling machine supports all of these. Many types of sauces that can be produced using a hot sauce bottling machine include Habanero sauce, Louisiana-style hot sauce, Chipotle sauce, Ghost pepper sauce, BBQ hot sauce, Jalapeno sauce, Buffalo wing sauce, Tabasco sauce, Sriracha sauce, Vinegar-based hot sauce.

Before producing hot sauce using a hot sauce bottling machine it is important to notice that the machine can be applied for the any type of sauce bottling and allows the viscosity of the same sauce. Travelling temperature whether hot or cold can affect the quality of sauce if it is not filled in the right type of bottle.

3. What Are The Applications Of A Hot Sauce Bottling Machine?

Hot sauce bottling machines are mostly installed in food processing and sauce manufacturing industries. Some of their applications in these industries are

- Food Processing Industries

Variety of sauces and condiments are packed in food processing industries using a hot sauce bottling machine. Pepper sauce, jam, chili sauce and other types of hot sauces are filled in multiple shaped bottles using a hot sauce bottling machine.

- Packaging Industries

Packaging industries also apply these hot sauces bottling machine to package their products. This packaging of hot sauce bottles makes the customer more attractive towards the product and provides lucrative packaging options.

4.What Are The Features Of A Hot Sauce Bottling Machine?

Some of the features of a hot sauce bottling machine are

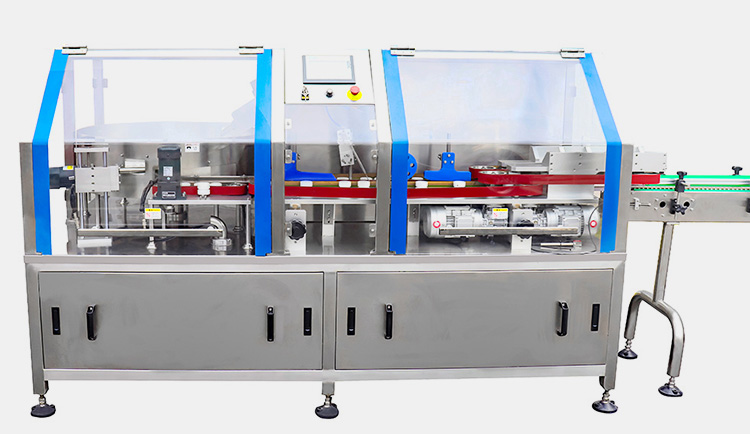

- Variety of Caps

Capping system of a hot sauce bottling machine has the most unique feature that it can apply different types of caps also of different sizes. Whether it is a screw cap or a snap-on cap, the capping system purely depends on the production requirement of the manufacturer.

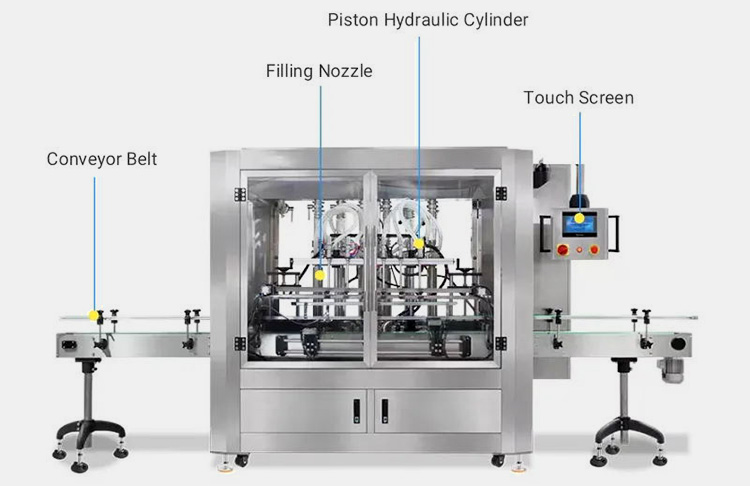

- Filling nozzle

Filling nozzles are mainly made up of stainless steel and are used in dispensing the hot sauce into the bottles. The filling nozzle can be adjusted to accommodate different bottle sizes and also of different materials.

- Orientation system

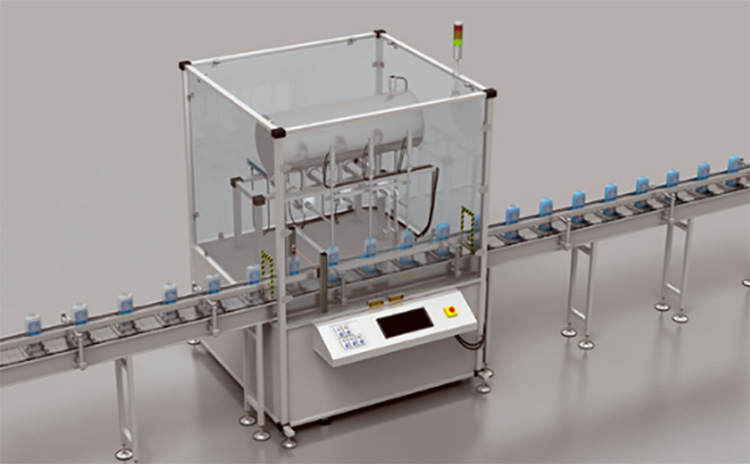

Hot sauce bottling machine has a bottle orientation system that orientates the bottles rightly before it reaches the filling nozzle. It is directly supported with the conveyor system and body sensors that indicate the presence of bottles under the filling nozzle.

- Variable Speed

Depending upon the requirement of production and annual manufacturing goals, the hot sauce bottling machine has the capability that its speed can be controlled. This feature allows the operator to control the production speed and stops the system whenever any mishap occurs. The speed of filling system remains in sync with the speed if conveyors.

- Cleaning System

A hot sauce bottling machines has an internal machine cleaning system that allows easy cleaning of the machine without any human access. The cleaning system is that much efficient that it removes all the waste or overflow sauce within the system.

- Adjustable Height

Hot sauce bottling machine has an adjustable height feature that allows the operator to adjust the height of the machine according to the height of the conveyors. The height can also be adjusted according to the other equipment present in the system to make sure proper filling of hot sauce is carried out.

5. What Are The Advantages We Can Get From A Hot Sauce Bottling Machine?

Hot sauce bottling machines are used in multiple industries to provide efficient filling of sauces. These machines have number of advantages for which they are preferred the most. Some of the benefits that a buyer can get while buying of hot sauce bottling machines are

- Bottle Handling

Hot sauce bottling machine has highly effective holding and controlling of bottles throughout the filling and capping process. By this the risk of bottle damage, breaking and material wastage can be reduced to a greater level.

- Improved Efficiency and Accuracy

With compare to traditional or manual bottling machines, hot sauce bottling machine are able to fill and cap sauce bottles in an efficient and faster manner with greater accuracy. Due to this advantage the productivity of an organization can be multiplied and also the involvement of labors can be reduced to produce similar bottles. The bottling done by hot sauce bottling machine prohibits overflow even if it is moved to any part of world.

- Consistency

Hot sauce bottling machines fills the bottle with same amount of hot sauce in every process. By this product consistency can be achieved using a hot sauce bottling machine.

- Automation

Highly automated machines are now available in the field of hot sauce bottling machines. The machine from feeding of bottles to its packaging, each step is done on complete automation. Machines are able to automate many of the tasks that can decrease the labor requirements needed to operate the bottling line.

- Hygienic Bottling

Highly hygienic and safe packaging of hot sauce bottles is done using a hot sauce bottling machine. The machines are designed in a way that it can clean and sanitize its process automatically to meet the international standards.

6. What Are The Working Principles Of A Hot Sauce Bottling Machine?

A hot sauce bottling machine has a simple working principle. The machine undergoes gravitation force and obeys following operational method.

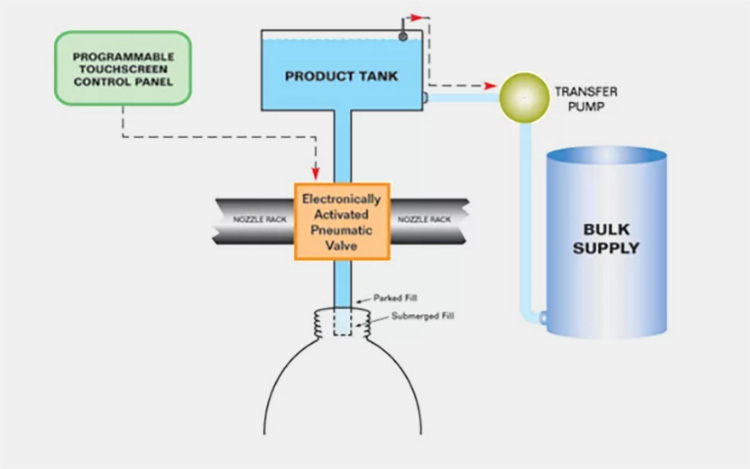

- A typical hot sauce bottling machine works under the combination of pressure and gravity.

- Initially the bottles are fed in the conveyors from which they are moved further to the system. On the other hand, pre-heating of bottles also remains in process to prevent cooling and thickening of hot sauce material.

- The hot sauce is filled in the filling unit and from there it is pumped into filling lines. The sauce travels due to the gravitational pull and leaves the filling nozzle once the signal of bottles presence is generated.

- The level of hot sauce is fixed and the same amount is filled in bottles.

- The filled bottles are then entered into the sealing system in which the sealing of bottle cap is performed.

7. What Are The Main Components Of A Hot Sauce Bottling Machine?

A hot sauce bottling machine is divided into different units. These units have components in them which play important role in the operation of a hot sauce bottling machine

- Filling Unit

A filling unit is the one that is responsible for filling bottles with hot sauce. The filling unit includes upper hopper that is filled with the hot sauce. From the hopper and complete channel is connected till the filling nozzle from which the sauce is dispensed into the bottles. The filling unit is designed in a way that it fills bottles in a quick and precise way to ensure that each one of the bottle gets filled with the correct amount of hot sauce.

- Capping Unit

In the capping unit, the sealing of bottles is done once they are been filled with the right type of hot sauce. A capping unit usually includes a capping head that applies caps on to the bottles and after that a torque control unit that ensures that the caps are fixed with the right type of cap and the required force is applied on it.

- Labeling Unit

Once that hot sauce is filled properly with hot sauce and the cap is tightened, the labeling unit applies variety of labeling designs to the bottles of hot sauce. This unit includes a label applicator which is responsible in the application of labels on to the bottles and after that a label inspection system that verifies the presence and implementation of accurate labels.

- Control Panel

A control panel has all the operating and monitoring options that are associated with a hot sauce bottling machine. The panel has a series of buttons and switches that allow the operator to control the different components of the machine, from this control panel the operator continuously monitors the working and display screen indicates the machine status. Errors are generated on these screens if any of them occurs.

- Conveyors

The moving of bottles from one stage to another is done through these conveyor belts. Series of conveyors are there that transport the bottles from the filling unit to the capping unit. Once the caps are fixed in the capping unit, the conveyors move them to the labeling unit for label implementation. At last the bottles travel to end of the system.

8. What Types Of Hot Sauce Bottling Machine Are There?

Out of various types of hot sauce bottling machines, some include

a. Piston Hot Sauce Bottling Machine

Piston hot sauce bottling machine uses a piston to fill bottles with hot sauce. A piston is used to pump the sauce into the bottles via a filling nozzle. Piston hot sauce bottling machines are typically used for large volume production and are well suited for larger businesses.

Working Principle of Piston Hot Sauce Bottling Machine

- In a piston hot sauce bottling machine the bottles are placed beneath the filling nozzle and the operation is then started.

- Hot sauce is filled in particular cylinders where the temperature is maintained by using a heating element that is covered around it.

- The up and down movement of piston present inside the cylinder of nozzle creates suction power. This suction force moves the sauce downwards and then out of the cylinder.

- An upward suction at the same time releases the hot sauce from cylinder to the bottle. The process is repeated until the bottle gets filled up to its mark.

- Further the bottles are moved to the packaging process where the bottles are provides with cover packaging.

b. Overflow Hot Sauce Bottling Machine

Pump is used to fill bottles with hot sauce in an overflow hot sauce bottling machine. The sauce is pumped into the bottles via a filling nozzle, and the level of the sauce is controlled by an overflow mechanism. Overflow type hot sauce bottling machines are used for large scale industries.

Working Principle of Overflow Hot Sauce Bottling Machine

- Hot sauces are initially filled in the hopper that is present above the production line in an overflow hot sauce bottling machine.

- Temperature of hot sauce filled in hopper and cylinders is maintained by using a heating element that covers both of them.

- Once the operation gets started and bottle reaches the filling nozzle, the hot sauce is pumped and gravitational pull causes consistently flow of sauce into the bottle. The fill level is maintained and controlled by rim of overflow on each interval. This overflow rim ensures that the bottle is filled to its maximum level.

- The excess sauce gets re-circulated back into the filling system and the same cycle is repeated.

c. Servo-driven Hot Sauce Bottling Machine

Servo-driven hot sauce bottling machines have servo motor and PLC control system to control the filling volume, speed and precision. These machines are used for high-precision production where complete feedback is received.

Working Principle of Servo-driven Hot Sauce Bottling Machine

- This is one of the most accurate and precise way of filling hot sauce in bottles as servo motors is highly efficient in their working principles.

- Servo motors are use in this type of machine for filling the volume and releasing of hot sauce into bottles.

- Once the bottles reach the filling nozzle, the servo motor operates by pushing the hot sauce into the bottle. Sensors are used to detect the filling level and cut the operation of servo motor as it reaches to its maximum height.

- Fast production can be achieved with this type of hot sauce bottling machine.

d. Volumetric Hot Sauce Bottling Machine

Volumetric hot sauce bottling machine uses a volumetric measuring device to fill bottles with hot sauce. The sauce is dispensed into the bottles from filling nozzle, and the volume of the sauce is controlled by the measuring device. Machines are ideally used for higher-volume productions.

Working Principle of Volumetric Hot Sauce Bottling Machine

- In volumetric hot sauce bottling machines, the hot sauces are filled into the measuring chambers and the temperature of it is maintained by associating a heating element to the surrounding of measuring chamber.

- Volumetric hot sauce bottling machine also obey the same working principle like other types of hot sauce bottling machine but the only difference lies is the accurate dispensing of hot sauce.

- Accurate amount of hot sauce is released once the bottle comes underneath the filling nozzle and the system shuts down when it reaches its maximum input value.

- The bottle is then taken out of the system in an efficient manner.

e. Gravity Hot Sauce Bottling Machine

Principle of gravity is used to fill bottles with hot sauce in gravity hot sauce bottling machine. The sauce is poured into a hopper at the top of the machine, and it flows down into the bottles via a filling nozzle.

Working Principle of Gravity Hot Sauce Bottling Machine

- A gravity hot sauce bottling machine focuses on the force of gravity regardless of any other automated way.

- The filling nozzle is positioned above the desired filling level. By this the hot sauce is filled in the bottle by gravitational pull.

- The bottle is filled to its maximum level and then moved toward the next packaging level.

9. What Are The Differences Between A Hot Sauce Bottling Machine And Tomato Sauce Filling Machine?

Some of the differences between hot sauce bottling machine and tomato sauce filling machine are

- Material Viscosity

Hot sauce bottling machines fills thinner and liquid like viscous materials that has low density in nature.

More thickly viscous paste of tomato sauce with a higher flow rates can be filled using a tomato sauce filling machine in a precise and accurate manner.

- Material Consistency

The material flow rate in a hot sauce bottling machine is a bit fast, high and consistent manner as the hot sauces are of low viscous.

Whereas, a tomato sauce filling machines works with slow flow rate as the material is of greater viscosity and thicker in nature. Thick material flows out from the filling nozzle at a slow pace into the bottles.

- Bottle Sealing

Seamers are present in a tomato sauce filling machine to seal the caps of bottles.

Caps in a hot sauce bottling machines are sealed by ordinary screw tightening and no special sealers are present in it.

10. What Are The Auxiliary Components That Are Associated With A Hot Sauce Bottling Machine?

Several auxiliary components are associated with a hot sauce bottling machine that work to ensure smooth bottling process. Some of the auxiliary components that are present along with a hot sauce bottling machine are

- Capping Machine

In some of the hot sauce bottling machines, capping machines are integrated or associated at the end which is used to install and tight caps on the bottles. An automated system feeds the cap on the top of bottle and then screw mechanism tightens the cap by ensuring airtight sealing.

- Bottle Unscrambler

Bottle unscramblers are also used as an auxiliary component for proper feeding of empty sauce bottles to the filling system of hot sauce bottling machines. It orientates right size and shaped bottles into the system that can be used further for filling of hot sauce.

- Bar Code Injector

Some of the hot sauce bottling machines also uses bar code injector which makes each of the bottles with a separate, identical number.

- Quality Checker

For ensuring proper quality and filling height, quality checkers are installed in the exit channel of a hot sauce bottling machine.

11. What Common Factors Should Be Considered Before Purchasing A Hot Sauce Bottling Machine?

While purchasing a hot sauce bottling machine, some of the factors that should be kept under consideration are.

- Speed and Precision

The manufacturer should check the machine specifications including speed and precision at which the bottles will be filled. It should be kept under consideration that the machine may fulfill high-speed production with precision. Selecting the machine with low productivity for a higher volume production setup can cause a lot of money and time loss.

- Bottle Size and Shape

The manufacturer should consider the size and shape of the bottle in which the filling process is to be carried out. The machine accommodating different size and shape of filling bottles with hot sauce can cause a positive impact on the buyer. The machine accommodates every type of size and shapes of bottle are more effective.

- Viscosity

The viscosity of the hot sauce will also impact the type of machine you need. A machine that is designed to handle a thinner sauce may not work well with a thicker sauce, and vice versa.

- Production Volume

The production volume is one of the most important factors to consider when purchasing a hot sauce bottling machine. It is important to choose a machine that handles greater volume of hot sauce that can increase businesses.

- Maintenance and Warranty

Manufacturers of hot sauce bottling machines that offer greater service and maintenance of the machine are important to be considered. Machine that holds the greater warranty duration and good after-sales service are the best ones.

Conclusion:

Demand of hot sauce bottling machines is now increasing drastically day to day. Due to this number of manufacturers of hot sauce bottling machines have now evolved in greater numbers. Before buying these machines it is important to consider number of parameters. We Allpack also provide you solutions for hot sauce bottling machines. In case you still find any query, contact us or visit our website http://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide