Lubricant Oil Filling Machine: The Complete Buying Guide In 2024

Do you deal with thick, viscous liquid which is non polar and hydrophobic? Are you looking for a machine which would easily fill this liquid in a safe and effective package? Then fret no more! Because in this article, we will tell you about the perfect machine which would package your liquid efficiently. That machine is called lubricant oil filling machine.

This machine is used in several industries to fill liquids safely in protective packaging. It is versatile, cost-effective and a highly efficient machine. It also comes in different forms, each have their own unique characteristics to cater to your requirements. In order to know exactly which specific type of this machine would be suitable for you, let us discuss in detail about this incredible machine.

1.What Is Lubricant Oil Filling Machine?

Lubricant oil filling machine can fill liquids in bottles of any shape or size. This liquid can be of any texture, thickness and viscosity. From aqueous type of liquids to highly viscous, lubricant oil filling machine has the ability to fill all of them, making it the go to equipment for your factory.

It uses the concept of vacuum pressure filling to fill bottles in the best way possible. In this way, the liquid doesn’t spill off and the bottle is able to store it without any wastage.

2.What Are The Advantages Of Lubricant Oil Filling Machine?

No matter what kind of liquid product you deal with, this machine is the go to choice for you to ensure an effective packaging for your product. Let us discuss the benefits this machine has to offer.

Accurate Filling

One of the best features of this machine is that it fills all the bottles with exactly the same amount of liquid. So you won’t have to worry about unequal filling since this machine uses modern software for error free filling.

No Wastage

This machine will not make losses for your factory since it uses latest technology filling nozzles to ensure that all the liquid is poured inside the bottles and does not spill around the machine.

Increased Production Speed

This machine support adding the number of filling nozzles. So if you want to increase your production scale, you can simply increase the number of nozzles. In this way, the machine will be able to fill greater number of bottles.

Versatility

Whether you deal with cooking oils, engine oil or diesel, lubricant oil filling machine has the capability to fill all these liquids in the best way possible. So you can easily install this machine in your factory without having to worry about its effectiveness.

It Calibrates On Its Own

You don’t have to worry about readjusting the height if you use different bottles during the process. The machine calibrates on its own and gives real time detection of filling and capping of bottles.

3.What Are The Applications Of Lubricant Oil Filling Machine?

This machine can be used not in one, but several industries. It has the power to remodel according to the industry it is going to serve. Let us discuss each of these industries below.

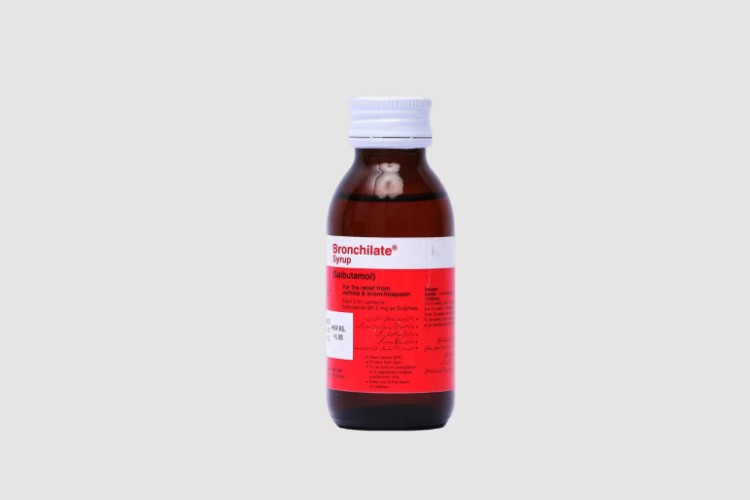

Pharmaceutical industry

In this industry, it is quite critical to maintain the potency and efficacy of the medicines to prevent any form of contamination. So this machine would be perfect to fill these medicinal drugs in bottles and vials to ensure safe treatment of patients.

Chemical industry

Many chemicals such as solvents, plasticizers, paints, dyes and pigments require a machine which would package them as efficiently as possible. Lubricant oil filling machine is an excellent option to fill these vulnerable and volatile compounds securely.

Food industry

If you are involved in the production of cooking oil, ketchup, chocolate syrups, sauces and require a filling machine, then this is the machine you should install in your assembly line for accurate filling.

Petroleum industry

This industry is involved in the manufacture of petrol, diesel, motor oil, engine oil. These highly viscous oils might get spilled if not filled properly in bottles. The use of lubricant oil filling machine would prevent this since it uses vacuum pressure filling of bottles, minimizing wastage and complete filling of the oil into bottles.

Agriculture industry

This industry deals with production of chemical fertilizers, pesticides and herbicides. The use of this machine proves in this industry, an efficient filling method is provided to pack these agricultural products in containers.

4.What Are The Main Components Of Lubricant Oil Filling Machine?

There are several components of this machine. Each have a role to play in running this machine. Let us take a look at these components below.

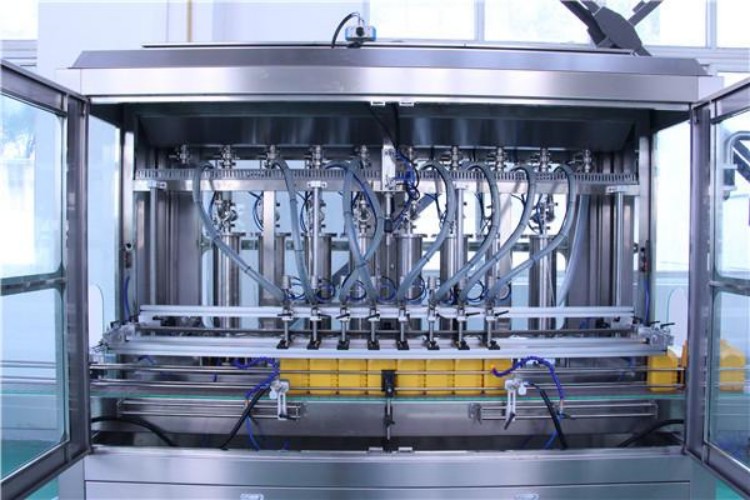

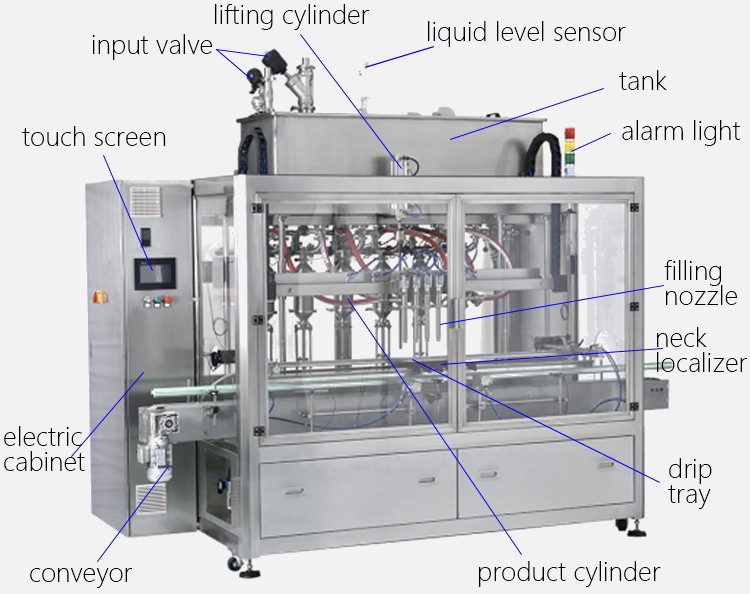

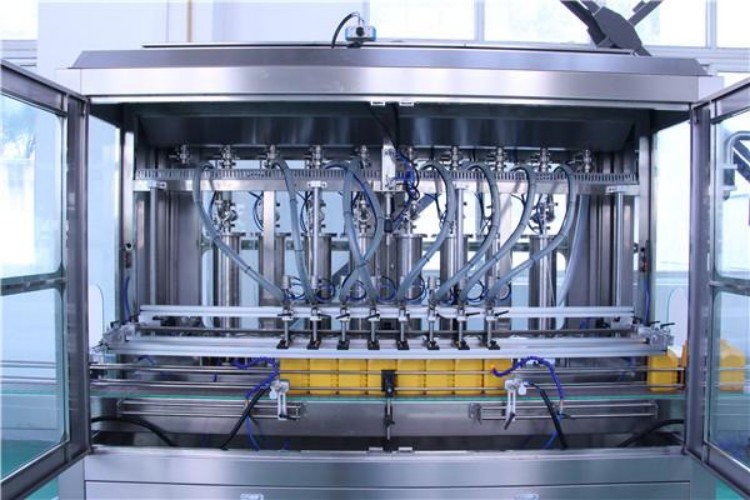

- Filling nozzles:these nozzles after undergoing vacuum pressure fill the bottles volumetrically.

- Touch screen:this is an important part through which the worker controls all the parameters of the machine including the speed, pressure and frequency. He can monitor the process by using this interface.

- Input valve: depending on how much liquid needs to flow inside the bottle, you can control the amount by using input valve.

- Lifting cylinder: this part helps to lift the other components of the machine, thus creating a balance and preventing any breakage of parts.

- Liquid level sensor: as the name suggests, this sensor can be used to detect how much liquid is being filled into the bottle and if it is in line with the parameter set by the worker.

- Tank: this is the main body in which the liquid is stored before it flows out into the bottles by filling nozzles.

- Alarm light: this lightis to inform you when there is a safety hazard and help to immediately halt the operation.

- Neck localizer: this part helps in positioningthe nozzles for accurate filling and to prevent any wastage.

- Drip tray: in case small amount of liquid drips from the nozzles, the drip tray will collect the residue, ensuring cleanliness of the machine.

- Product cylinder: before the desired liquid flows from the nozzles into the bottle, it is stored in the product cylinder.

- Conveyor:this part conveys the empty bottles automatically from one part to another so that they can undergo the whole filling process

- Electric cabinet:this part contains an electric box inside made up of electric wires and components and initiates the power of the machine working at a voltage of 220 V.

5.What Is the Working Principle Of Lubricant Oil Filling Machine?

The mechanism of this machine is quite simple, and you wouldn’t have a hard time learning how this machine works. The steps required to run this machine are:

Step 1: Bottle Feeding

The first step is bottle feeding, the bottles are fed into the lubricant oil filling machine through the conveyor belt, at this moment, the sensor of the machine detects the empty bottles and the machine begins to work.

Step 2: Bottle Filling

When the empty bottles are prepared, the lubricant oil need to be filled into them, in the filling station, the liquids are filled into bottles through different methods according to different machine types, such as piston, gravity, net weight, etc.

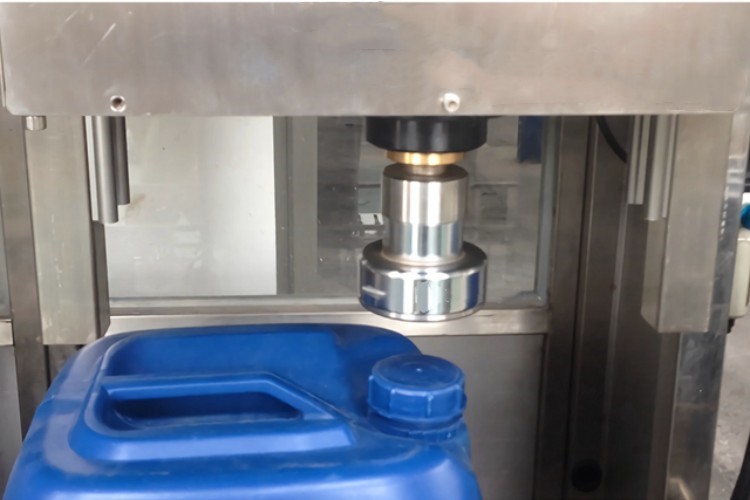

Step 3: Bottle Capping

The next step is bottle capping, when the bottles are filled with lubricant oil, they are conveyed to the next station to be sealed, caps are put on the bottle mouths and then be pressed.

Step 4: Bottle Labeling

Finally, the bottles need to be labeled, the lubricant oil filling machine applies labels on the bottles efficiently. The purpose of this step is to tell the information of the product and promote brand, after labeling, the products are ready to be distributed.

6.What Are The Types Of Lubricant Oil Filling Machine?

There are many types of this machine which have different specifications. They are classified based on two groups, one is based on automation and the other is based on working principle. Let us discuss each of these types below.

- Based on automation

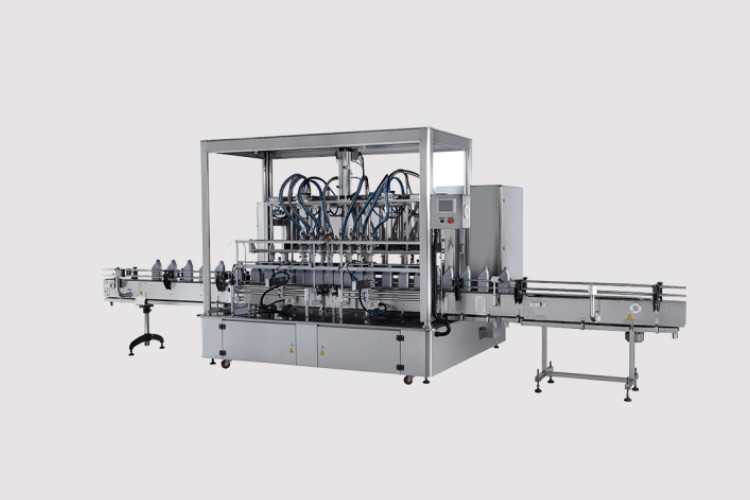

Automatic Lubricant Oil Filling Machine

Automatic Lubricant Oil Filling Machine-Photo Credit: KWT Machine Systems

This type, as the name suggests works on its own, that is, all the process right from carrying the bottles in conveyor belt to filling them through nozzles, the machine does it on its own without the need for human intervention. The process simply can be monitored through PLC control.

This type is ideal for factories with high production output. However, it is relatively expensive so it can only be afforded by medium to large scale businesses.

Semi-automatic Lubricant Oil Filling Machine

In this type of lubricant oil filling machine, the worker needs to place the containers to be filled in conveyor belt and after this carry it to the other part of assembly line. It is relatively cheaper than automatic lubricant oil filling machine so it is ideal for medium scale businesses and has greater production speed than manual lubricant oil filling machines.

- Based on working principle

Rotary Lubricant Oil Filling Machine

Rotary Lubricant Oil Filling Machine-Photo Credit: Biner Ellison

This machine is multi-functional since it has the ability to carry out the filling, capping and labeling process on its own. It consists of circular cylinders in which the bottles are continuously moved through the conveyor belt and filled with the desired required by nozzles.

This type can fill any liquid, from aqueous solutions to highly viscous liquids. Moreover, it has high production speed. So if your factory deals with many kinds of liquid, then this machine is the one for you.

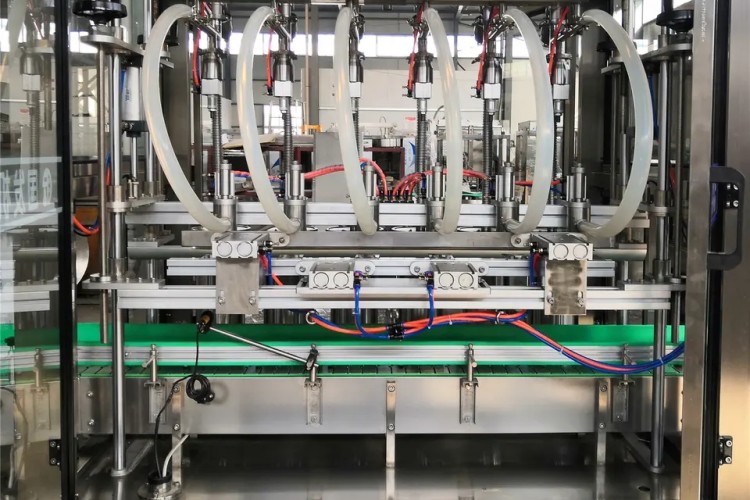

Overflow Lubricant Oil Filling Machine

Overflow Lubricant Oil Filling Machine-Photo Credit:Liquid Packaging Solution

This type is ideal for filling lubricant oils. It is equipped with filling nozzles which are set with determined values of how much lube oil needs to be filled inside the bottle or container. This ensures accuracy and maximum efficiency and prevents the overfilling of lubricant oil or inaccurate filling.

It is ideal for use in petroleum, pharmaceutical, agriculture and cosmetic industries. It is more suitable for filling lighter motor oils of low viscosities or for those liquids which need to be filled at exact level to look more appealing when kept at a shelf.

Vacuum Lubricant Oil Filling Machine

Vacuum Lubricant Oil Filling Machine-Photo Credit:Bhagwatipharma

The working principle of the vacuum lubricating oil filling machine is to create a vacuum environment in the bottle. During the filling process, the machine sucks out all the air in the bottle, so that a vacuum environment is formed in the bottle, then the liquid flows into the bottle smoothly.

This type of lubricant oil filling machine is perfect for filling thin or volatile lubricants, and can also be used for filling shampoos, sanitizers, juices, sodas, and more.

Gravity Lubricant Oil Filling Machine

Gravity Lubricant Oil Filling Machine-Photo Credit:Liquid Packaging Solution

You can judge by the name of this machine that it uses the principle of gravity to fill the product inside the bottle or container. The machine fills the liquid stored in a reservoir which flows down into the bottle by the help of gravity.

It is a cost-effective and efficient machine ideal for small scale factories or businesses. It can be used to fill cooking oil, lubricant oil, olive oil, coconut oil etc.

Piston Lubricant Oil Filling Machine

Piston Lubricant Oil Filling Machine-Photo Credit:Comarkmachine

Piston lubricant oil filling machine, also known as volumetric lubricant oil filling machine, it consists of hopper, cylinder, valve, piston and nozzles. The liquid sits in the hopper. As the valve opens, the product moves from the hopper into the cylinder as the piston withdraws, eventually filling the empty bottles by the nozzles.

This accounts for highly accurate and volumetric filling of the bottles. This machine is ideal for viscous or thick liquids such as mayonnaise, peanut butter, jam etc.

Net Weight Lubricant Oil Filling Machine

Net Weight Lubricant Oil Filling Machine-Photo Credit:vkpak

Net weight lubricant oil filling machine, as the name suggests, possesses a weighing balance which is used to measure the amount of product being filled in a bottle or container. It is ideal for large scale industries where there is high production capacity since it can be used for lubricant oils weighing from 5 kg to 30 kg.

Working at a voltage of 220V to 380V with filling capacity of 100 to 600 pieces, this machine is equipped with automated system and PLC control to monitor the whole process.

7.What Is The Auxiliary Equipment Of Lubricant Oil Filling Machine?

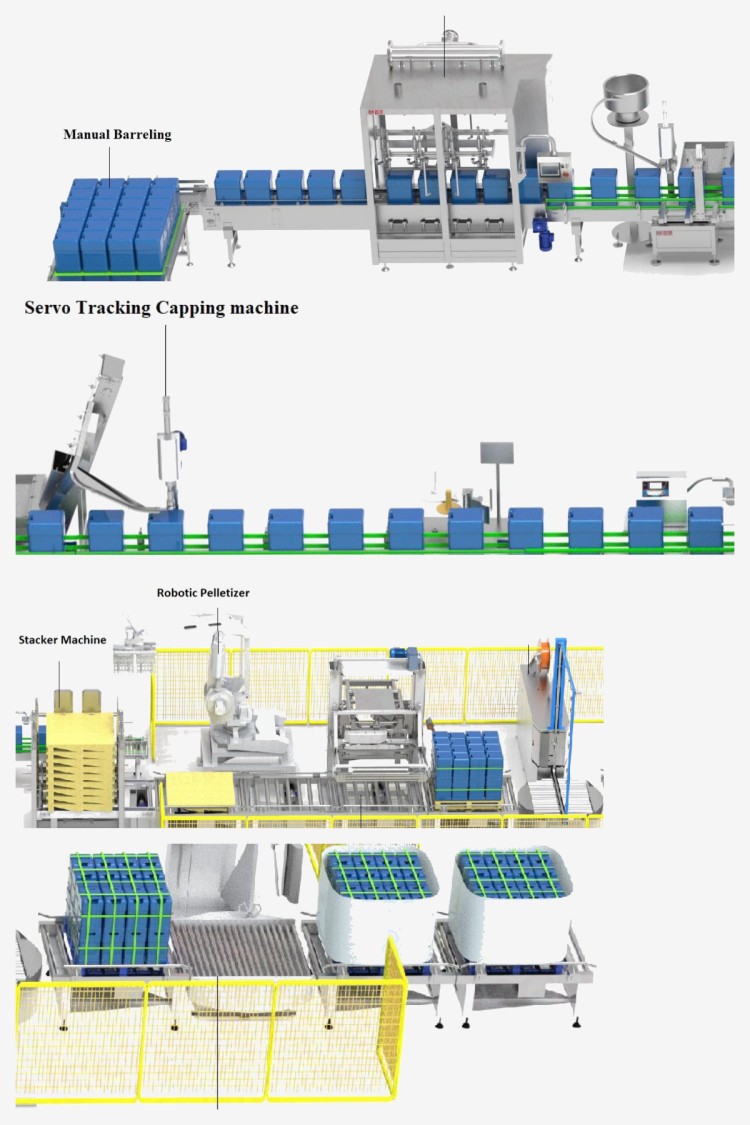

The production line of lubricant oil filling machine consist of sophisticated equipment which work together in the complete packaging of the product, making it ready to be shipped for sale. The equipment used are:

Manual Barreling Machine

This machine will be perfect to install in your lubricant oil filling line since it has the capability to give a refined look to the containers or bottles which have sharp, rough edges and a dull appearance. This machine can smooth them out and polish them, giving an aesthetic and shiny look to your bottles.

Induction Sealing Machine

This machine will be an integral part of your factory since it is used to provide an air tight seal to the bottles. It does this by applying an electromagnetic field to the bottles, sealing them off from the external environment. A strong, hermetic seal will protect your filled bottles from damage or contamination.

Servo Tracking Capping Machine

This automatic machine has the ability to cap the filled bottles. The process is monitored by the PLC control which can automatically cap the bottles as they move through the conveyor belt, providing an efficient lid for closing the bottles. It can cap around 30 bottles per minute.

Stacker Machine

After the bottles have been cleaned, filled, capped, they are carried by stacker machine which load them onto pallets or shelves so that they can be transported to the area where they can be wrapped and shipped out for sale.

Robotic Palletizer

This modern, advanced machine is used to palletize your products on pallets, shelves and trays. It is a fast process which uses a robotic arm to load or unload the stacked bottles onto trays. It will be an excellent choice for your factory if you deal with mass production.

Horizontal Strapping Machine

This machine, as the name suggests is used to wrap the palletized goods horizontally. It consists of an automatic lateral compactor which compacts the filled bottles before strapping them. It also has an anti-vibration frame which provides a firm stability when the strapping process is taking place.

Automatic Wrapping Machine

Lastly, this machine is installed at the end of the production line where it automatically wraps the product so that they can be shipped safely to their destination. The machine uses plastic film which is placed in a rotating film roll. As the product approaches it, it instantly wraps around it, providing a secure packaging to the bottles.

8.What Types Of Liquids Can Be Filled With The Help Of Lubricant Oil Filling Machine?

Several kinds of liquid products can be filled with this machine which are produced in industries such as pharmaceutical, chemical, food, agriculture cosmetic and many more. So if you are from any of these industries, then this machine is the perfect choice for your factory.

Lubricant oil

Lubricant oil, also known as lube, it is a thick, viscous liquid which is used in engines or motor vehicles, mechanical components of machines and metallic surfaces to reduce friction and wear and tear between them. Lubricant oil filling machine is the number one choice for filling this into bottles.

Cooking oil

One of the most common liquid which can be filled by lubricant oil filling machine is cooking oil which is used virtually in all dishes. This hydrophobic non polar liquid comes in different varieties such as sunflower oil, mustard oil, canola oil, olive oil etc.

Petrol

This yellowish flammable liquid is used in engines for combustion and to drive vehicles. Using the lubricant oil filling machine to fill petrol in bottles would be the best way to package this liquid safely.

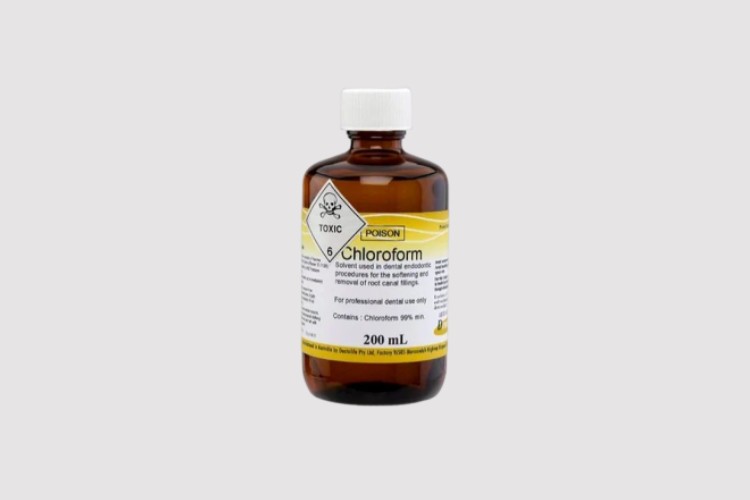

Chloroform

Chloroform, a colorless liquid comes from chemical industry and is used as a solvent to dissolve many kinds of liquid. This solvent is filled in bottles by lubricant oil filling machine.

Shampoos

Many cosmetic products such as shampoos, lotions and creams are filled in bottle containers and pouches by the help of lubricant oil filling machine.

9.How To Increase The Lifespan Of Lubricant Oil Filling Machine?

In order for the machine to work smoothly and for long period of time, you need to make sure that you are regularly cleaning and maintaining this machine and keeping an eye out for any problem which might occur. Let’s discuss some of the points which would help us in increasing the lifespan of this machine.

- Regular checkup

Make sure you routinely check the machine for any fault or problem. This will ensure that this machine does not experience any major fault and cost you significantly to repair it.

- Staff training

Train your staff and machine operators with up to date information because in case of machine downtime, they will be the ones who would know exactly where the problem lies and fix it, saving you from huge financial losses.

- Cleaning

It is important to clean your machine with appropriate tools to remove any dust particles or pollutants which might harm your machine.

- Inventory of spare parts

Always keep extra spare parts in an inventory so that if one of the parts get damaged, you can immediately replace it with a spare one. In this way, the machine can continue to operate and fill bottles routinely.

10.What Are The Problems And Troubleshooting Of Lubricant Oil Filling Machine?

- Machine can not start

Sometimes there is fluctuation of voltage which might cause a short circuit, causing cable burns. As a result, the power supply is damaged. Check for any faults in the electrical wires and power box and change the burnt wires with new ones. Make sure to test run the machine before starting the operation to prevent any explosion or damage to the machine.

- The machine fills the bottles inaccurately

The filling nozzles with time worn out or get bend, causing irregularity in their shape. As a result they will not be able to fill the bottles with precision and there will be wastage of liquid. Or the pressure at which they are filling is not enough or the valves are not opening and closing systematically.

Check the filling nozzles for any damage and replace them. Make sure the pressure value is adjusted accordingly and inspect the valves for any abnormal function.

- Overfilling

The machine is overfilling the bottles, creating foam like texture. This occurs when the parameter set amount of liquid is too high or the seals are loose. You need to lower the flow rate, tighten the seals and check whether the valves are leaking or not.

- The filling nozzles are not aligned with the bottles

Sometimes, the neck localizer fails to align the nozzles and bottle together. Replace the neck localizer with a new one and readjust the height and depth at which the nozzles are inserted inside the bottles.

11.What Factors Should Be Considered Before Buying Lubricant Oil Filling Machine?

To decide whether buying lubricant oil filling machine would be the best choice to fill your bottles or not, there are some factors which you need to consider which would help you in deciding whether it’s worth investing in this machine or not. These factors are:

- Your production capacity

The production capacity of your factory greatly influences the type of machine you will buy. If your factory needs to fill thousands of bottles in a single day, then you need to consider buying the automatic lubricant oil filling machine. if you have a medium production capacity then semi-automatic lubricant oil filling machine would be the better option for you.

- Type of liquid you deal with

The different viscosity of liquid affects the machine you will buy. If you deal with thick, viscous liquid, then piston lubricant oil filling machine is best for you. If you deal with medium to low viscous liquids then you can opt for vacuum filling lubricant oil filling machine.

- Financial limitations

If you have a high budget and would have no problem in buying an expensive machine then automatic lubricant oil filling machine would offer you multiple features and benefits. However, if you cannot afford to buy it, then manual or semi-automatic lubricant oil filling machines are also available to offer you multiple features at a lower cost.

Conclusion

After reading this detailed article about lubricant oil filling machine, you would have a clear idea about this machine. If you decide to install a lubricant oil filling machine in your factory, then it will surely reap multiple benefits and huge profits. No matter which industry you belong to, if you want a machine which can efficiently fill your bottles, then lubricant oil filling machine is the best choice for you!For more information and details, visit allpackchina.com

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide