Cotton Inserter: The Complete Buying Guide in 2024

Why cotton plugs are there in pill bottles? Inserting cotton is a conventional practice that has been employed since Bayer first introduced this trend for aspirin bottles. As a result, their longstanding applications are still followed by pharmaceuticals, nutraceuticals, and many other industries.

Today, our topic is basically all about cotton inserter, their importance, work, and role in business and we will discuss their breakthrough benefits and much more. So, if you’re among those readers who’re planning to purchase the machine; you’re at the right place. Please read on!

1.What Is A Cotton Inserter?

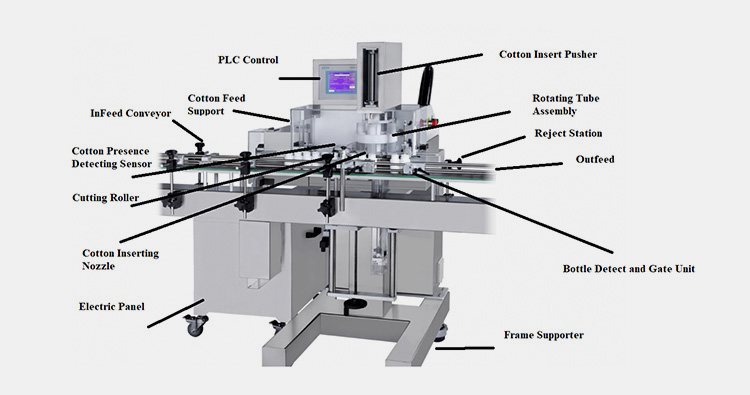

Cotton Inserter

A cotton inserter is a modern machine that basically relays on a series of cotton holding supporters and cotton roll knives and detecting sensors that help in detecting bottles and the presence of cotton roll and allow the machine to cut precisely and add cotton into individual bottles respectively. The machine performs this function accurately and safely. The machine is featured with high speed cotton moving rollers that allow smooth passage for un-rolling the cotton reel and driven by PLC unit and servo motor controlled.

This machine is significantly important in the healthcare system as it is capable to deal with large production capacity without the headache of manual inserting or continuous vigilance. This is an excellent addition that gives promising results in boosting your business.

2.Why Is Cotton Inserter Important For Packaging Containers?

A cotton inserter is widely accepted equipment that is important for packaging products, especially in the healthcare sector. This is because every consumer love to see their product welcome them when they open a new packaging. A cotton inserter plays a beneficial role across the different fields of packaging. Some of them are discussed below:

An Extra Layer of Protection

Inserting cotton in your medicine was a conventionally used method of packaging since hundreds of years ago. Today, cotton inserters do this job without the need for manual handling, manpower or error of contamination. Thus, you can achieve the safest packaging with cotton inserter with minimum risk of lost revenue.

Perfect of Broad Range Products

Not all solid dosage forms and products are the same. A cotton inserter is a robust solution that can grant you peace of mind as it is compatible with a broad range of products and packaging types, such as fragile, supplements, solid dosage, in bottles, containers, vials,.etc. Thus, the machine helps to offer products safely into the consumer's hands.

Easy to Do

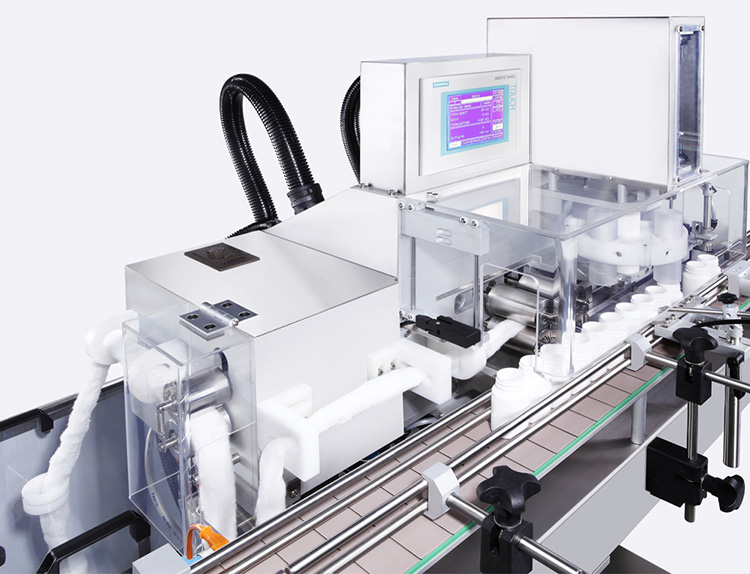

Picture Courtesy-COUNTEC

Today, an advanced series of the cotton inserter is quick easy to use equipment where an operator clicks the following keys on the PLC touchscreen, and the remaining procedure is handed over to the machine. This machine is reliable for your packaging operation without worrying about errors.

Easy to Integrate

A cotton inserter is an excellent solution when it comes to attaining results in a production line. This machine allows easy integration and fast packaging solution.

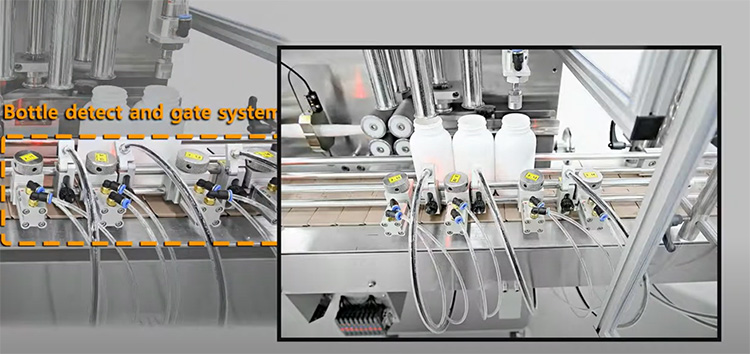

Strong Detection System

This machine is equipped with strong sensors that can detect if cotton is finished or not aligned to the unit. Once it notifies you, it would be easier to manage the situation by correcting and proceed the process. Moreover, the machine is featured with a rejection unit where incorrect bottles or any issues can ultimately lead them to be put in the rejection unit and allow smooth processing.

3.Where Is A Cotton Inserter Used?

A cotton inserter has various industrial applications. Some major industries are discussed below:

Pharmaceuticals Industry

The pharmaceutical industry deals with manufacturing and supplying medication. There are various product packaging items such as vials, bottles, containers, jars, and others, w a cotton inserter is used to place cotton piece after filling the medicine. This is required as it safe pills, tablets, or other items from breakage, and scratches, or for easy transportation. Besides, this cotton placement ensures that medicines are protected from humidity, light, creating odor, or chances of tampering (if removed or disturbed).

Nutraceuticals Industry

A cotton inserter is involved in the nutraceutical industry offering similar benefits as in pharmaceutical companies. Nutraceutical products such as vitamins, and supplements in the form of capsules, pills, and tablets need similar factors for product protection, such as the need for stable packaging, avoiding humidity, protection against light, or prevention of odor. A cotton inserter is used to stabilize the quality standards of nutraceutical items.

Chemical Industry

A cotton inserter is an essential equipment used in the chemical industry for packaging various solid products such as pH tablets, salts, buffers, hygroscopic substances, and organic and inorganic salts. The purpose of inserting cotton into the packaging containers is to retain their stability and quality.

Cosmetic Industry

A cotton inserter is commonly associated with a cosmetic industry that offers individual packaging of cotton balls that are needed for various activities in beauty salons, or for personal use. For instance, skin cleansings, facials, relaxation, removing or adjusting makeup, etc.

4.How Cotton Inserter Works?

The working of the cotton inserter is a pretty simple process. We have explained them in a more simpler way with the help of some illustrations.

STEP 1: Material Feeding

This step has two sub-sections.

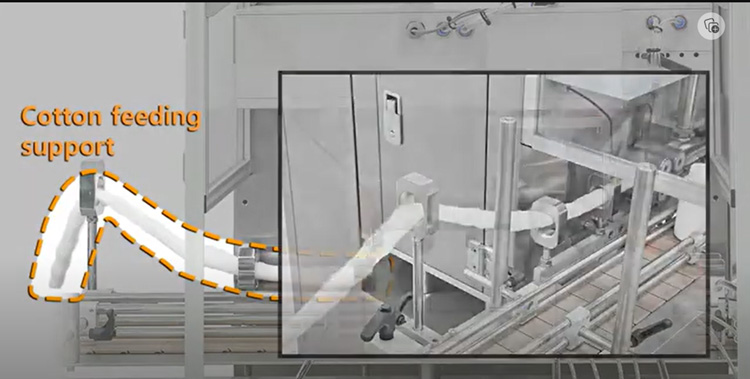

Cotton Roll Setting: This process is accompanied by the setting of cotton roll that is adjusted via spreading roll and fixed into the roller, and cotton feed support unit that helps in facilitating smooth run. A cotton roll starts unrolling when the process begins. This step is performed manually.

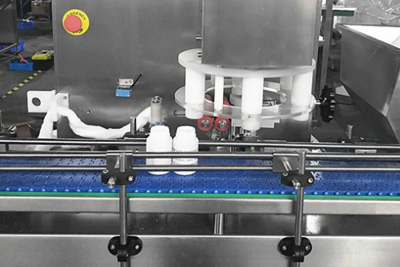

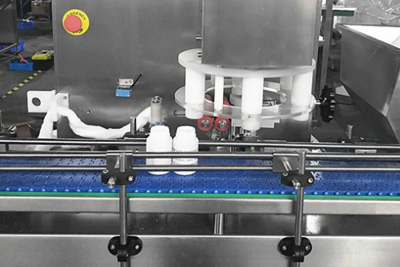

Bottle/Container Feed-in: Here bottles or containers are entered into the machine by the help of a conveyor belt which acts as a transporting medium.

STEP 2: Cotton Cutting and Inserting

Once the bottle reaches a cotton inserting unit, The presence of a bottle detector senses the presence of bottles and a cutting knife cut the cotton precisely and positions them into each available bottle. The process of cotton inserting become more efficient with the presence of a cotton pusher that helps in pushing a cut section to insert properly inside the bottle.

This filling of the cotton process is followed by rotary tube insertors that rotate and inserts cotton into each bottle.

STEP 3: Rejection

Those bottles that are not compliant with the process are sent back to the rejection unit for further assessment. The approved bottles are moved to the next machine for further production steps such as capping, induction sealing, etc.,

STEP 4: Bottle Discharge

Once the cotton inserting process is completed; the final product is discharged via an outfeed pathway such as a conveyor.

5.What Are Cotton Inserter Components?

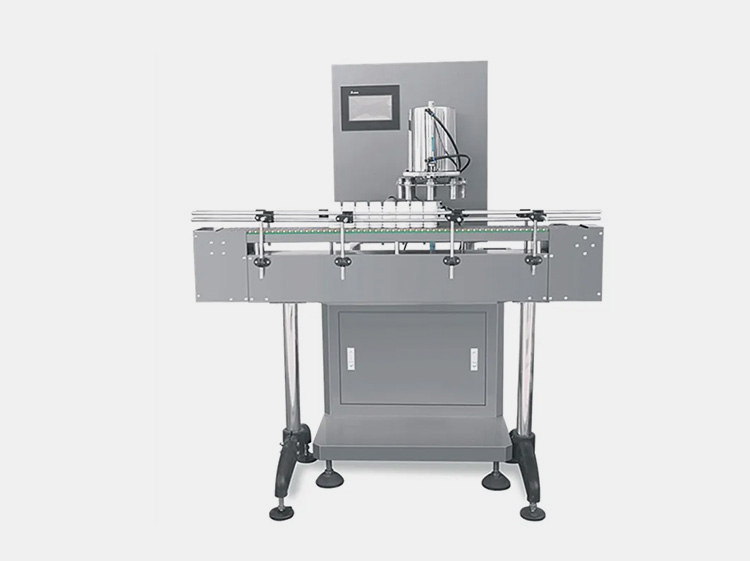

A cotton inserter is a modern machine that is featured with various functional parts; each component has its own distinct function. These are described below:

Parts of Cotton Inserter

| PLC Control | The Programmable Logic Controller or PLC unit works as the brain of the machine. User infeed required data using touchscreen interfaces. It receives various commands and signals and begins processing up to the command of the operator. Moreover, the machine also receives alerts, messages, store data, speed of conveyor, number of bottles, and troubleshooting parameters. |

| Cotton Inserter Pusher | A pneumatic unit that mechanically pushes the cotton pieces toward the cotton inserting nozzle to facilitate the smooth functioning of the process. |

| Cotton Feed Support | This unit is accompanied by supporting the cotton feed into the system and allowing easy and smooth movement toward the cutting and inserting units of the machine. |

| Infeed Conveyor | The machine is featured with an infeed conveyor which is responsible for providing a pathway for entry of containers that moves toward filling/cotton inserting unit followed by discharging. |

| Cotton Presence Detecting Sensor | This sensor is responsible for the availability and absence of the cotton roll for the filling procedure. If the cotton material is finished it senses and notifies on the PLC screen by a feedback system. |

| Rotating Tube Assembly | This is a circulatory tube assembly that releases the cotton piece into the cotton-inserting nozzles. |

| Reject Station | If bottles are not corrected, or reached with any error, the machine senses and rejects them into the reject station to separate the bottles from the accepted lot. |

| Outfeed | Once the bottles are fed with cotton or the process is finished. It is transferred to other machines using a conveyor or outfeed. |

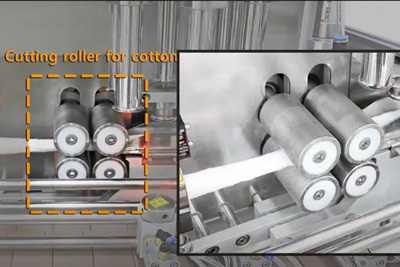

| Cutting Rollers | These rollers are responsible for cutting the mentioned measurement of the cotton material prior to the insertion procedure. |

| Cotton Inserting Nozzles | These nozzles are accompanied by inserting cotton material in each bottle respectively. |

| Bottle Detect and Gate Unit | This unit is composed of sensors that pick and detect the presence of the bottle and allow processing and ensure the right movement of the bottles. |

| Electric Cabinet/Panel | All wirings, plugs, connections, switches, and other electrical components are placed safely in the electrical cabinet of the machine. |

| Frame Supporter | The frame structure of the machine is made up of stainless steel. However, the machine is supported and held by designated tyres and steel rods that protect the machine against vibration and ensure easy movement. |

6.How Is a Cotton Inserter Classified?

The cotton inserter has various types according to size and working. For instance:

BASED ON AUTOMATION

Automatic Cotton Inserter

Picture Courtesy- NMJ

This machine works automatically that requires minimum involvement of manpower. User just need to click the INPUT and add the required protocol; rest of the function is performed by machine itself. This machine is ideal in running large production processes that offer accurate cutting and placement of cotton using fast detector system and features automatic and software functionality for reliable outcomes.

Semi-Automatic Inserter

This machine relies on manual involvement where placement and unloading bottles from the machine. User has to stand throughout the process and monitor the procedure. Semi-automatic inserter is suitable for small to moderate production lines as it can deals hundreds of bottles per hour. This is a cost-economical offer where user can obtain maximum benefits rapidly.

BASED ON WORKING PRINCIPLE

According to working principle, a cotton inserter is sub-categories into the following:

Pneumatic Cotton Inserter

Picture Courtesy- CVC

This machine utilizes mechanical arms that facilitate picking up and positioning of the cotton into each bottle or container. This is a flawless machine that uses Air Jet and vacuum pressure to operate the tasks.

Mechanical Cotton Inserter

Mechanical cotton inserter-Picture Courtesy:COUNTEC

Mechanical cotton inserter works by pushing cotton pulling rollers by use of cotton pusher by continuously up and down movement of pushing rods. These rods are responsible for inserting cotton inside the bottle accurately.

7.What Is the Production Line of A Cotton Inserter?

The production line of the cotton inserter is based on the following set of the machines such as:

| Machine | Description | Working Principle |

| Bottle Unscrambler | This machine is required to orient bottles in an upright position for the next machine. A bottle unscrambler is a compact unit that offers time-saving properties by providing materials in the perfect direction for fast filling and counting tasks. | A set of random bottles mechanically sort the bottles with the help of a vibratory and shaky tray that allows the movement of bottles and fixes them and a narrow channel that facilitates them to the next machine. |

| Counting and Filling Machine | The production line of the cotton inserter is composed of a counting and filling machine that facilitates the counting and filling of pills. | The sensor detects the presence of the bottles and allows a number of pills, capsules, or tablet one by one as infeed by the operator. If the bottle is not there the counting and filling won't be occurred. |

| Cotton Inserter | Once the packaging material is filled in the bottles, a cotton inserter is required for placing a piece of cotton inside the bottle. | The cotton roll is opened upon applying pressure by cotton roll feeders that allow easy movement of cotton that are precisely cut by cotton roll cutters and positioned in the bottles with the help of equipped sensors. |

| Capping Machine | In the packaging line, a capping machine is also a significant piece of equipment that ensures 100% security by firmly tight capping over the neck of containers, bottles, stand up pouches, etc., | The caps released from the hopper are dropped over the bottleneck and twisted using grippers equipped in the machine. This machine is automatic ensuring end-user with complete protection of their product. |

| Induction Sealing Machine | Every product packaging is incomplete without tamper-evident sealing. An induction sealing machine is worth-adding machine to the production line of a cotton inserter. Moreover, this machine ensures your product is safe against light, temperature, and moisture. | An electromagnetic heat frequency is radiated from the coil of the induction sealing machine that melts the layer of film fixed in the caps of the bottle. once the film is cool down, it forms a strong bond with the bottleneck in the form of an unbreakable seal. |

| Labeling Machine | The final and important machine of the cotton inserter production line; the labeling machine plays an important role in providing information, manufacturer message, improving aesthetics, and another relevant knowledge. | The labeling roll is fixed in equipped assembly supporter that helps in the opening of the film that firmly moves and sticks on the assigned container where the roller press allows the pressing of the label for the finest application. There are various types of labeling machines such as self-adhesive, wet glue, hot glue, and others that are selected on the type of requirement and shape of application. |

8.Is Cotton Inserter and Desiccator Inserter Same?

Certainly not! A cotton inserter and a desiccator inserter both are different machines. Both of them are utilized in industries for different packaging purposes.

A cotton inserter, as you have read above is used to insert cotton pieces into the packaging container, bottle, jar, or bag for protecting the aesthetic, potency, quality, fragrance, and efficacy of the product. Whereas a desiccator inserter machine is used for inserting a desiccator in order to protect moisture sensitive products or those products that become degraded in the presence of moisture. Hence, this machine places a desiccator into each packaging container.

A cotton inserter machine has pushers that help in pushing cotton pieces inside the bottle. Whereas, a desiccator inserter machine does not need a pusher, though the desiccator directly drops down after passing through cutting knives.

A cotton inserter use rayon, cotton, and wool as a cutting material whereas a desiccator inserter uses a desiccator strip, and desiccant packs as a cutting material.

9.What Are The Problems And Troubleshooting Of Cotton Inserter?

| Problem | Troubleshooting | Picture |

| Jamming of cotton feed support | Correct the alignment of the joints, and position them correctly. Reset the setting using PLC. Run a test to confirm the smooth operation. |  |

| Inaccurate Cotton Insertion | Adjust the setting of the machine. Visualize the mechanical and movable parts and correct the obstruction. Correct the alignment of feeding supports. Correct the cutting setting and measurement of the machine.

Calibrate the cotton inserter and assess the blockage in the alignment. |

|

| The machine doesn’t Sense the presence of the Bottles | Clear the sensor by wiping them with a dry and clean cloth. Recheck the sensor setting on the machine and re-evaluate the process. |  |

| Bottle without Cotton Plug | Sometimes machines send bottles without cotton inside them should be dealt with by lowering the speed of the conveyor.

Plus, correct the size of the cotton up to the bottle size. Check if the cotton roll alignment is flexible and easy to move and cut. Reset the settings using PLC. Determine whether the cutting roll cutting is accurate and capable to cut on time. Clean the sensors and determine test run. |

|

10.What To Look for In A High-End Cotton Inserter?

A cotton inserter is an important equipment of every production line. Therefore, it is primarily important to look for the following high endpoints when buying a cotton inserter.

Your Production Capacity

Picture Courtesy- CVC technology

Determining production capacity and required output is mandatory when buying a cotton inserter. This will help you to select whether to pick a semi-automatic or automatic cotton insert with the expected outcomes. For instance, running a large scale and selecting a semi-automatic won't be a correct decision or vice versa.

Integrating with Other Machines of the Production Line

Picture Courtesy-CVC

If you’re looking for the machine that best fits your production line, then you must discuss it with your manufacturer. Let them know about the types of machine you have and find the features of cotton inserting machine if it offers flexible integration properties or not.

Reliable Manufacturer & Supplier

This is deemed important to contact vendors who offer promising services and reliable machinery to their customers. For that, we would recommend searching for Google reviews, and website, and contacting them for consultation.

Pocket Friendly Equipment

Picture Courtesy- SED

Last but not least! The purchase equipment must be in your budget. For this, assess the available models, and machines and pick the right one. If machine is a bit expensive and giving you incredible profit, then you must not compromise the deal instead. Moreover, look for options such as small or semi-automatic in this way is also a good option that gain expected revenue.

Conclusion

A cotton inserter is useful machine suitable for various shapes such as round, square flat with narrow or wide mouth diameters bottles. This machine performs promising task in medical, healthcare, chemical, food, and related industries. The machine is excellent for providing effective packaging and easy transportation of goods. If you’re planning to add this machine; do not hesitate to contact us. Allpack Team welcomes to all queries guidance and machine’s quotation in a timely manner. Happy Shopping.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide