Cellophane Wrapping Machine:The Complete Buying Guide In 2024

The display of products is crucial. Whether it is for the purpose of protecting products or attracting your attention, cellophane wrapping is the best choice. Have you noticed cellophane wrapping in your life? Are you familiar its application and effect?

AIPAK Cellophane Wrapping Machine

The cellophane wrapping machine can provide the perfect cellophane wrapping solution and effect for your products. How is cellophane wrapping invented and why are they so popular with packaging industry now? Follow the complete cellophane wrapping machine buying guide, and you will feel its complete charm!

1.What Is Cellophane and Cellophane Wrapping?

Cellophane

Cellophane-sourced: cankey

The cellophane, also called as cellophane film, or biaxially oriented polypropylene film (BOPP), is a transparent, moisture-proof packaging film with excellent mechanical properties for your different products. It is processed longitudinally and transversely, and specially applied to various product box and cartons over-wrapping.

Cellophane Wrapping

Cellophane Wrapping-sourced: lovegzmk

The cellophane wrapping refers to a means of using cellophane films to wrap your product cartons, various arts and crafts in various packaging industries. This packaging should be rigid enough to be folded and creased without tipping over, so that the packaging or outer packaging process can proceed smoothly.

2.What Are The Advantages And Disadvantages Of Cellophane Wrapping?

As a type of transparent plastic wrapping with unique properties, there are advantages and disadvantages for cellophane wrapping, including:

Advantages of Cellophane Wrapping:

Good for Display

Good for Display-sourced: shiputec

The cellophane wrapping has a translucent appearance and a crisp feel, which is very suitable for displaying your products. In addition, it is also suitable for packaging bouquets, gift baskets or small foods such as candy, nuts, popcorn and chocolate.

Low Permeability

In life, most cellophane wrappings are used in packaging. It has low permeability to moisture, bacteria, grease and air, and will not affect your food taste.

Environmental Protection

Environmental Protection-sourced: flaticon

The genuine cellophane films are made of organic cellulose. It is a more natural and environmentally friendly packaging material. After your use, this material can be biodegraded, thus protecting the environment.

High Transparency and Glossiness

High Transparency and Glossiness-sourced: ima

The cellophane wrapping is generally transparent plastic wrapping. It has high transparency and glossiness, which can make your product clearly visible and can well protect your product from damage, moisture, steam and dust.

Disadvantages of Cellophane Wrapping:

High Production Cost

High Production Cost-sourced: advertisingweek

The cellophane film is an environmentally friendly organic material. Therefore, its production process is more complicated, the production cost is higher with shorter shelf life. If you do not use within a certain time frame, it will begin to turn yellow.

Shorten Product Shelf Life

The cellophane film is a material with excellent breath-ability. For long-term storage of food and medicine, it has a low barrier effect on the penetration of moisture, bacteria, grease and air, which will shorten the shelf life of your product.

Easy to Tear

Easy to Tear-sourced: sollas

Because it is a packaging material made of organic cellulose, the cellophane wrapping is very thin and easy to tear, and the protection of your product has a certain period of time.

3.What Is Cellophane Wrapping Machine?

AIPAK Cellophane Wrapping Machine

The cellophane wrapping machine, also called as over-wrapping machine, is a general-purpose device that uses cellophane films to wrap various cardboard boxes or square products. It can provide beautiful product display effects, and make the product high-end, so that customers have the desire to buy.

The over-wrapping machine is suitable for the outer packaging of carton in various industries such as pharmacies, cosmetics, food, stationery and electronic products. And it is very suitable for cigarettes, small cosmetics, small skin care products, perfumes, nail polish, poker, condoms, CDs, DVDs, Blu-ray boxes, etc.

4.What Industries Are Cellophane Wrapping Machine Mainly Applied?

The cellophane wrapping machine is mainly applied in pharmaceutical industry, food industry, beauty industry, stationary industry, electronics industry, etc.

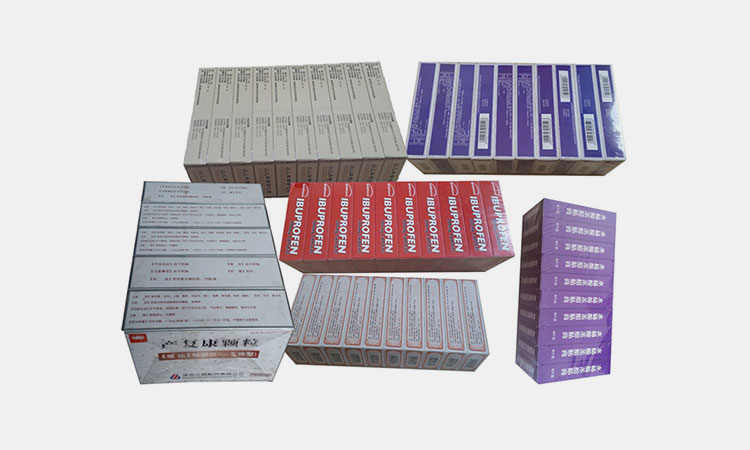

Pharmaceutical Industry

Pharmaceutical Industry-sourced: wanbonmachinery

Using the cellophane wrapping machine, it can provide your medicine carton and box with anti-counterfeiting and moisture-proof transparent film. This can improve grade and decoration quality of your product including various tablets, hard capsules, soft capsules, pill bottles, liquid bottles, injection heads, injections, vials, eye drops, etc.

Health Supplement Industry

Health Supplement Industry-sourced: sellhimvs

Various health care and supplement boxes and bottle carton can use cellophane wrapping machine to improve your product quality. The health care and supplement carton boxes include the vitamins, minerals, herbs and botanicals, probiotics, and more.

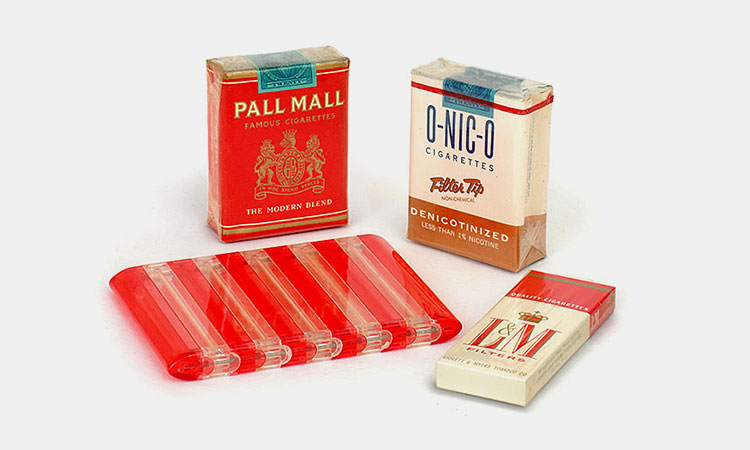

Food Industry

Food Industry-sourced: cartonservice

The cellophane wrapping machine can offer you the reasonable, advanced, stable plastic packaging for food products. The food products in food industry include cigarettes, biscuits, bread, nuts, dry fruits, cereal, candies, sauces, condiments, grain, cheese, pasta, chocolate, etc.

Beauty Industry

Beauty Industry-sourced: szdoho

There are plenty of beauty and cosmetics products that are widely applied by the cellophane wrapping machine for high quality and protection. The beauty and cosmetics products include toner, lotion, essence, eye cream, facial mask, perfume, hand cream, liquid foundation, powder, shampoo, hair essence, nail polish, etc.

Stationary Industry

Stationary Industry-sourced: customboxesshop

The cellophane wrapping machine can guarantee the cleanliness and hygiene of the stationary products over-wrapping. The stationary products include pens, paper, books, notebooks, erasers, solid glue, file bags, drawing boards, utility knives, staplers, tapes, ID cards, account books, calculators, etc.

Electronics Industry

Electronics Industry-sourced: luxury-paper-box

The cellophane wrapping machine can offer you the waterproof and moisture-proof effect for all your electronics products, including earphones, computers, electronic bracelets, electric toothbrushes, mobile phones, game consoles, phone cards, cameras, speakers, equipment parts, etc.

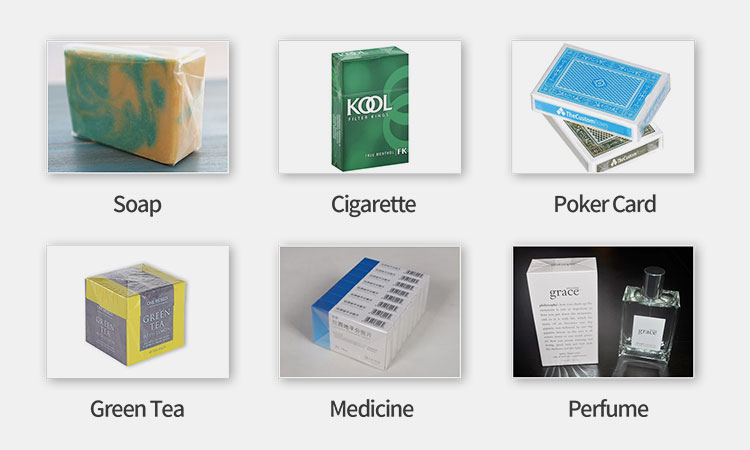

5.What Products Are Mostly Wrapped By The Cellophane Wrapping Machine?

The products that are mostly wrapped with the cellophane wrapping machine are the most common items in life. They are:

Perfume Carton

Perfume Carton-sourced: ybspackaging

The cellophane wrapping machine is suitable for automatic BOPP film wrapping and packaging of various perfume carton with tear tape. You only need to change different molds to package perfume cartons of different sizes. The double-sided wrinkle shaping device can make the perfume carton wrapping more beautiful.

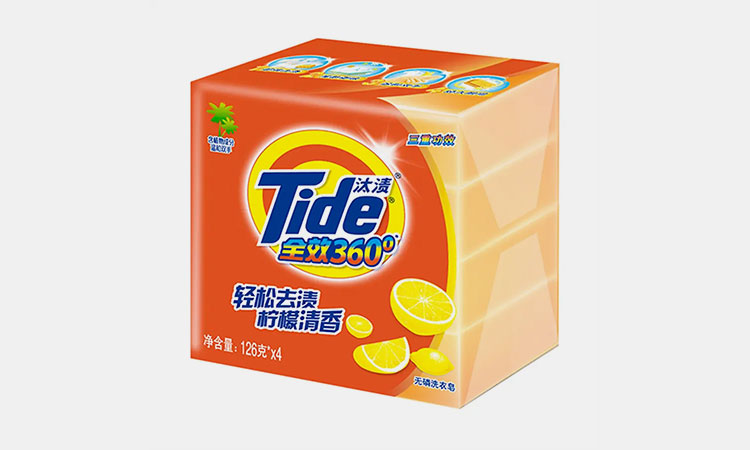

Cigarette Box

Cigarette Box-sourced: depidiomas

The cellophane wrapping machine can provide "curling folding" packaging for your cigarette box, so that each of your cigarette box packaging has a neat gift packaging appearance. By adding tear tape to the cigarette box, you can open the package easily.

Spice Box

Spice Box-sourced: leser

The cellophane wrapping machine mainly uses BOPP film to complete wrapping and packaging for your spice box. It not only plays an anti-counterfeiting and moisture-proof role, but also improves the grade of your spice box.

Medicine Carton

Medicine Carton-sourced: felins

Various medicine cartons apply the cellophane wrapping for product anti-counterfeiting, moisture-proof and protection. With closed feeding, the cellophane wrapping machine can provide you with safe, effective and high-quality medicine carton wrapping and packaging.

Tea Box

Tea Box-sourced: mardenedwards

Whether the tea box contains tea bags, loose tea, herbal tea or other, the cellophane wrapping machine can provide you with high-quality tea box wrapping and packaging. In addition to being beautiful, it can also provide added value to your tea.

Cosmetics Box

Cosmetics Box-sourced: mardenedwards

If you use the cellophane wrapping machine, you can achieve precise and perfect packaging for your cosmetics box. Not only will there be no scratches or flaws, it can also improve the display of your products. By adopting a folding packaging at both ends, your cosmetics box can look more like a work of art.

Condom Box

Condom Box-sourced: qcpacking

The cellophane wrapping machine can provide high-quality BOPP wrapping for your condom box. It can make your condom box moisture-proof, waterproof, oil-proof, dust-proof, anti-counterfeiting, and easy to store.

Playing Card Carton

Playing Card Carton-sourced: printninja

In addition to playing cards, the cellophane wrapping machine can also be applied for wrapping and packaging scratch cards, small cards, etc. It can provide you with stable and reliable playing card carton packaging with firm sealing and smooth and beautiful appearance.

6.What Are The Benefits Of Cellophane Wrapping Machine?

Why do most businesses use cellophane wrapping machine to package products in boxes and cartons? Perhaps the advantages of this packaging method can bring great progress to your products.

Wide Application

Wide Application-sourced: wanbonmachinery

The cellophane wrapping machine can be used in many industries such as perfume, cards, cosmetics, pharmaceuticals, chemicals, etc. You only need to change a variety of different molds, without adjusting the height of the two workbenches of the machine, and it can be used for packaging of different products.

Exquisite Packaging

Exquisite Packaging-sourced: ima

The cellophane wrapping is usually composed of cellophane film and easy-tear line. It can provide your product with a charming packaging effect, not only moisture-proof, dust-proof, anti-counterfeiting, but also make the product cleaner and improve the commercial value of the product.

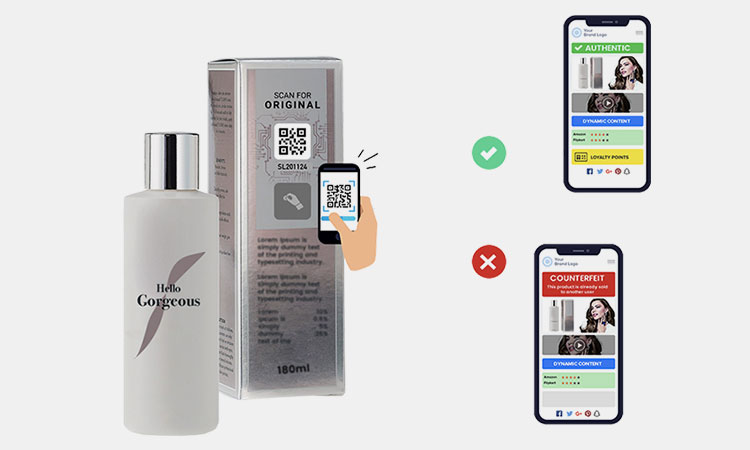

Anti-counterfeiting

Anti-counterfeiting-sourced: neurotags

You can print the company logo or trademark on the easy-tear line by the cellophane wrapping machine according to your needs, which can play an anti-counterfeiting role and provide your customers with a good shopping experience.

Save Packaging Materials

The cellophane wrapping machine is the most economical and affordable among all shrink packaging machines. It can fold and heat-seal the film so that the film completely wraps the product. Almost no waste film is generated, which can greatly save packaging materials for you.

Easy Operation

Easy Operation-sourced: tam-tokyo

With compact and reasonable structure and stable & advanced performance, the cellophane wrapping machine is very easy to operate and maintain. The equipment has various protection devices and fault prompts, that the maintenance and repair can be carried out according to the fault prompts of the equipment.

7.What Are The Types Of Cellophane Wrapping Machine?

There are three main types of cellophane wrapping machine, including the manual type, semi-automatic type, and automatic type.

Manual Cellophane Wrapping Machine

Manual Cellophane Wrapping Machine-sourced: greatbond

The manual cellophane wrapping machine is suitable for over-wrapping a small volume of products in a shop. It is a tabletop type for your easy moving and operation which saves your space. It is widely applied for outer over-wrapping of any kind of boxes and cartons such as soap, playing cards, note pad, soup cube, snacks, etc.

Semi-automatic Cellophane Wrapping Machine

Semi-automatic Cellophane Wrapping Machine-sourced: soonpack

The semi-automatic cellophane wrapping machine can be widely used for outer over-wrapping of various products such as food, beverages, medicines, video discs, hardware, cosmetics, books, toys, electronic products, etc. It can provide you with manual box and carton film wrapping but auto film folding and heat sealing.

Automatic Cellophane Wrapping Machine

Automatic Cellophane Wrapping Machine-sourced: tesmachinery

The automatic cellophane wrapping machine can wrap various items such as candies, biscuits, food and non-food products in cellophane with full automation and less labor works. Whether it is round or square, box, tray or block box and carton, it can wrap them all to present a perfect packaging effect.

With the tear line with pull ring, you can easily open the package. It can provide beautiful product display effects, and make the product high-end.

8.What Are The Components Of Cellophane Wrapping Machine?

Different types of cellophane wrapping machine consist of different parts, and they may differ a lot.

Components of Manual Cellophane Wrapping Machine

Components of Manual Cellophane Wrapping Machine-sourced: greatbond

Film Cutting Blade

The film cutting blade is designed for the BOPP film cutting. If your product carton or box is different, the film width can be controlled by adjusting the position of the film cutting blade. So, this manual cellophane wrapping machine can be applied for a wide range of product box and carton wrapping and packaging.

Cable Pulling Rack

The cable pulling rack of manual cellophane wrapping machine is used for placing and controlling the position of your pulling wires. This rack can hold all kinds of pulling cables with an inner diameter of not less than 3 CM.

Adjustment Gear

The adjustment gear is specially designed for adjusting the tightness of the roll films. During use, the tightness of the roll film is very crucial. Before use, you need be sure to adjust the tightness of the roll film.

Temperature Control Panel

The temperature control panel can display your heat sealing temperature in real time. Through operating the control panel, you can set sealing temperature as needed. It is easy for you to operate. You can adjust the equipment to the most suitable heat sealing temperature through automatic adjustment or manual adjustment.

Heating Plate

By adjusting the temperature control panel with right heat sealing temperature, you can place your product box or carton with films for side heat sealing. Made of stainless steel, the heating plate is durable and beautiful. It can heat uniformly, helping to create good packaging effect.

Components of Semi-automatic Cellophane Wrapping Machine

Components of Semi-automatic Cellophane Wrapping Machine-sourced: soonpack

Heat Sealing Device

The heat sealing device can offer you the constant temperature for your heat sealing and over-wrapping. Through the heat sealing device, you can adjust the sealing temperature both automatically and manually. With the proper heating sealing, it can offer you the neat and beautiful box and carton over-wrapping.

Control Panel

Each semi-automatic cellophane wrapping machine is equipped with an independent control panel for your easy operation with different box and carton over-wrapping. Through the control panel, you can adjust the machine's operating speed, the machine's work surface height, the loading and unloading chain.

Hemming Structure

The hemming structure, also called as hem folding system, is designed for the folding of the wrapping films for your box and cartons. When the products are pushed into the slot, the hemming structure will wrap the products with film and then fold them to facilitate the heat sealing at the back.

Box Placement Mold

The box placement mold can help you put the box and carton into the mold, transporting and packing box and carton automatically. You can change the box place mold for your needs and requirements, so that you can over-wrap different products in a wide range.

Ironing Board

The ironing board is used for the final heat sealing for the box and carton. After your products are wrapped with film, folded on both sides, folded on the top and folded on the bottom, you need to manually complete the front and back heat sealing.

Switch Button

The switch button is used to control the entire operation and stop status of the equipment. Through a simple design, the semi-automatic cellophane wrapping machine can be operated and maintained easily without any difficulty.

Main Machine

Made of stainless steel material, the main machine is highly adaptable, fast and fully packaged. With humanized design, it is easy for you to use, operate, maintain and repair.

Components of Automatic Cellophane Wrapping Machine

Components of Automatic Cellophane Wrapping Machine-sourced: tesmachinery

Knife Structure

The automatic cellophane wrapping machine adopts a new type of double rotary film cutting knife. It can overcome the defect of easy wear of the traditional fixed single rotary film cutting knife, making your film cutting complete and beautiful.

Control Panel

Each automatic cellophane wrapping machine is equipped with independent control switch and temperature controller for your easy operation. The control panel can adjust the machine's running time, speed, cutting frequency, and sealing temperature.

Folding Mechanism

The folding mechanism, also called as hod mould, is the main shaping device. It can cut your film according to the size of your box and carton, and complete the first sealing. The folding mechanism is a turret shape. Through continuous rotation, the boxes and cars on the turret complete the folding and first sealing of the film in turn.

Film Loading Mechanism

The film loading mechanism is equipped with independent film holders for packaging film and security line. It has a sturdy structure, easy film change, and can be applied to your product films of different sizes.

Protective Cover

The protective cover is a transparent and sturdy cover for the heat sealing device. Its main function is to block the heat sealing module. This can keep the product clean and dust-free, and protect the you from unnecessary accidents when approaching the heat sealing device.

Heat Sealing Mechanism

The heat sealing mechanism can complete the heat sealing of the four sides of the product and output the finished product. This step is the key and the last step of cellophane wrapping. The temperature of each side of the heat seal can be controlled separately, and can also be started and stopped separately.

9.What Is The Working Principle Of Cellophane Wrapping Machine?

Working Principle Of Aipak Cellophane Wrapping Machine

The working principle of cellophane wrapping machine is simple and easy to follow, you can learn from the process below:

- Firstly, you need to put the box and carton into the card slot. You can use an automatic feeder to help you automatically or manually implant the box and carton into the card slot.

- When the box and carton are put into the card slot, they will be pushed from the back by the film cutter.

- After the product is wrapped by the film, it will be pushed into the corresponding mold cavity by the turret.

- If the turret rotates 90degrees, through the action of the film folding swing arm, one side of the film will be folded from the outside to the inside at the top sealing part.

- The pre-sealing swing arm on the other side will fold the other side of the film from the outside to the inside for pre-sealing.

- After the pre-sealing is completed, the folding swing arm and the pre-sealing swing arm will retract respectively.

- When the turret rotates another 45degrees, the long sealing component will long seal the box. And the push rod of the discharge pusher will push the box and carton out of the turret mold cavity and then enter the side sealing part.

- At the side sealing part, the box and carton will be folded on both sides, top folded, bottom folded, and front and back side sealed in sequence.

- Finally, it will enter the shaping part after being pushed by the box at the back.

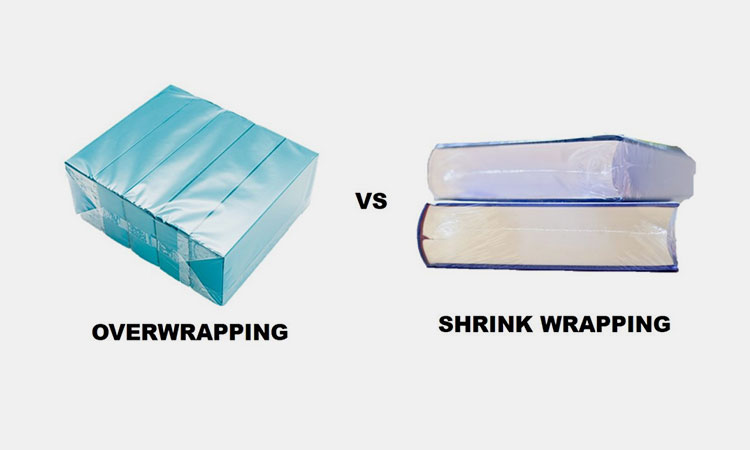

10.What Are The Difference Between Cellophane Wrapping Machine And Shrink Wrapping Machine?

Difference Between Cellophane Wrapping Machine And Shrink Wrapping Machine-sourced: eliter-packaging

| Cellophane Wrapping | Shrink Wrapping | |

| Images |

Cellophane Wrapping-sourced: sedpharma |

Shrink Wrapping-sourced: maripak |

| Explain | l Also known as over-wrapping or tuck and fold wrapping;

l It is a style of film wrapping packaging which is only applicable to containers, cartons, boxes, objects with flat sides; |

l It is a process that involves wrapping a product in clear plastic film and then heating it to make it shrink into a tight package; |

| Cellophane Wrapping Machine | Shrink Wrapping Machine | |

| Images |

AIPAK Cellophane Wrapping Machine |

|

| Explain | l Also known as over-wrapping machine;

l It uses cellophane films to wrap various cardboard boxes or square products for displaying and protection effects; |

l Also known as L-sealer;

l Uses a centre-folded PO film that has the product placed inside and sealed using a machine with an l-shaped sealer to create a bag, shrinking the bag to wrap the products; |

| Packaging Style | l Film folding on the end-side where the fringe of films are tucked and then folded to be sealed together thus forming a diamond-shaped appearance; | l Uses shrink film to wrap the product or package outside, and then heats it to shrink the packaging material and wrap the product or package tightly; |

| Films | l BOPP, BOPLA, BOPET, etc.; | l PVC, polyolefin, or polyethylene; |

| Application | l Suitable for boxed and carton products;

l Tobacco products, pharmaceutical products, luxury products, drinks, digital products, etc.; |

l Also can be used to package special-shaped products;

l Almost for any products;

|

| Purpose | l Enhance the appearance;

l Improve a sense of superiority; l Protect the product from containment; |

l Keep the item secure during movement;

l Protect products from dust, dirt, moisture, and UV rays; l Stabilize, unitize, clean, or tamper-resist products; |

| Packaging Effect | l Cellophane wrapping is more beautiful than shrink packaging and can increase product sales; | l It is mainly used to wrap products for protection, but lacks aesthetics; |

| Advantages | l Cost for less;

l Consume less energy; |

l The seal is clear and firm;

l The contraction is tight and the appearance is beautiful; |

| Working Principle | l Use partial heat sealing;

l Apply a cutter to cut the packaging film into the required length; l Make use of a conveyor to transport the carton to the predetermined position, and then wrap and fold it to form a well-designed packaging style; |

l Use overall heat shrinkage;

l When the heat shrink film is heated at high temperature, the area of the packaging film is reduced; l It makes the packaged product fit more closely and can quickly wrap the product with a layer of film; |

11.How To Troubleshoot And Maintain The Cellophane Wrapping Machine?

How to Troubleshoot Cellophane Wrapping Machine-sourced: touchpoint

Following the steps and information below, you will learn how to troubleshoot your cellophane wrapping machine easily:

| Problems | Reasons | Solutions |

| Start Or Stop Problem | l Generally caused by power supply or line problems; | l Check the power connection to ensure that the power connection is effective;

l Check whether the line connection is effective; |

| Unstable Film Tension | l Film tension is unstable, which will lead to unstable packaging quality;

l It may be that the tension is not adjusted properly; l The tension device is faulty; |

l Check the working and installation of the tension device;

l Re-adjust the tension device; |

| Insufficient Sealing | l The sealing temperature is not enough;

l The sealing part is damaged by the high sealing temperature; |

l Adjust the temperature of the sealing line;

l Replace the sealing knife; |

| Loud Noise | l The machine is not installed correctly;

l Some parts are missing or installed in the wrong position; |

l Check all parts of the machine and install them well;

l Maintain the machine regularly to ensure smooth operation; |

How To Maintain Cellophane Wrapping Machine-sourced: task4work

After troubleshooting, you shall pay attention to the daily maintenance:

| Steps | Reason | Techniques |

| l Correct setup and calibration; | l Optimize efficiency;

l Shorten production cycle; |

l Configure settings;

l Adjust the conveyor speed to ensure correct alignment for the specific product to be packaged; |

| l Check the cylinder drive parts; | l Ensure the cylinder moves flexibly; | l Repair the cylinder in time; |

| l Check the sensor; | l Ensure the sensor is always in the same plane and in the same straight line; | l Repair or replace the sensor in time; |

12.How To Choose The Right Cellophane Wrapping Machine For Your Business?

Choosing the right cellophane wrapping machine will bring you a lot of benefits for your business, including increase your productivity, lower your costs, and reduce labor works, etc.

Your Productivity

Your Productivity-sourced: makemebetter

There are manual, semi-automatic, and automatic cellophane wrapping machines for your choice. The automatic type can achieve your productivity improvement. If you want to increase your production volume and production efficiency, the automatic cellophane wrapping machine can improve your over-wrapping of more product types.

Equipment Durability

When you make a long-term investment, the durability of the machine is also an important consideration. Although cheap machines are attractive, you also need to consider the maintenance costs of the equipment. Generally, equipment with better quality parts will be more durable and support the replacement and update of parts.

Equipment Adaptability

Equipment Adaptability-sourced: penglaichina

It is crucial to have a more adaptable cellophane wrapping machine. Because you need to deal with different container shapes and sizes for different products. To improve productivity, you can try to choose a cellophane wrapping machine with higher automation and richer molds.

Automation Degree

Automation Degree-sourced: tesmachinery

If you are a small business, then having a manual or semi-automatic cellophane wrapping machine is perfect. However, for medium and large enterprises, it is more appropriate to choose a cellophane wrapping machine with higher automation. This can not only improve production and efficiency, but also facilitate subsequent maintenance.

Conclusion:

The cellophane wrapping or over-wrapping can bring you wide application and benefits in almost each industries. This complete buying guide of cellophane wrapping machine explained its role and significance from almost every aspect. If there are more you want to know, come to us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide