Automatic Labeling Machine: The Complete Buying Guide in 2024

Do you know product labeling is the gateway to boosting your brand? When it comes to labeling, the manufacturing and packaging world is struck with various challenges that have transitioned the progress towards the advanced development of the labeling machine which has met the demand of today's market. Indeed, automation comes first when solving the requirement of industries, an automatic labeling machine is a significant piece of equipment that is used to bring fast, accurate, and perfect solutions from small to multinational firms. If you’re planning to invest in the automatic labelling machine; then this blog is designed up to your requirements. Don’t miss the chance to go through it!

1.How To Define an Automatic Labeling Machine?

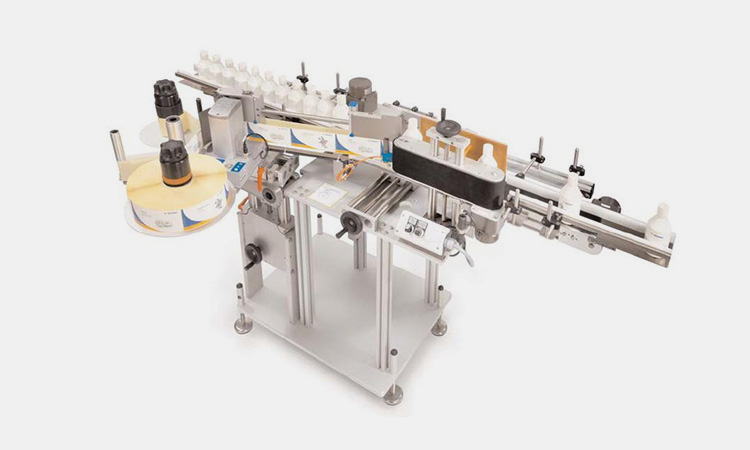

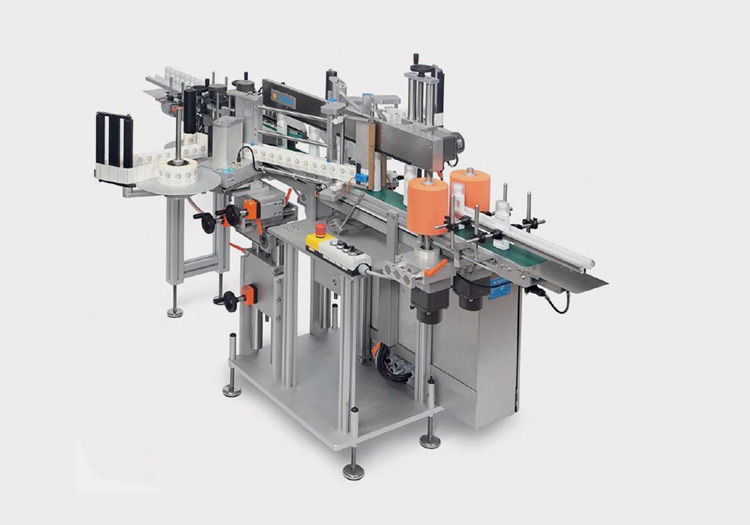

Automatic Labeling Machine

Automatic labeling machine is a label applicator equipment which uses almost no human interference for placing labels on any product’s packaging surfaces. An operator would only require filling the reels of label into the machine and checking for any occasional mistakes by the machine. The machine is designed in such a way to carry out labeling in different orientations like around the product’s side, wrapped around labeling, labeling for top and bottom surfaces, and tamper proof labeling. It can apply labels on products of different shapes and sizes. Due to its quick and efficient working capability, it has brought good returns on investment for industrialists.

2.What Is the Importance of Automatic Labeling Machine In Industries?

Today automatic labeling machines find their best spot at many industries due to its significant performance. For example:

Food & Confectionery Industry

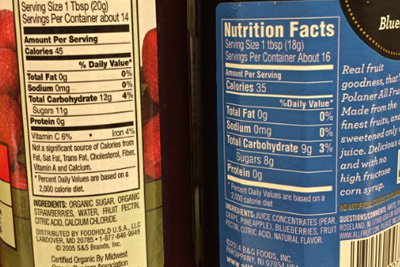

A major sector of this industry products like bakery items such as biscuits, rice crackers, bread, processed poultry, dairy items like milk, butter, yoghurt, cheese, prepared food items such as readymade dishes, chips and snacks, frozen food items, jams, fresh fruits and vegetables are packaged and labeled using this machine.

Beverages Industry

Many beverages like mineral water bottles, breweries, edible and inedible oils such as cooking oil, body oil, hair oil, lubricant oil, juices etc. are labeled using this machine.

An automatic labeling machine enables finished labeling for your products of different shapes and sizes. Automatic labeling and shrink sleeve or self-adhesive labeling are used.

Pharmaceutical Industry

Pharmaceutical manufacturing surely requires the use of this versatile machine as labeling is an essential part of its industry. From labeling of liquid medicines to parenteral solutions requiring stick on labels and side labels, to tablets, capsules and lozenges being packed in boxes and blister packs requiring print labeling or side labeling or top and bottom labeling, all can be handled accurately with an automatic labeling machine.

Cosmetics Industry

Another important sector of industry is the cosmetics industry which uses this automatic labeling machine for giving final touch to their finished products.

Petroleum jelly, lip balm, talcum powder, hair products, skincare products, shampoo bottles, soap boxes etc. are some of the products which need self-adhesive type of labeling.

Chemical Industry

Chemical products like toilet cleaners, detergent powder pouches and boxes, dishwashing liquid, hand sanitizer, glue and adhesives, and some other miscellaneous items which may be hazardous as well require labeling through the use of this machine.

Veterinary Industry

Veterinary industry deals with production and packaging of formulation useful for animals. The automatic labeling machine is used for labeling products like pet food such as snacks, proteins bars, and pet medicines such as antibiotics, antipyretic,.etc...

3.What Is the Working Principle of The Automatic Labeling Machine?

Step 1: Activation of Sensor & Label Opening

The process begins with the entrance of bottles, containers, or any assigned product which shows presence that is detected by highly sensitive sensors. Once the presence is detected, the label opening becomes initiated and dispensing procedure becomes starts. The label support unit stretches the label roll which was adjusted already by operator, and it starts moving for dispensing.

Step 2: Labeling & Roller Pressers

When respective products are reached to the machine, the label accurately positioned on exact area and gently stick on it followed by roller presser that helps in exerting pressure on the surface to adhere the film properly. This is an important step as it protects the development of unwanted labeling problems such as air bubble, or misalignment etc.,

Step 3: Process Cycle

As the label is properly applied on the products, it leaves the system and enters to the next synchronized machine. This process is facilitated by conveyor belt that proceeds a continuous movement of the products. Side by side, new products are entered into the machine to maintain consistent movement of the labeling. The presence of detectors ensures the labeled products are correctly applied once they leave the machine.

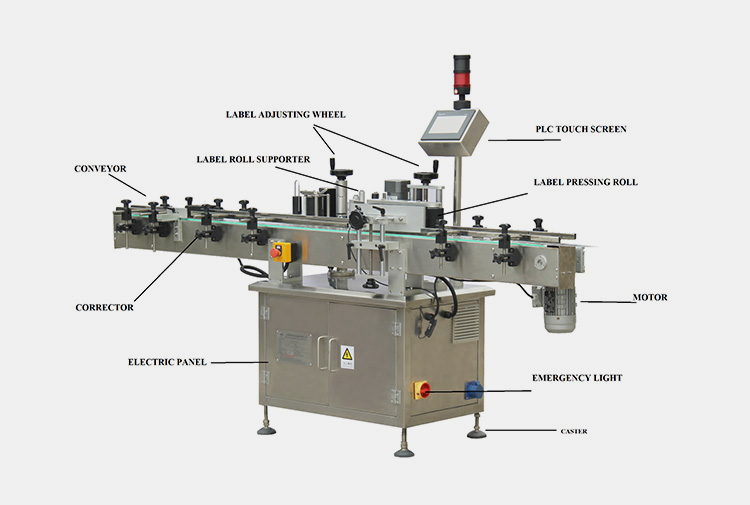

4.What Are the Main Parts of An Automatic Labeling Machine?

An automatic labeling machine is advanced equipment used everywhere as it offers a bundle of advantages.

PLC Touchscreen

A ‘Programmable Logic Controller’ is a computerized set up that helps in modulating multiple key parameters involved in the labeling procedure. A touchscreen is the source of interaction with the machine, you to make a set-up initiate the process.

Label Adjusting Wheel

label is always available in film roll; a user has to adjust the label before procedure. This is made possible using label adjusting wheels equipped on the top counter or frame of the machine. This unit ensures the label is properly fixed and aligned for smooth working.

Label Roll Supporter

This unit helps in the holding of the label; this unit ensures that label roll feeds the film evenly without errors of obstruction.

Conveyor

This unit is typically meant for transporting products inside and outside the machine. It ensures that the flowability of the items are accurately supplied and once labeling is done it moves products to the next machine.

Label Pressing Roll

After labeling is done, the label press roll is utilized to apply pressure on the labeling surface in order to avoid air bubble, wrinkles, or any other error. The label press roll specifically used to adhere the film firmly on the container.

Motor

The running of automatic label machine is accessible by the help of motor that ensures a mechanical motion to the various components of the machine and a conveyor.

Emergency Light

This unit is equipped for a safety purpose which lightens if any problem and error in the unit occurs. This unit is designed to grab an immediate attention of a technician to provide an immediate response or intervention to ease the operation and avoid mishap.

Corrector

Each product for label is properly aligned and following uniformity which is due to a ‘corrector’. This unit detects if any incorrect or misalignment triggers among the labeling products hence it ensures the entire entrance and discharging of the product is corrected.

Electric Panel

an electric panel is a hollow box that contains electrical components including plugs wires, relays, switches and breakers. All electrical connections / wirings are controlled or managed via electrical panel.

Caster

Any equipment that can be easily moved from one place to another as per need during maintenance, cleaning, or adjustments requires a platform with wheels known as casters. Casters have a mechanism that prevents unnecessary movement of the machine during operation.

5.Why Choosing the Right Automatic Labeling Machine is Essential for Packaging?

Looking into the advantages that you can take of purchasing an automatic labeling machine for your industry, you’ll be amazed to know that even though it seems costlier it has good terms profit.

Increased Production Speed

The speed of automatic labeling machine is seen to be greatly faster than the manual labeling process or even twice faster than a semi-automatic labeling machine. This for sure scales up production throughput.

Accurate and Perfect Labeling

Compared with human work done manually, labeling by the process of an automatic labeling machine induces less chances of error and results in an accurate and precise labeling. Whereas work done by humans may result in wrong orientation of label placed on the product or might not have been stuck properly that would result in it being peeled off.

Lesser Workforce Requirement

Automatic Labeling Machine- Picture Courtesy: CDA USA

Installation of an automatic labeling machine would automatically require less human labor comparatively. This is because as manual or semi-automatic machine would require an operator for almost whole procedure, in use and automatic labeling machine operator would only be required to load reels, replace the printing labels and clean and check the printer.

Safety Precaution

Automatic Labeling Machine- Picture Courtesy: CONSUNG

While using a manual or semi-automatic labeling machine, probably the chances of labor getting injured are present. Repetitive application of labels on products may cause musculoskeletal problems. Reducing the workforce and using an automatic labeling machine instead would bring safety measures.

Flexibility In Application

Automatic Labeling Machine- Picture Courtesy: Result Group

Application of labels through an automatic labeling machine opens versatility of choices for putting labels of different shapes and sizes. A manual labeling machine might not have such options in a single piece of equipment.

6.What Is the Complete Production Setup of An Automatic Labeling Machine?

An automatic labeling machine can work with integrated equipment to give a complete ready to transport and sale product. We have briefly described the production line associated with automatic labeling machine.

| Machine | Working Principle | Picture |

| Bottle Unscrambler | The random bottles are fed into the machine where rotary disc and blowers allow them to adapt alignment via dropping them into available pockets or channels. Once containers are fixed into the channels they are supplied to the next machine in an upright position. |

Picture Courtesy- Seppa Solution |

| The packaging production can be run smoothly if the supplied material is well-organized and oriented. A bottle unscrambler ensure the containers, bottles, vials, and related products are properly aligned for the processing. | ||

| Counting and Filling Machine | The machine is equipped with vibratory channels that helps in movement of pills, tablets, capsule gently. Upon entering to the feeding heading a sensor detects products where counting and filling is attained when it passes through the pathway and drops into available container. |

Picture Courtesy: SED Pharma |

| A counting and filling machine helps in the filling of product using sensors, and important units that ensures a formulated product is fully counted and accurately packed into each container. | ||

| Desiccant Inserter | This is a mechanical process, where knives cut the individual strip pack and insert them into each available bottle, container, or related product and allow them to move to the next machine. |

Picture Courtesy: CVC Tech |

| Medical and health related products are always prone to degradation in the presence of humid environment. To avoid this problem, moisture absorbents are inserted by desiccant inserter. | ||

| Capping Machine | This machine works by rolling or twisting caps by using pneumatic pressure around each neck of the container. |

Picture Courtesy: Weighpack |

| To secure pack products you need to close them properly by using capping machine. This machine is the 4th important unit of production line that ensure containers are safe and secure till fully used by consumers. | ||

| Automatic Labeling Machine | With the help of supporting rollers, pressure and compressing rollers, a dispensed label is uniformly placed and pasted over the surface of the product without chances of unwanted errors. |

Picture Courtesy:BigPAC |

| To complete the packaging line, labeling is considered as the most important and unavoidable process. Automatic labeling machine is fast and efficient tool that affixes label over the surface of the product that promotes branding, marketing, providing information and necessary details. |

7.How To Classify an Automatic Labeling Machine?

An automatic labeling machine is an adaptable equipment that offers a broad range of classifications depending on various parameters, such as design, working capacity, size, printing, and much more. Please find a comprehensive review below:

Automatic Labeling Machine: Based on Working Automation

| Machine | Details |

| Semi-Automatic Labeling Machine

Picture Courtesy: HERMA |

The machine works by automatic feeding of protocol using PLC touchscreen and giving you a large working output. Here, you need to put the label into the machine, load and unload the labeling product manually. This machine is useful and handy equipment used for small to moderate production lines as it offers limited benefits and not suitable if require labeling in the bulk. |

| Automatic Labeling Machine

Picture Courtesy: VKPAK |

This machine is recommended in a large production line that works as robot. Machine itself analysis and runs the procedure with the help of sensors, robotic arms, and automatic controlling of entire process. This is a great solution need no manpower and can be run for a longer time without monitoring the process. User can only put and adjust the labeling roll, the remaining process can be deal by the machine itself. |

Automatic Labeling Machine: Based on Machine Design

| Machine | Details |

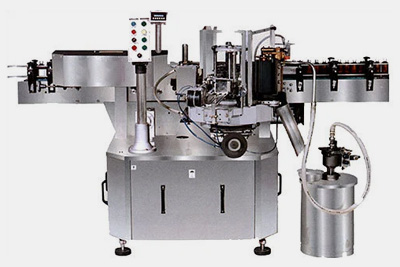

| Automatic Rotary Labeling Machine

|

This is a compact solution where application of labeling process take place by movement of carousel in a circular way so that labeling can be done when container spins around the labeler. This is a high-speed machine where fast application of labeling is taken place using a smaller surface area. |

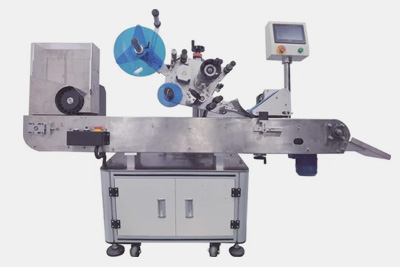

| Automatic Linear Labeling Machine

|

In automatic linear labeling machine, products come to labeling assembly in a linear direction where machine applies labels on each product and allow them to leave the system one by one. This machine is commonly used method used in various production and packaging industries. |

Automatic Labeling Machine: Based on Printing Ability

| Machine | Details |

| Automatic Labeling Machine with Printer

|

This is the advanced version and commonly used for larger production lines where immediate printing and labeling processes take place simultaneously using a single machine. As the product moves and enters the machine, the machine prints the label via laser printing, inkjet, thermal-transfer, or other. The printed labels are directed and applied over the product and leaves the machine. |

| Automatic Labeling Machine without Printer

|

An easy to maintain and easy to use machine that requires pre-printed label roll to fix and adjust on the machine. Machine is simple in structure with fewer components as compared to with automatic labeling machine with printer. |

Automatic Labeling Machine: Based on Adhesive Characteristics

| Machine | Details |

| Automatic Labeling Machine with Hot Melt Glue

|

The labeling machine works by using hot-melt glue for applying labels over the product’s surface. The glue becomes suitable for attaining stickiness when heated. This is the rapid and efficient way of labeling which is commonly utilized in packaging procedures across the globe. |

| Wet Glue Sticker Labeling Machine

Picture Courtesy: NK Industry |

This machine uses wet-glue for the labeling sticking procedure. The method of gluing is similar to apply and paste method which is of course a conventional method of sticking. |

| Self-adhesive Automatic Labeling Machine

Picture Courtesy: Reliable Machinery |

This machine has properties where you just need to apply ready to use label, in this case machine just has to peel off and apply the label on the object. |

Automatic Labeling Machine: Based on Label Position

| Machine | Details |

| Automatic Wrap-around Labeling Machine

Picture Courtesy: AESUS |

When using rounded objects, such as jars, containers, bottles. This machine is worthwhile as it can easily apply and stick labels either partially or fully cover them without any risk of displacement, wrinkle, or error. |

| Automatic Three Roller Labeling Machine

Picture Courtesy:Altech |

This machine uses three adjusting and supporting rollers that helps in positioning and alignment of the labeling. Automatic three roller labeling machine is suitable for larger industries that gives 100% accurate results offering crumpling and chances of disoriented labeling of the products. |

| Automatic Front and Back Label Machine

|

This machine is used when the consumer has to apply label only at the front and back of the object’s surface. This is simple and easy to work equipment that can cater packaging products designed in various shapes such as rectangular, square or narrow shaped. |

| Automatic Flat Object Labeling Machine

Picture Courtesy: SZHX |

This is another simple automatic labeling machine which is suitable for label application required for flat surfaces such as cartons, boxes, books, and other related packaging products. |

Automatic Labeling Machine: Based on Machine Orientation

| Machine | Details |

| Automatic Vertical Labeling Machine

Picture Courtesy: Crown Packaging |

Automatic vertical labeling machine works in the vertical direction on the surface of product packaging. This machine is suitable for label application of tall shape products such as lip-stick, foundations, tubes, eye liner, vessels, etc. This machine is basically used for pharmaceuticals, food, nutraceuticals, and related companies. |

| Automatic Horizontal Labeling Machine

Picture Courtesy: Hindustan Industry |

This machine applies labeling on the object following horizontal fashion. An automatic horizontal labeling machine is suitable when you need to label the product on flat surface objects such as boxes. Books and cartons yield maximum adhesive output and uniformity. |

8.What Types of Packaging Containers Are Used by Automatic Labeling Machine?

Automatic labeling machine is designed according to the different types of packaging material it would be handling.

Glass

The machine is suited for glass. Automatic labeling machine can adhere labels on the side, front and as whole wrap around the glass packaging. When manufacturing labels for glass, it is necessary to keep in mind to design such a label that is moisture proof, heat, and acid resistant.

Plastic

Automatic functioning, self-adhesive automatic labeling machine is used to handle bottles containers, boxes and pouches of various types made up of plastic that is used by many industries.

Tin

Manufacturers amongst many industries use tin packaging for their products, which can also be labeled using an automatic labeling machine. Tin packaging needs two labels, one for the circular lid and the other rectangular label for the side of container.

Paper

Automatic labeling machines are compatible to work with products made up of paper which is commonly used in food, retail, and fabric packaging industries.

9.What Shapes and Sizes of Packaging Material Are Used By Automatic Labelling Machine?

An automatic labeling machine is versatile enough to handle labeling of the following products:

Bottle

Automatic labeling machine with custom printed or self-adhesive types of labels are suitable to go with bottles which are designed usually in cylindrical shape. Although round, square and wine shaped bottles are also found.

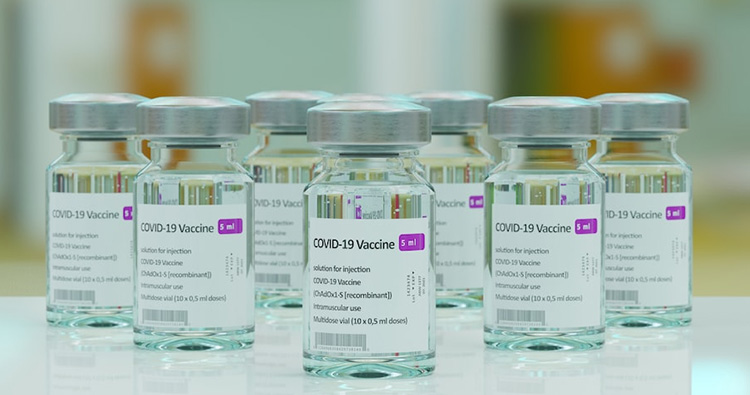

Vials and Ampoules

Vials and ampoules are small glass shaped containers that are respectively long neck and narrowly designed and round mouthed cylindrical bottles. Automatic labeling machine with small labels can be adjusted for its application accordingly.

Jars and Containers

Automatic labeling machine with offers labeling with different shapes jars and container such as square, rectangle, oval and some irregular shapes and sizes. Usually printed, adhesive sticker labels are used to give an aesthetic and consistent labeling.

Boxes and Cartons

Automatic labeling machine is ideal solution for labeling items such as boxes and cartons that are commonly used in pharmaceuticals, cosmetics, and food industries as a secondary packaging needs this machine for easy tracking, identification and branding.

Can

Automatic labeling machine is suitable for labeling products dispensed in cans such as fragrances’, body spray, room sprays etc. that are mostly designed narrow cylindrical shapes.

Bags/Pouches/Sachet

Automatic labeling machine is featured with bag labeling properties that is mostly done by vertically or horizontally over the bag. This kind of labeling is mostly required in food, pharmaceutical, and other industries for product branding.

Batteries

Automatic labeling machine is recommended for labeling batteries that includes information such as voltage, safety, brands, symbols etc.,

10.How To Maintain an Automatic Labeling Machine?

Automatic Labeling Machine- Picture Courtesy: Result Group

| Maintenance Points | Description |

| Regular Cleaning | This is an important part of the maintenance where regular cleaning of dispenser, pressing roller and moveable parts of the machine is done. The cleaning includes sensors, and moveable components as well. |

| Lubrication | The greasing and lubrication of moveable parts is an essential element of regular maintenance that ensures flexible operation with minimum downtime. |

| Calibration | Every consumer must keep in mind that regular calibration of equipment is always a good sign of achieving accurate output. Calibration of external and internal (software) aspects must be done regularly such as roller, supporters, sensors, PLC system, and other. |

11.What Are the Basic Problems and Solutions of Automatic Labeling Machine?

An automatic labeling machine performs complex jobs with simple procedures. Like any other machine, there are some common problems that might arise in this case too. We have discussed below the basic technical problems and solutions related to automatic labeling machines.

| Problem | Solution | Picture |

| Misalignment and Deviation of Labeling

This is very common condition when labels are positioned deviated from desirable place. |

This problem occurred due to misalignment of the label roll supporters that helps in proper placement of the label to provide correct orientation.

To correct this problem please ensure rollers are properly adjusted and labels are supplied and fixed around each supporter very well. Reset the machine and begin the process. |

|

| Wrinkled or Air Bubble in Label

This is another common problem accompanied by wrinkles or air-bubbles on the labels.

|

The presence of air-bubble or wrinkle ultimately rejects the batch as the machine is failed to adhere label properly.

To solve this problem, check the setting of press roller and determine the intensity of the pressure applied on each label after sticking procedure. |

|

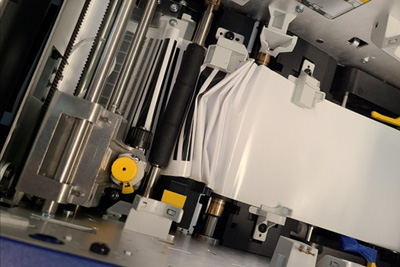

| Labels are Jammed

The common condition accompanied by an automatic labeling machine which is failed to move the label properly. |

As we discussed below, a label roll is set and adjusted by an operator on the various supporting units featured in the machine. The purpose of supporting rollers is to facilitate smooth movement of the labels.

To solve this problem, re-adjust the fixation of label roll. Check if label roll is adjusted tight and unable to move smoothly. |

|

| Improper Adhesion

Sometime, labels are unable to stick properly. |

The labels are easy to fall and slipper from edges.

To solve this problem, check the amount of glue present on the back of the film. Calibrate the machine’s settings. |

|

12.What Points to be Considered for Purchasing Automatic Labeling Machine?

When purchasing a automatic labelling machine, there are some points to be considered for better options:

Your Production Need

Picture Courtesy: CEROS

Determine your production goals, for example, expected run time of the machine, how much output do you expect per hour, etc., This would help you to choose whether to go for larger or smaller equipment.

Funding

This is an important point that help you in deciding in selecting model, automation, size, and type of the machine. Keeping budget in mind will help in tailoring the right option of the machine that best fits to your facility.

Integration

Automatic Labeling Machine- Picture courtesy: Wenzhue

If you are planning to adjust your machine in the production line then must confirm whether the machine is flexible to integrate with other machines of the production line.

Manufacturer

Picture courtesy- Dingo

Always consider the manufacturing and supplying company as well-reputable with possible higher reviews. Allpack is Chinese leading company that offering high quality products across the globe.

Conclusion

In conclusion, automatic labeling machine is not only a machine, but this is a gateway to the best marketing and promoting your brand via excellent working output with accurate application over each product. This machine is an excellent tool for conveying your message to consumers in an advanced manner. If you are looking to purchase the automatic labeling machine; Allpack is the hub that offers broad range of labeling tools best fit for production lines in an economical way. Want to Know More? Please contact us to find out different models and Quotation.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide