Bottle Packing Machine: The Complete Buying Guide In 2024

Scrolling down to get the best bottle packing machine? That's great! You have come to the right place. Well, this buying guide about Bottle Packing Machine is especially composed to bring in your knowledge not only the access to suitable machine but also enlighten you with different aspects of a bottle packing machine.

Bottle packing machine is becoming inevitable in medical industry, veterinary sector, food industry, and other non-food industries like cosmetic where the quality of products is retained by accurately packing them in bottles. So, these filled bottles must be packed in a safe way for which Bottle Packing Machine is used. What this machine basically is? How it functions? And what are its benefits? To know keep reading!

1.What Is A Bottle Packing Machine?

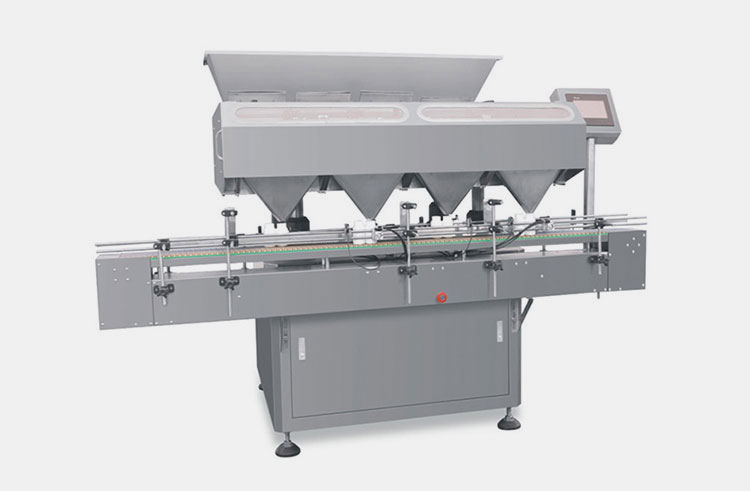

JF-A160-16 Medium Speed Automatic Multifunction Capsule Tablet Pill Counting Line

Bottle packing machine refers the large assembly of interconnected machines which perform the task of packing different types of bottles. These machines include a bottle unscrambler, tablet counting machine, desiccant inserting machine, capping machine, induction sealer, and labeling machine.

In this way, bottle packing machine can be described as a comprehensive bottle packing line where the machine is responsible to process bottles from different phases. The machine can handle multiple products encompassing tablets, capsules, pellets and various sizes and shapes of bottles. Moreover, it is highly efficient and support precise way for bottles packing.

2.Explain The Benefits Of A Bottle Packing Machine?

Bottle packing machine can give you lots of benefits by ensuring the safety and integrity of products as well as bottles. These advantages are as follows:

High Automation

High level automation icon- Picture Courtesy: supplygym.com

Medium and large-scale industries are the busiest places consistently working to meet the best possible production targets. Similarly, bottle packing machines will always give you efficient work with least manual interference and high accuracy rate. It can be easily understood by looking into the fact that high speed bottle packing machine by Allpack has the highlight output ratio of packing 90 bottles per minute.

Enhance Protection

Bilayer tablets bottle- Picture Courtesy: usana.com

Bottle packing machine can give your bottles high level of protection against dust, moisture, and light. For instance, their corrosion resistant stainless-steel body ensure that tablets, capsules, and candies being processed are in protected environment.

Multi Tasking

Another most fascinating attribute of a bottle packing machine is that it is multi tasking in a way that it performs the task of bottles unscrambling, filling, desiccant inserting, capping, sealing, and labeling etc. So, it removes all the bothers being made for undergoing the bottles from different stages separately.

Versatility

Bottles of different flavored gummies- Picture Courtesy: pipelinevalor.globo.com

Another most significant advantage of a bottle packing machine is its versatility that extends to numerous industries and multiple types of bottles with varying shapes and sizes. So, no matter what kind of bottles and products you are processing, this machine will always be ready to pack them.

High Precision

Softgels precisely arranged in heart shapes- Picture Courtesy: usana.com

Bottle packing machine has automatic system to carry out the different steps of bottle packing. All these units have fitted detection system to counter the errors; counting unit remove the broken pallets, bottle detector reject unfilled bottle, desiccant inserting unit fill one bag in one bottle. Similarly, the machine gives you high precision in each and every step of bottle packing.

3.What Type Of Bottles Can Be Packed By Using A Bottle Packing Machine?

A bottle packing machine is best suitable to process all kinds of small to large bottles with varying shapes and material. Following is the brief description:

Plastic Bottles

Capsule plastic bottles- Picture Courtesy: helloglow.co

Plastic bottles are commonly used bottles for packaging of pills, confectioneries, chocolate balls, and laundry powder etc. So, all kinds of durable and thin plastic bottles are suitable to be packed by a bottle packing machine without harming their structure.

Glass Bottles

Woman multi vitamin gummies display- Picture Courtesy: mariannetaylor.com

Glass bottles are highly hygienic and completely safe from corrosion and bacterial presence due to which pharmaceutical solid drugs, food tablets, and chemical chlorine tablets are often delivered in glass bottles. Therefore, different types of small to large glass bottles can be easily packed together by using a bottle packing machine.

Jars

Mouthwash tablets in jar- Picture Courtesy: zerowastenest.com

Jars are large, big containers usually made from durable glass. As they are having larger capacity to hold products, most of the confectioneries like gummies, jellies, and beans are delivered in jars. Hence, jars can also be packed by a bottle packing machine.

4.Enlist The Products Which A Bottle Packing Machine Is Capable To Process?

You may wonder after knowing that how many products are eligible to be counted and packed by a bottle packing machine. Let's explore these all one by one!

Tablets

Tablets presentation idea- Picture Courtesy: plentylifestyle.usana.com

Tablet is a solid form of dosage made from the compression of dry powders. Tablets are the top priority of most of the healthcare industries to deliver drugs. Apart from this, confectioneries can also be in form of tablets like milk tablets and chocolate tablets etc. So, a bottle packing machine can perfectly count and pack all forms of tablets into bottles.

Capsules

Softgel capsules- Picture Courtesy: hubshifa.com.au

Capsule is among other form of drugs through which both liquid and solid dosage can be delivered. Hence, all kinds of hard gel and softgel capsules are eligible to be processed by this machine.

Candies & Bubble Gum

Multiple colorful candies in jar

Candies and bubbles are hard confectioneries often in sweet and occasionally in sour taste. They are also meant to be packed in bottles after precise counting for which a bottle packing machine is best suitable.

Chocolates & Gummies

Chocolate gummy bears in bowl- Picture Courtesy: gazedandenthused.com

Chocolate balls are the most favored by people of all ages. Similarly, gummies are now found everywhere in pharmaceutical, nutraceutical, and food industries. That's why, you can employ this bottle packing machine to not only count but undergo them through all the essential steps of bottle packing.

Pellets & Seeds

Pumpkin seeds- Picture Courtesy: treehugger.con

Pellets, seeds, and similar granules are often abundant in amount that it is impossible to pack them manually. Hence, a bottle packing machine is made in such a way to support all these goods for their correct packing in bottles.

Laundry Pods & Shooting Balls

Laundry pods

Laundry pods are small plastic film pouches encasing liquid detergent, while as shooting balls are spherical soft balls used for shooting by kids. A bottle packing machine can be utilized to pack these items in different bottles.

5.How Does A Bottle Packing Machine Work?

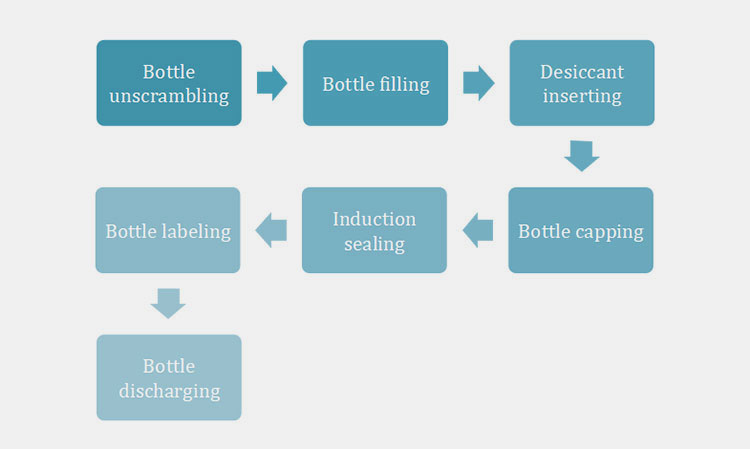

Bottle packing machine adopts a very straightforward and consistent operation. Starting from bottle unscrambling, it ends with providing a finished bottles after labeling step. The underlying steps will clearly demonstrate its working process in detail:

Bottle Unscrambling

Bottle unscrambling- Picture Courtesy: Icon equipment

The very initial step of a bottle packing machine starts with bottle unscrambling. This task is performed by the bottle unscrambler. The bulk of bottles is loaded onto the machine's rotary disc. When the disc adopts rotary movement, these bottles start taking the place in molds which are located at the corner.

Similarly, the position of bottles is set in a way where the bottles stand in upright position with opening on the top side. These bottles are then sequentially moved towards filling machine through conveyor.

Bottle Filling

Bubble gum filling into bottles- Picture Courtesy: cremer.com

The second step is bottle filling which is carried out by the second unit of a bottle packing machine. This unit perform dual tasks of product counting and their filling into bottles. In addition, the material is dropped from hopper onto vibratory trays and then counted in counting compartments.

Afterwards, these counted objects are accurately filled into bottles through filling heads. When the bottles are filled, they are detected by the sensors located on conveyor. If any bottle remains unfilled, it will be rejected by the machine.

Desiccant Inserting

Desiccant bag inserting into bottles- Picture Courtesy: accutekpackaging.com

When bottles get filled with counted products, they are conveyed to the desiccant bag inserting machine. The machine when detect the presence of bottles, start pulling the adjoined desiccant bags from roll, cut the bags, and dispense these silica gel bags into bottles by following the principle of one bottle one desiccant bag.

Bottle Capping

Bottles capping process- Picture Courtesy: accutekpackaging.com

The fourth step encompasses bottles capping and screwing. When bottles are conveyed to capping machine, it first supplies the filled bottles with caps. Similarly, the caps are well screwed by the spindle on both sides. Ultimately, an airtight closure of bottles is realized.

Induction Sealing

Bottles undergoing induction sealing- Picture Courtesy: trumarkindia.com

Proceeding further, the capped bottles are processed for stringent sealing by induction sealer. As the bottles move by the induction sealer, an electric current is applied to the induction coil which in turn radiate magnetic field. This magnetic field heats the foil to melt at an exact temperature and stick to the neck of bottle. Hence, airproof sealing of bottles get completed.

Bottle Labeling

Bottle labeling- Picture Courtesy: Wire Labeling Machine

This is the final step of a bottle packing machine where filled and sealed bottles are passed through the labeling phase. When bottles are conveyed to this unit, the machine start pulling labels from label rolls, peel them, and apply them around the bottles. At the same time, fur brush tightens the labels around every passing bottle.

Bottle Discharging

Bottles discharging is the last step, when finished and packed bottles are conveyed by the conveyor from bottle labeling machine to a bottle collection unit.

6.Describe The Different Units Or Components Of A Bottle Packing Machine?

Bottle packing machine is a long assembly of different units which perform respective task to carry out appropriate bottle packing. Their explanation is given below:

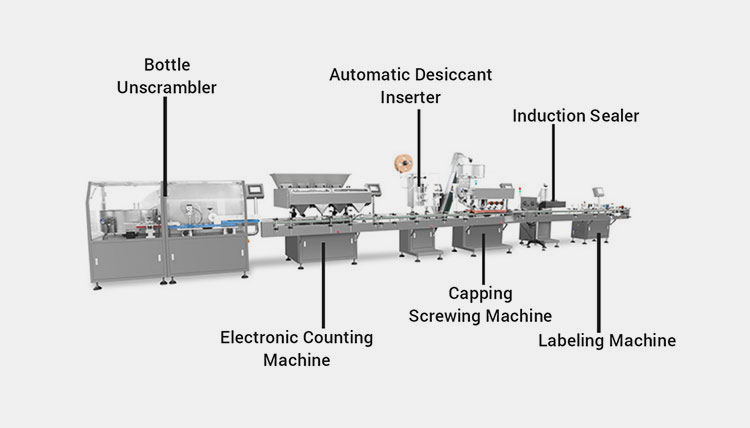

Components of Allpack's JF-2000-32 Automatic Multifunction Capsule & Tablet Pill Counting Line (High-speed Line)

| No | Machine | Description | Structure |

| 1 | Bottle Unscrambler | Bottle unscrambler is an automatic machine that constitute the very initial part of a bottle packing machine. It is used to align the randomly positioned bottles by processing them in a rotary disc. | It is made up of several components including a hopper, unscrambling station, conveyor, electric cabinet, main frame, and control system etc. |

| 2 | Electronic Counting Machine | Electronic counting machine is one of the core part of a bottle packing machine. Its function is to accurately count the large number of objects and precisely fill them in separate bottles. | The structure of an electronic counting machine is robust with main parts including a stainless steel body, hopper, rotary trays, counting compartments, detection system, dust collection system, empty bottle rejection system, touch screen, and filling heads. |

| 3 | Automatic Desiccant Inserter | Automatic desiccant inserter is yet another crucial part of a bottle packing machine integrated for the purpose of supplying filled bottles with silica gel bags. | It consists of a feeding supplier, support roller, jog belt assembly, sensor, fix guide, cutting knives, outfeed, adjustment screws, electric panel, and control system etc. |

| 4 | Capping Screwing Machine | Another unit of a bottle packing machine is a capping screwing machine. This unit perform the function of supplying bottles with caps and screwing them tightly. | The machine is made up of a cap elevator, bottle separator, cap feeding chute, cap pressing part, capping part, synchronous belt, conveyor, and machine frame. |

| 5 | Induction Sealer | Induction sealer is an excellent part of the bottle packing machine designed to ensure the capped bottles with stringent sealing. It uses an electromagnetic radiation to melt the foil of caps, so, that it will stick to bottle mouth | The overall structure of an induction sealer is made up of a compact structured stainless steel body, induction coil, heating system, conveyor, speed regulator, and induction sealing head etc. |

| 6 | Labeling Machine | The labeling machine constitute the last part of a bottle packing machine. It simply works to label finished bottles with self adhesive labels. | It is an assembly of various components comprising label plate, label pressing fur brush, conveyor, label pulling wheels, electric system, and label peeling mechanism. |

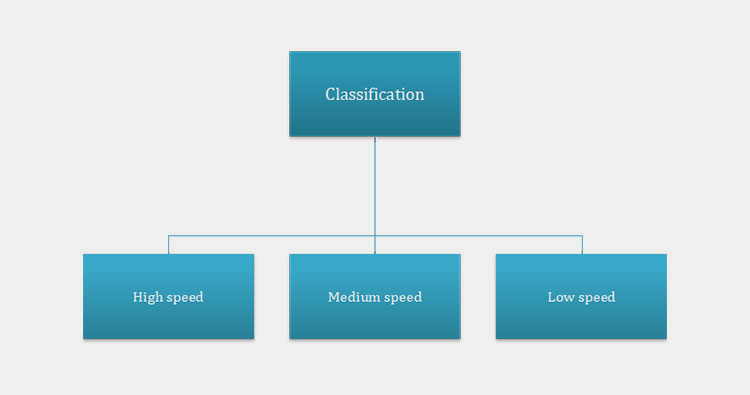

7.What Is The Classification Of A Bottle Packing Machine?

Bottle packing machine by Allpack can be simply divided into three types on the basis of their speed. They are as follows:

High Speed Tablet, Pill, Capsule Bottling Line

As the name indicates, this is the most efficient bottle packing machine with exceptional production output of 90 bottles per minute. This machine is highly suitable for large and extra-large production facilities such a as pharmaceutical industry, veterinary industry, and food industry etc.

The body of high-speed automatic bottling line is complex enough due to the integration of a high-speed bottle unscrambler, 32 channel tablets counting machine, automatic desiccant iserter, high speed capping screwing machine, water-cooled induction sealer, and high-speed round bottle side face labler

Medium Speed Tablet, Pill, Capsule Bottling Line

Allpack JF-A160-16 Multi-function Tablet, Pill, Capsule Bottling Line (Medium-speed Line)

Medium speed bottling line is another type of bottle packing machine made for meeting the daily production targets of medium to large industries. It has excellent capacity of finishing up to 80 bottles in a minute.

Its structure is medium sized compared to high-speed bottle packing machine. The different machines used in its formation include a bottle unscrambler, electronic counting machine, automatic desiccant inserter, capping screwing machine, induction sealer, and round bottle side face labeler.

Low Speed Automatic Bottling Line For Capsule/Tablet

Allpack JF-A100-12 Low Speed Automatic Grain Capsule Tablet Pill Counting Line

Another most precise bottle packing machine is the low-speed bottling line. It is cost-effective compared to the other two types yet give you utmost production figure of packing 50 bottles in just 60 seconds. So, you can get benefitted from this reliable bottle packing machine whether you are running a medical industry, processing cosmetic supplements, or producing food items.

The body of a low-speed counting line is small compared to other types of tablet counting lines and is composed of a rotary bottle unscrambler, automatic tablet counting machine, desiccant inserting machine, capping machine, induction sealer, and a labeling machine

8.Where Do A Bottle Packing Machine Is Used?

Bottles are the most convenient packaging objects which are used for storing and delivering different types of products encompassing tablets, capsules, and candies etc. It thus implies, that almost every industry has a demand for bottle packing machine to ensure security to their goods. Let's discover few of the prominent ones!

Nutraceucal Industry

Presentation of nutraceucal gummies- Picture Courtesy: usana.com

The use of various nutraceuticals in form of tablets, capsules, and gummies tomato is common nowadays. Similarly, their packaging in bottles is the first choice of every manufacturer. That's how the relevance of a bottle packing machine can be found in nutraceucal industry.

Confectionery Industry

Various confectioneries- Picture Courtesy: dollarsweets.com

Another notable field where the use of a bottle packing machine is appreciated is confectionery industry. Here, with the help of this machine, bottles of candies, chocolate, gummies, and bubbles can be packed through different stages.

Healthcare Industry

Supplements presentation idea- Picture Courtesy: biovitamine.calivita4.me

Healthcare industry is an area which is constantly engaged in the manufacturing and packaging of drugs both in solid and liquid form. In this way, bottles are always preferred to keep the drugs safe and protected against environmental elements. Hence, a bottle packing machine is then used to ensure further integrity to all these bottles at the end.

Cosmetic Industry

Women picking hair vitamin gummy from bottle

Another area is cosmetic industry which is having a good demand for a bottle packing machine to pack the assembly of bottles containing softgels, gummies, and tablets for glowing skin, healthy hairs, and strong nails.

Agricultural Industry

Plant growing from seed- Picture Courtesy: thisismygarden.com

Agricultural industry is one of the notable areas where the use of a bottle packing machine is inevitable. It is because this sector is continuously working to deliver seeds, grains, and pellets which are counted and then packed into bottles through a bottle packing machine.

Chemical Industry

Chlorine tablets- Picture Courtesy: walmart.com

Last but an important one is the chemical industry where bottle packing machine is employed to count and pack the tablets, laundry pods, and pesticides pellets into range of bottles.

9.How To Clean And Maintain A Bottle Packing Machine?

Including in your manufacturing line a bottle packing machine is a big decision and good investment that require your constant involvement in its successful functioning. You need to keep it clean and maintained all the time for smooth working throughout its working life. The below easy steps are helpful in this way:

Operators maintaining a machine- Picture Courtesy: insidernavigation.com

Cleaning:The presence of debris and dust on your bottle packing machine can badly affect the quality and hygiene of bottles especially those of food and pharmaceuticals. So, make sure to clean your bottle packing machine regularly with non-abrasive, clean, and dry cloth especially the hopper, knives, and conveyor etc.

Lubrication:For a bottle packing machine, it is always a conveyor and chains which contribute to the smooth running of bottles from one place to another. It is thus necessary to keep these parts lubricated all the time.

Parts Changeover:It is important to examine the machine before and after completing its daily task. It will help you identify the wear and tear of parts in machine whose timely replacement is significant. You can make the most frequently changeover parts ready on your shelf, so, that the possible downtime in production can be minimized.

Machine Adjustment:Bottle packing machine also require regular adjustment of its parameters such as the speed of conveyor, frequency of heat, and length of film etc. Hence, before starting new operation, it is crucial to adjust the relevant commands in advance.

Keep it Dry:When processing products like detergent pods there is a chance that the liquid spill over machine which result in the corrosion. Here what you can do is to keep the machine dry and clean all the time.

10.What Quality Standards Should A Bottle Packing Machine Meet With?

A bottle packing machine is meant to securely pack the empty bottles by passing them through different stages. These stages are responsible for ensuring whether the product inside bottles is processed in hygienic environment or not. Now, how can it be examined? The answer lies in checking the quality standards of machine. These are explained below:

ISO quality standard icon- Picture Courtesy: qualitymag.com

ISO:A bottle packing machine must comply the safety standards established by International Organization for Standardization.

GMP:The structure of a bottle packing machine should be made from 304 stainless steel as regulation by Good Manufacturing Practices.

CE:If a bottle packing machine is to be used in European Union, it should first comply to the CE's safety regulations.

FDA:As bottle packing machine is often used for drugs and food materials, therefore, it is necessary for it to be certified by the Food and Drug Administration.

11.Diagnose The Common Errors Of A Bottle Packing Machine?

To troubleshoot the common errors of a bottle packing machine, it is necessary to have clear information about each component and its function as we have explained above. In this question, we have highlighted some of the major issues along with their possible solutions which can occur during operation:

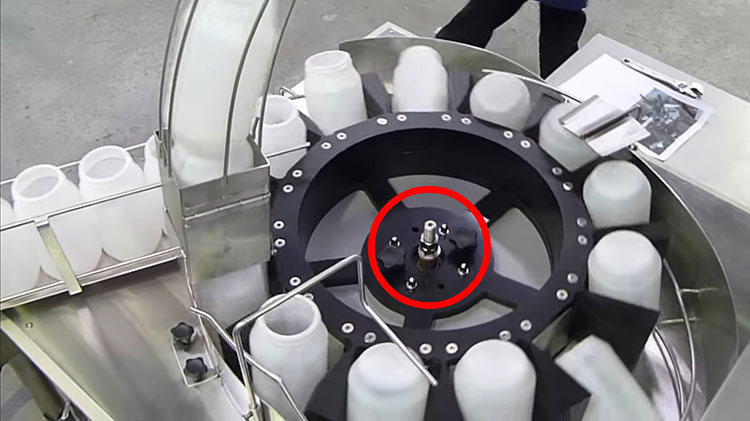

Bottle Unscrambler

Encircled transmission gear of bottle unscrambler- Picture Courtesy: Icon Equipment

False unscrambling of bottles

It is caused by the error in sensor, moving disc, or machine setting.

You need to restart the machine and clean sensors for accurate functioning.

Bottle get stuck in moulds

Sometimes, the friction of transmission gears results in the stagnancy of rotary disc which in turn leads to bottles jamming.

It can be solved by lubricating friction plate, fixing it, and modifying its working specifications through control board.

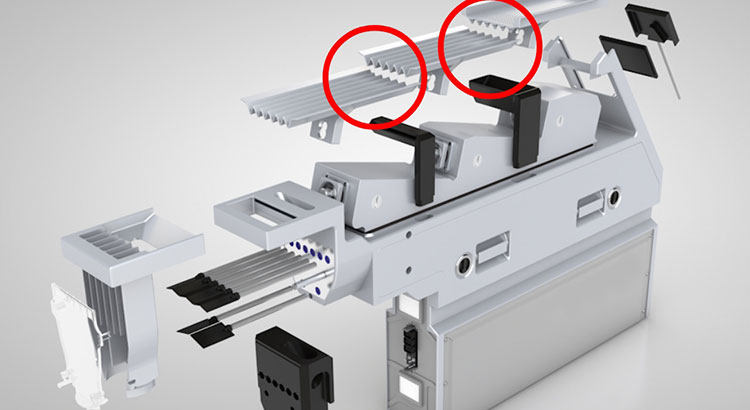

Electronic Counting Machine

Encircled vibratory trays- Picture Courtesy: cremer.com

Incorrect counting

The wrong placement of rotary trays causes under counting and polluted sensors results in over counting of objects.

Such issues can be tackled by ensuring the right positioning of vibratory trays and keep the sensors free of dust and pollution.

Bottle filling issue

When the size of bottle is small and the height of filling head is up, the counted objects get scattered while their filling into bottles.

So, you can simply fix the problem by adjusting the height of filling head in accordance with that of the bottle size.

Desiccant Inserting Machine

Encircled supporting shaft of a desiccant inserting machine- Picture Courtesy: accutekpackaging.com

Jamming of desiccant strip

The only reason responsible for this issue is the wrong setting.

To solve it, you need to reset the machine with all the essential parameters required for desiccant inserting into bottles.

Wrong cutting of desiccant bags

This happen when the length for cutting each bag is false.

Therefore, you are required to adjust the length for cutting each desiccant bag as per the length of each bag.

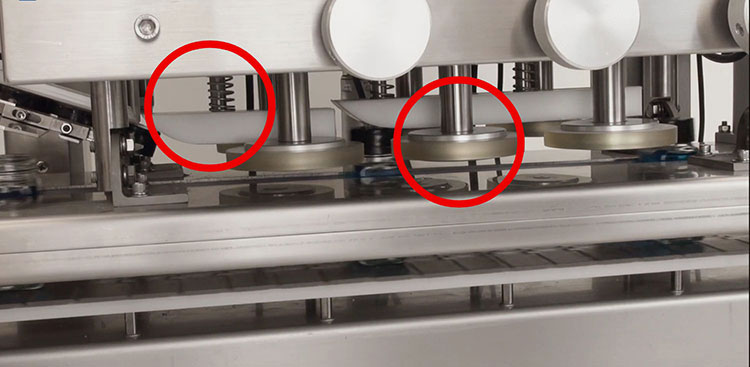

Capping Machine

Encircled bottle capping machine- Picture Courtesy: accutakepackaging.com

Loose capping

The reason is wrong positioning of caps and application of pressure.

This can be resolved by adjusting the machine and rightly placing the caps on bottles.

Cap Breakage

Using inappropriate and small size of caps often get break when screwing pressure is applied.

Make sure that you use the caps with suitable sizes to that of the bottle opening.

Induction Sealer

Presenting induction sealing issue- Picture Courtesy: quatropack.com

Burning of foil liner

It happens when the speed of conveyor is too slow due to which the foil gets more heat and gets burned.

Increase the speed of conveyor and adjust the temperature of machine to avoid burning.

Weak sealing of foil

Various factors are responsible for this issue comprising the inadequate temperature and too heightened induction sealer head.

So, you are required to increase the temperature of induction sealer and adjust the height of sealing head.

Labeling Machine

Encircled fur brush- Picture Courtesy: Wire Labeling Machine

Blistering of labels on bottles

This happen when external particles trapped inside the label during their application over bottles.

It can be solved by placing clean bottles on labeling machine and making sure that the surrounding environment is free from dust and pollution.

Weak adherence of labels to bottles

This result when label is not approximately pressed by the fur brush around bottle.

Tightening the place of fur brush can end this issue.

12.Factors To Consider When Buying A Bottle Packing Machine?

Now, after studying the different types of bottle packing machine, it would be clear to you that there are multiple types of machines available in the market for meeting the end of bottle packing. But how will you choose the ideal machine for your business? This is conundrum most of the manufacturers confront. So, we have some essential tips for you to follow:

Desired Output

Multiple vitamin tablets bottles- Picture Courtesy: packageinspiration.com

The most important factor to determine on part of manufacturer is the expected ratio of production. For instance, are you running a moderate level local business or controlling the large scale international business? Answering this question will indeed help you to opt for the machine that can give you desired output.

Quality Assurance

Quality assurance icon- Picture Courtesy: medium.com

No doubt the quality of bottle packing machine which you wish to buy must be in your top priorities for consideration. It simply implies checking the brand reputation, the quality assurance given by supplier in form of warranty policy, and machine's compliance to national and international quality standards.

Cost of Machine

Checking the cost- Picture Courtesy: k-house.in.ua

Considering cost of the machine is something that must not be neglected as it can lead you to further troubles regarding expensive packaging. So, make sure you have a broad insight about different types of bottle packing machine and their prices and opt for the pocket friendly one.

Availability of Spare Parts

Multiple spare parts in & outside carton boxe- Picture Courtesy: anzael.com

It is a matter of fact that machines are made up of small to large components and spare parts which, at some point, need to be replaced. Therefore, it is necessary to ask the vendor for the availability of spare parts and if possible, purchase the most useful spare parts in advance.

Conclusion

We are about to conclude this comprehensive buying guide about a Bottle Packing Machine with a reminder that bottle packing machine is the inevitable requirement of today's industries. The reasons are numerous; however, the ultimate one is rapid globalization where a thing produced in one corner of the world has a chance to reach the other corner. It is only possible when you ensure the best possible safety of your goods in form of primary packaging by using a bottle packing machine. So, if you want to be the first in taking this step then contact Allpack to get the best bottle packing machine. For further information please visit our website.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide