Automatic Label Applicator: The Complete Buying Guide in 2024

Do you know how an automatic label applicator can scale up the business? An automatic label applicator has been always a first choice when companies start their business and want to scale up their profitability with high-performance and quality products.

Yes, companies begin this journey with small or manual machines but as demand increases, they move to automatic ones. Indeed, this is a reliable investment worldwide with no worries about potential errors or using manpower.

Today, we are talking about automatic label applicators and their challenging role in today’s market. Read this blog if you are planning to purchase this equipment and looking to integrate it in your facility.

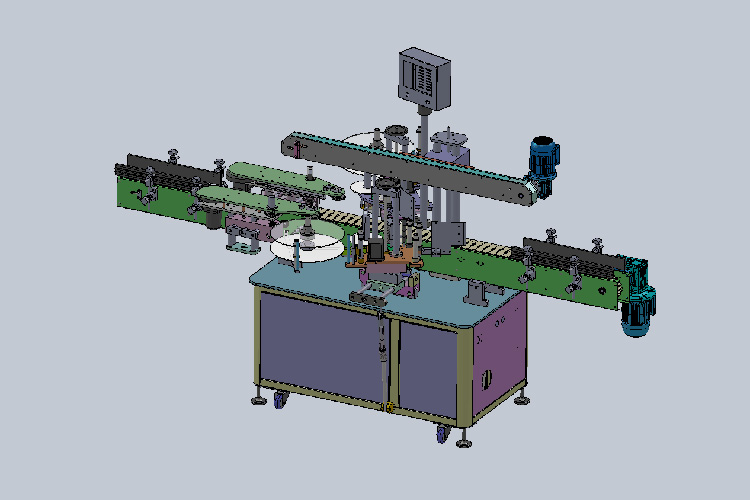

1.What is Automatic Label Applicator?

Automatic Label Applicator

This is an efficient machine used in various manufacturing and packaging industries for the purpose of applying labels on the surface of products. This machine offers the application of labels on various shapes of the surface area i.e., round, curved, cylindrical, flat, etc., to enhance the appearance and improve the brand by conveying important information and consumer communication. This is a user-friendly solution that’s made up of durable material that helps in positioning labels with better alignment and offering overload protection to end-user.

This machine is presented with broad categories that we’ve discussed below. Each category plays a significant role in the packaging world which facilitate small to large production with multiple designed containers, boxes, bottles, bags, etc.,

2.What Industries Used Automatic Label Applicator?

No matter what packaging production line is, integrating label applicator is mandatory. Automatic label applicator is an important machine that have significantly broad series of industrial applications to attain good branding, fast and accurate positioning of the labels. The commonly used industries are mentioned below:

Nutraceutical Industry

This industry deals with manufacturing and supplying of healthcare products produced from natural sources in order to meet nutritional deficiencies or maintain nutrition in human body. Automatic label applicator is a prime machine used in the production line of nutritional industry to enhance brands as well as providing important information mentioned on each label of the bottle so consumer can read and follow the instruction. For e.g., dose, ingredients, side-effects, precaution, etc.,

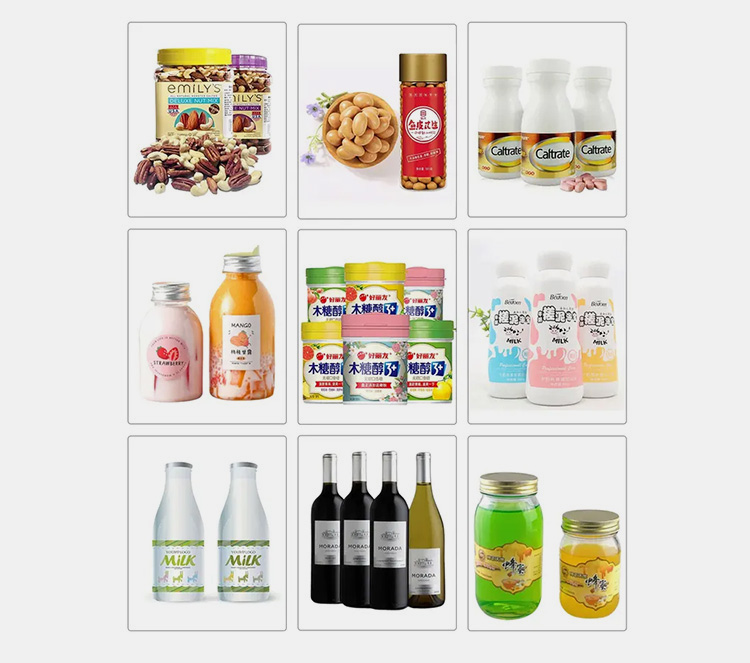

Food and Beverage Industry

Automatic label applicator is an essential tool for food and beverage industry for application of labels on containers, bottles, jars, of products like ketchup, mayonnaise, sauces, spices, powders, flours, dairy products, juices, yogurts, milk, fresh pulps, purees, etc.,

Chemical Industry

Automatic label applicator is used in chemical industry to ensure the chemical products such as acid, alkaline, organic, inorganic solvents, bleaches and other product are packed with appropriate labelling on their bottles/jars/containers to meet regulatory needs.

Pharmaceutical Industry

This industry is considered as a leader of the healthcare sector where each and every product is sensitive and bring positive health outcomes to the patient. Whether syrups, capsules, caplets, tablets, pills, or any packaging of products; that is definitely incomplete, without consider automatic label application in the production line.

Cosmetics and Personal Care Industry

In this industry, the aesthetic appearance of the product can be improved by using proper and attractive labels. Hence, the significance of automatic label applicator can be ignored in packaging of skincare products, make-up products like foundations, mascaras, etc and personal care products such as shampoos, body lotions, facemasks etc.,

Automotive Industry

Automatic label applicator is used in labelling of products like engine oil, brake oil, cleaners, shiners, or hardware products. This machine is integrated with filling and packaging line to bring efficient workout.

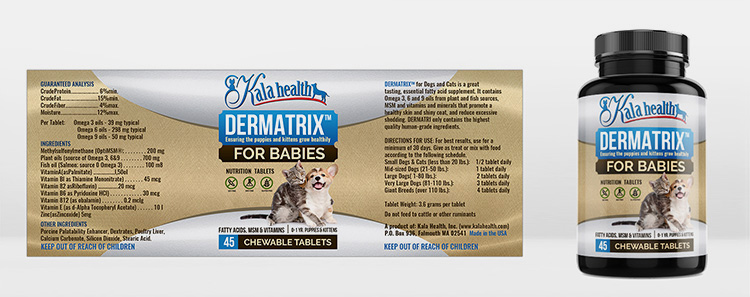

Veterinary Industry

This industry deals with animal healthcare products such as injectables, tablets, capsules, ointments, and food products such as grains, cookies, rusks, etc., which need automatic label applicator in the production line.

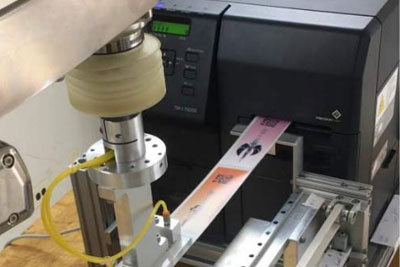

3.What is the Working of Automatic Label Applicator?

An automatic label applicator is an adaptable machine offering a simple working principle. For your understanding, we have demonstrated the working principle in a few steps. Have a look!

| STEP 1 : Load Labeler

Ensure that labeler is the right type and can be compatible with the machine. Manually position the labeler on the holder which must be aligned. Now follow the thread pathways featured in the machine via rollers. Once, label is positioned well, adjust the tension and run the test to assess if alignment is perfect. |

|

| STEP 2: Adjust Conveyor and Load Containers

Adjust the conveyor where it can allow the flexible entrance of containers onto the machine. Once, containers are subjected to labelling station it become sensed by detectors and allow applicators to position labels on assigned area followed by measurement accurately. This process applies label one by one by the help of air blowers, or self-adhesive method. The containers/material is pressed ensuring proper adhesion. |

|

| STEP 3: Discharge

Now, labeled product will transport from conveyor where they leave the unit and enter to other machines that involved subsequent packaging machines for final shipping. |

|

4.How beneficial Automatic Label Applicator is?

Automatic Label Applicator is a beneficial machine for your business as it helps you improve various parameters. The list of benefits is discussed below:

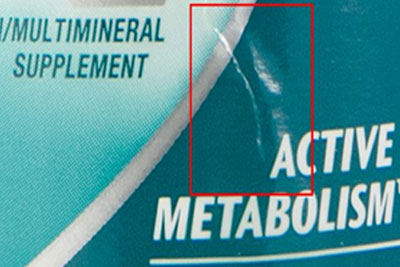

Protecting your Business Against Tampering

Automatic label applicator

There are some important sectors such as healthcare, food, nutraceuticals, and beverages where anticounterfeit packaging is of prime importance. That’s why it is observed that the market size of the labelling applicator has grown from USD 106.3 billion in 2020 and is expected to grow to USD 188.2 billion by 2025. This machine provides you with significant services where counterfeiters are unable to break this technology and make it harder to make replace it with another product.

Track and trace

By label applicator, products are easy to track, and trace followed from the supply chain to end-user. The machine is capable of providing barcodes, information (batch no. manufacturing and expiry date etc), coding, and others that make easy implementation throughout the packaging process and retail purposes.

Product identification

You can give production identification by assigning particular identification marks, logos, and brand name through labelling. This artwork generally provides for marketing and sale purpose by giving ultimately product identification and boosting the purchasing value.

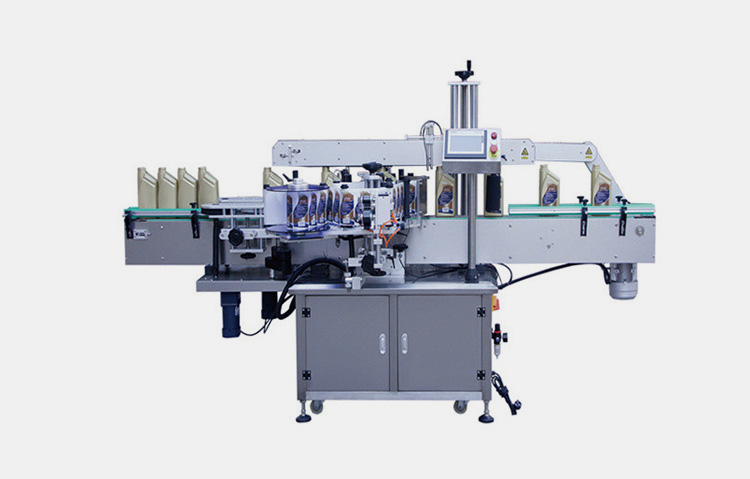

Integrate with the Production Line

Automatic Label Applicator

An automatic label applicator can be fully integrated and best networked with other machines using mechanical and software integration ensuring users with flexible operation, quick product changeover, real time fast labeling and status visualization.

Connect with consumers, boost sales and build loyalty!

Today, everyone is curious to know about the product before they buy. Automatic label applicator is used a powerful promotional pathway that helps in connecting manufacturers to consumers by easy sticking of promotional labels by single click and generate loyalty and awareness of your brand among consumers across the globe.

Easy to Use

Automatic Label Applicator- Picture Courtesy- Accraply

Today, automatic label applicators are featured with easy programmes that helps to integrate user data and allow them to operate procedure just by a single click. This is an ideal machine where you can interpret data, knowing or visualizing entire insight information by PLC screens. If you need to change label or add design or any other task, automatic label applicator can offer various features in efficient way with no downtime.

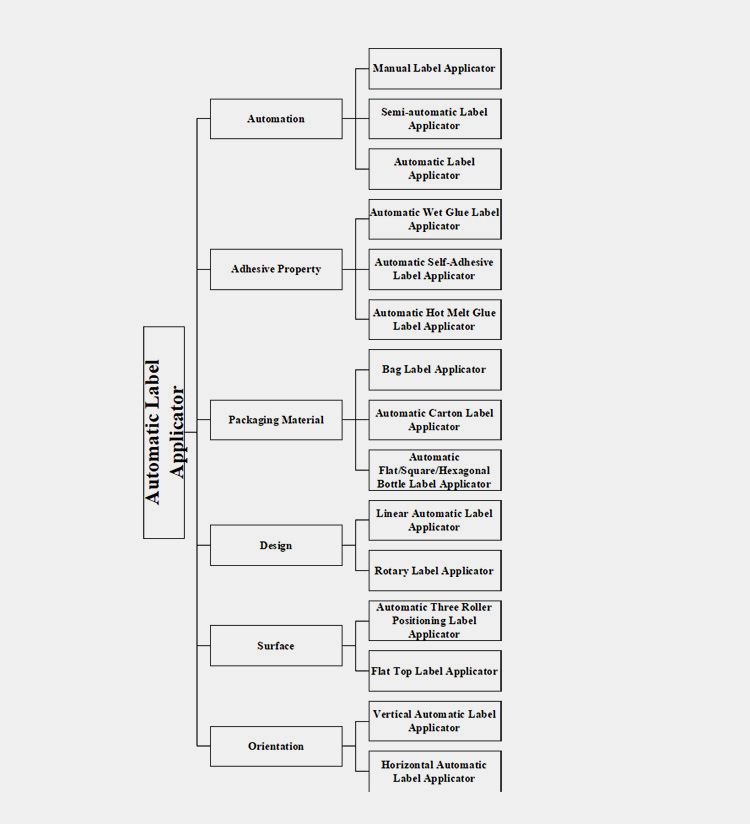

5.What are the Types of Automatic Label Applicator?

An automatic label applicator is a versatile machine with so many various types. Mentioned below are important categories of automatic label applicator. Have a look.

BASED ON AUTOMATION

Label applicator machine is divided into three sub-types depending on automation:

Manual Label Applicator

Manual label applicator

A manual label applicator machine is a simple device that strictly needs human intervention for the labelling procedure. A roll is adjusted on the dance arm where labelling is executed on the product by manually operating the machine and loading and misloading of the product. Here, operator has to set labelling position and alignment themselves. This is small machine which is suitable for small businesses for the cost-effective process.

Semi-automatic Label Applicator

Semi-automatic label applicator- Picture Courtesy :Fineco

This machine is capable to deal thousands of labels per hour. This machine is suitable for those production lines that are seeking to increase productivity and looking to enhance the aesthetic presentation of the product. A fast and reliable option where loading and discharge of the product can be done manually while remaining of the task can be operated by the machine itself. This machine is suitable for small to moderate production facilities, and perfect to control the need of manual labelling.

Automatic Label Applicator

Automatic label applicator

This machine works automatically without needing human intervention for product infeed and outfeed as well as placing of label on to the container. A technician has to put data onto the machine while of the task can be performed by machine itself. This machine offers flexible features to be integrated with other machines of the production line and can be utilize features of pressure sensitive and glue adhesion properties.

BASED ON ADHESIVE PROPERTY

Due to adhesive properties, an automatic label applicator is categorised into the following three types.

Automatic Wet Glue Label Applicator

Automatic wet glue label applicator-Picture Courtesy:VKPAK

This machine works on dispensing layers of wet glue or cold glue for the application of the labelling on the products. This is commonly used for labelling task for jars, bottles, containers made up of glass or plastic or containers with tin material. A thin film of glue can help in adhering the label on container surface making the strong bond with aesthetic appearance on the end-product.

Automatic Self-Adhesive Label Applicator

Automatic self-adhesive label applicator-Picture Courtesy:Result Group

This is also known as pressure- sensitive label applicator by utilizing this machine. The equipment offers sticky back label that us bond on the product using high pressure. This machine is used for labelling with various shapes and size of products e.g., flat or curved surfaces. The packaging material can be glass, plastic, tin, or paper.

Automatic Hot Melt Glue Label Applicator

Automatic hot melt glue label applicator-Picture Courtesy:Cawone

This machine utilizes thermoplastic hot glue that melts upon providing high temperature and applied a thin layer of glue is on the label and pressed over the product. Upon application, label cools down and form a bond with the object upon solidification.

BASED ON TYPE OF PACKAGING MATERIAL

Automatic label applicator is categorized into the following sub-types depending on type of the labelling material such as:

Bag Label Applicator

For packaging, there are various types of bags available that are either made up of plastic, paper, or fabric. An automatic labelling machine is designed to apply label on filled bags or empty bags effectively before the process of palletization. This machine is ideal for offering different orientation labels on different packaging materials such as flat bags, stand-up pouches, paper bags, and zipper bags, with top and bottom labels, size labels, with high precision with no chances of skewing or wrinkling.

Automatic Carton Label Applicator

Automatic carton label applicator-Picture Courtesy:Methew

This machine is designed to apply labels on cartons or boxes on its various sides such as corners or adjacent sides of the box and is well suited for high-speed production lines. This machine carried a broad selection of labelling marking, and applying ensuring products are lined up with right labelling machine and labels can stay firm throughout the shipment and cleared, readable and scannable.

Automatic Flat/Square/Hexagonal Bottle Label Applicator

Automatic flat bottle label applicator

An automatic bottle label applicator is featured with high-sensors offering improved stability and no-error operability for smooth applications of labels on bottles having flat, square, hexagonal round shapes and various sizes. This machine is highly recommended in companies associated with the manufacturing of pharmaceutical medicines, nutraceuticals supplements, food and beverages etc., This is available in various automations such as semi-automatic, digital, and automatic machine.

BASED ON DESIGN

An automatic label applicator machine is a versatile addition in the packaging world to ease the tasks. Moreover, the machine is hooked to different designs, so user can pick them up to their requirements, Such as:

Linear Automatic Label Applicator

Linear automatic label applicator-Picture Courtesy:Vpack

This machine is accompanied by a linear structure that can facilitate your functioning of labeling in a straight or linear fashion. This machine is a simple that works with the help of conveyor to integrate this tool with other equipment of the production line. The machine offers straight-forward entrance of packaging products and dispense them once they’re applied with labels. Products likes, bottles, jars, cans, boxes, containers, and other relevant material can be subjected to this machine where they infeed and discharge by following linear pathway. This machine is high speed, very accurate, and stable performance, and look elegant in appearance.

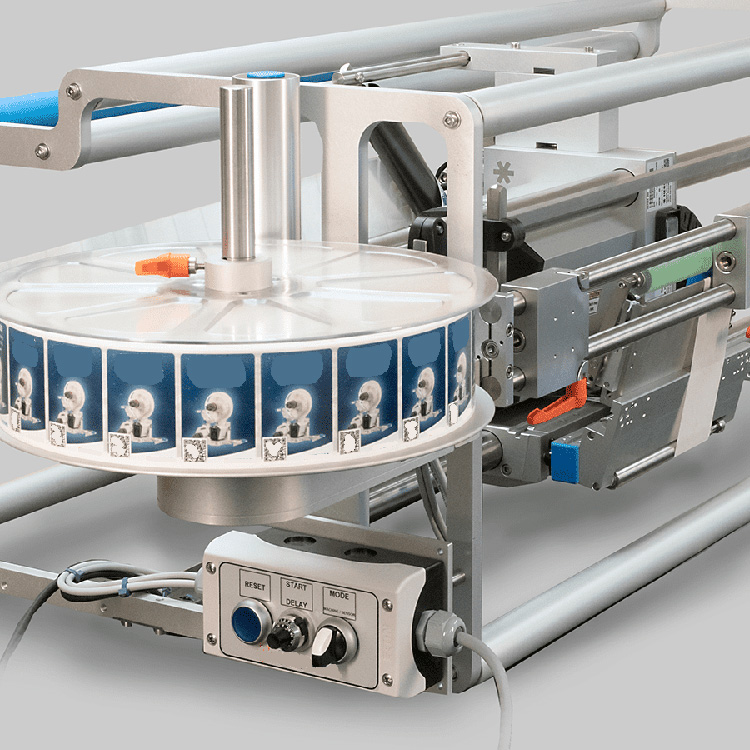

Rotary Label Applicator

Rotary label applicator-Picture Courtesy:Quadrel

This machine is composed in structure where a rotatory table circulates around the central axis where infeed of products are subjected into the loading platform; upon spinning the rotary table, products like bottles, cans, or jars, etc rotates gently and applied with labels respectively. The rotary label applicator is fastest solution of attaining labelling tasks, that’s why this machine has major applications in factories like pharmaceuticals, nutraceuticals, food, or any other company offering a bulk business.

BASED ON LABELING SURFACE

Choosing a labeling applicator is a tricky job; this is because every product has different packaging shapes, surface. Though, you can’t use single machine or a label applicator for every product. On the basis of labelling surface, the labelling applicators are divided into the following:

Automatic Three Roller Positioning Label Applicator

This machine is featured with three rollers that help in placing of label over the product. The presence of three rollers assures you that each placement of label is positioned accurately without chances of misallocation or wrinkling. This machine is useful in applying labels on products with cylinder, elongated or circular shaped such as jars containers, bottles.,

Flat Top Label Applicator

Flat top label applicator-Picture Courtesy:SZHX

This machine is designed to apply label on the packaging products with slight curved shape or just flat in nature. Such as cartons, trays, or other products. This machine is used to place label for emerging your brand, conveying messages such as barcoding or relevant information e.g. date of manufacture, date of expiration, etc.

BASED ON LABELLING ORIENTATION

There are two types of labelling applicators that are specifically designed for applying labels on the products, respectively.

Vertical Automatic Label Applicator

Vertical automatic label applicator-Picture Courtesy:CTMLAB

This machine is excellent when it comes to applying labels on the vertical side of the packaging product such as jars, bottles, lipsticks, mascaras ampoules, or container with prominent vertical or elongated area. A vertical automatic label applicator is particularly useful equipment in attaining an accurate, even, and smooth displaying of label positioning the vertical surface. This machine has importance in food pharmaceutical, chemical, automotive and other relevant factories.

Horizontal Automatic Label Applicator

Horizontal automatic label applicator-Picture Courtesy:Herma

There are various packaging products are designed with a prime horizontal surface area such as cartons, boxes, flat trays etc., For those products, a horizontal automatic label applicator machine is applied as it can apply labels over the top surface of the packaging and assure you an accurate and the best result via sticking them on the horizontal plane for cleared aesthetic and visual friendly labels to display.

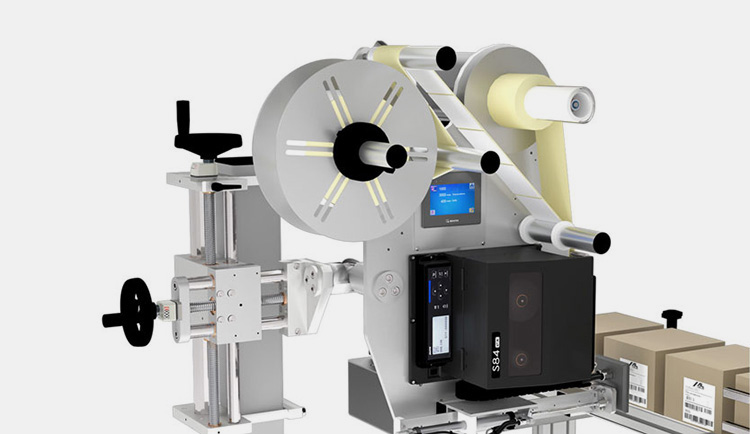

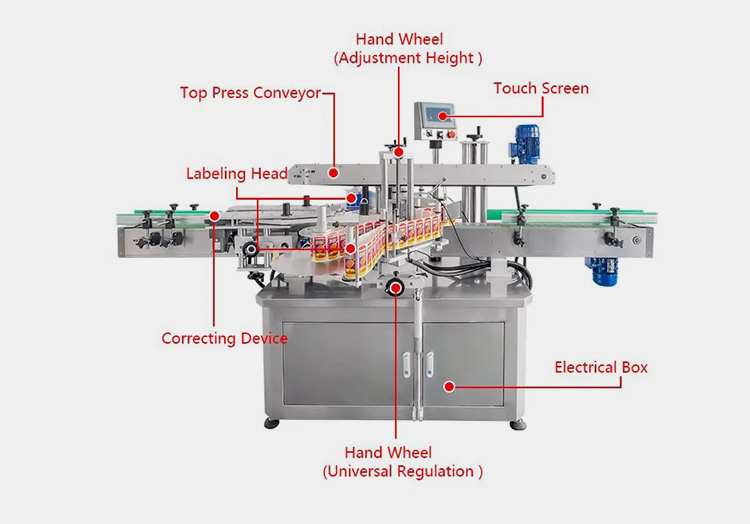

6.What are parts of Automatic Label Applicator?

| Hand Wheel for Adjustment

Height |

This unit is helpful in the adjustment of vertical label head label applicator facilitates the setting of various shapes and sizes of containers, bottles, jars, etc for proper positioning of the label. |

| Top Press Conveyor | A top press conveyor helps in the alignment of packaging products to remain stable and steady correctly for the application of labels over their surface. This unit plays an important role when the product is flat or with a curved surface. |

| Touch Screen | This unit works as the brain of the machine that offers visualizing, integrating, interpreting, and notifying messages on the screen. Plus, you can feed in data by touching keys available on the screen for operating and helps in troubleshooting the common problem. |

| Labeling Head | A labeling head is an important part that helps in the adjustment of labels for smooth processing. Once you fix the label roll, it can ensure applications via air-blow, wipe-on, or pressure-sensitive mechanism for sticking on the product accurately and precisely. |

| Correcting Devices | Correcting unit ensures the accurate positioning of the label with the help of proper alignment, guiding of bottles/containers, and sensors. The prime purpose of this unit is to protect the misalignment of the labelling product. |

| Electrical Box | An automatic label applicator is equipped with an electrical box that holds various important electrical components such as plugs, switches, relays, electrical drivers etc to control and run the machine. |

| Hand Wheel Universal

Regulation |

This is also a manual regulator where it is adjusted according to the size and shape packaging material. You can regulate this unit depending on the orientation of the label head. |

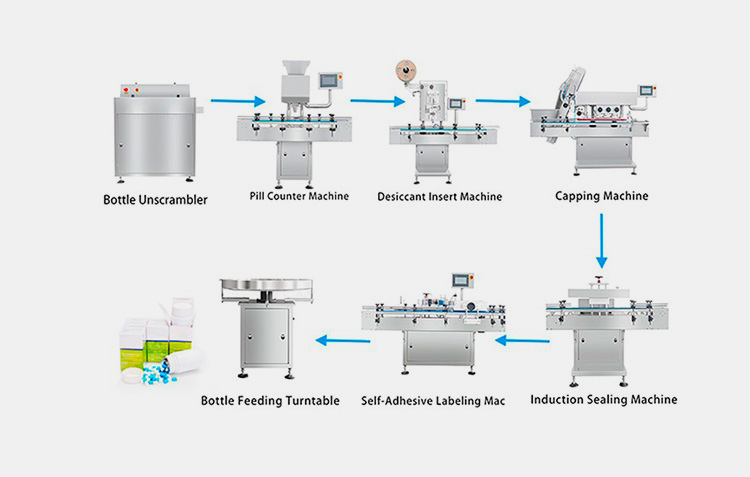

7.What is the Production line of Automatic Label Applicator?

The first impression is the packaging of the product and the foremost key player in marketing is its label. Labeling machines are highly competitive tools among industries to make their product presentable. These machines can be used for the same purpose in a wide range of use for both large and small enterprises.

| Bottle Unscrambler

|

Bottle unscrambler receives the bulk of containers in random positions inside the large hopper to hold thousands of bottles. These containers are aligned in a standing position upon the conveyor system to be filled, sealed and labelled easily. The speed of the bottle unscrambler is faster and can easily attach within the production line. |

| Counting And Filling Machine

|

A counting machine and filling is an assembled and versatile system based on the vibrational motor for counting pills accurately. It is a highly reliable machine for high bulk processing with less human exposure. This machine is programmed to alert broken particles during counting and filling with less than a 1% of chance of error and a 99% of accuracy rate. |

| Desiccant Inserting Machine

|

These machines are highly significant in industries like pharmaceuticals, cosmeceuticals and nutraceuticals. It helps to secure the products from moisture, volatiles and odour from dryness and extend their shelf life. |

| Capping Machine

|

Capping machines are highly automated to secure filled containers or bottles by using dual servo motors to seal without damaging the bottles. These machines can be easily operated and installed within the setup of the production line. |

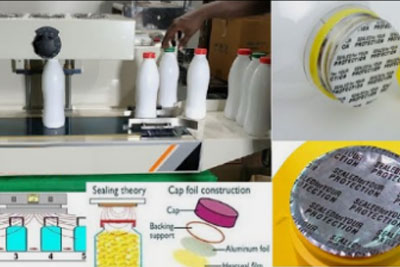

| Induction Cap Sealing Machine

|

Induction cap sealing machines can enhance production speed with high throughput rate to maintain the quality of the product. These machines are programmed with precise heating even in small areas for pinpoint sealing. |

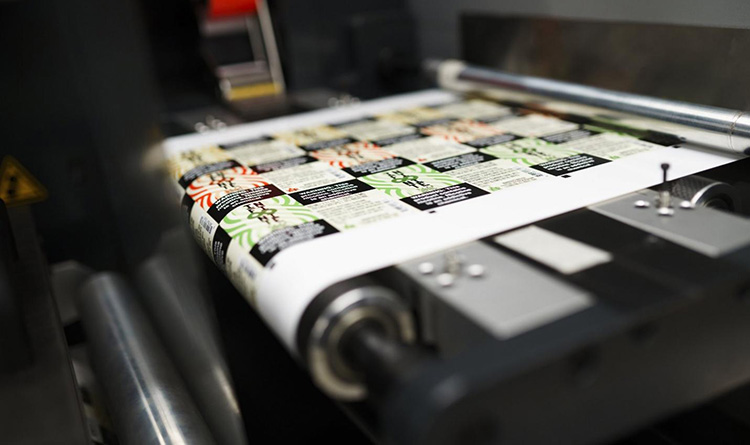

| Automatic Labelling Applicator

|

These machines are highly automated with advanced technology for labelling products with low cost and quality assurance. it has specialised applicators along with rollers to apply adhesive printed labels horizontally or vertically. Their working efficiency ranges from thousands of bottles per hour. |

8.What are the General Problems and Solutions of Automatic Label Applicator?

If you’re running with any problem during label applicator procedure, the discuss below guideline would help you to solve the issues.

LABELS CURLING AWAY FROM CONTAINER

| Possible Cause | Troubleshoot | Picture |

| This could be caused when a quantity of adhesive is too much.

Insufficient roller compression over stick labels. The container surface might be wet/humid. |

Regulate the meter blades to allow the optimum amount of adhesives.

Use clean wipers and sufficient pressure to stick the label properly. The surface of the container must be dried so labels can be glued evenly. |

|

WRINKLING OR BLISTERING OF LABELS

| Possible Cause | Troubleshoot | Picture |

| The wrinkling or blistering could occur if the concentration of the glue or adhesives are too much.

If the surface of the label is grain. Incomplete coverage of the adhesive. The surface of the bottles/containers are wet. |

Meter blade of the equipment is useful in the adjustment or regulating the amount of glue or adhesive. So, it should be controlled.

Ensure if the glue coverage is completed and evenly distributed. Blistering can be cause when surface is humid so it must be cleaned and dry for proper application of the labels. |

|

FAILURE TO PICK LABELS OUT OF HEAD

| Possible Cause | Troubleshoot | Picture |

| This is the common problem caused when loading head is gripping label tightly.

Threading term is used to adjust the alignment of the label in the machine is sometime too fixed or tight. |

For this problem, you must loosen the labels gripping by re-apply them and run the test again. |  |

LABELS TEARING IN MACHINE

| Possible Cause | Troubleshoot | Picture |

| This problem can be arisen due to building of adhesive on the labelling unit. Also, low tear resistant label is used. | Clean up the glue and re-asses the labelling unit. Plus, try fresh adhesive and identify right tear resistant paper/label. |  |

9.What to Look for Purchasing a Right Automatic Label Applicator?

Now matter how rapid and efficient your filling, capping, induction sealing production unit is, your overall productivity would be limited if you’re facing problem in adding right automatic label applicator for packaging them. So, read below guides, that must be highlighted when purchasing the machine.

Determine Efficiency

You must start securitizing the machine after determining your required efficiency and assess the capability of the machine to deal with. If you’re adding semi-automatic, or modular label applicator, it will give hundreds of bottles per hour in a cost-economical way. This is good for moderate production. However, an automatic machine is a little expensive but can yield thousands of bottles/hour allowing you to hit large outcomes with justified investment.

Evaluating Your Setup

Before making the final purchase, assess the setup you want to plan and determine the significance of the machine in your line. Also, evaluate the chances of downtime and management to run the system flexibly.

Quality

How accurate the machine will give the result? The purchase machine should be faster and more accurate in term of application over various shapes, and sizes of a container with reduced changeover time would be beneficial for you.

Space and Equipment

Determine the size of equipment that must be best fit to the size of installation space for easy accessibility. Adjusting a large automatic label applicator in a compact and congested room would affect the efficiency of the production line. Your manufacturer/supplier may help you in this matter by recommending the right size equipment for overall production design.

Container and Label Considerations

For labeling perfectly, you must know the type of container subjected to the procedure. Whether you’re using glass, aluminum, plastic material, and what surface for the labeling application you’re planning for. Moreover, you must determine about unusual shape taper that machine can properly affix with distinct dimension. For this purpose, you can decide right machines such as front-back label applicator, wrap-around, or vertical, or horizontal etc.,

Choosing a Machine Partner

Automatic label applicator-Picture Courtesy:Packaging Machine

Choosing the right machine partner for your production line will depend more on than the machine itself. Because when buying a machine from a reliable supplier will also begin the new journey to growing relationship with that company. Your selected company must be reliable, competitive, and promising in the term of equipment, and guidance, and offer good types of machinery in your budget.

Conclusion

A high-quality automatic label applicator must be a prime goal of every company. To invest better can support your business for long term, an automatic label applicator is a versatile addition that can offer labeling with boosting your business via excellent aesthetic and branding. Allpack is the name best known for offering modern labeling technology with tremendous customer service. Today, we have stepped the labelling industry in up to the high level by easy to use and cost-economical machines. Want to purchase? Send us message for Quick Response!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide