Automatic High Speed Bottle Unscrambler: The Complete Buying Guide In 2024

In a world where only change is constant, technology is surpassing all the conventional means of industrial processing including manual filling, packaging, mobilization and much more. Now, whether you are running any liquid production firm in pharmaceutical field or food sector, chemical sphere or cosmetic zone, cutting edge equipment are available to address your problems regarding uplifting your production and convenience.

Among them, automatic high speed bottle unscrambler is one of the topnotch machines with the ability to revolutionize your existing manufacturing by replacing manual labor with advance automatic bottle feeding functioning. In this way, you can get dual benefits of cost reduction and superior output. If you want to take advantage of its resilience and speedy performance with simple maintenance, make sure to know all about automatic high speed bottle unscrambler by absorbing this review. Let's take a start and explore the information provided below!

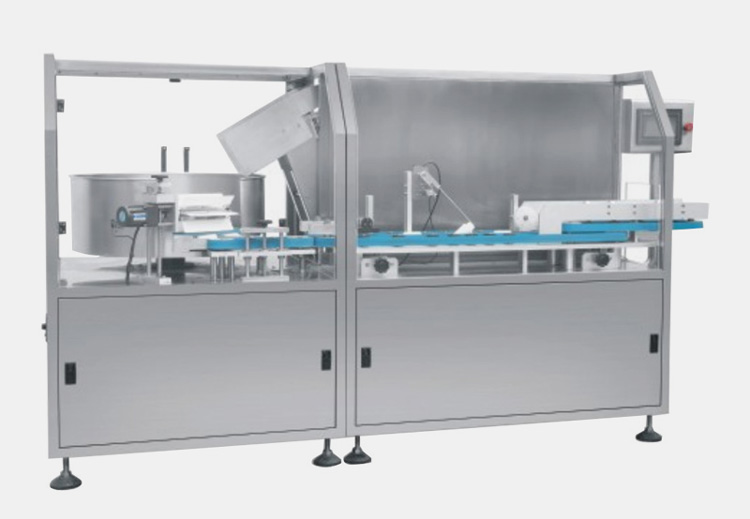

1.What Is An Automatic High Speed Bottle Unscrambler?

An automatic high speed bottle unscrambler is a machine designed to innovate the industrial processing by automating unscrambling of bottles. It works through systematic process of taking randomly positioned bottles from hopper and feeding them onto conveyor belt in a serialized manner while ensuring accuracy and efficiency.

Made with quality stainless steel the machine is highly compact and durable for processing bulk containers at once. In addition, the feature of adaptability and precision is adding more to its suitablility for all kinds of plastic and non-fragile bottles in a variety of shapes and sizes. Furthermore, the device is more desirable for large scale industries for fostering hassle-free bottle handling replacement of labor.

2.What Are The Benefits Of Using An Automatic High Speed Bottle Unscrambler?

Automatic high speed bottle unscrambler carries along with it vast array of benefits which can not only increase your production volume but also show great versatility in terms of applicability. Some of these features are as follows:

High Level of Automation

One of the key attributes of the machine is high level of automation it possesses. For instance, the bottle spreading, turning, transmission, positioning and detection are all done by machine automatically. This eventually reduces the time spent on manual feeding of bottles and leads to fast processing.

Resilience

This renowned machine is highly resilient for processing all and sundry bottles in terms of shapes, sizes and material. In addition, flat, square, round and special shaped bottles can be easily unscrambled by it.

User-friendly

With simple structure, scientific control system, and automatic nature, the machine has fixed setting in advance. Thus, it requires minimal training for execution and espouses uncomplicated method of operation.

High Speed

Another and most crucial benefit of automatic high speed bottle uncrambler is its speed proficiency. The automatic dispersal of bottles speeds up the process by feeding over 150 bottles in a minute, eventually, uplifting the production outcome.

Ensures safety

With integrated features of utility model and soft handling the machine ensures bottles's safety by keeping their integrity.

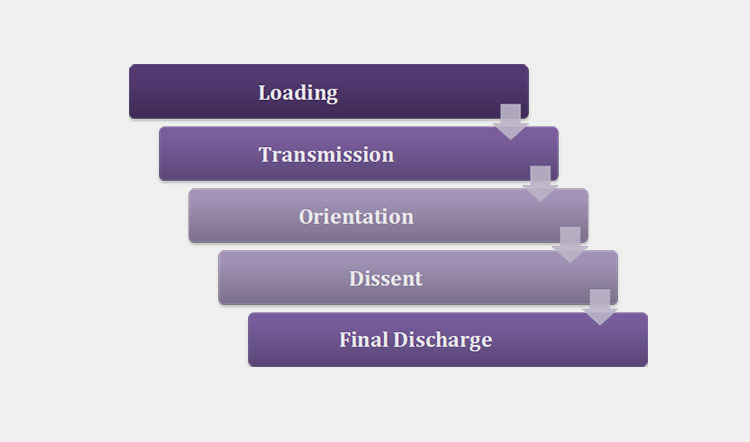

3.How An Automatic High Speed Bottle Unscrambler Works?

The machine’s course of action is quite simple and undemanding. By looking into the underlying steps, you will easily get how an automatic high speed bottle unscrambler works:

Loading

The process of unscrambling begins with loading bulk of empty bottles into hopper.

Transmission

Picture Courtesy: HO-MA

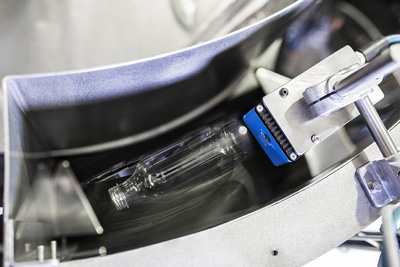

Now, with the help of exit conveyor, bottles are swiftly taken from storage hopper and transmitted into the unscrambling station.

Orientation

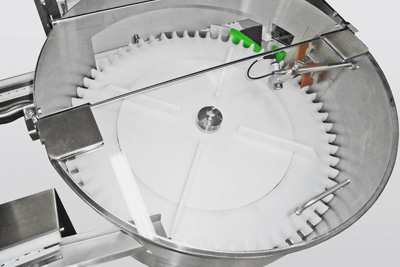

The bottles spread over the turntable, whose constant rotation enable them to fill the hollow molds. At this point, bottles are oriented through aligner and agitator.

Descent

Picture Courtesy: TRAKTECK

Once the bottles are accurately positioned, they will be moved forward in an upright position through moving disc. Meanwhile, bottles will be released from molds by a steel bar which works as barrier and align the bottles to move in linear direction.

Final Discharge

Picture Courtesy: TRAKTECH

Finally, the bottles will be delivered to conveyor belt in serialized manner with the help of vacuum.

4.Describe The Various Components Which Make Up An Automatic High Speed Bottle Unscrambler?

An automatic high speed bottle uncrambler is made up of several key components which are described below:

Hopper

Hopper is a hollow container where bulk of bottles is poured before unscrambling, to feed the machine with bottles. It is connected with exit conveyor which accomplish the task of transporting empty bottles by carrying them in portions.

Unscrambler Station

It is a large circular station made up of stainless steel where the unscrambling of bottles occurs. It holds inside it the distributor disk, molds, agitator, and turntable channel which collectively move the bottles and align them in right position.

Distributor Disk

Distributor disk is a round turntable located inside the unscrambling station with series of plastic molds in its border. Its function is to orient the bottles’ positioning by constant revolution.

Molds

Molds are empty holes present in series of form at the end of distributor disk. They help in holding empty bottles or containers.

Air Blower

A type of fan that is located right above the distributor disk whose constant revolution causes air blow thus prevent bottles jamming.

Agitator

Steel agitator is attached to the unscrambler station which change the direction of positioned bottles towards conveyor.

Conveyor

It takes the oriented bottles from unscrambler funnel and transports them towards further processing.

PLC Control System

It is considered as the brain of an automatic high speed bottle unscramble which control the entire processing of machine. Through attached HMI, user interacts with machine and communicates the desired commands to control system.

Electric Cabinet

Electric cabinet is the powerhouse of the machine which protects electrical wires and other equipment by preventing electric shocks.

Protector

Protector is the glass cover around the machine which is useful in providing safe and dust proof environment for processing.

Main Frame

Main frame of the machine is compact and durable made up of stainless steel. It is the supportive device for machine which prevent shaking and allow stable performance during operation.

Movable Casters

Wheels are usable for easy transportation of machine from one place to another.

5.Which Kind Of Bottles Can Be Processed By An Automatic High Speed Bottle Unscrambler?

An automatic high speed bottle unscrambler is capable of processing large number of bottles with respect to different sizes, shapes as well as material such as:

With respect to size

Bottles with diameter of φ20~φ100mm and height from 40~240mm can be easily unscrambled by using this machine.

With respect to Shape

All shapes of bottles including flat, square, oval, rectangle, round and irregular bottles are perfectly eligible to be processed by the machine.

With respect to Material

An automatic high speed bottle unscrambler is the best suitable for feeding all sorts of plastic and metallic bottles comprising PET, PE, PVC, HDPE, aluminum and steel respectively.

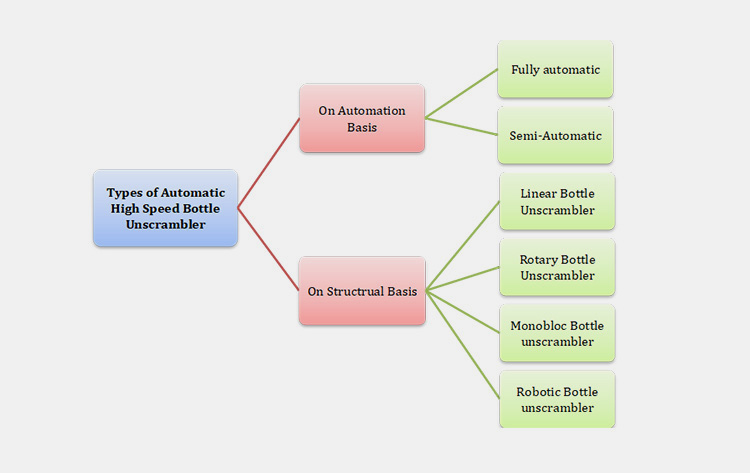

6.What Are The bottle unscramble Types Of Automatic High Speed Bottle Unscrambler?

An automatic high speed bottle unscramble can be classified into two broad categories. This division will make you enable to understand the potential nature of the machine. They are as under:

Fully Automatic Bottle Unscrambler

Picture Courtesy: CVC

Fully automatic bottle unscrambler is heavy-duty cutting edge equipment with superior quality stainless steel construction that independently carries out entire process of bottle unscrambling. With high speed, it has the potential to process highest possible number of 150 pieces per minute through self operated mechanism. Whether round or square, flat or irregular, the machine can feed flexible range of PET, HDPE, and PP bottles. This makes the machine appealing for almost all industrial sectors encompassing food, beverage, medical, cosmetic and other enterprises.

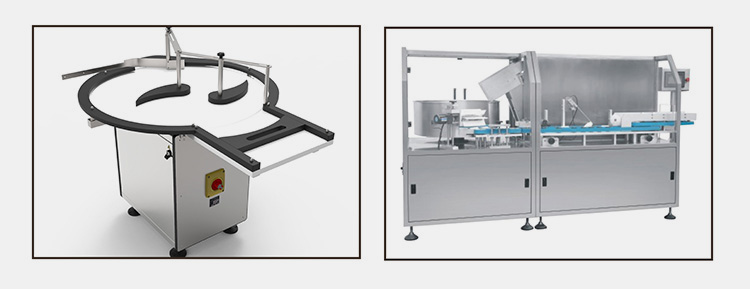

Semi-Automatic Bottle Unscrambler

Semi-automatic bottle unscrambler on the other hand requires minimal intervention of the user to feed turntable with empty bottles. However, the process is then automatically preceded via machine. It produces relatively less outcome as compared to fully automatic machine. Its precise and simple body leads to convenient handling and easy mobilization of the machine. Industries running small to medium capacity under 5000 BPH are likely to be benefited by this solution.

Automatic Linear Bottle Unscrambler

Picture Courtesy: KWT Machine System

Automatic linear bottle unscrambler is employed to handle the wide range of plastic bottles inclucing cylindrical, square and rectangular containers into production line. It is well known for its fast adaptation to different bottles without changing tools. It functions through centrifugal disc on which bottles are supplied and oriented with fast pace. Hence, it suits the need of producers from diverse sectors such as oil and lubricants, cooking oil, and beverage industry etc.

Automatic Rotary Bottle Unscrambler

Picture Courtesy: TRAKTECK

Rotary bottle unscrambler is highly proficient in its task of unscrambling bottles with height from H 50-300mm and diameters from D 25-90mm. The machine uses high pressure blowing fan for bottle orientation, thus reduces high energy cost spent on compressed air. The ingenious funnel system enable simple and fast changeover resulting in production of 12,000 bottles per hour, unfolding 40% increase in its efficiency. The machine is well-equipped to comply all the demands of food, non-food and personal hygiene enterprises.

Automatic Monobloc Bottle Unscrambler/Rinser

Monobloc bottle unscrambler is the composition of two equipment, designed for performing the task of rinsing and unscrambling bottles before they reach to production line for filling. This complex solution aims at facilitating the firms which are highly sensitive in terms of maintaining the hygiene in their processing such as pharmaceutical, surgical and food sectors. In addition, the unified management followed by high productivity and easy maintenance are making the machine cost-effective.

Robotic Bottle Unscrambler

TRAKTECH

As the name indicates, this advance and innovate bottle unscramble works by intelligent robotic system. The robot picks and places bottles by means of vacuum gripper. The robotic picking line mechanism is achieved by using detection system. This feature makes the area of machine more comprehensive where all types of plastic bottles can be positioned accurately irrespective of their size and shape. It is more suitable for pharmaceutical, daily chemicals, and cosmetic industries.

7.How An Automatic High Speed Bottle Unscrambler Is Different From Semi-Automatic Bottle Unscrambler?

There are certain differences between automatic high speed bottle unscrambler and semi-automatic bottle unscrambler which may be clearly understood by looking into the table below:

| No | Features | Automatic High Speed Bottle Unscrambler | Semi-Automatic Bottle Unscrambler |

| 1 | Automation | Highly Automated, independent in processing | Semi-automatic, requires user intervention |

| 2 | Structure | Complex with different components | Relatively simple |

| 3 | Speed and Capacity | 18,000 bph | 5000 bph |

| 4 | Bottle Range | Multi-format no parts changeover required | May require change of tool for different bottles |

| 5 | Application | Large scale production line | Medium to small businesses |

8.Enlist The Applications Of An Automatic High Speed Bottle Unscrambler?

This machine can be utilized in huge number of industries which are shown below:

Pharmaceutical Industry

It must not be surprising to say, that pharmaceutical industry will always be on the top of the list whenever the question arises about uses of an automatic high speed bottle unscrambler. It implies that, pharmaceutical industries from all over the world are taking advantage of this machine for processing tablets, pills, vaccines and syrups etc.

Chemical Industry

The machine also suits need of chemical industry where it is used for fulfilling their job of processing daily chemicals such as detergents, surface cleaners and other organic and non-organic chemicals.

Cosmetic Industry

Another industry, which is constantly engaged in the production and filling of lotion, shampoo, hand wash and other items into bottles also requires advance equipment. Therefore, an automatic high speed bottle unscrambler becomes an undeniable need for it.

Beverage Industry

All types of beverages including juices, wine, soft drinks and fresh pulp have non-stop consumption; consequently, industries are looking forward for efficient solutions. Here comes the need for automated liquid filling lines of which the automatic high speed bottle unscrambler is an inevitable part.

Food Industry

Like other firms, food industry is also involved in food supply chain where much emphasize is made on on ready-made food. Hence, this sector is also included in the broad spectrum of automatic high speed bottle unscrambler application for using it to accomplish the processing of products like ketchup, honey, sauces, edible oil etc.

9.Which Measures Can Be Taken To Maintain The Efficacy Of An Automatic High Speed Bottle Unscrambler?

Even though an automatic high speed bottle unscrambler is in itself a complete solution for undertaking bottle unscrambling, certain steps must be taken in order to keep it on right track and achieve maximum output. These are highlighted below:

Regular Maintenance

Before starting operation, remember to check the power connection of machine, also check the screws if they are loose and need to be tightened. Along with that, you may be required to check and reset the functional parameters of machine as per your daily need of production.

Lubrication

Lubrication of machine is essential to avoid friction and jam of machine parts. Therefore, the movable parts should be well lubricated to achieve faster and smooth performance of machine.

Proper Cleaning

Air rinser, compressed air and a dry soft cloth can be used to clean and wipe out all the dirt and dust of machine. It eventually helps in providing secure environment for bottles to process by eliminating the possible toxins released during continuous movement of PET bottles.

Timely Parts Renewing

It is important to monitor each part of machine before and during operation. In case of finding any abnormality or irregular noise, make sure timely renewability of parts as it may impact the overall performance of machine.

10.Can Automatic High Speed Bottle Unscrambler Be Integrated With Other Machines?

Automatic high speed bottle unscrambler can be easily integrated with other machines to make production lines for processing liquids, solids and other stuff. These machines include:,

Labeling machine

Labeling machine is a device used to apply adhesive stickers or labels over the empty or filled bottles of different sizes. Most of the industries prefer to integrate automatic high speed bottle unscrambler directly with labeling machine, while others may opt for a liquid or powder filling machine to be connected with it before labeling.

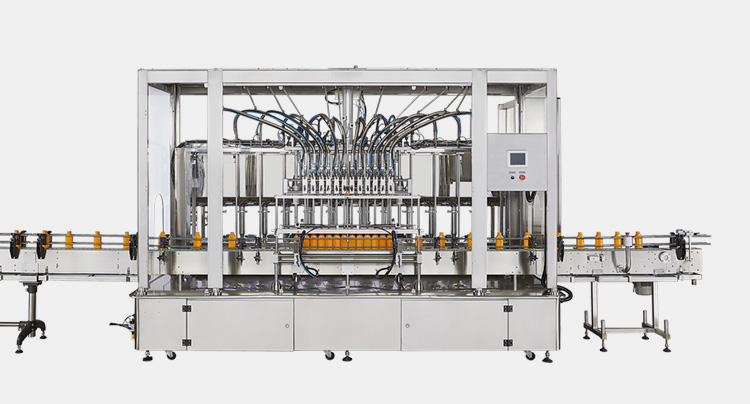

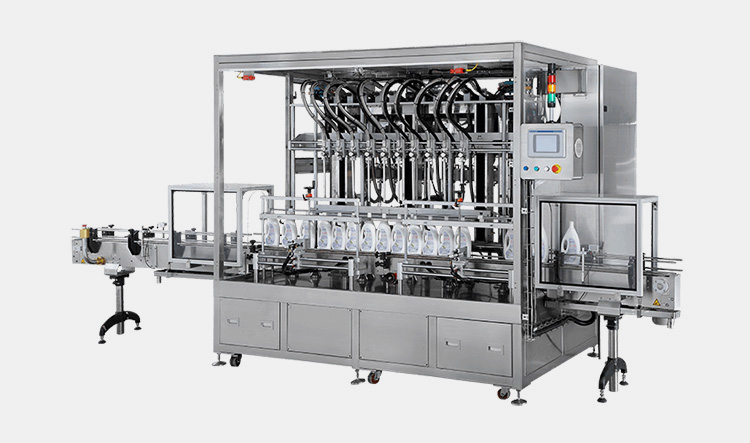

Liquid Filling Machine

Picture Courtesy: KWT Machine System

Liquid filling machine is used to fill the bottles and containers with precise amount of liquid. It is therefore, connected with automatic high speed bottle unscrambler for the ease of operation in producing large volumes.

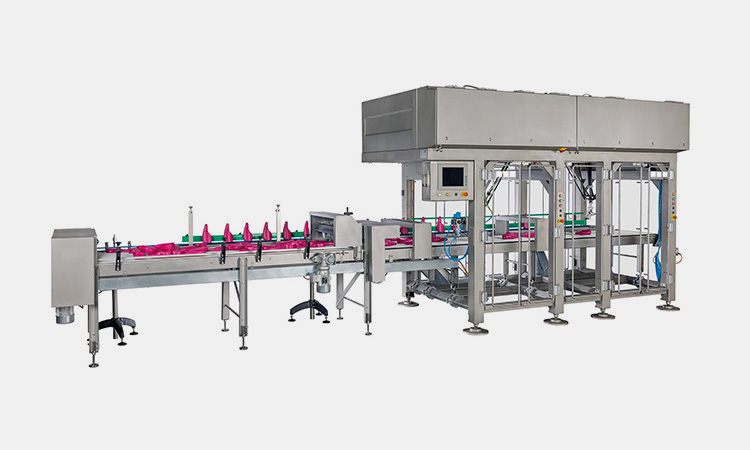

Powder Filling Machine

Picture Courtesy: CVC Technologies

Products such as milk powder, medicine powder and condimentsetc., require advance technology to be filled in bottles and containers. For this purpose, powder filling machine has been introduced and to automate the process, automatic high speed bottle unscrambler is all time appreciated.

Tablet Counting Machine

Picture Courtesy: King

The machine can also be linked with tablet counting machine which is responsible for counting tablets, pills and capsules in bottles.

Bottle Capping Machine

Picture Courtesy: Bellartx

This machine is designed to cover the filled bottles with caps through technology. Hence, it is eligible to be included in the production line of which automatic high speed bottle unscrambler is already part.

Induction Sealer

Induction sealer is one of the key equipment when dealing with liquid or solid packaging in bottles. By using electromagnetic radiation, this machine tightly seals the bottles neck with aluminum foil which get stuck to the bottleneck when heated. It thus prevents inside content from harmful ultraviolet rays and humidity.

11.Elicit The Solutions To Common Problems Encountered While Using An Automatic High Speed Bottle Unscrambler?

While using an automatic high speed bottle unscrambler you may encounter minor issues which if not eliminated can create barrier in your way towards successful processing. Therefore, few possible troubleshooting are discussed below for your ease:

| No | Problem | Cause | Solution | Picture |

| 1 | Bottles get chocked in mold | It happens when bottles are larger or smaller than adjustment of distributor disk | It can be solved by adjusting the height of distributor disk and width of outfeed unit |  |

| 2 | Bottle with mouth downward do not get rejected | There is insufficient air supply by air blower | Increase the blower supply |  |

| 3 | The distributor disk get stuck | It is due to friction or damaged gear | Lubricate the motor under disk and replace gear if damaged |  |

12.Which Factors Must Be Considered In Order To Purchase Topnotch Automatic High Speed Bottle Unscrambler?

Choosing the right machinery for your business is not an easy job. Therefore, we have gathered some of the crucial factors which if followed will definitely lead you to make a sound purchase of the best automatic high speed bottle unscramble. These include:

Production Volume

Firstly, make sure to have a look towards your existing production and answer certain questions including your current production and how much increase do you want to make by adding automatic high speed bottle unscramble. It will help you to decide which model do you need like fully automatic or semi-automatic.

Type of Bottles

Another factor to consider is the type of bottles you are using, as it will influence your processing. For example, linear bottle unscrambler can feed limited types of bottles, but if you have containers with different shapes and sizes, then rotary bottle unscrambler is best option.

Auxiliary Devices

It is a matter of fact, that you will need other supportive devices for automatic high speed bottle unscrambler such as bottle capping machine, induction sealer or labeling machine. Hence, it is significant to make a list of these machines, to complete the production line for your manufacturing.

Technical Assistance

From installation of machine to technical training of staff, the support of vendor is required in every initial step. This elicits the importance of technical assistance on part of manufacturer, hence; do not forget to satisfy yourself by looking into the remote support provided by seller.

Quality Assurance

While making such big purchase, you should at least get quality assurance confirmed by the supplier in form of warranty. Moreover, you can also go for examining the quality of machine in by checking its compliance with the regulations fixed by GMP, FDA and ISO.

Conclusion

An automatic high speed bottle unscrambler is becoming the obligatory machine for almost every industry. Without its use, the production efficiency of your firm will surely face certain challenges of time waste, labor cost and low output. Therefore, one must acknowledge its importance and take suitable decision on right time to make their business more productive, lucrative and effective, for which the only solution is an automatic high speed bottle unscrambler. If you are intending to go for it, feel free to approach us via given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours