Automatic Capsule Filler: The Complete Buying Guide in 2024

Did you know that automatic capsule filler is a gateway to a successful business? Hand capsule filling has given birth to modern automatic capsule fillers. This machine is equipped with cutting-edge technologies that fill capsules in no time. With automation and fast operating parts, it has become the need of industries, especially pharmaceutical and nutraceutical. Adding this device to your production, offers you exceptional results in terms of decreasing your operational expenses, giving you precision in every fill, and bringing you a high return on investment.

Let’s get an insight into every aspect of automatic capsule filler, from application to benefits, from working to parts, and so much more.

1.What Is Meant By Automatic Capsule Filler?

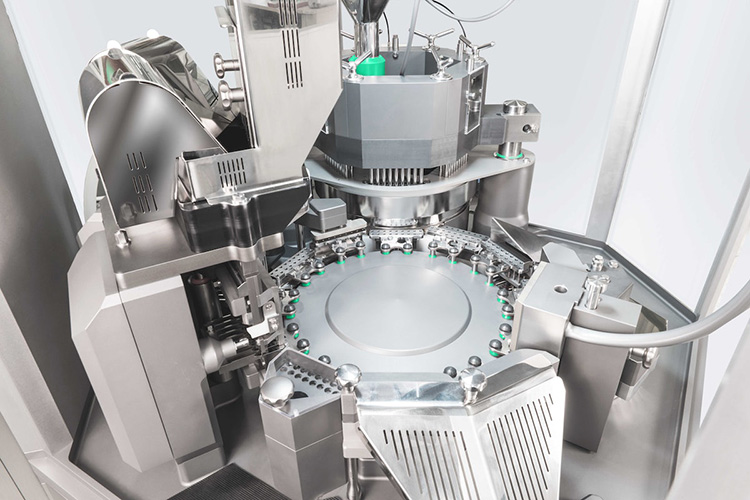

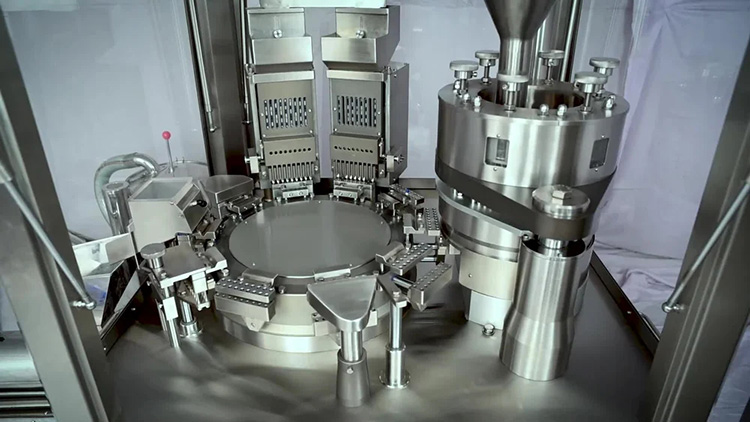

Automatic Capsule Filler- Picture Courtesy: Aipak Pharmaceuticals

It is a machine also called an automatic encapsulator or automatic capsule filling machine that performs autonomous filling of capsules. This machine comes with state-of-the-art gadgets and control systems that assist in performing every capsule filling operation like rectification, separation, capsule rejection, and capsule ejection itself.

Automatic capsule filler is an integral component of capsule manufacturing lines in the pharmaceutical, nutraceutical, and herbal industries. This instrument is essential in loading solid, semi-solid, and liquid, active drug ingredients inside one- and two-piece capsules. This machine automates production lines and fills more capsules in a relatively short period.

2.Why Automatic Capsule Filler Is Useful In Industries?

Automatic capsule filler is useful in different industries because it offers a wide range of benefits. Due to its automatic, it eliminates the chance of filling errors. Some of the handy benefits of automatic capsule filler are detailed below:

Easy to Operate

Easy to Operate Automatic Capsule Filler- Picture Courtesy: Aipak Pharmaceutical

The automatic capsule filler is customized with the latest and intuitive touchscreen display that makes it very easy to program and operate this equipment. Moreover, different data recipes are pre-saved in the processor, consequently, it is easier to adjust the machine setting with one swipe of a finger.

Accuracy in Fill

Precision in Automatic Capsule Filler- Picture Courtesy: Harro Höfliger

Powders are uniformly distributed inside the hopper which ascertains the accurate powder flow direction and unhindered flow. This results in accuracy in capsule filling. This accuracy is of immense importance in the pharmaceutical industry where perfect doses should be delivered to patients

Decrease Product Loss

Low Product Loss in Capsule Filling- Picture Courtesy: Harro Höfliger

This machine is equipped with high-tech control systems such as slide gates due to which product wastage is cut down. Moreover, the use of such technology also decreases drug dust generation, consequently increasing system safety.

Removal of Defective Capsules

Rejection of Faulty Capsules in Automatic Capsule Filler- Picture Courtesy: Oncology. tmz

Highly advanced sensors present in this machine aid in the detection of empty and non-separated capsules. These capsules are automatically removed from the system, resulting in superior-quality capsules. This in turn decreases the rate of product recall.

Lower Downtimes

Lower Downtime With Automatic Capsule Filler- Picture Courtesy: Healthcare Packaging

This machine is designed in such a way that is easily accessed and disassembled for instant maintenance, cleaning, and lubrication. Sometimes, automatic capsule filler is offered with a removable hopper that allows for quick wiping out of sticky powder or semi-solid residues.

3.In What Kind Of Industries Automatic Capsule Filler Has Found Its Use?

Automatic capsule filler is found in every industry that involves the loading of powdered or other types of ingredients inside a pod or capsule. A list of important industrial applications of automatic capsule filler is penned below:

Pharmaceutical Industry

Automatic Capsule Filler in Pharmaceutical Industry-Picture Courtesy: Mankind Pharma

No pharmaceutical industry is complete without automatic capsule filler. This machine fills a vast range of drug ingredients whether coarse or fibrous, gummy or fluffy inside the capsule with high precision both individually and in combination. Moreover, it has flexibility in filling gelatin, HPMC, starch, pullulan capsules, etc.

Nutraceutical Industry

Automatic Capsule Filler in Nutraceutical Industry- Picture Courtesy: News Medical

Different combinations of vitamins, minerals, and other supplements are possible because of the automatic capsule filler in the nutraceutical industry. The weight consistency of automatic capsule filler makes it popular among different nutraceutical manufacturers. Furthermore, a customized blend of various supplement materials is easily processed and filled inside a capsule in microseconds using this machine.

Herbal Industry

Automatic Capsule Filler in Herbal Industry-Picture Courtesy: Mednext Pharma

As different herbal formulations have varying densities, these herbal and Ayurvedic formulations require high tamping force for cylinder carat compression. Hence, manufacturers have designed a special type of automatic capsule filler to aid in this endeavor.

Food Industry

Coffee Capsule Pods-Picture Courtesy: Expert Review

A distinct kind of automatic capsule filler is employed in the food industry for packing capsules and pods with liquids, coffee, cocoa, coconut, coffee concentrate, tea powders, and milk powder. This machine also has a sealing station that seals the cups or capsule pods.

Cosmetic Industry

Automatic Capsule Filler in Cosmetic Industry-Picture Courtesy: Skincare.com

In the cosmetic industry, automatic capsule filler is employed for loading different skincare pastes, herbal masks, oils, fragrances, essences, skin polishes, dyes, etc. in capsules. This machine is also essential in the manufacturing of beauty pearls and bath bombs in the cosmetic industry.

Veterinary Industry

Automatic Capsule Filler in Veterinary Industry-Picture Courtesy: Daily News

Yes, automatic capsule filler has also found its use in the pet care industry. The health of pets is of huge concern, so manufacturers are using this equipment to create pet capsules to treat different diseases. Capsule is an effective way of medicating pets.

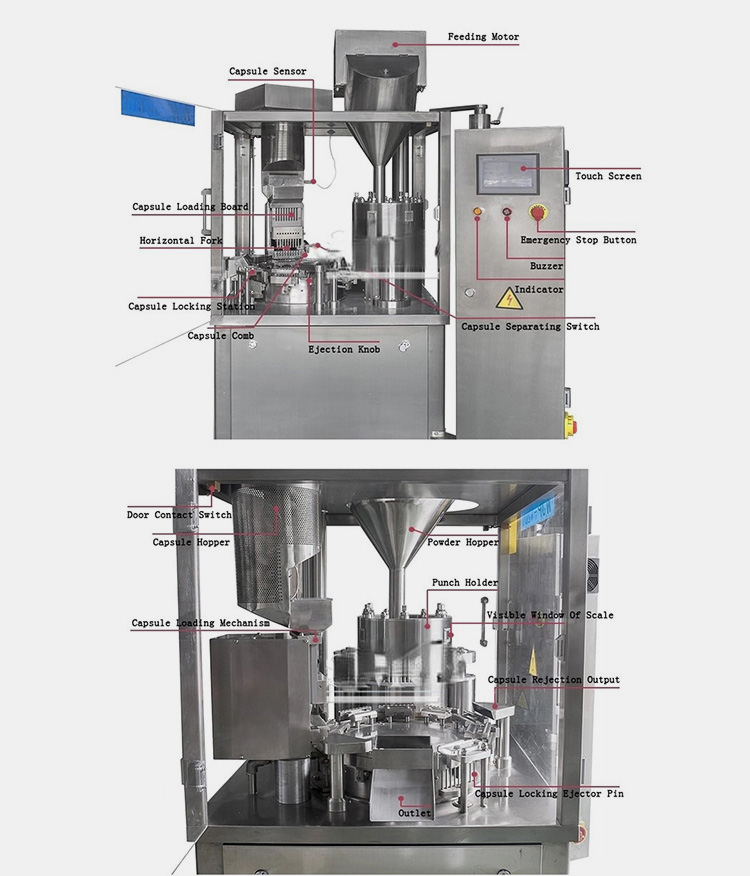

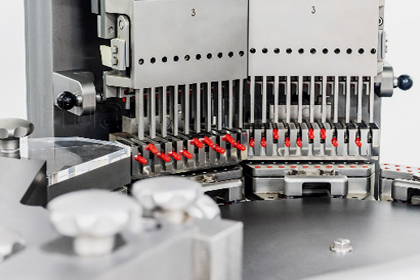

4.What Are The Basic Components Present In Automatic Capsule Filler?

Automatic capsule filler is a sophisticated system consisting of technologically advanced parts that have a specific part in the filling of capsules. A list of these components in automatic capsule filler is given below:

Parts of Automatic Capsule Filler-Picture Courtesy: Shanghai Medical

| Capsule Sensor | It is the highly sensitive parts that accurately monitor the level of empty capsules in the capsule hopper. It notifies the operators that the level of the capsule is below a threshold and to reload capsules in the hopper. |

| Capsule Loading Board | This is also called a capsule magazine and is responsible for correctly aligning capsules. This plays a vital role in capsule rectification. The magazine has several slots in which capsules are oriented in such a way that the capsule body is at the bottom while the cap is at the top. It is a way of ensuring that capsules are positioned correctly for separation. |

| Horizontal Fork | It is present between the capsule hopper and separation station and is comprised of two rows of pins that grab the capsules around the middle while the vertical fork positions them in right standing order. This component is essential in the rectification process. |

| Capsule Locking Station | After filling of capsules, the capsule locking station comes into play and locks two halves that are cap and body of the capsule together. It has different kinds of mechanical parts for instance cams and a lever that permanently joins two parts of the capsule together. At this station, upper and lower trays come in contact with each other to secure capsules. |

| Capsule Comb | It is the part that drives the separation of the capsule cap and body for filling. Moreover, it stops the stickiness of the capsules. |

| Ejection Knob | It is present at the periphery of automatic capsule filler and assists in the manual removal of defective and accurately filled capsules from the equipment. It also unblocks the jamming of capsules. It is a lever-like structure that forces capsules into the capsule outlet. |

| Capsule Separating Switch | This component is responsible for the separation of capsules. It detects the properly oriented capsules in the capsule separation unit and signals the start of capsule disjoining. |

| Indicator | It is like a feedback system and notifies the operator about the running status of the automatic capsule filler by lightning. It indicates errors as well as the correct working order of the machine. |

| Buzzer | It is a sound alarm that indicates the jamming or defect in the automatic capsule filler. Moreover, it could signal the filling of the capsule batch. |

| Emergency Stop Button | It is a knob or a switch that is pressed in case of electric incidents or fire hazards to immediately stop the machine without the need for a hard shutdown. |

| Touch Screen | It’s an intuitive display system where different operational parameters are input and adjusted. With the touch screen, it is easier to modify machine settings than pressing different buttons one by one. |

| Feeding Motor | It is present at the top of the powder hopper and is essential in powder flow from the hopper to the filling station. It provides a consistent supply of powders to the filling area. |

| Door Contact Switch | It is a safety mechanism that ensures the safety of the operator while the machine is running. Furthermore, it also decreases outside contamination of the capsules during filling. |

| Capsule Hopper | This is a conical-shaped hopper containing bulk quantities of capsules for the smooth filling operation. Typically, large loads of capsules are inserted in this hoper before the start of the machine run. |

| Capsule Loading Mechanism | It is also called loader assembly and consists of various components such as a magazine, push block, finger block, etc, It starts from the main shaft and extends to the separation unit. Through the cam loader, capsules go inside the magazine while the push block aligns them in the right position. The finger block forces the capsules into the upper segment. |

| Outlet | It is a chute in which capsules are transferred after successful filling and quality inspection. |

| Capsule Locking Ejector Pin | It is a tiny pin present at the capsule locking unit and assists in the removal of locked capsules from the automatic capsule filler by exerting pressure on the body of the capsules. |

| Capsule Rejection Output | This is the outlet or chute in which empty capsules, cracked, broken and defective capsules are placed. The rejection system of automatic capsule filler pushes these capsules into the rejection outlet. |

| Variable Window of Scale | It is a safety feature that allows the workforce to monitor the progress of capsule capsule-filling operations. |

| Punch Holder | It is a metallic device that compresses the powders inside the capsule. During capsule filling, the punch is lowered, and presses the powders inside the capsule body. |

| Powder Hopper | Before batch processing, operators usually place a significant quantity of powders in the powder hopper. Sometimes the powders are loaded inside the hopper by the pump system. A powder hopper is a cone-like structure present normally at the top of the equipment. |

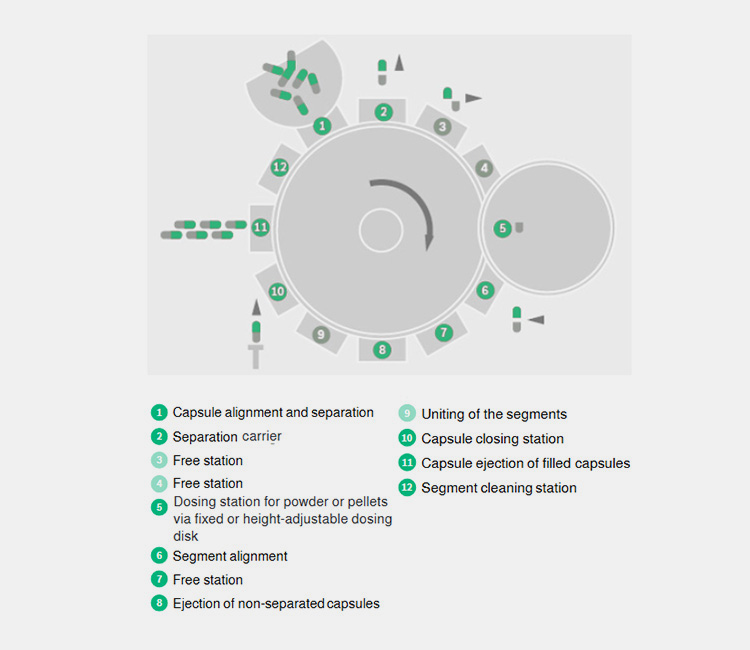

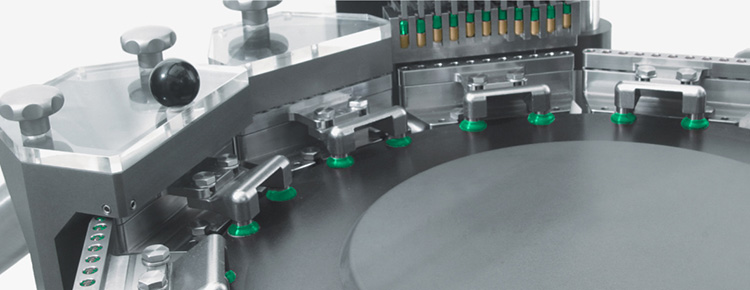

5.What Are The Working Steps Of Automatic Capsule Filler?

Working of Automatic Capsule Filler-Picture Courtesy: GKF Capsylon

The working of automatic capsule filler is divided into different automated and coordinated steps that occur with high precision for accuracy in capsule filling.

Loading of Starting Substances

Loading of Empty Capsule-Picture Courtesy: Harry Davis & Company

First, the bulk quantities of empty capsules and ingredients are placed inside their hoppers. From these hoppers, the empty capsules move to the capsule delivery plate while active ingredients go to a filling station.

Rectification of Intact Capsule

Rectification of Capsules in Automatic Capsule Filler-Picture Courtesy: GKF Capsylon

Since the empty capsules have intact caps and bodies, these parts must be first separated for capsule filling. Thus, for separation, the capsules are transported to capsule delivery plates with numerous slots for accommodating intact capsules.

Next from these slots, capsules freely fall on a horizontal fork that acts on the middle of the capsule body while at the same time, the vertical capsule aligns to fix their orientation consequently, the bodies of capsules are in a downward direction.

Separation of Capsule Parts

Separation of Capsules Parts-Picture Courtesy: Pharma Manager

In the next step, the capsule tray is transported to a separation station where capsules are separated by a vacuum divider. The divider system is lifted upward to separate caps from capsule bodies. In this way, the caps are left in the upper portion of the capsule tray while capsule bodies are in the lower part. Both these tray parts are then transported to their separate areas.

Filling Active Ingredients

Capsule Filling- Picture Courtesy: Aipak Pharmaeuticals

The body of the capsules runs towards the filling station where a quick adjustment measurement allows convenient setting for an optimized amount of active ingredient into each capsul. The filling procedure is based on simple filling rule where six filling rods automatically assists the filling. The unseparated or failed capsules are recycled automatically prior to reaching the filling station.

Locking of Capsules

Locking of Capsule-Picture Courtesy: Smpnutra

Rotation of upper and lower trays is done in synchronization to overlap the axis of trays. At this instant, the baffle plate located at the top of the capsule plate and the pin present at the bottom of the tray move for locking of capsules.

Capsule Ejection

Capsule Ejection Unit-Picture Courtesy: Gaoger Machinery

In the final step, the pin forces the locked capsule outside of the tray while compressed air propels the capsule into the collection outlet.

6.What Are Various Capsule Sizes Filled By Automatic Capsule Filler?

Automatic capsule filler is a versatile machine and can easily handle different capsule sizes with tooling changeover. It can fill 000-5 capsule sizes and also can fill safety capsule sizes in the range of A to E. Capsules between the size 000 to 0 are regarded as the largest capsule while capsules from 1-5 are considered as smallest.

Some important information about capsule size is:

| 000 Size

|

It is one of the largest available capsules with a length of about 26.1 mm. It can accommodate the heftiest dosage of about 1000 mg and can hold a volume of 1.37 ml. A teaspoon can hold three 000 sized capsules. |

| 00 Size

|

It is one of the most widely utilized capsule sizes and has a length of 23.4 mm. It can encapsulate 735 mg of dose with a volume of 0.91 ml. 5 ‘00’ sized capsules are loaded in one teaspoon. |

| 0 Size

|

It is the second most frequently used capsule size. This capsule size is in the range of 21.6 mm and can load 500 mg of drug dose having a volume of 0.68 ml. A teaspoon can have 7 of these capsules. |

| 1 Size

|

It is smaller with a length of 19.4 mm. This size can encapsulate an ingredient dose of 400 mg and a volume of 0.48. A teaspoon can contain 9 1-sized capsules. |

| 2 Size

|

It is widely used by the pharmaceutical industry but is not the preferred choice of the nutraceutical industry. It has a length of 17.6 mm and a holding dose of 0.36 ml. A teaspoon can fill 11 of these capsules. This size is perfect for small children and elderly people who face difficulty in swallowing medication. |

| 3 Size

|

It is not widely popular in the medicine industry because it holds a smaller volume of 0.27 ml. A teaspoon can carry about 15 of these capsules. It is used for treating small cats and dogs. |

| 4 Size

|

It is the second smallest capsule size and has a length of 14.3 mm. It can accommodate a volume of 0.2 ml. A single teaspoon can accommodate 20 four-sized capsules. |

| 5 Size

|

It is one of the smallest available capsule sizes in the market as denoted by the fact that a teaspoon can hold 35 of these capsules. It is usually used for giving a small trial dose of about 0.13 ml. |

7.What Are The Material Types Filled By Automatic Capsule Filler?

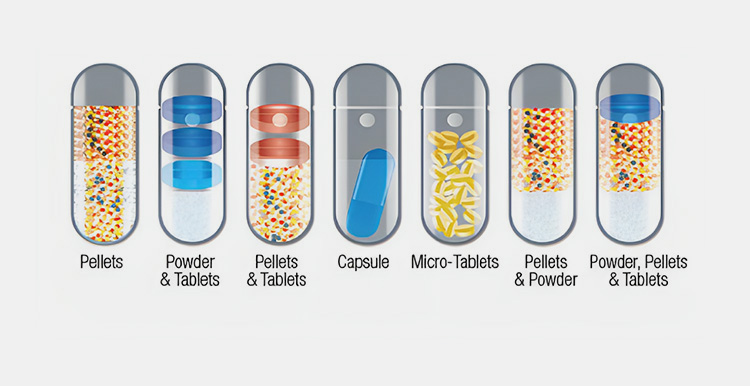

Fill Materials Type in Capsule-Picture Courtesy: Contact Pharma

Automatic capsule filler has different kinds of toolings and filler systems for filling wide-ranging materials. Some of the examples of material types filled by automatic capsule filler are:

Powder

Powder in Capsule-Picture Courtesy: Dragon Herb

It is the most widely filled material by the automatic capsule filler. Many pharmaceutical, nutraceutical, and herbal industries fill capsules with different kinds of powder formulations. These powders are finely ground materials that are readily absorbed in the bloodstream.

These materials are usually dosed inside the capsules by mechanical vibrations while the sensor present in the powder supply hopper detects the level of powders inside the hopper. Accuracy in powder filling is achieved using a spring plunger that removes the trapped air from the powder.

Granules

Granules in Capsules-Picture Courtesy: LCI Corporation

They are formed by the combination of active ingredients and excipients. Granules are often used in capsule preparation because sometimes powders segregate, resulting in non-uniform dosage. To avoid this, granules are prepared from aggregation or granulation of powder solution.

There are vast varieties of granules such as effervescent granules, coated granules, non-coated granules, entero-released granules, and sustain-released granules. A special component called a measuring box is utilized by an automatic capsule filler for dosing granules inside the capsule body. Moreover, two filling heads are employed for loading two-layered granules.

Pellets

Pellets in Capsules-Picture Courtesy: Farmacapsules

These are spherical balls with a size of 0.2-2 mm. Their smooth surface distinguishes them from granules. Pellets are small beads that can be modified to gradually release drug substances such as caffeine, zinc, and vitamin B6. Since pellets are hard and dense, it is best to limit the moisture content in capsules for better results.

Tablets

Tablets in Capsules-Picture Courtesy: Harro Höfliger

A special filling unit is present in automatic capsule filler to dose various kinds of tablets like mini-tablets, sustain-released tablets, etc., inside the capsules. These are larger than granules and are usually filled in capsules to avoid irritation of the stomach which could happen if tablets are swallowed without any encapsulation.

Combinations

Fill Material Combination in Capsule-Picture Courtesy: Farmacapsule

Fill materials are also encapsulated in combination to have maximum therapeutic and synergistic effects. This allows the dosing of different incompatible ingredients. Combinations of liquids + pellet, pellet + tablet, tablet + powder, micro-tablets, etc., are filled inside the capsules using specialized kinds of filling devices and more than one filling unit. This allows the loading of ingredients of two different profiles such as immediate release and delayed release in one single capsule.

8.What Is The Difference Between Semi-Automatic Capsule Filler And Automatic Capsule Filler?

Although both these machine types are employed for filling capsules, there exist some significant differences between these two devices. Some of these differences are discussed below:

| Semi-Automatic Capsule Filler | Automatic Capsule Filler |

Semi-Automatic Capsule Filler-Picture Courtesy: Aligned |

Automatic Capsule Filler- Picture Courtesy: Aipak Pharmaceutical |

| Semi-automatic capsule filler depends upon human supervision for loading and removing capsules and for programming aspects. | It is a completely independent unit capable of carrying out every step of the capsule filling itself. It just requires a human operator to program machine parameters. |

| It has a lower output capacity than automatic capsule filler. | Since it is a fast unit with the latest technological parts hence are more productive filling hundreds of capsule per minute. |

| It has a smaller footprint and is available mostly in horizontal configurations. | It has a larger footprint and is available in vertical configurations. |

| It is less accurate in capsule filling. | It is equipped with sensors and rejection systems that reduce the error rate to 0.01%. |

| It is less expensive. | As it is equipped with state-of-the-art gadgets and has higher productivity, it is more expensive. |

9.How Can You Maintain Automatic Capsule Filler?

Maintainentance of Automatic Capsule Filler-Picture Courtesy: Multi-Fill

Preventive maintenance is directly correlated to the long and healthy functioning life of automatic capsule filler. Here are some tips for maintaining your automatic capsule filler.

| Daily Maintenance | Thoroughly clean the machine to get rid of unwanted powders and other foreign objects.

Check the alignment of the upper and lower tray. Examine nuts and screws daily and if they are loose then tighten them. Wipe and clean the filter bag. |

| Weekly Maintenance | Examine the oil quantity in the vacuum pump and top it up if needed.

Turn off all electric switches and fully clean the electric cabinet with the vacuum. Inspect the working order of the piston cylinder that fluidizes powders. |

| Monthly Maintenance | Clean the cam assembly units and apply a new coat of grease to the chains.

Properly tighten all the cables and lines of the equipment. Inspect the working condition of solenoid coils present in the pneumatic or piston system Calibrate all the sensors and ensure that the locking unit is in proper working order. Remove old oil from the vacuum pump and refill it with new oil. Examine and clean the capsule rejection area. |

| Biannually Maintenance | Examine and replace the damaged link mechanism with a new bush assembly

Replace defective tamping pins Check the working condition of the motor bearing Apply a new grease coat to block rollers. Fasten the joints of the pneumatic system |

| Yearly Maintenance | Replace seals if old seals are defective

Check the vacuum pump for faults and replace it if required. Completely clean all mobile segments with kerosene oil and lubricate segments as well as bearings. Check the motor and timer belt for damage and replace them if needed. |

10.What Are The Different Problems And Their Troubleshooting In Automatic Capsule Filler?

Every type of automatic capsule filler is bound to face some kind of failure during its lifetime. But with troubleshooting, you can cure defects in the functioning of a machine.

A few important troubleshooting tips are discussed below for your information.

| Cause | Solution | Image |

| Inaccurate Rectification | ||

| The use of plastic containers for transporting capsules can instigate electric charges impeding rectification | Always utilized stainless steel containers for moving capsules |

Rectification of Capsule Picture Courtesy: Huada Pharma |

| Damaged to Capsules | ||

| Improper alignment of rectifier block | Calibrate and level the alignment of the rectifier block |

Damaged Capsule-Picture Courtesy: Sensum |

| Splitting of Capsules After Filling | ||

| A high quantity of powder inside the capsules | Adjust the powder filling speed

Adjust the amount of powder according to the weight limit of the capsules |

Splitting of Capsule-Picture Courtesy: Sensum |

| Deforming of Capsules | ||

| Inaccurate alignment of the upper and lower tray | Check and fix the alignment of the upper and lower capsule tray |

Deforming of Capsule-Picture Courtesy: Sensum |

| Popping or Elongation of Capsules | ||

| Excessive locking pressure

Overfilling of capsules |

Reduce the locking pressure

Adjust the amount of active ingredients in capsules |

Elongation of Capsule-Picture Courtesy: Sensum |

| Telescoping | ||

| Large gap in counter bearing system causes unalignment of the cap and body

Machine components are not properly aligned |

Close the gap in the counter bearing to properly align the cap and body

Check the alignment of machine component |

Telescoped Capsule-Picture Courtesy: Sensum |

11.How To Buy The Perfect Automatic Capsule Filler For Your Business?

An automatic capsule filler comes with a high price tag therefore its selection for business is a vital decision that should be taken after careful consideration to find a perfect match between automatic capsule filler and business goals.

Here is the list of some important points that should be taken into account before purchase:

Size of Potential Equipment

Automatic Capsule Filler-Picture Courtesy: Aipak Pharmaceutical

First, do your math and check whether you have enough floor space to accommodate large-sized automatic capsule filler. If not, it is best to opt for a machine with a smaller footprint. Moreover, machine size is directly related to power usage and output capacity.

Access Production Needs

Capsule Filling Production-Picture Courtesy: Soulyam Packing Machine

Next, ask yourself the question how many capsules do you need to fill per day? This is the way to estimate your production needs. If the number of capsules packaged per day is higher, then go for automatic capsule filler with higher production capacity. Instruments with more production capacity will aid you in satisfying high-market needs.

Size of Capsule

Capsule Sizes-Picture Courtesy: Express Pharma

Different automatic capsule filler have their specific capsule filling sizes. The capsule size is calculated by the amount of dosage per capsule in milligrams. It also depends upon the density of the formulation. Therefore, it is imperative to identify your capsule size so that you can look for an automatic capsule filler that will handle it.

Quality Standard

GMP Quality Standard-Picture Courtesy: AMSBIO

It is a way to check the quality and design hygiene of your automatic capsule filler. Different standardized quality tests such as cGMP, CC, CE, and ISO ensure that raw materials and parts used for manufacturing automatic capsule filler are of high quality, which in turn provides you with great work experience in the long run.

Inspect Safety Features

Shock Proof Electric Cabinet-Picture Courtesy: Assembly Magazine

There are many odds that accidents can occur during normal machine runs. So, look for safety gadgets like explosion-proof frames, shock resistance motors, advanced gadgets, sensors, and alarm systems that alert if there is the possibility of hazard during capsule filling operation.

Conclusion

Automatic capsule filler is an efficient turnkey solution in productions that routinely process large batches of capsules. With its advanced gadgets and control system, it has accuracy in capsule fill. It is ideal for optimizing productions with high-quality results and lower product wastage. If you are looking for automatic capsule filler then you are at the right place. Visit our main Allpack website to get pricing and details of world-class automatic capsule filler.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide