Shrink Film VS Stretch Film

Shrink Film VS Stretch Film

Are you confused about What type of packaging film actually you need? Well, don’t worry! This is normal. Because many of you think that they’re the same. Therefore, knowledge about these terminologies is mandatory for packaging purposes.

So if you’re a manufacturer, buyer, or purchaser you must go through this blog; here, we talked about the major pinpoint differences between shrink film vs stretch film. Let’s get into it!

1.What Is A Shrink Film?

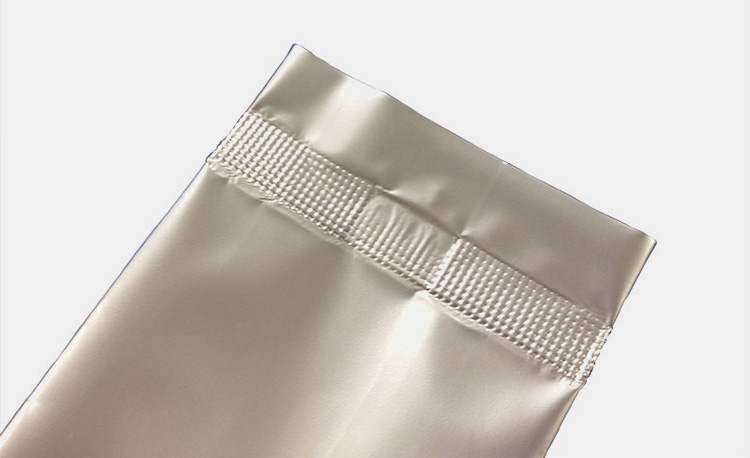

Shrink film is a strong, durable, and stretchable polymer that is used to wrap around goods and products to protect them. It is made of polymer based plastic which includes polyvinyl chloride (PVC), polyethylene, and polyolefin.

Shrink film works on the basis of the heating process. The film is heated at a certain temperature with the help of an electric gun, gas heat gun or a conveyor heat tunnel. As a result, the film tightly adheres to the product, enclosing it and protecting it from any damage. This film can be used to wrap various kinds of products such as bottles, food products, consumer goods, etc.

2.What Is A Stretch Film?

Stretch film is a thin elastic polymer used to wrap around pallets or boxes. It is primarily made up of linear low density polyethylene, resins which are obtained from petroleum industry. These films easily enclose the goods inside, protecting it from any harm or damage during shipping, storage and distribution process.

Since the stretch film is transparent, the goods inside can be easily identified or scanned, making its use extremely convenient. They are highly versatile and come various designs, shapes, sizes and length which can be customized according to the customer’s needs.

3.What Are The Differences Between Shrink Film And Stretch Film?

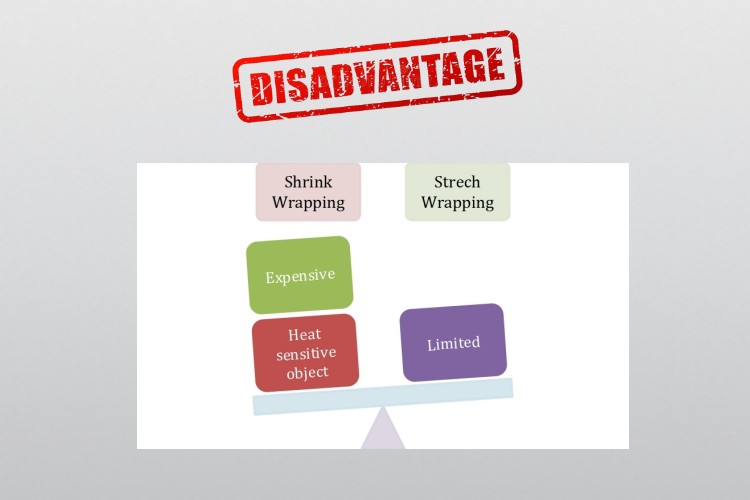

The shrink and stretch films are not only ideal for wrapping boxes, products and other consumer goods but also serve as a protective barrier against the external environment or any kind of damage. Despite these similarities, they have a major difference which involves heating. In shrink film, heating is applied to the film. After cooling, the film shrinks around the item more tightly, forming a protective layer over the item which can then be sent for shipping. Moreover, it does not have the capability to stretch unlike the stretch film.

In stretch film, no heating is applied and the elastic film is wrapped around the box tightly. This film has the capability to stretch by 300% and when it tries to come back to its original shape, it firmly grasps the box it is wrapped around.

4.What Are The Types Of Shrink Film?

Shrink film consists of 3 types known as polyvinyl chloride (PVC), polyethylene and polyolefin. Let us discuss each type below.

Polyvinyl chloride ( PVC )

Polyvinyl chloride is well known to be lightweight, versatile and for its relatively cheap cost. It is one of the most common material to package goods due to its durability and effectiveness. It can be used for a number of products such as toys, furniture, bags, electrical appliances etc.

Polyolefin

Polyolefin is the strongest and the most durable type of shrink film available out there. Due to its high strength it is an excellent choice for goods which require high quality protection against any damage. They are used in various industries to make products such as caps, face masks and high performance filters.

Polyethylene

Polyethylene is just like polyolefin except it contains ethylene which undergoes polymerization. It can be molded into various flexible packaging to make products like bottles, toys, bags etc. polyethylene itself has 3 forms known as high-density polyethylene, low-density polyethylene and linear low density polyethylene.

5.What Are The Types Of Stretch Film?

Stretch film has 2 common types known as hand stretch and machine stretch film. Let us discuss each type below.

Hand stretch film

Hand stretch film, as the name suggests is used to manually package goods. This film has smaller width as compared to machine stretch film in which the worker manually wraps the film around the concerned item. It is ideal for small scale businesses where the workshop or warehouse deals with low volume goods rather than high volume ones since the packaging is done manually, thus making the process time consuming.

Hand stretch film is further divided into 3 categories

- Blown hand film stretch: ideal for heavier items due to its load bearing property and high resistance.

- Cast hand stretch film: this type should be used when there is a need for tear resistance and superior puncture when the goods are being transported from one place to another.

- Banding hand stretch film: this film offers extremely resistant cling for top banding pallets and is ideal for packaging smaller goods.

Machine strech film

Machine stretch film is strong, versatile, durable and highly resistant which is specially used for high volume goods. They have the unique capability of providing high strength and puncture resistant load retention needed to protect vulnerable goods.

Machine stretch film is further categorized into following types

- Blown stretch film: this film is made by the process of blown extrusion in which resins are heated and blown into a bubble which in turn is converted into a sheet that is rolled and applied to a core tube.

- Cast stretch film: this film is made by the process of cast stretch in which resins are heated and fed through a series of cooled rollers which then solidifies the film.

- Pre-stretched film: this film, as the name suggests is already stretched before it is used, that is, during the manufacturing process.

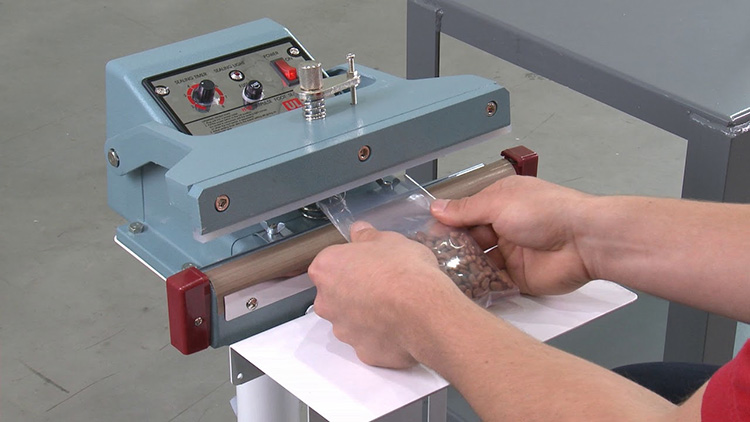

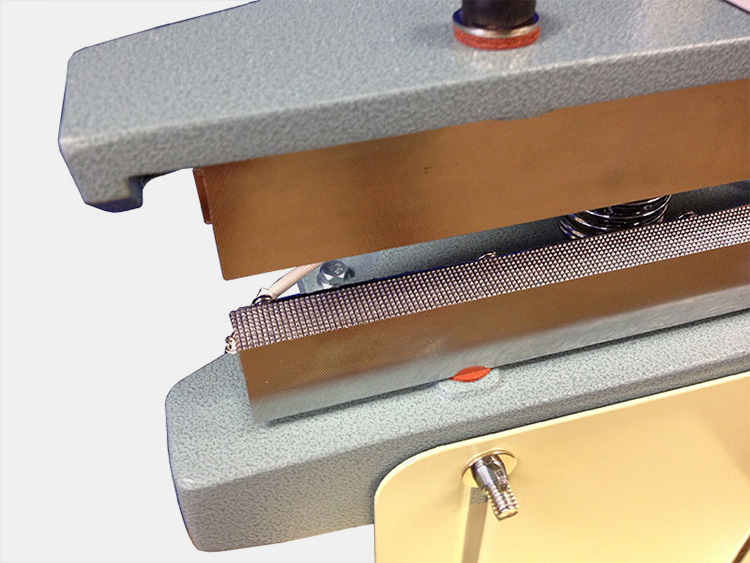

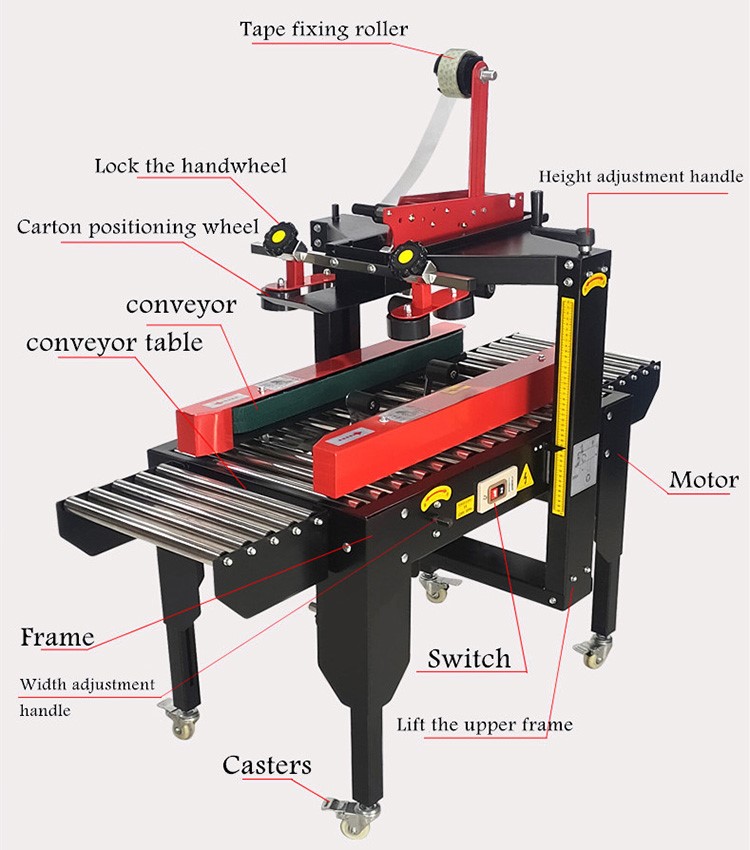

6.What Types Of Equipment Is Used To Apply Shrink Film?

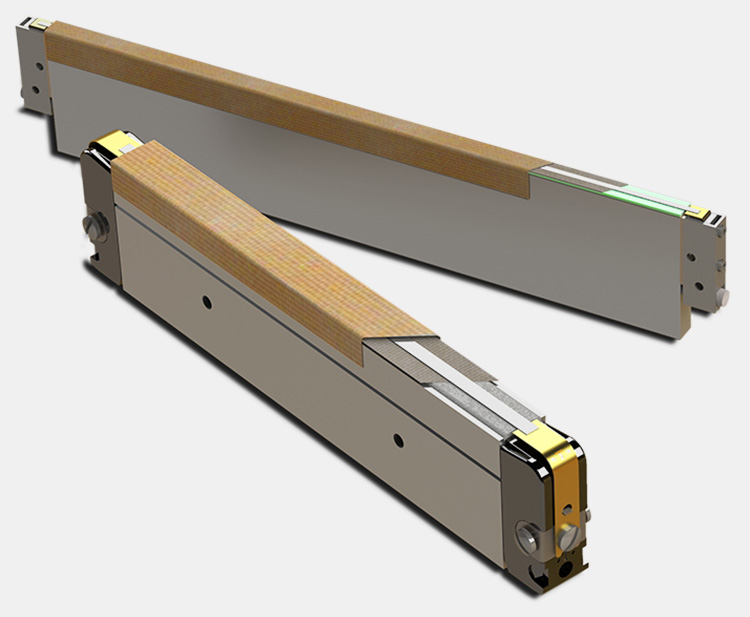

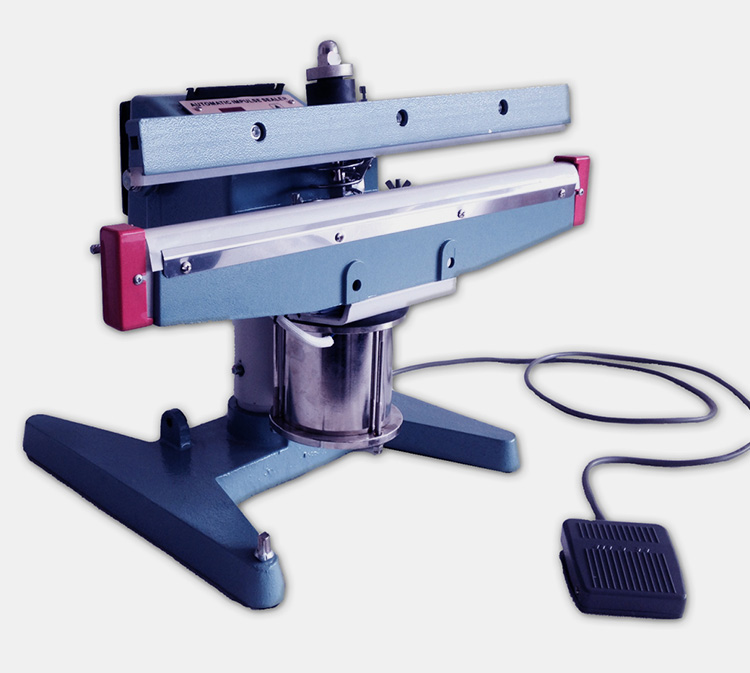

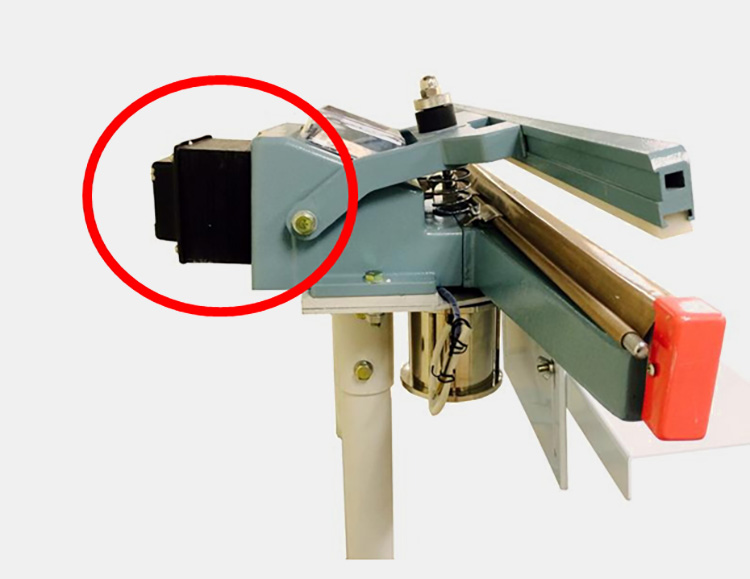

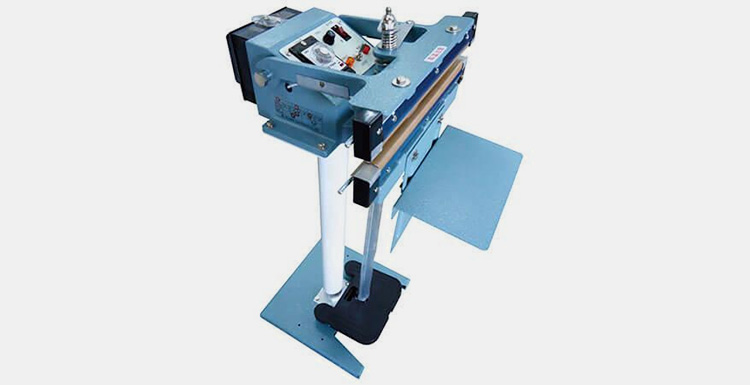

The following equipments are used to apply shrink film

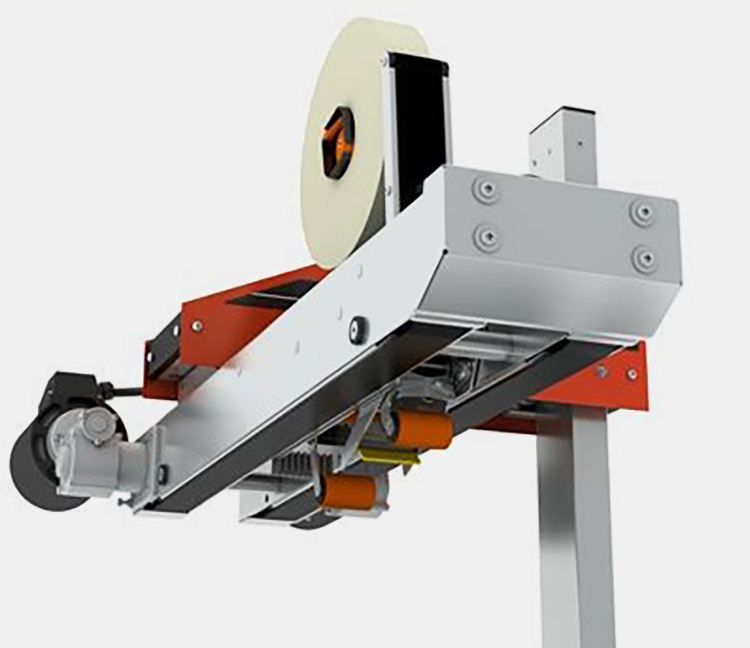

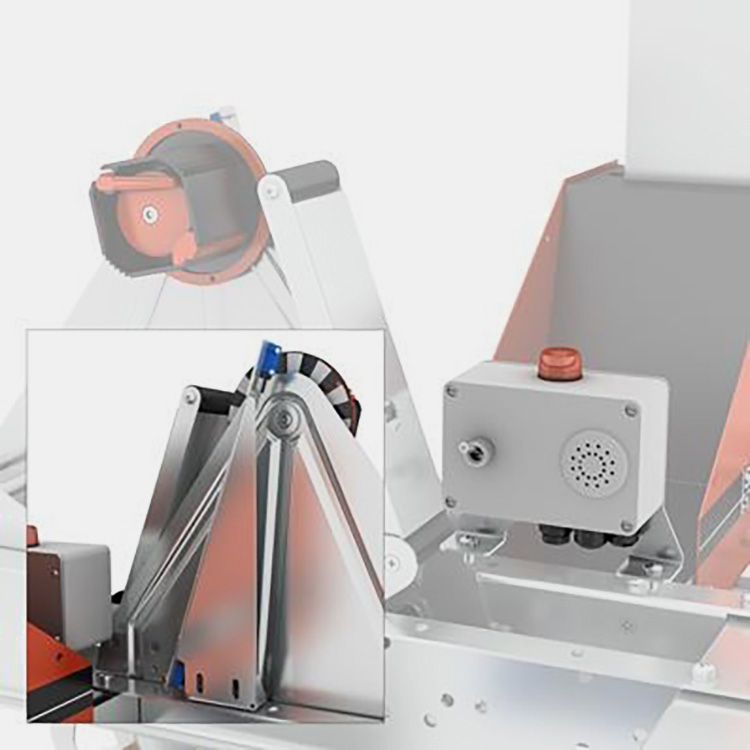

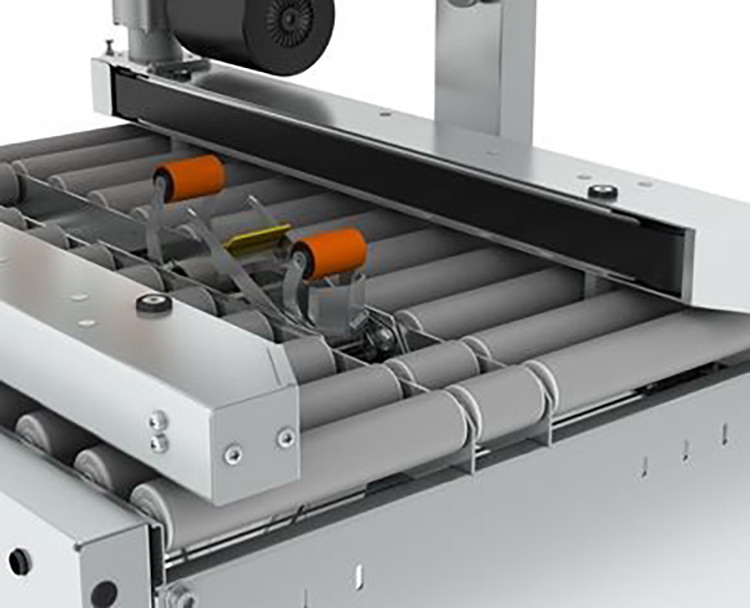

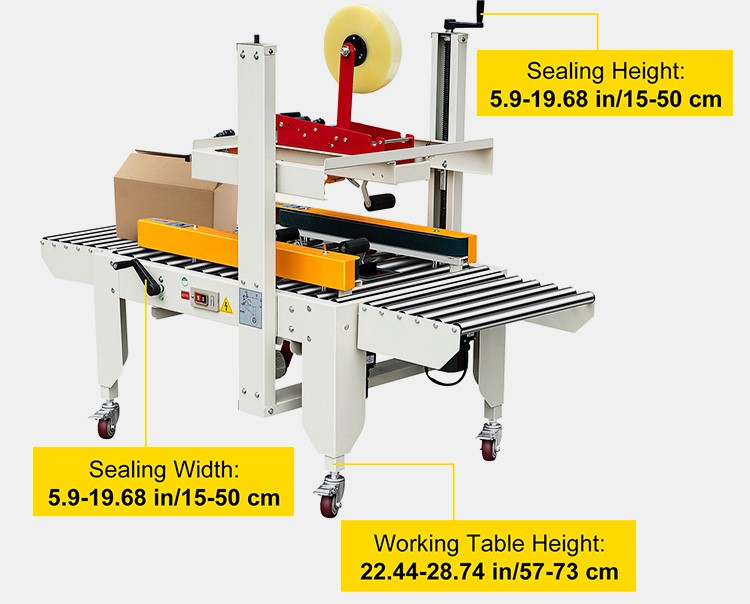

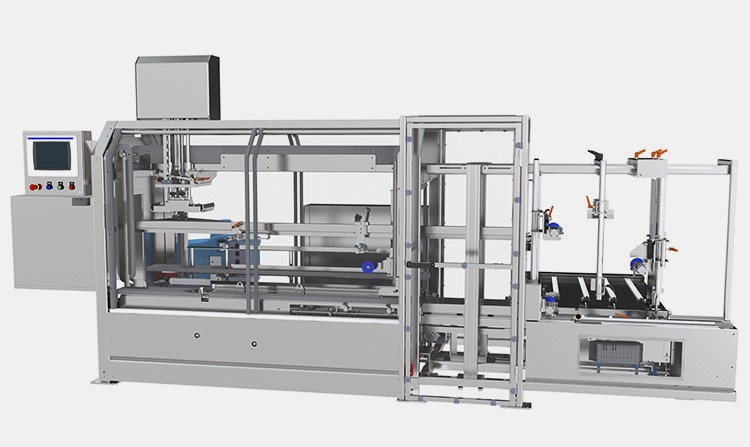

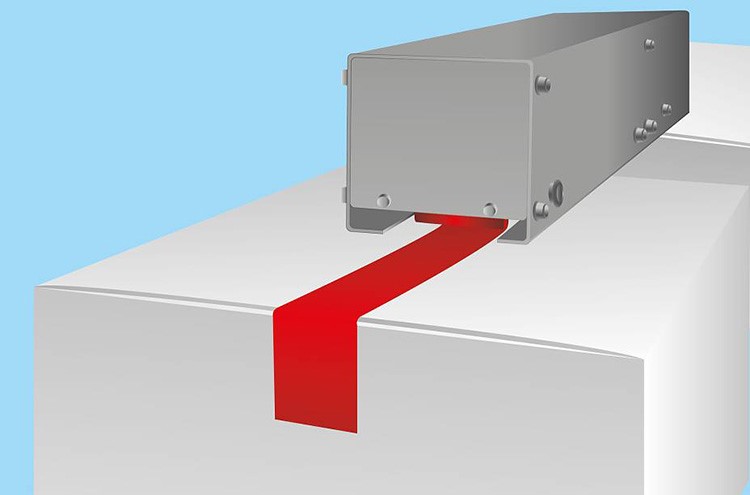

Automatic side sealers

This equipment is high speed which uses continuous motion to wrap the product. It does this with the help of a mechanical arm which trims and clings the film around the product. Due to its high speed, it is an excellent choice to use it in industries which need to wrap thousands of products in a single day.

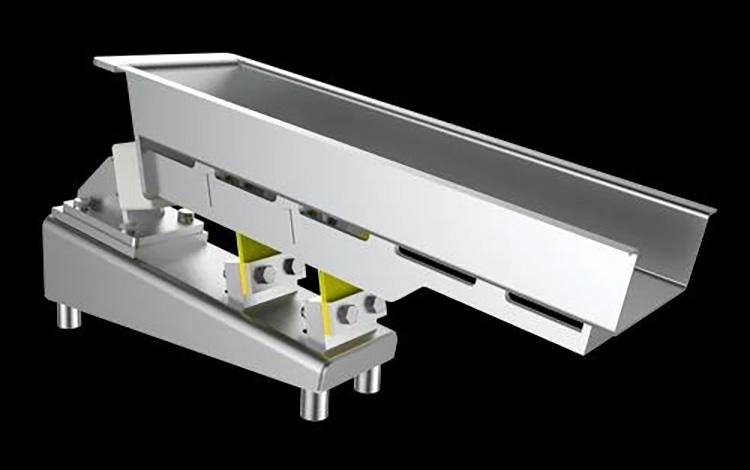

Shrink tunnels

Shrink tunnels use a certain temperature to further shrink the film which has already been tightly adhered with the help of a shrink wrap machine. It comes in single and dual chamber format in which the dual chamber has the ability to package goods at a faster rate.

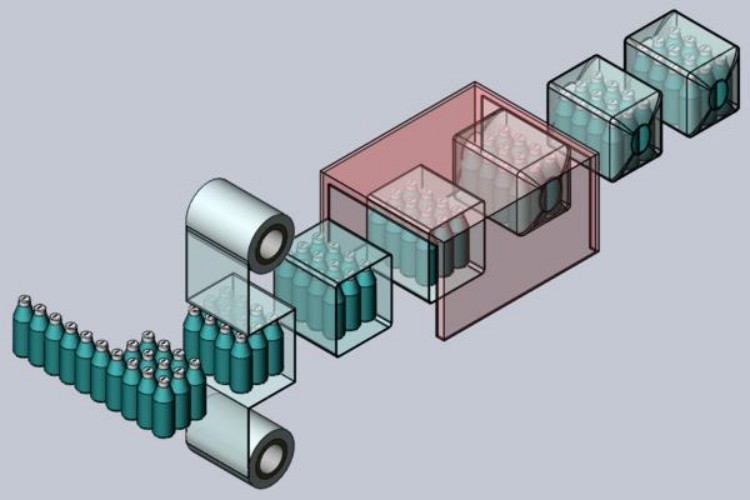

Shrink bundling machine

This type is used to wrap cans and bottles in which a horizontal sealing arm is used for the wrapping process.

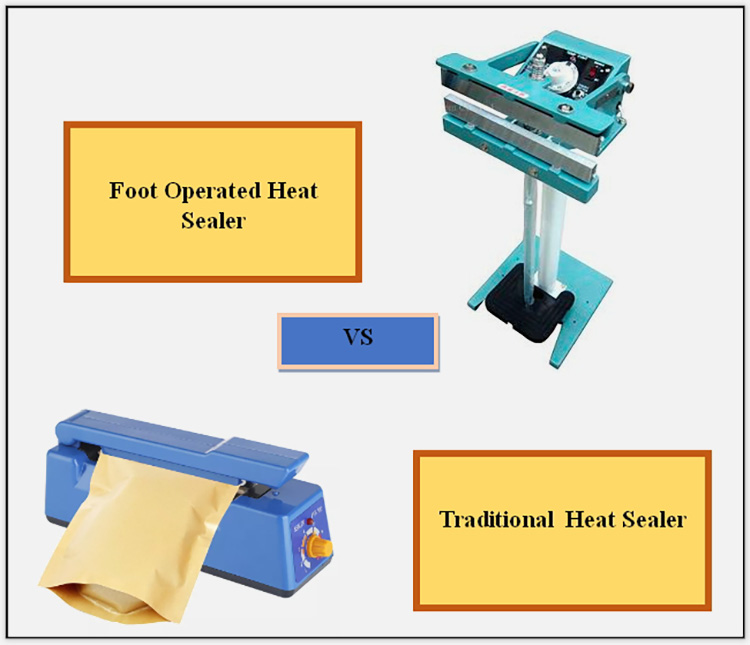

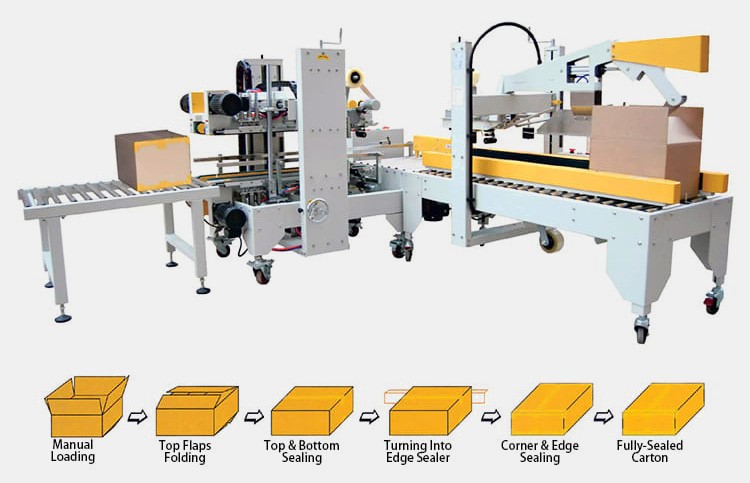

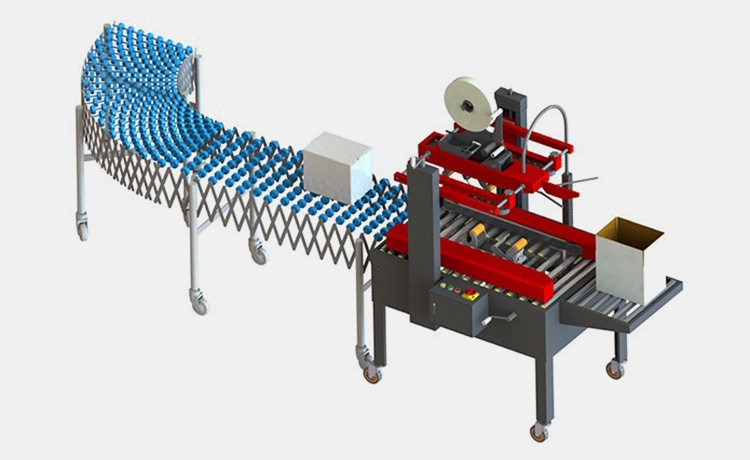

7.What Type Of Equipment Is Used To Apply Stretch Film?

The following equipments are used to apply stretch films

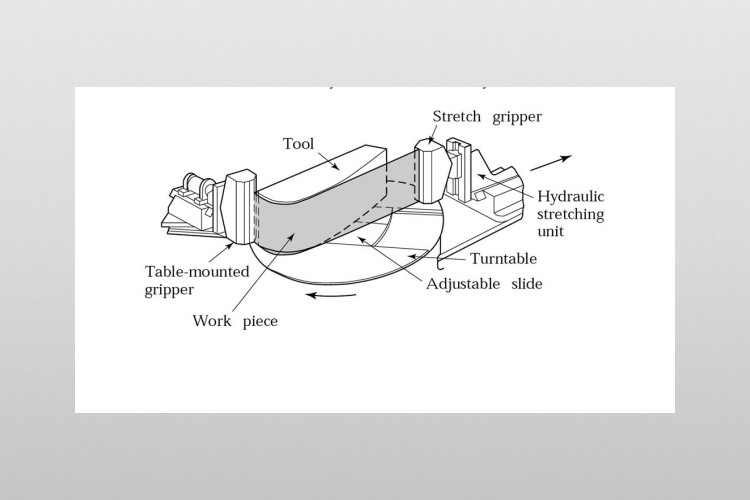

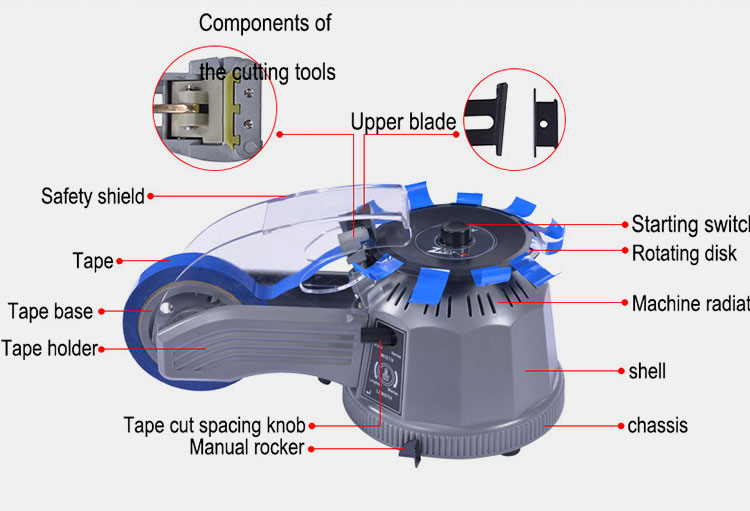

Turntable stretch wrappers

This type is ideal for small to mid-range packaging of 20-40 loads/hour. It uses a motorized rotating platform to rotate the pallets held in their position. They either come in automatic or semi-automatic form.

Rotary arm stretch wrappers

Rotary arm stretch wrappers use a mechanical arm which rotates around the load. They are an excellent choice to wrap products which are either too heavy or very light. They also come in automatic and semi-automatic formats and have the capability to package 40 loads/hour.

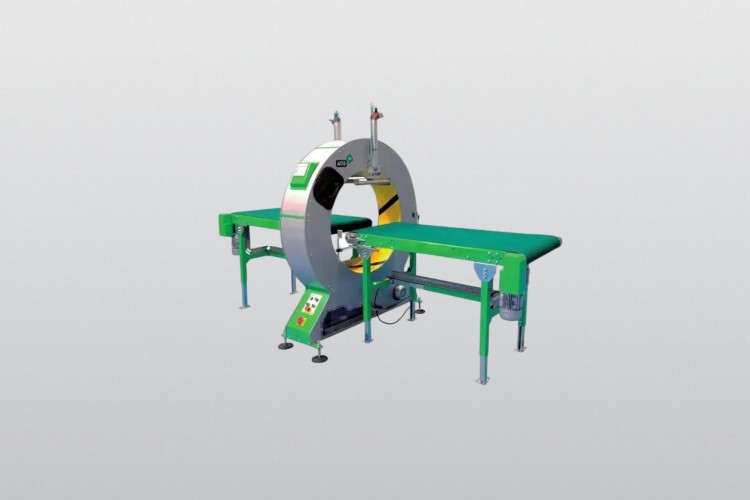

Orbital horizontal ring stretch wrappers

This type is ideal for wrapping long and wide loads. It wraps the product with the help of a vertical rotating ring and is a good choice for products such as doors, windows, textiles, pipes etc.

8.What Are The Benefits Of Shrink Film?

Using shrink film in your business is an excellent choice to wrap your manufactured goods. Due to its number of favorable features, it is the go to choice for a lot of buyers. Let us discuss its benefits below.

Protection

One of the most important benefit of using shrink film is that it provides an excellent protection to the goods it is wrapped around. It stops the interaction of the environment with the product, thereby preventing it from degradation or damage.

Increased shelf life

Since the product is preserved and remains fresh due to the protective layering of the film, it maintains its efficacy, increasing shelf life.

Ability to market brands name

Any company or brand which is using shrink film to wrap their products have the option to print their brand logo on it, thus helping the company to promote its brand.

Customizable

This feature is one of the main reasons why shrink film is so popular across all the industries because it can be made in any shape, design, color and size, according to the products requirement. It can add a glossy effect to the product, making it visually pleasing to the eyes.

Environment friendly

Shrink film not only caters to the needs of the industries but is also very safe for the environment. Its types which include polyethylene and polyolefin are made of recyclable materials, thus making shrink film sustainable.

Cost effective

The use of shrink films has eliminated the need for corrugated packaging. This greatly reduces the cost of packaging goods, thus generating more profits.

9.What Are The Benefits Of Stretch Film?

Stretch films are one of the strongest and most durable type of film out there. It provides numerous benefits and its demand has been increasingly growing for the past few years. Let us discuss the benefits below.

Protection

Stretch film like shrink film provides a strong protective layer to the product inside. It prevents the entry of dust or pollutants from going inside.

Versatility

Stretch film can be made in different shapes, design, color and size. Thus it has the ability to wrap any kind of product, ranging from light weight products to heavy weight products.

Cost effective

Stretch film is much cheaper than shrink film since the equipment used to make it is less expensive than the other equipment employed for other types of films.

Environmental friendly

Stretch film like shrink film is made of recyclable materials, thus it does not pose a serious threat to the environment, making its use extremely sustainable.

10.What Is The Working Principle Of Shrink Film?

The working principle of shrink film is based on the behavior of molecule. The molecules of shrink film are arranged in random orientations. When the heat is applied to the film, these random moving molecules align and orient themselves in a particular direction. When they are cooled, these molecules set themselves in a stretched form where they revert to their original form after sufficient heat is applied to it.

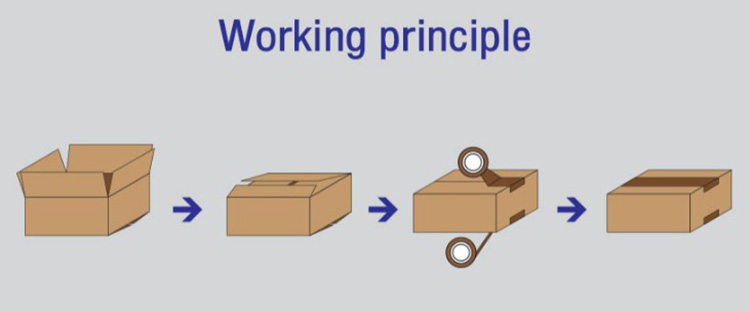

11.What Is The Working Principle Of Stretch Film?

The working principle of stretch film is based on elasticity. The molecules of stretch film are elastic, that is, when tension is applied to it, they have the ability to return to their original shape. The elastic recovery in stretch film helps to keep the product tightly bound, keeping it in place.

Conclusion

After discussing all the points above concerning shrink and stretch film, we can see that both the films have their own unique characteristics and features which can cater to different businesses and industries. Even though stretch film is cheaper and stronger than shrink film, it is ideal for some kind of products whilst the shrink film is ideal for other kinds. Nevertheless, both the films are one of the best out there to package products and the buyer can easily use them for his business without any worries!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Shrink Film VS Stretch Film Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours