Case Sealer: The Complete Buying Guide In 2025

Large quantity of finished products is now travelling from one place to another. For protection and proper sealing of boxes or cartoons case sealers are used to ensure proper packaging which protects products from getting damaged.

For selecting an appropriate case sealer according to the production requirements, it is necessary to get all related information before buying a machine. This article contains all the necessary information regarding case sealers so take the most from it.

1.What Is A Case Sealer?

A case sealer is mostly used in packaging industry or industries where products are packed with sensitive care. A case sealer is basically a packaging equipment which is used to pack a carton or box in a highly efficient manner. A carton is placed on the conveyor and the tape rollers roll on both sides of the carton.

In this manner, the carton gets sealed from all the sides. A carton sealer ensures safe travelling of products even if it is to be delivered to a longer distance. This type of sealing reduces human efforts to a large level and gives quality packaging.

2.What Are the Application Of Case Sealers?

Case sealer also called carton case sealer, is most popularly used in carton packaging industry where large numbers are to be packed in limited time. Traditionally, this method was done by the operator himself, but it was much time consuming and also the packaging was not done in a proper manner. Case sealer has now provided packaging industry a great benefit in clean carton packaging of products.

Other than packaging industry, all industries like food, manufacturing, goods, wood, cosmetic, chemical, pharmaceutical and paper are packing their products in cartons or boxes are now focused on using these case sealers for their packaging process. Case sealer increase productivity in an exponential manner and helps industries to become more economically stronger.

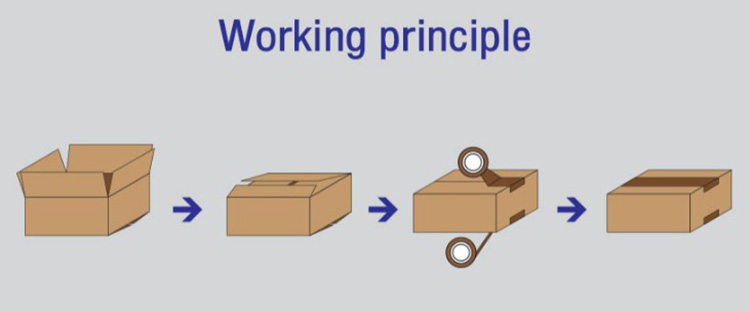

3.What Are the Working Principles Of the Case Sealer?

The working principle of a case sealer is not as complex as other sealing options. It only follows the few procedures.

- Initially all the products are kept inside the carton or box and then sent to the conveyor of a case sealer.

- All external and internal parameters including power, conveyor speed, tape rolling speed and other are maintained for proper sealing.

- The carton is then placed on the conveyor manually and then it automatically travels to the path towards the machine.

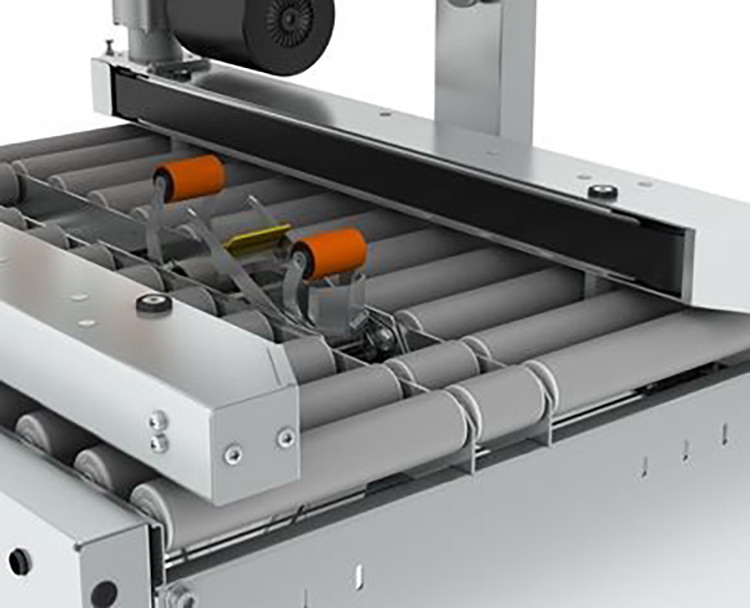

- As the carton enters the sealing area, both up and down tape sealing rollers roll on the surface of it and seal the carton from upside down.

- The motor then drives the carton out of the system and in this way the sealed carton is received at the end of conveyor system.

- In this simple procedure, highly efficient sealing is performed on carton with precision and accuracy.

4.What Are the Main Components Of A Case Sealer?

The main components present in a case sealer are

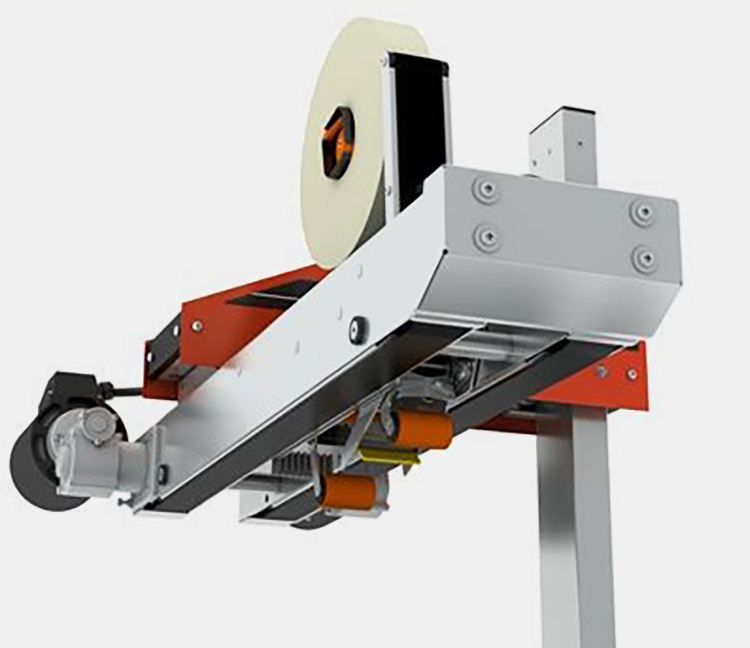

- Tape Dispensers

This is the heart of a case sealer because it holds the main sealing tape in it and dispenses over the products. The tape dispenser rolls over the carton when it is feeded to the system. The important feature of a tape dispenser is that it only releases a desired amount of tape according to the size of carton.

Tape dispensers are available in different width and sizes ranging from 25mm to 100mm for an overlap tape of up to 70 mm

| S.NO | Tape Width | Tape Range | Tape Overlap |

| 1 | 30mm | 25-30mm | 50mm |

| 2 | 50mm | 38-50mm | 50 or 70mm |

| 3 | 100mm | 65-100m | 70mm |

- Pillars

Pillars are the one which forms the assembly of a case sealer. They are of different size and width according to their placements. They are also incorporated with air cylinders and gas springs.

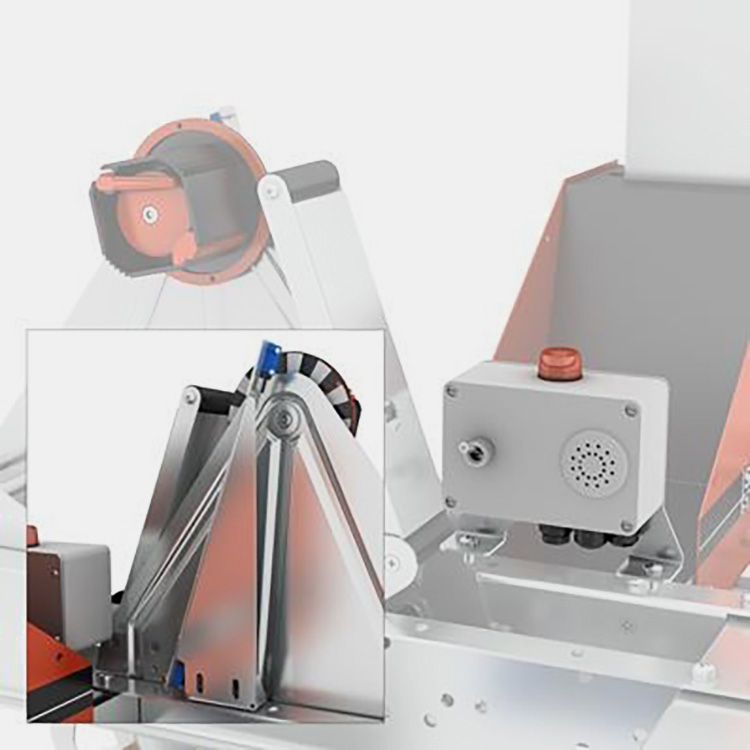

- Tape Alarm

Tape alarm is an indication unit that monitors and supervises the process of sealing. This system monitors the knife and roller movement with its photoelectric eyes. Whenever some mishap or warning occurs, the tape alarm generates an alarm both in audio and video form. In the meantime, it also holds the rest of process. It indicates following warnings.

- If the roller tape gets empty.

- If the roller tape is about to get empty

- If there is no tape on the roller

- If the tape is not properly cut and the roller still pulls out tape.

- Motors

For ensuring the movement of cartons or boxes and properly sealing, some motor driven units are their which are moved using motors. Also, the conveyor system is moved using these motors.

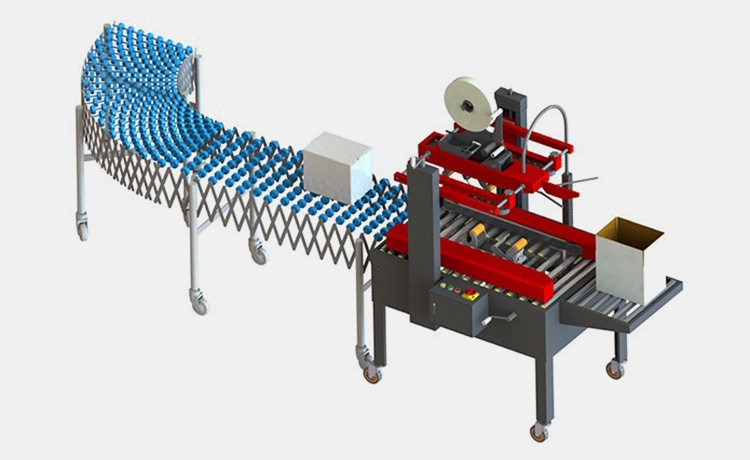

- Conveyor System

Conveyor systems are there in a case sealer machine for proper in and out of a carton or box. These conveyors easily make delivery of boxes to the system and inline the system.

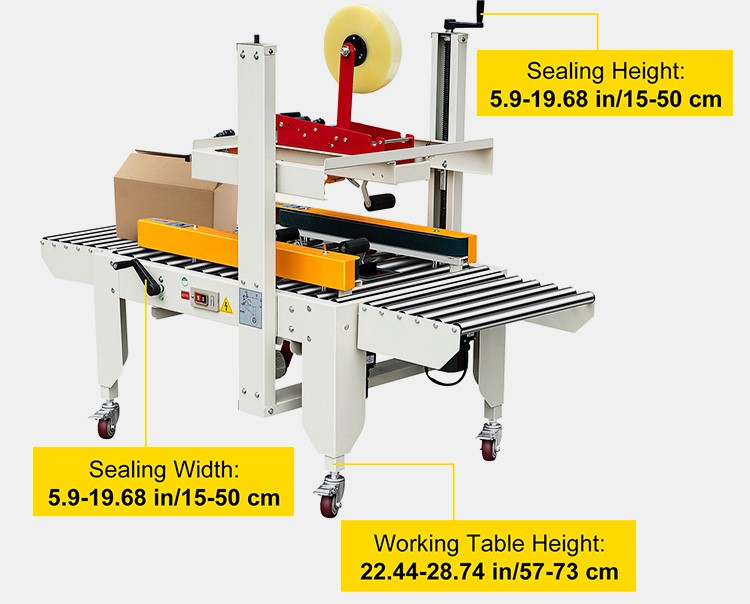

5.What Are the Features Of the Case Sealer?

- Packaging Range

Carton Packaging for Different Ranges – photo credits: abcpackaging

Case sealers are highly versatile that they provide a wide range of packaging standards. It can be customized to any range according to the length, width and height of the carton or box. No matter what material the box is made up of, a case sealer can seal it with high perfection and precision.

- Common Power Input

One of the most important features of a case sealer is that it does not require any special type of input power supply. It can be plugged in any of the range of voltage available in the global world.

- Customized Conveyor Length

Another feature of a case sealer is that it is not utilized for only a single length box or carton. The input conveyor and whole system can be adjusted according to the packaging box. The conveyor speed and movement is also controlled according to that particular situation.

- Machine Structure

Most of the case sealers are made up of stainless steel due to which they are highly durable and last for a longer period. The environmental condition does not harm the sealer that much due to its composite body structure.

- Machine Working Speed

Last but one of the unique features of a case sealer is their speedy packaging. The rate of products sealed in a prescribed time is much higher than done by traditional sealing methods. This increases the productivity of an industry and allows producing number of cartons in an hour without any human effort.

6.How Many Types Of Case Sealers Are Available There?

Case sealers are primarily available in two types. These types are then further divided according to the construction of machine and its application. The two types of case sealers are

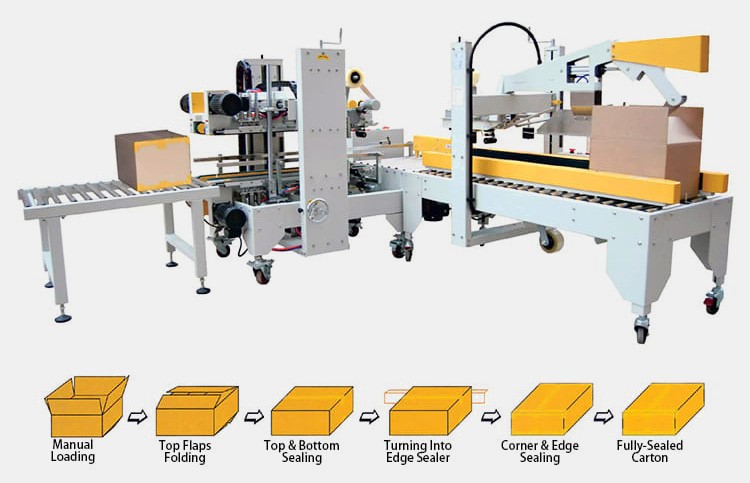

- Semi-Automatic Case Sealer

In a semi-automatic case sealer, both human and machine interface are present and different stages. Initially the carton is placed by the operator and flaps all the interfaces either minor or major. Then the carton enters the system and tape sealer is applied. Also, after the sealing application the carton is manually received at the other end.

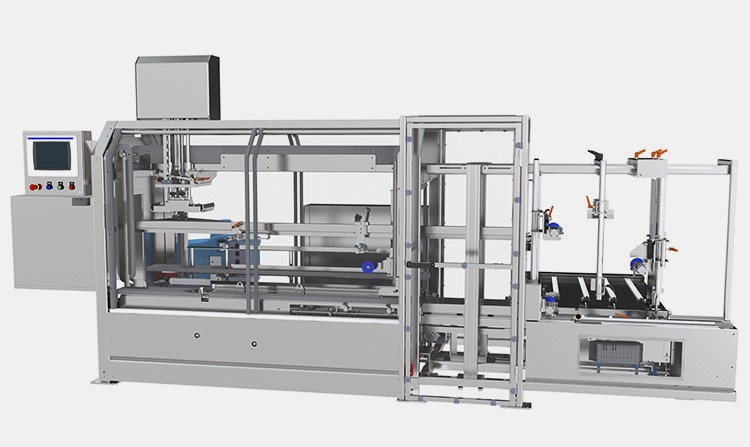

- Fully Automatic Case Sealer

While in a fully automatic case sealer, all the procedures are performed by the machine itself. Sometimes the operator only places the carton on the entrance if the machine is isolated from the rest procedures.

Otherwise, the whole product placement, flapping of carton edges, sealing, and quality check all are done by the machine itself. Also, a proper conveyor system allows the entrance and exit of cartons.

7.What Are The Differences Between Case Sealers And Case Erectors?

Some of the differences between a case sealer and case erector are

- Case Sealer Vs Case Erector

A carton or case is kept in a case sealer, here the machine folds both the top and bottom flaps of the object and seals it uniformly.

In a case erector, the carton or box first gets shaped and then flaps of all sides are sealed properly.

Case Erector – photo credits: pearsonpkg

- Operation

The working method of case sealer is very easy as the box is pushed into the sealing system manually or by conveyors first. Here the holders present inside the system hold it and then activates both the sealing shafts. Top and bottom shafts allow the sealing of box neatly by the rolling of tape on it.

The method of case erector is entirely different. A flat cardboard is pushed into the sealing system and there it gets it actual shape. As the box or carton gets it shape, the tape is then applied to all the sides.

Operation of Case Erector – photo credits: questindustrial

- Machine Parts

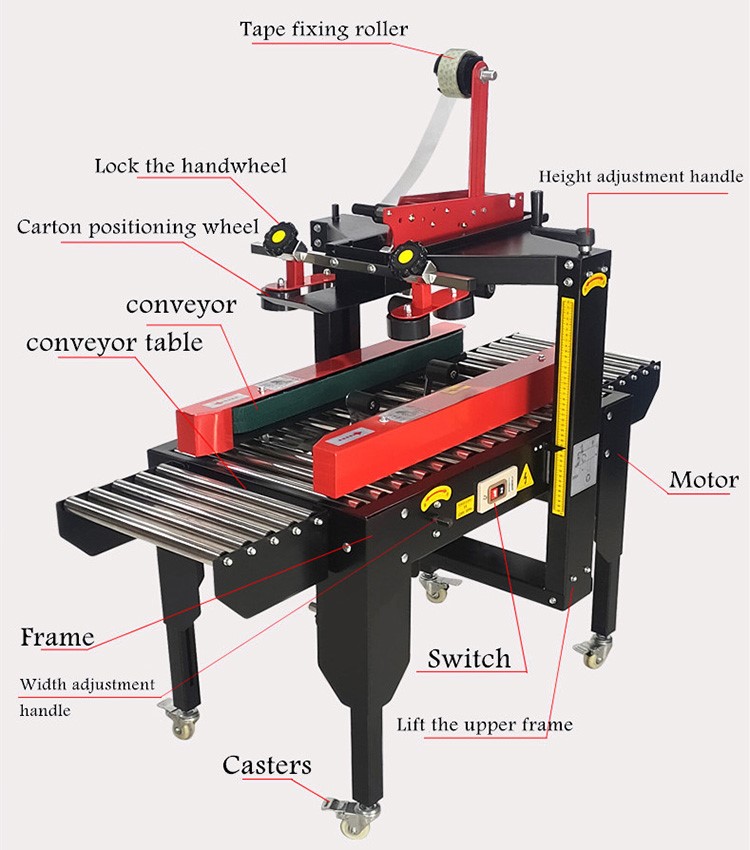

The main machine parts of case sealers include tape fixing roller, handwheel lock, carton positioning wheel, conveyor, conveyor table, frame, casters, switch, motor, and height adjustment handle.

A carton sealer is mostly comprised of a taping mechanism, bunch of tapes and it holders, hard metallic structure and conveyor belts.

Parts of Case Sealer

Parts of Case Sealer – photo credits: made-in-china

The main machine parts of case erectors include touch screen HMI, power switch, press plate, side belt, electrical cabinet, foot pad, emergency switch, side belt width adjustment, air inlet, blank magazine, case height adjustment, protective cover, blank retainer, vacuum sucker.

Most importantly, a taping wheel is present in a case erector which is responsible to perform taping on all sides and standing shafts to make the carton or box stand from flat surface.

Parts of Case Erector

Part of Case Erector – photo credits: sirosilo

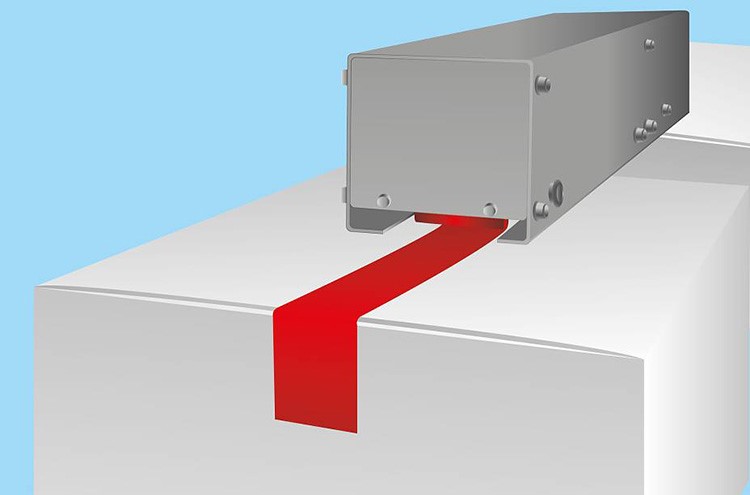

- Sealing Sides

In a case sealer, only the top and bottom flap of box are flapped by the machine and are only sealed accordingly.

Sealing Sides of Case Sealer – photo credits: youcipack

A case erector folds and seals all sides of a box or cartons but keeps one side of it opened for placing product in it.

Sealing Sides of Case Erector – photo credits: sting-pack

- Sealing Speed

3 to 5 cartons or boxes are sealed in a second while using a case sealer but in case of a case erector, the productivity increases to 5 to 7 boxes per second.

8.What Types Of Tape Materials Are Used To Seal In A Case Sealer?

Most used taping material in a case sealer are

- Box Sealing Tape

Sealing tape are easily available anywhere and are preferred to be used as a sealing option. They are used as lubricating and sealant material to combine two surfaces of any material.

A box sealing tape is a bit weaker in sealing strength as compared to adhesive tape but are more economical.

- Adhesive Tape

An adhesive material is usually a combined form of adhesive film and bonding material that joins two surfaces together with greater strength. An adhesive tape can easily be used instead of screws or ropes.

A case sealer ideally uses this type of taping material because the product must travel longer distances. An adhesive tape can also be used in low temperature conditions which makes it highly useful than other types of sealing tapes.

9.What Are the Benefits You Can Get From A Case Sealer?

Reason to Buy a Case Sealer – photo credits: americansurplus

There are various advantages of the case sealer that you can purchase a case sealer including increasing productivity, avoiding material waste, proper sealing position, product security, product presentation.

- Increasing Productivity

Packaging Productivity – photo credits: insitepackaging

Case sealers are used to increase the productivity to a large level which was near to impossible with traditional methods. Manual sealing takes a lot of time whereas automatically and within a minute a case or carton gets sealed with perfection. It directly increases the production rate on daily basis.

- Avoiding Material Wastage

Carton Waste – photo credits: rethink

Using a case sealer ensures that all sides of a box are proper and evenly sealed so that no material wastage takes place. A single strip is continuously applied on the whole case which also avoids multiple times application of tape. In this way the applied tape is also saved.

- Proper Sealing Position

Proper Sealing Position – photo credits: tesa

Previously, an excess quantity of taping on sealed cartons was received. But now using a case sealer, tape is applied on proper positions within a system and no excess tape is used. In this manner sealing with efficient length and position is done.

- Product Security

A single layered sealing on cartons with consistency allows the product to be highly secured. It ensures better security of products no matter how far it must travel. A case sealer decreases pilferage rate and increase security of products during transportation.

- Product Presentation

Cartons – photo credits: hazel4d

The product which is packed in a case sealer is highly presentable in nature. It is packed in a level that the customer gets directly attracted to it and wishes to have a case sealer

- Less Damage to Products

Protection of Products – photo credits: shursealsecure

Using ordinary means of sealing like scissors, staplers, straps or glue has high probability of product damage. These cannot completely secure the product and in a result both worker and products loss can occur.

Case sealer on the other hand provides unbreakable sealing to case so that the product and its surrounding both get secured. Also, the repairing cost reduces to a distinct level while using a case sealer.

- Operators Safety

As the product gets secured, it reduces the chance of any accident with its motion. The employee or operator that carries the carton is completely safe and there is no chance of any injury to the operator. A case sealer also reduces human efforts, fatigue, injuries and machine breakdowns.

10.What Are The Common Faults And Their Remedies That Are Faced In A Case Sealer?

Some of the possible errors that are faced in a case sealer are

- Insufficient Sealing

The most popular error or fault that is faced in a case is of insufficient application of sealing. Due to this the packaging is not proper done and hard kneading or peeling is present which can further crack the sealing in transportation. This factor mainly arises because of the improper setting of parameters like temperature, pressure, conveyor speed etc.

This error can be removed if proper sealing pressure and conveyor is maintained and synchronized with each other.

- Edge Breaks

Another problem faced in case sealer is of shrinks or edge breaks. This problem is created because of improper sealing temperature.

The error can be rectified if the sealing temperature is maintained according to the product and tape material that must be packed.

- Wrinkles Formation

Carton Wrinkles – photo credits: prempack

Wrinkles are formed due to the failure of sealing that is caused by static electricity. As the result case sealers applies tape with wrinkles and also the inward attraction of contents takes place.

Properly static electricity supply can minimize this problem.

- Product Contamination

There are possible scratch marks or ways that can contaminate products due to improper cleaning of parts that are present in a case sealer.

Proper parts clean schedule if done will reduce the chances of product contamination.

11.Which Factors Are Necessary To Be Noticed Before Buying A Case Sealer?

There are six important factors that should be kept under consideration before going for purchasing a case sealer

- Sealing Range

The most important factor before selecting a case sealer is to check its versatility and compatibility. Because it is not necessary that only a single sized carton is to be sealed every time. There can be different sizes according to the situation. So, the manufacturer should select the machine after complete study of whether it is compatible on uniform size or also on random sizes.

Random case sealer can give lot of productivity and economical advantage to the manufacturer. It is always a good decision to select a random case sealer rather than a uniform case sealer.

- Weight of Case

The weight handling capability of a case sealer should also be one of the important concerns for the buyer. As the products that are being packed vary in weight, it can directly affect the speed of conveyor. As a result of it poor quality taping will be performed. So, select the sealer with maximum weight bearing capacity according to production setup.

- Production Volume

A more productive machine can drastically increase the productivity of any industry. Before buying a case sealer it should be kept under consideration that how much number of cases can be sealed in a day. After complete analysis of production volume of any business right type of sealer can be selected. Anticipation of volume is an important task before selecting a case sealer.

- Labor Involvement

Machine with high automation can reduce the labor cost and increase the production cost. So, machine should be selected keeping in mind that is the labor necessary or not or fully automated machines are required.

- Size of Case

Case sealer in which the industry is interested to invest should be compatible with small to large cartons. Size is an important factor which ensures that the machine will seal number of cartons regardless of their sizes.

- Working Environment

Another important factor for considering in a case sealer is that in which environmental conditions the industry will use it. Environmental conditions can directly affect the structure of a case sealer. As in high humid conditions, case sealer made up of stainless steel are more preferred.

Likewise in normal working conditions, simple enameled steel body structured case sealer can be used. While checking the environmental conditions, machine size and its placement should also be considered according to the area available within territory.

Conclusion

Case sealers are more popular among industries because of their quick, efficient and reliable packaging of cartons or boxes. But it is always necessary to be aware of all the factors that should be considered before purchasing a case sealer. You can always contact our customer support team or visit our website http://www.allpackchina.com for more details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours