Foot Operated Impulse Sealer: The Complete Buying Guide In 2025

Foot Operated Impulse Sealer: The Complete Buying Guide In 2025

Are you looking for a reliable, efficient and cost effective way to seal plastic bags quickly and easily? If your answer is yes, then investing in a foot operated impulse sealer could be the perfect solution for your needs.

This type of sealer uses an electric current to heat up a strip that runs along the bag or pouch sealing it shut with minimal time and effort. With its precision cutting capabilities, adjustable timer settings and self-contained operation, this versatile tool can make light work of your packaging requirements while saving money on packaging materials costs.

Read on as we explore everything you need to know about our foot operated impulse sealers – from its construction materials to different types available – so you can make an informed decision on which model best suits your unique requirements.

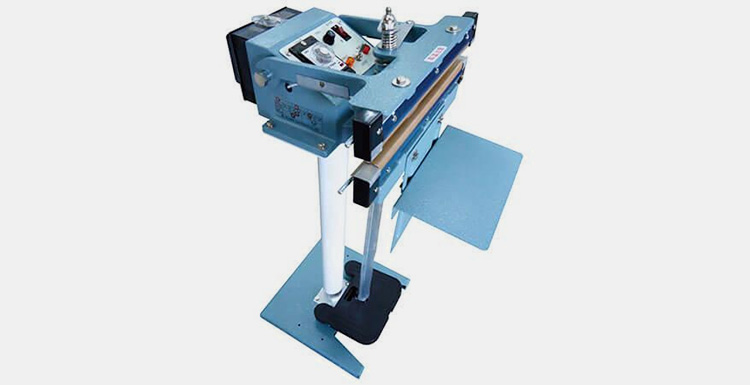

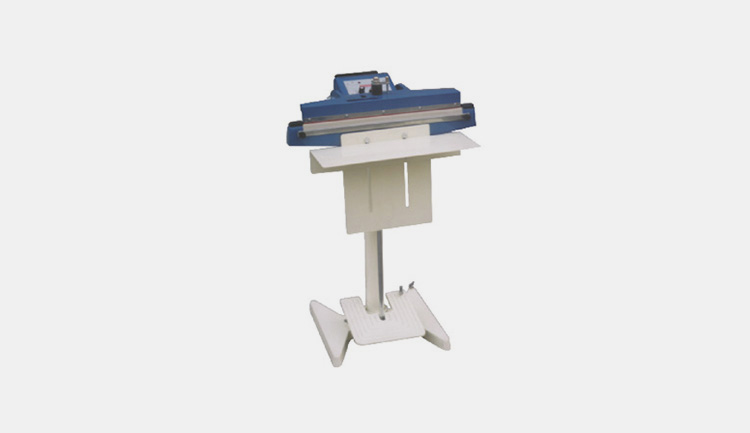

1.What Is A Foot Operated Impulse Sealer?

Foot operated impulse sealers are machines used to heat seal materials such as plastic and paper. They use an electrical impulse of current that is sent through a heating element to quickly generate enough heat to melt the material together, creating an airtight seal.

Foot operated impulse sealers are typically used in industrial settings for bagging and packaging production runs. Also, these machines are used in a variety of industries, from food and beverage production to medical supplies.

2.What Type Of Materials Can Be Sealed Using A Foot Operated Impulse Sealer?

A foot operated impulse sealer is a device used to seal various materials quickly and securely. They include:

Plastic Bags

Foot operated impulse sealers are perfect for sealing plastic bags quickly and efficiently. They can be used to create airtight seals, ensuring that the contents of the bag stay fresh for longer periods of time.

Poly Tubing

Poly tubing is commonly used in food packaging, and foot operated impulse sealers are perfect for quickly and securely sealing this material. This ensures that food remains safe and fresh until opened by the consumer.

Heat Shrink Film

Foot operated impulse sealers can be used to place an airtight seal on heat shrink film, keeping the contents of the package secure and uncontaminated from outside elements.

Aluminum Foil

Foot operated impulse sealers can be used to seal aluminum foil bags and pouches, providing an airtight seal that keeps contents safe and fresh for longer periods of time.

Paper Bags

Foot operated impulse sealers are also suitable for use with paper bags, allowing them to be quickly sealed and ensuring that the contents remain secure.

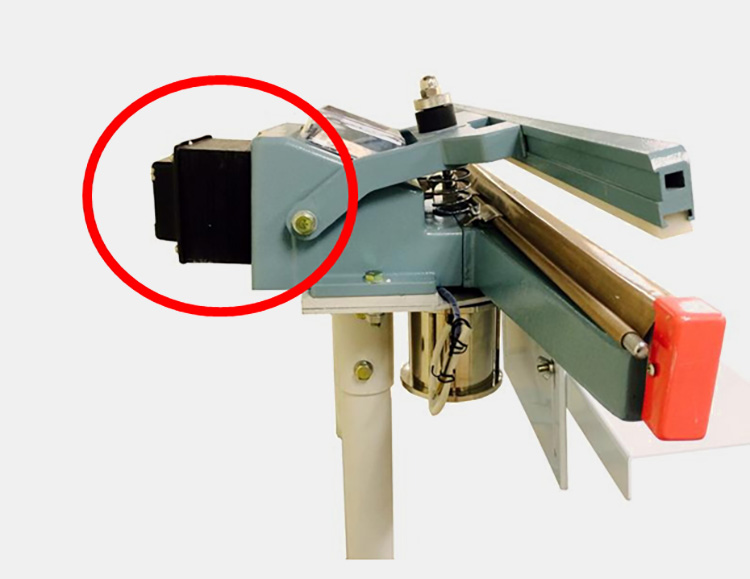

3.What Are The Components Of A Foot Operated Impulse Sealer?

The main components of a foot operated impulse sealer include:

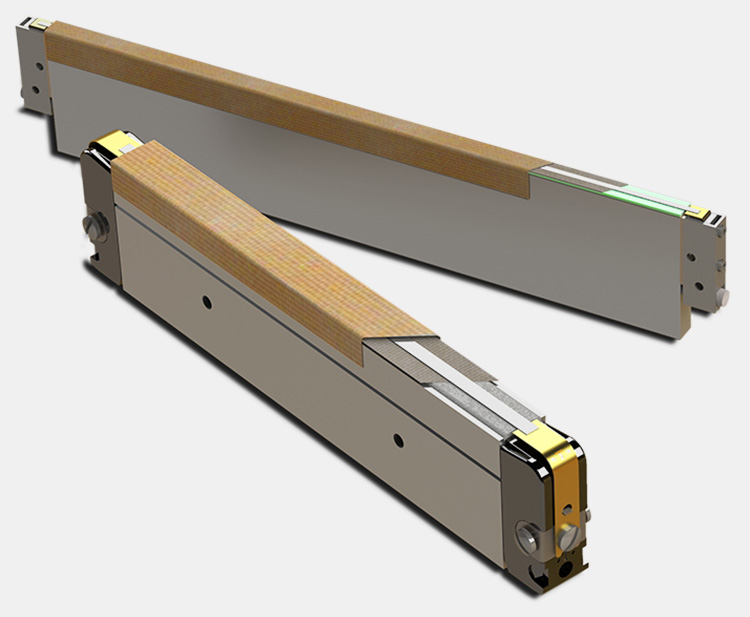

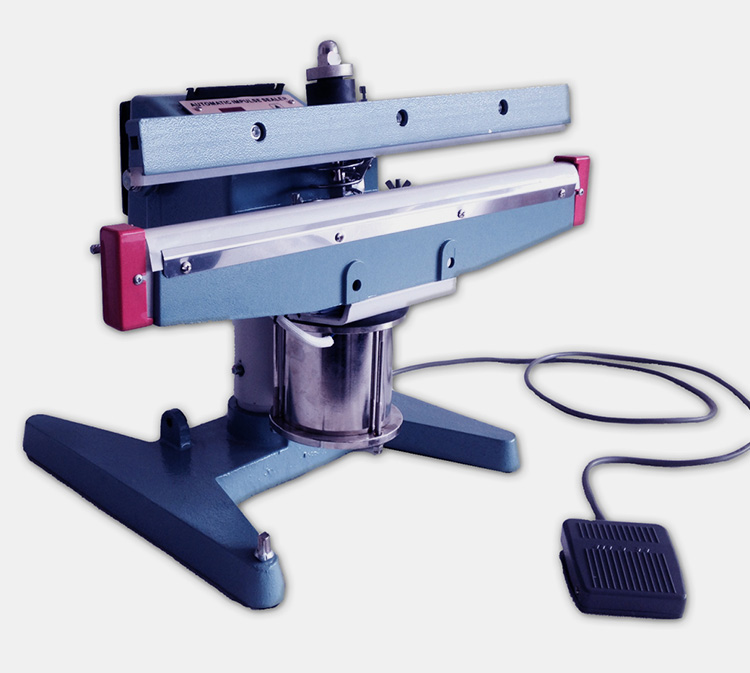

Foot pedal – This operates the sealing process by activating an electric impulse that triggers the heating element contained in the sealer jaw.

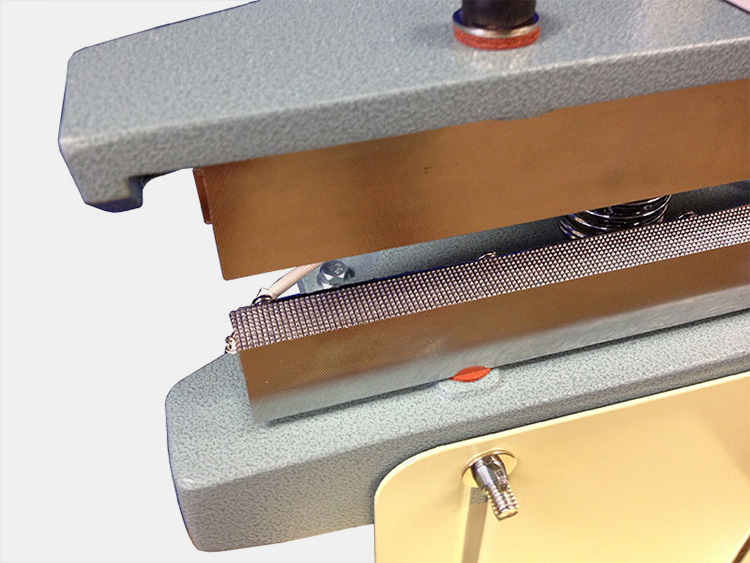

Heating element – This is the part of the sealing process that actually melts or fuses the plastic material together, creating a seal.

Sealing jaw – The sealer jaw houses the heating element and contains two plates that clamp down onto the material when the foot pedal is activated, pressing them together to form a seal.

Timer – This helps to ensure that the correct amount of heat is applied to the material when sealing, preventing it from becoming too hot or burning. It also ensures a consistent seal every time.

Cooling system – Once the sealing process is complete, a small fan cools down the sealer jaw and the material for easy manipulation afterwards.

Foot rest – A footrest is attached to the foot operated impulse sealer so that it can be used with both feet, ensuring a steady and secure seal every time.

Heat control knob – The heat control knob allows you to adjust the temperature of the heating element as needed for different materials and thicknesses.

Safety guard – A safety guard helps to prevent accidental contact with the hot surfaces of the foot operated impulse sealer while it is in operation.

4.How Does The Sealing Process Work With A Foot Operated Impulse Sealer?

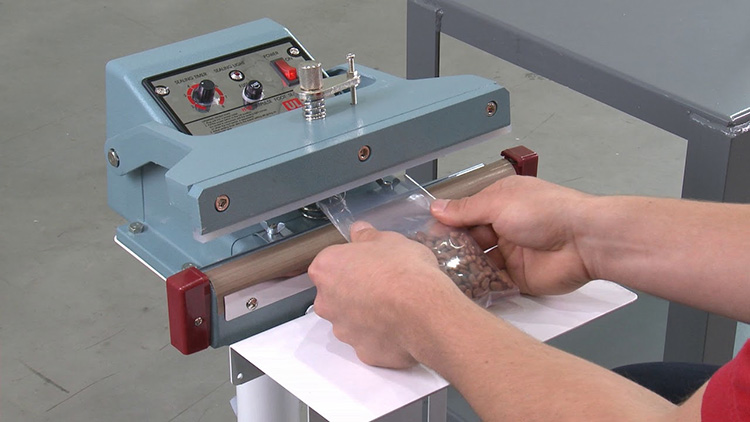

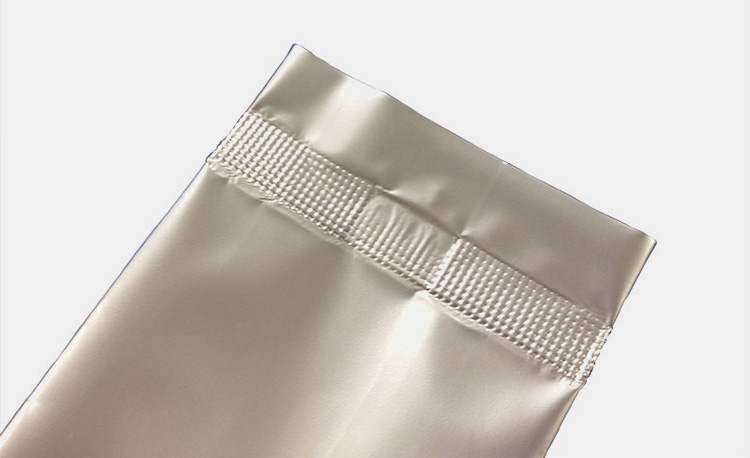

Foot operated impulse sealers work by heating a wire in the form of a strip that is contained inside the machine to very high temperatures. This heated strip then melts the plastic material which is placed between it, thus creating an airtight seal.

To begin the sealing process, the plastic material that needs to be sealed must first be placed between two metal jaws that are part of the machine. The jaws then hold the plastic in place while a timer counts down until it reaches zero.

Once the timer reaches zero, a foot pedal is pressed which sends a small electrical impulse to heat the wire strip contained inside the machine. This creates an intense heat which melts the plastic, forming an airtight seal around it.

Once the seal has been created, the foot pedal can be pressed again to release the jaws and remove the plastic from the machine. The entire process takes only a few seconds to complete and can be repeated multiple times with minimal effort.

5.What Are The Advantages Of A Foot Operated Impulse Sealer?

Foot operated impulse sealers are faster and more efficient than traditional hand-operated sealers.

Foot operated impulse sealers require less operator fatigue, as the operator does not need to constantly hold down a button or lever to operate the sealer.

Foot operated impulse sealers can be used for larger, thicker materials as they generate a large amount of heat and pressure while sealing.

Foot operated impulse sealers are safer to use than hand-operated sealers, as the operator does not need to deal with hot surfaces or wires that could cause burns or electrical shocks.

Foot operated impulse sealers are more cost effective, as they require less energy and time to operate.

Foot operated impulse sealers are able to consistently provide a strong, airtight seal, ensuring that the packaged products stay secure.

Foot operated impulse sealers have adjustable heat settings, allowing for easier customization of the type of seal required for different types of products.

Foot operated impulse sealers are more versatile, able to be used for a wide range of sealing applications including plastic bags, pouches and tubing.

6.What Are The Applications Of A Foot Operated Impulse Sealer?

Food Industry

Foot-operated impulse sealers are commonly used in the food industry to package and preserve perishable goods. The heat generated by the sealer creates an air-tight, watertight barrier that is ideal for keeping food fresh and safe from contaminants.

Medical Field

Foot operated impulse sealers are used by medical professionals to package and seal medical items, such as syringes, bandages, gauze pads, and other medications. The foot pedal allows for a consistent and sterile sealing process that helps to protect the integrity of the product.

Cosmetic Industry

Foot operated impulse sealers are used for packaging cosmetics and other beauty products, such as lip balms, makeup, lotions, and creams.

Manufacturing Industry

Foot-operated impulse sealers can also be used in the manufacturing industry for packaging finished products. They provide a reliable way to package goods quickly and efficiently, reducing time wasted in manual sealing processes.

Retail Industry

Foot-operated impulse sealers are used in retail stores to package goods and improve the customer experience. They can quickly and securely seal bags, giving customers peace of mind that their purchases are safe from damage or tampering during transport.

Textile Industry

Foot operated impulse sealers are used in the textile industry to make tight and secure seals on garments, fabrics, and other items made from fabric. The foot pedal mechanism allows for a stronger and more uniform seal than can be achieved using manual techniques.

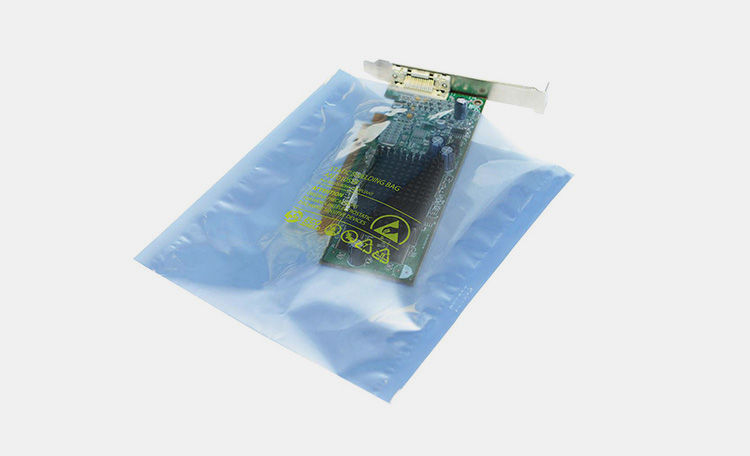

Electronic Industry

Foot operated impulse sealers are used in the electronic industry to create airtight seals on components such as circuit boards, connectors, and wires. The foot pedal offers precise control over the sealing process and ensures a strong level of protection against moisture, dust, and other contaminants.

7.Are Foot Operated Impulse Sealers Available In Different Sizes And Material?

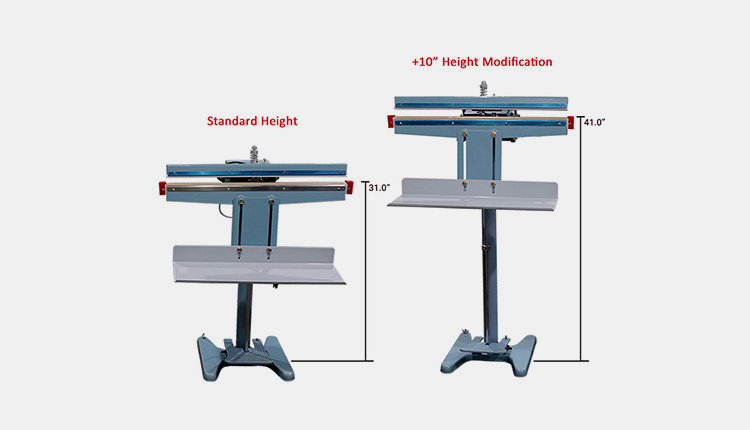

Yes! Foot operated impulse sealers come in a variety of sizes and materials, allowing you to tailor the sealer to your specific packaging needs.

The material used for foot operated impulse sealers can range from polyethylene, polypropylene and other plastic film materials. The size of foot operated impulse sealers can vary depending on the model and type of sealer.

Some foot operated impulse sealers can range in widths of up to 18 inches, while others are more compact, ranging from 6 inches in width. Depending on the purpose and size of the material being sealed, foot operated impulse sealers can be adjusted to meet your desired requirements.

Additionally, many foot operated impulse sealers are available with adjustable temperature and impulse time settings, allowing you to customize the sealer to your specific needs.

Overall foot operated impulse sealers offer a wide range of sizes and materials for you to choose from making the ideal choice for many packaging tasks. With their customizable settings and adjustable size, foot operated impulse sealers are an efficient and reliable solution for any sealing needs.

8.What Are The Different Types Of Foot Operated Impulse Sealers Available On The Market?

There are several different types of Foot Operated Impulse Sealers available on the market. These include:

Foot Pedal Impulse Sealers

Foot pedal impulse sealer are manually operated and require the user to press a pedal to activate the sealing process. This type of sealer can be used for light- to medium-duty applications.

Foot Pedal Impulse Clam Shell Sealers

Foot pedal impulse clam shell sealers are similar to foot pedal impulse sealers, but they feature two heat sealing jaws that cut and seal the plastic material in a single step. This type of sealer is ideal for medium- to heavy-duty applications.

Foot Pedal Impulse Band Sealers

Foot pedal impulse band sealers use a conveyor belt to move the material through a heated band that cuts and seals the plastic material. These sealers are mainly used for continuous sealing applications where high throughput rates are needed.

Foot Pedal Impulse Foot Sealers

Foot Pedal Impulse Foot Sealers are designed specifically for sealing thermoplastic bags. This type of sealer features a foot pedal to activate the heater, and they are suitable for sealing all types of plastic materials.

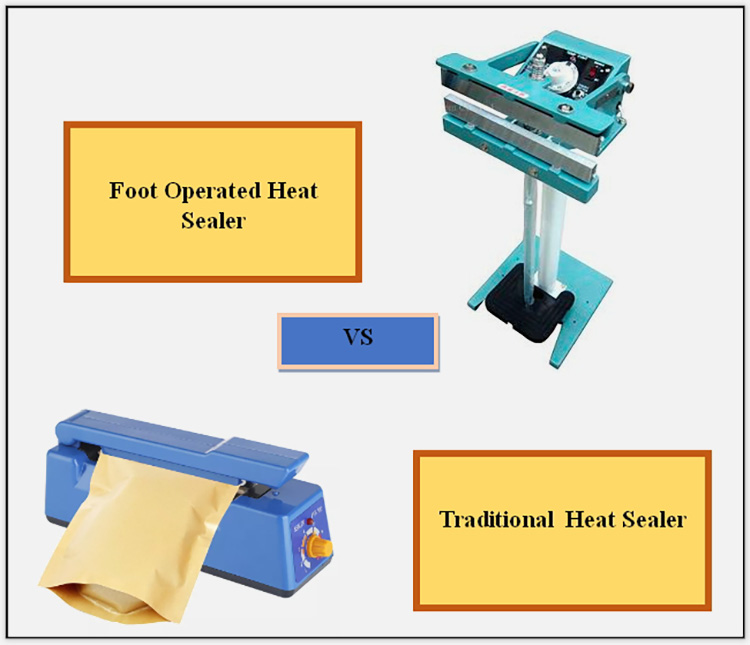

9.What Are The Differences Between A Foot Operated Impulse Sealer And A Hand Operated Impulse Sealer?

Foot Operated Impulse Sealer

Hand Operated Impulse Sealer

a) Mode of Operation

A foot operated impulse sealer requires the user to press down on a foot pedal in order to activate the heating element and seal the material. This type of machine allows for hands-free operation, making it more efficient and easier to use than a hand operated impulse sealer.

Hand operated impulse sealers on the other hand require the user to squeeze a handle in order to activate the heating element and seal the material. This type of machine is more suitable for smaller-scale operations, as it does not require a foot pedal or foot switch.

b) Size and Scale of the Job

Foot operated impulse sealers are generally recommended for larger scale sealing operations, while hand operated impulse sealers are better suited for smaller jobs.

c)Type of Material That Needs to Be Sealed

Foot operated impulse sealers can provide more control over the temperature settings and pressure used for sealing different materials, making them better suited for sealing plastic bags. Hand operated machines, on the other hand, are better suited for paper or fabric sealing materials.

10.What Type Of Products Can Be Sealed Using A Foot Operated Impulse Sealer?

Food Products

Foot operated impulse sealers are commonly used to package food items such as chips, snacks, and other typical snack foods. They can also be used to seal bags of vegetables, fruits, meats, and other food products before they are frozen or refrigerated.

Clothing

Foot operated impulse sealers can be used to sealed plastic wraps around clothing, such as jackets, coats, and other apparel items.

Pharmaceuticals

Foot operated impulse sealers are often used for sealing pharmaceuticals such as pills, capsules, and tablets.

Medical Supplies

Foot operated impulse sealers are often used to package medical supplies such as bandages, gauze, and other sterile items.

Cosmetics

Foot operated impulse sealers can be used to package cosmetic items such as creams, lotions, face masks, powders, and other beauty products. This helps keep the product fresh and prevents leakage or spills.

Retail Products

Foot operated impulse sealers can be used to package retail products such as clothing, toys, books, and other items. They help to ensure that the contents of the packages are secure and intact when delivered to customers.

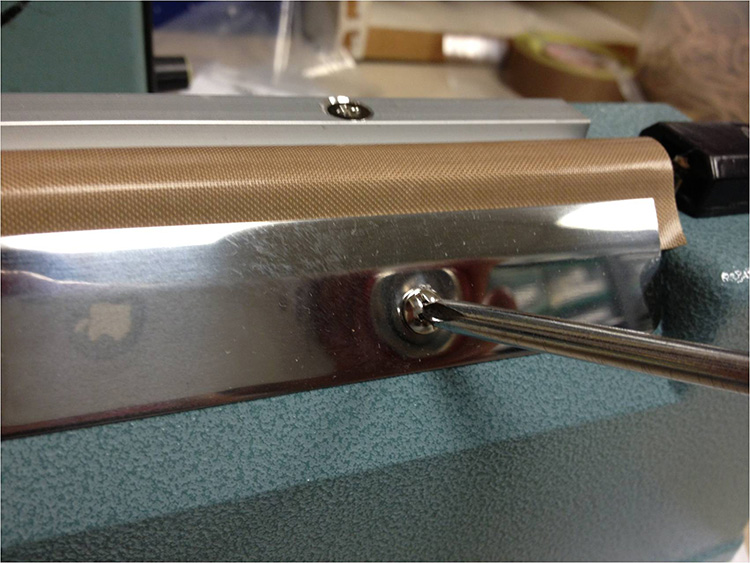

11.What Maintenance Tips Should You Follow To Keep Your Foot Operated Impulse Sealer In Good Condition?

Clean the foot operated impulse sealer regularly

Be sure to clean the foot operated impulse sealer after every use. This will help keep food particles and other debris from building up on the machine. Use a soft, damp cloth to wipe down both the inner and outer surfaces of your sealer.

Keep moving parts oiled

The foot operated impulse sealer has several moving parts, and it’s important you keep them oiled with a lightweight machine oil. This will help ensure that the foot operated impulse sealer runs smoothly and efficiently.

Check for any signs of wear

Inspect your foot operated impulse sealer regularly for any signs of wear. Look for any frayed wiring, loose screws, or cracked parts. Replace any broken parts immediately to avoid further damage and ensure proper operation of the foot operated impulse sealer.

Store properly

When not in use, store your foot operated impulse sealer in a dry place at room temperature. You should also cover the foot operated impulse sealer with a dust cover or plastic bag to help keep it clean and free from corrosion.

12.How Can You Troubleshoot A Foot Operated Impulse Sealer When It’s Not Working Properly?

If your foot operated impulse sealer isn’t working properly, there are a few things you can do to troubleshoot the issue.

First, check to make sure that the power cord is plugged in and that the sealer is turned on. If the sealer is still not working, check to see if the heating element is damaged. If the heating element is damaged, it may need to be replaced.

You should also check the foot petal for any damage or issues. If there are any problems with the foot pedal, try cleaning it and making sure that all connections are properly secured. If this doesn’t resolve the issue, you may need to replace it.

If your foot operated impulse sealer is still not working, it may be due to a problem with the timer. Try resetting and testing the timer first to see if that resolves any issues. If this doesn’t help, you may need to get the timer replaced.

Finally, check for any obstructions in or around the foot operated impulse sealer. Make sure that there are no objects blocking the sealer from performing its job properly.

13.How Can You Choose The Right Foot Operated Impulse Sealer For Your Needs?

Consider the size of your product

Foot operated impulse sealers come in a range of sizes that are suitable for different sized products, so it’s important to choose one with a sealing length and width that match your needs.

Think about the speed you need

Foot operated impulse sealers vary in their sealing speed and how quickly they work to seal different products, so consider the speed you need for your application before making a purchase.

Determine the material of your product

Foot operated impulse sealers are designed for use with specific materials such as polyethylene, polypropylene, nylon, and other thermoplastic films. Knowing what material your product is made from will help you choose the right foot operated impulse sealer for it.

Evaluate any additional features

Foot operated impulse sealers may offer extra features such as adjustable temperature control, foot pedal activation and safety guards that can help make sealing easier and more efficient. Consider these features when making a purchasing decision.

Compare prices and reviews

foot operated impulse sealers come in a range of prices, so it’s worth comparing different models to find the best deal and read reviews from other customers to get an idea of how well they work.

Evaluate the customer service

Foot operated impulse sealers should come with good customer support from the manufacturer or retailer in case you have any questions or need help with installation or maintenance. Make sure to check this before you make a purchase.

14.Do You Need Any Special Training To Use Foot Operated Impulse Sealers?

No special training is required to operate foot operated impulse sealers. This type of packaging machine uses foot pedals instead of hand levers and buttons to start the sealing process.

The foot pedal is connected directly to the heating elements and a foot switch, allowing you to initiate the sealing process quickly and easily. All you have to do is place the material in the machine, press down on the foot switch and wait for the seal to form.

This makes foot operated impulse sealers an ideal choice for you who are looking for a simple and easy way to package their products. With its foot pedal operation and easy-to-learn process, foot operated impulse sealers provide a safe and efficient method of sealing products.

15.AreFoot Operated Impulse Sealers Suitable For High Speed Application?

Yes! Foot operated impulse sealers are highly suitable for high speed applications. These sealers are designed to provide a reliable and consistent sealing operation, with quick changeover capabilities, and the foot operated impulse sealer provides an economical solution for large production runs.

The foot operated impulse sealer is also able to offer superior results in terms of speed, consistency and accuracy. This means that foot operated impulse sealers are well suited to applications where high speed, accuracy and reliability are critical.

CONCLUSION

The foot operated impulse sealer is an innovative solution for sealing and packaging your items quickly and smoothly. With its simple yet highly efficient design, this product is a must-have item for anyone looking to improve their production process without increased costs. From large business to small home craft projects, it’s perfect for any situation. If you would like further information about this great product don’t hesitate to contact Allpack who are leading specialists in packaging supplies across china. Their knowledgeable staff will be more than happy to help you with answers to any questions that you might have. You won’t regret investing in this amazing product – get in touch with Allpack today!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Foot Operated Impulse Sealer: The Complete Buying Guide In 2025 Read More »