Automatic Tape Dispenser: The Complete Buying Guide In 2025

With the increasing population of world, industries and factories are now focused on producing products with higher precision, quality, and greater productivity. In this regard, automatic tape dispenser is also one of the most liable products used for dispensing tape on cartons, boxes and plastics with uniformity and precision. So, read the complete blog to take the most of it.

1.What Is the Automatic Tape Dispenser?

Automatic tape dispensers also called as automatic tape cutting machine, adhesive tape machine, are applied for holding the tape and cutting the tape to pack the cartons or boxes. It is used due to its rapid tape dispensing capability on packaging bags, cartons and boxes.

2.What Are the Applications of Automatic Tape Dispensers?

The automatic tape dispensers are mainly applied in packaging industry, and it can pack cartons, boxes, electromechanical products, files and so on.

There are number of industries that are busy in using these automatic tape dispensers because of its advance features and quality packaging. An automatic tape dispenser can be applied in all type of factories, industries, households and companies where packaging of boxes, cartons, bags takes place.

- Carton Industry

Automatic tape dispenser can be applied in carton industry for cutting the tapes and sealing the cartons and boxes.

- Automobile Industry

Automatic tape dispenser can be applied in automobile industry for sealing in the assembly of auto parts, protecting the body during painting, sealing small holes in the body, reducing noise, etc.

- Architecture Industry

Automatic tape dispenser can be applied in architecture industry for sealing building doors and windows, elevators, glass walls, solar elements.

- Printing Industry

Automatic tape dispenser can be applied in printing industry for adjusting the printing quality and reduce the time for changing rolls.

- Electrical Industry

Automatic tape dispenser can be applied in electrical industry for sealing the goods in transportation, ensuring the safety of electrical appliances, and can also be used for panel fixing, surface protection, etc.

Whether it is a carton industry, automobile industry, architecture industry, printing industry, electrical industry, all types of industries are now using automatic tape dispenser to get more better-quality packaging of products with fast output ratio.

3.How Many Types of Automatic Tape Dispensers Are There?

There are three main types of automatic tape dispensers in the current conditions and are used in different types of industries, factories and households including water activated automatic tape dispenser, automatic electronic tape dispenser, pneumatic tape dispenser.

- Water Activated Automatic Tape Dispenser

Water activated automatic tape dispenser is the type of automatic tape dispenser specially used for holding and cutting water activated tapes including ultra durable water activated tape and white water activated tape. This type of tape is very environmentally friendly.

When the packaging is unpacked, this tape can generally be recycled, dissolved directly in the soil, and used as fertilizer.

- Automatic Electronic Tape Dispenser

Automatic electronic tape dispenser is the type of automatic tape dispenser specially that mainly driven by electricity. It has the advantage of being faster and easier to operate than a manual dispenser. But the electronic tape dispenser is more expensive.

Automatic electronic tape dispenser is suitable for commercial or factory use. Because the electrical tape dispenser is more efficient and suitable for large events and projects. It is a powered machine and does not require any manual operation to cut the tape.

- Pneumatic Tape Dispenser

Pneumatic tape dispenser is the most expensive of the three tape dispensers. Pneumatic tape dispenser is the most efficient and fastest tape dispenser among the three tape dispensers. Pneumatic tape dispenser is best suited for industrial applications. Pneumatic tape dispenser is most suitable for encapsulating large cartons.

With all these types of automatic tape dispenser, you may apply them in different uses with high efficiency.

4.What Are the Main Components of the Automatic Tape Dispenser?

Different types of automatic tape dispensers have different main components, and you will learn from the main components from the types of water activated automatic tape dispenser, automatic electronic tape dispenser, pneumatic tape dispenser.

- Main Components of Water Activated Automatic Tape Dispenser

There are total twelve main components of the water activated automatic tape dispenser including the top cover, operating guide, brush assembly, water bottle, water tank, roll guides, lower platen, heating equipment, brush pressure adjusting device, shear blade, drive wheel, manual handle for shear blade.

- Main Components of Automatic Electronic Tape Dispenser

There are three main parts of the automatic electronic tape dispenser including the front part, the back part and the panel part.

The Front Part

There are nine main components for the front part of the automatic electronic tape dispenser including pressure roller, digital display, tape exit, soft tape bracket, blade set, adjustable level for tape, sensor, tape bracket, and “pinch roller elastic” button.

The Back Part

There are seven main components for the back part of the automatic electronic tape dispenser including tape bottom bracket, switch, fuse holder(built-in fuse), powder cord socket, tape separator(spare), auxiliary bracket.

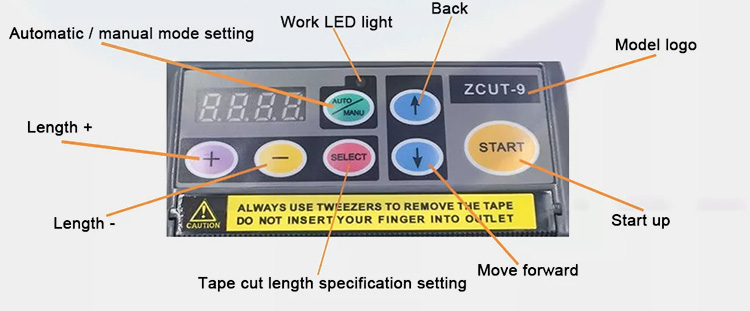

The Panel Part

There are nine main components for the panel part of the automatic electronic tape dispenser including automatic/manual mode setting, length+, length-, tape cutting length specification setting, mode forward, start up, model logo, back, work LED light.

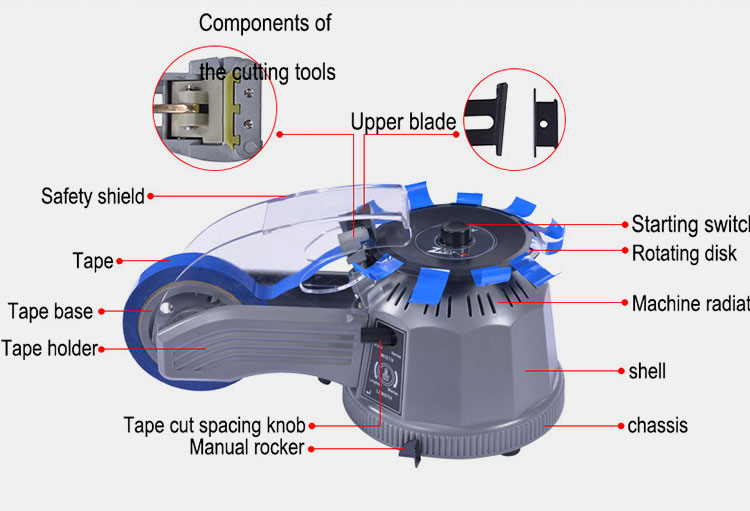

- Main Components of Pneumatic Tape Dispenser

There are thirteen parts of the pneumatic tape dispenser including safety shield, tape, tape base, tape holder, tape cut spacing knob, manual rocker, chassis, shell, machine radiate, rotating disk, starting switch, upper blade, components of the cutting tools.

The parts composition of pneumatic tape dispenser is the most complex and the most parts tape dispensers among the three styles. This needs to be more maintained and monitored. When put into use, you need to pay more attention to the way you use it.

5.What Are the Features of the Automatic Tape Dispenser?

All the automatic tape dispensers have the similar features and the details are as the following below:

- Applied for Two Roll Tapes At the Same Time

Automatic tape dispensers can handle two rolls of tape at the same time and cut them at the same time.

- Applied for Various Types of Tapes

Automatic tape dispensers can cut different materials such as tape, adhesive tape, protective film, etc.

- Data Saving

Automatic tape dispensers have a memory function, and the original data will still be saved when the machine is turned off and on again.

- Cycle Cut

Automatic tape dispensers have the function of circular cutting, free to set different lengths of circular cutting, and can cut adhesive tapes of different thicknesses.

- Wheel Design

Tape cutting machines are usually designed with no rollers and have high safety performance.

6.What Are the Working Principles of the Automatic Tape Dispenser?

Like other dispensing equipment used in industries, automatic tape dispenser also has a simple operational procedure. The operation of an automatic tape dispenser is done in following steps.

- Initially, all the parameters including electrical, tape roll, length setting, edge cutting and others are done in an automatic tape dispenser.

- As the setting is done the roll of tape is filled with a new tape in a specific manner which is defined by the manufacturer itself.

- As the operator finds all the things in favor, it pushes the numbered button from where it selects the length of tape take is to be used to seal a packet.

- The machine is carried to the carton then and positions the place of taping and presses it down.

- The dispenser than releases the tape automatically and on the other hand the cutting of edges is also done as it reaches to the length selected previously.

- In this manner the tape bonds both the flaps of object with greater strength.

The working principles of the automatic tape dispensers are quite simple, because the they are totally automatic driven, and there is no labor work need. The only thing you need to do is to paste the tape to the cartons or boxes.

7.What Are the Advantages of the Automatic Tape Dispenser?

With various advantages of the automatic tape dispensers, you can fulfill your household purposes or you can bright your business. The main advantages of the automatic tape dispensers are user friendly, fast cutting, cut to pre-set lengths, reduction in movement, low risk of injury, far less fatigue of operator.

- User Friendly

Automatic tape dispenser is very user friendly because of their operation. The machine assists the operator to one select the type of cutting and the length of tape that has to be cut. Rest the whole work is done by the machine itself in a precise manner.

- Fast Cutting

In terms of fast cutting, the loaded tape comes out of the dispenser as it gets powered. The operator pushes the desired length and the tapes comes out quickly. When the operator positions the dispenser on cartons or boxes, it presses the flaps down and quickly seal it to make it secure from opening during transportation.

- Cut to Pre-Set Lengths

The key feature of an automatic tape dispenser is that it cuts the tape which is preset by the operator. The setting is done as per the requirement of box edges or by the desire of customer as well. Variety of options are available in an automatic tape dispenser to customize the setting of length of tape.

- Reduction In Movement

An automatic tape dispenser facilitates the operator to minimize the number of movements to pack a box or carton and also helps in increasing the productivity of an industry. Through a research it has been gathered that by using an automatic tape dispenser, the productivity of an industry increases by 21%.

- Low Risk of Injury

As mentioned above, when the number of movements is decreased it automatically results in low risk of any type of injury or accidents.

- Far Less Fatigue of Operator

In an automatic tape dispenser, the maximum work is done the machine itself rather than by the operator. As a result, the operator gets a greater comfort zone and gets less fatigue in operation.

After knowing about the advantages, there are also various packaging tapes for you to choose. Different types of tapes may applied to different types of tape dispensers.

8.What Tapes Are Mostly Applied In the Automatic Tape Dispenser?

There are various tapes that are frequently applied in the automatic tape dispenser including water activated tapes, scotch tapes, double sided tapes, fiber tapes, warning tapes, kraft paper tapes, etc. Here are the details as following below:

- Water-activated Tape

Water activated tape is made up of pure paper and has a reinforce of fiberglass in it for making it strength full. An automatic tape dispenser has an activated feature with water for proper dispensing of water activated tape. For this a water heater is also installed in it that aids the adhesion of bounding tape.

- Scotch Tape

The scotch tape is made on the basis of the BOPP original film after high-voltage corona to make one side rough, then coated with glue, and then divided into small rolls, which is the tape you use every day. Scotch tape is the most popular type of tape used for binding purpose and is available in different sizes and lengths.

- Double Sided Tape

A double-sided tape is used where both the surfaces of the material are to be used for sticking purpose. These tapes are a bit expensive so with an automatic tape dispenser, proper dispatching of tape is performed and which creates less chances of waste.

- Fiber tape

A fiber tape is usually used as a replacement of paper tape or in areas where patch holes are to be covered in dry walls. They are also best incorporated with automatic tape dispenser.

- Warning Tape

Warning tape is a tape made of PVC film as the base material and coated with rubber-type pressure-sensitive adhesive. Warning tape has the advantages of waterproof, moisture-proof, weather resistance, corrosion resistance, anti-static, etc. It is suitable for anti-corrosion protection of underground pipelines such as air pipes, water pipes, and oil pipelines.

- Kraft Paper Tape

Kraft paper tape is divided into wet water kraft paper tape and water-free kraft paper tape, which can be printed and screened according to requirements. Kraft paper tapes are produced using the pulp of a tree or wood. They are famous due to their stickiness and are widely used for secure sealing.

All these tapes are the most popular tapes that often applied in the automatic tape dispensers. And the different tapes need to be applied in different automatic tape dispensers.

9.What Are the Common Errors and Its Remedies That Occur In An Automatic Tape Dispenser?

When you are operating the automatic tape dispensers, there may be some common errors sometimes. You do not have to worry about this things, and here are the common errors in the operating process and its remedies. Your problems will be well managed if you after this guide.

| S.NO | PROBLEM | CAUSE | TROUBLESHOOTING |

| 1 | Problem in Powering On | Problem in the electrical unit of dispenser | * Check the power cord that it properly supplies the power or not

* Unplug the system and then plug it back * Reset the surge protector |

| 2 | No proper dispensing of tape | Insufficient tape quantity or improper placement of tape | * Check whether there is a tape or not

* Check the proper placement of tape * Verify the pressure roller that is it working properly * Check if there is any blockage within the system |

| 3 | No sufficient tape dispensing | Inadequately gummed tape prevents tape bonding inside dispenser | * Check the brushes of dispenser and water tank if it’s a water activated tape.

* Remove the excess glue from the brushes. |

| 4 | No proper adhere of water activated tape | Moistened of tape and no permanent bonding on surface. | * Check the adhesion of tape.

* Check the brushes of dispenser and water tank if it’s a water activated tape. * Check the operation of heater. |

If you encounter such problems in the process of operating the automatic tape dispenser in the future, you can directly refer to this form to solve them, or you can contact us directly. We very much welcome your inquiries.

10.How to Choose Right Type of Automatic Tape Dispenser?

Here are the tips for you to choose the right type of automatic dispenser for yourself, and the details are about tape thickness, production volume, shipping volume, maintenance.

- Tape Thickness

Cartons and boxes of different sizes, material and weight are available for packaging purpose in industries. With respect to that, the manufacturer has to decide that what type of automatic taping dispenser is required and what taping material will be applied on those particular cartons.

This is the key factor to chose the right type of automatic taping dispenser. To choose a right type of dispenser according to their taping thickness is as below

| S.NO | Automatic Tape Dispenser | Taping Material | Thickness

(mil) |

| 1 | Semi-Automatic Tape Machine | Water-Activated Tape

Kraft Paper Tape |

3.5 – 8.5 mil |

| 2 | Electric Taping Machine | Scotch Tape

Warning Tape |

2.0 – 3.5 mil |

| 3 | Kraft Tape Dispenser | Kraft Paper Tape | 6.5 – 8.5 mil |

| 4 | Definite Length Tape Dispenser | Double Sided Tape

Fiber Tape Acrylic Tape Warning Tape Scotch Tape |

1.5 – 16 mil |

The thickness of a tape is measured in mil and its measuring is equal to one thousandth of an inch.

- Production Volume

Information related to total production volume plays a vital role in choosing a right automatic tape dispenser as it provides the complete dynamics of an industry. With help of that the manufacturer can choose a best suitable dispenser to fulfill its requirement. Dispenser that allows multiple tape sizes and thickness are always a best choice to buy.

Electric tape dispensers and definite tape dispensers are best choice for companies that pack bulky and heavy boxes.

- Shipping Volume

Volume of shipping is one of the concerns a manufacturer thinks before choosing an automatic tape dispenser. Having a manual, semi-automatic or automatic tape dispenser depends on the number of cartons packed in an industry. The tape core diameter and tape width are considered at priority

| S. No | Dispenser Type | Tape Core Diameter

(Inch) |

Tape Width

(Inch) |

| 1 | Manual Tape Dispenser | 3 in | 1 to 3 in |

| 2 | Semi-Automatic Tape Dispenser | 1 to 3 in | 1 to 18 in |

| 3 | Automatic Tape Dispenser | 1 to 4 in | 1 to 5-7/8 in |

- Maintenance

Selecting a right dispenser also depends on how much maintenance cost it takes. Dispenser with less maintenance requirements are more ideal to select and it can reduce production downtime and can be economical

Conclusion:

Many industries are busy in using automatic tape dispensers and tend to buy the most suitable one according to their production setup. Where number of manufacturers are busy in producing these automatic tape dispensers. This buying can assist and guide you regarding an automatic tape dispenser and if still there is any confusion in your mind you can contact us or visit our website http://www.allpackchina.com/ .

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide