Introduction:

BS-1510G label shrink tunnel adopt hot ais circulating shrinkage, mainly for shrinking such containers as bottles, jars and cups etc. A variety of shrinking films, including PVC, POF etc. are applicable.

Features:

Adopts imported parts and S/s heaters;

The shrink temperature is adjustable, and the maximum is 250°C;

The conveying speed is controlled by a step less electronic speed controller; Only heat the cap of bottle, ensures products quality inside the bottle;

The shell of the machine is made of stainless steel or painted steel;

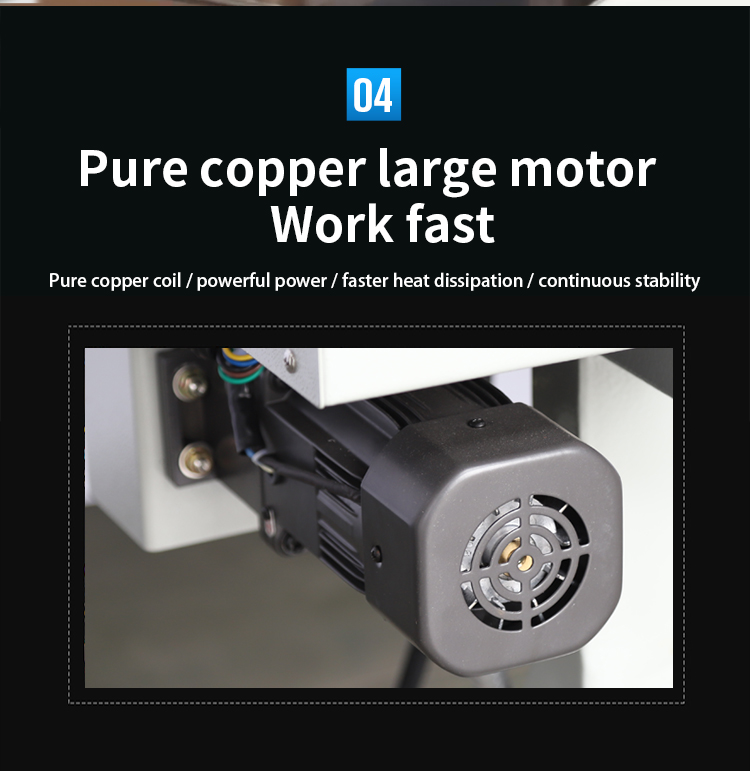

Adopt two blowing motors in low power, turbo air blowing ensure the labels position and without corrugation after shrunk;

Can meet all kinds of bottles just need to set and adjust the machine simply;

Can heat only part of the tunnel for some special requirement of the products so that can save the energy; This item can be connected with the production line.

Application:

BS-1510G label shrink tunnel and shrink label on the body as well as the cap of bolts.

Transport the bottles out from the tunnel after inserting the labels it can be used for foodstuff, beverage, pharmacy, cosmetics and pesticide industries.

Product Detail:

Specification:

| MODEL | BS-1510G |

| Voltage(VIHz) | AC 220/50 110/60 |

| Power (kw) | 4.5 |

| Packing Speed (pcs/hour) | 8000-12000 |

| Max.Packing Size(pxH) (mm) | 120×400 |

| Tunnel Size (LxWxH)(mm) | 1000×150×100 |

| Film Used | PVC, POF |

| External Dimension (LxWxH)(mm) | 1530×400×1300 |

| Net Weight (kg) | 180 |

Reviews

There are no reviews yet.