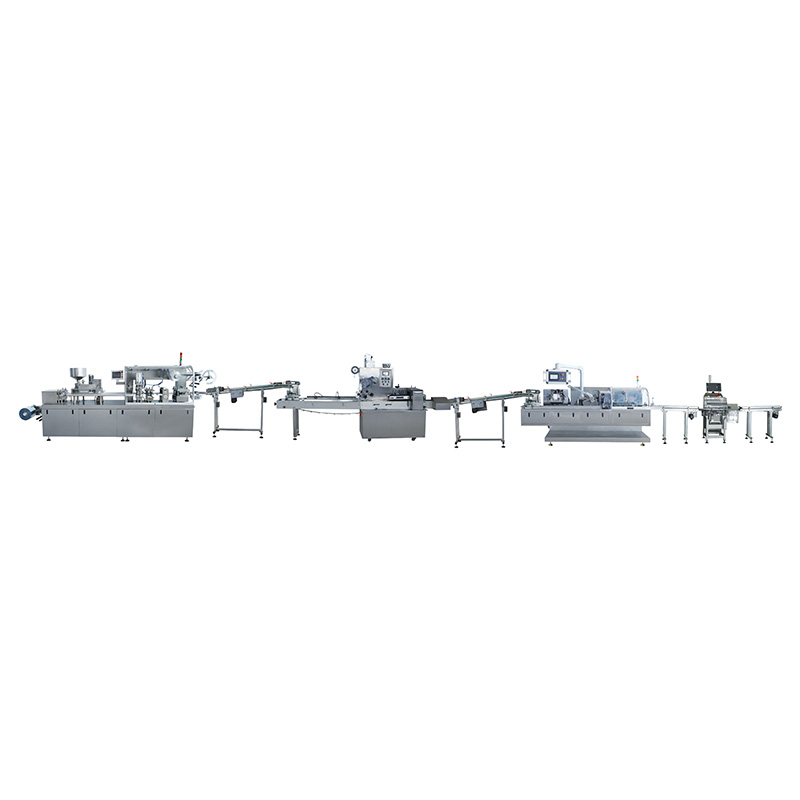

BZLX-120B Full Automatic Horizontal Blister flow wrap Cartoning Line

Allpack BZLX-120B full automatic blister flow wrap cartoning line is made of DPP-260 blister packaging machine,flow wrap machine and WZH-120 automatic cartoning machine.The production line can be used for packing of all kinds of capsules, tablets and other drugs (aluminum-plastic/aluminum-aluminum) with bubble caps. It can be connected with baling machine, inspection machine, packing machine and other subsequent equipment to form a complete and efficient drug packing production line.The design structure of the production line meets the requirements of GMP and GMP standards and the principles of ergonomics. It adopts advanced servo intelligent drive and PCL man-machine interface control.With feeding camera detection, lack of material detection, etc., to ensure the qualified rate of finished products.It can be separated into the elevator and the purification workshop after decoration.

Allpack BZLX-120B full automatic blister flow wrap cartoning lineFeatures:

1.The production line adopts an independent control system, with operation and maintenance flexibility.

2.Equipment set of mechanical and electrical, gas, light integration of high tech products, to ensure the product pass rate of 100%.

3.Hardware, software design of human nature, the whole line of automatic adjustment of production, saving waste of resources, improve production efficiency.

4.Device transition using soft connection, the production workshop space flexible layout, the effective use of space.

5.Equipment split packaging, transport, and more conductive to the use of the field of transport and installation.

Allpack BZLX-120B full automatic blister flow wrap cartoning line Technical Specification:

| Cartoning speed | 30-100box/min | |

| Carton box | Quality requirement | 300-350g/m2 (base on carton size) |

| Dimension range

(L x W xH) |

(65-180)x(35-85)x(15-50)mm

|

|

| Instruction | Quality requirement | 60-70g/m2 |

| Unfolded leaflet specification | (80-250)x (90-170)mm | |

| Fold range (L X W) | 1-4 fold | |

| Compressed air | Working pressure | ≥ 0.6 mpa |

| Air consumption | 120-160 L/min | |

| Power | 220v, 50Hz | |

| Overall dimensions | 4300(L)X1100(W)X1550(H)mm | |

| Weight | About 1600kg | |

Cartoning Machine Related Products