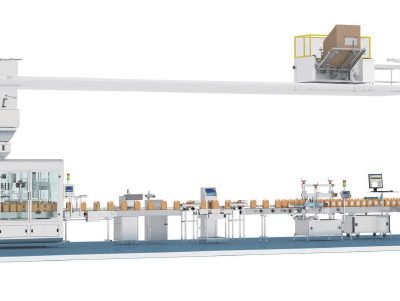

Allpack 5-30L Lubricant Oil Filling Machine Drum Filling Automatic liquid filling Line

Allpack 5-30L lubricant oil filling machine is suitable for filling high viscosity materials (such as lubricating oil, engine oil, gear oil, etc.) . The lubricating oil filling machine can be integrated with the capping machine, labeling machine, and film packaging machine to form a complete lubricating oil production line.With PLC plus man-machine interface, touch operation,the machine can do self-diagnosis of fault alarm at a glance.This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.With Accurate measurement, adopt servo control system, ensure the piston can always reaches constant position.When close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution.

Allpack 5-30L Lubricant Oil Filling Machine Features:

1.Machine adopts Panasonic servo motor to drive piston pumps, with high speed and high filling accuracy, also with very easy filling volume adjusted---adjusting on touch screen. Compared with traditional cylinder filling machine, it save lots of time!

2.The machine adopts full-auto PLC + human-computer touch screen control system. For different grams for example, 100ml, 500ml, 1000ml, we set three procedures, mode 1, mode 2, model 3``` The PLC can save these parameters for later use. Operators do not need too much complicated adjustments; the filling machine can switch between the three models easily.

3.Machine parts use stainless steel SUS304 & SUS316L. The machine use world word-class brand components, such as photo sensor---Keyence (Japan) PLC---Mitsubishi (Japan) Electrinic control part---Schneider (France) Touch screen---Delta (Taiwan China) Or MCGS(Beijing China) Cylinder--AirAc (Taiwan China)

4.There is a sensor on tank to start or stop the pump transfer liquid/ paste or stop transfer. It is automatically.

5.For hot filling, we make double tank, which can be heated to keep temperature for material inside. Also with a mixer inside to stir material even, ensure good filling accuracy.

6.To ensure the bottles and filling heads are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable. No bottle no filling.

7.The filling heads are specially made, with the function of anti-drop and anti-drawing & bubble-kill. Can make diving filling heads to move together with liquid level.

Allpack 5-30L Lubricant Oil Filling Machine Technical Specification:

CZ-6B Automatic Weight Filling Machine

1.Applicable Drum Size: Min: 200*140*320mm (L*W*H)

2.Max: 290*260*400mm (L*W*H)

3.Capacity: 400-500 Drums/hour (5L)

FXG-1D Follow Type Capping Machine

1.Applicable Bottle Size: Min: 140*120*300mm, Max: 260*300*450mm

2.Capacity: ≤1800BPH (5L)

3.Cap Size: φ20-70mm, Cap Height: 20-40mm

4.External Dimension: 1995*1300*2246mm (L*W*H)

TN-200LDS Drum Two Sides Self Adhesive Labeling Machine

1.Label Size: Min: 140*200*320mm, Max: 260*290*500mm

2.Capacity: 2500 Bottles/hour (5L)

3.Labeling Precision: ± 1mm

4.External Dimension: 3000*1720*140 (L*W*H)

Automatic Lubricant Oil Filling Machine Related Products