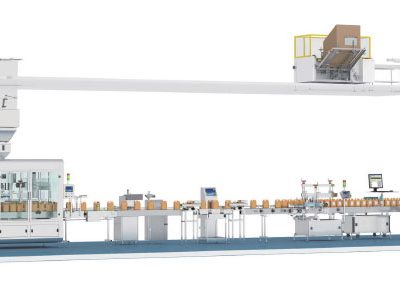

Allpack 5-30L Chemical Filling Machine Bleach Acid Lubricant Oil Drum Filling Automatic Liquid Filling Line

Allpack 5-30L chemical filling machine is made by a linear scale with roller, chain-driven drum in and out structure, fast and slow fillings (with dive function), material tank, weight control meter, and PLC control unit. This filling machine can do the auto-filling of different materials (with or without foam). Adopting a weight filling system (American METTLER TOLEDO weighing sensor and control meter, this chemical filling machine can ensure that high filling precision. The unique ball-to-go drums conveying method ensures smooth drum-out conveying after filling.

Allpack 5-30L Chemical Filling Machine Features:

1. The machine uses fast & slow filling valves, and diving filling heads do under-level filling which can avoid the foaming problem when filling.

2. The control system uses Schneider, which is more stable, safe, green, and low energy consumption.

3. A liquid tray that is controlled by an individual cylinder is installed under the filling nozzles. The externally placed PTFE plugs can make sure the drops will not leak out of the bottle after the filling head is closed.

4. The whole machine uses the frame of Stainless Steel 304 which perfect anti-corrosion effect. The stainless steel cover and the toughened glass door prevent the dirty air during filling from polluting the environment and are easy to clean. The sealing material of scale and product contact parts is fluorine rubber.

5. The machine has a material tank, equipped with a level detection system, and automatic coordination of feeding.

Allpack 5-30L Chemical Filling Machine Technical Specification:

CZ-6B Automatic Weight Filling Machine

1. Applicable Drum Size: Min: 200*140*320mm (L*W*H); Max: 290*260*400mm (L*W*H)

2. Capacity: 400-500 Drums/hour (5L)

FXG-1D Follow Type Capping Machine

1. Applicable Bottle Size: Min: 140*120*300mm, Max: 260*300*450mm

2. Capacity: ≤1800BPH (5L)

3. Cap Size: φ20-70mm, Cap Height: 20-40mm

4. External Dimension: 1995*1300*2246mm (L*W*H)

TN-200LDS Drum Two Sides Self-Adhesive Labeling Machine

1. Label Size: Min: 140*200*320mm, Max: 260*290*500mm

2. Capacity: 2500 Bottles/hour (5L)

3. Labeling Precision: ± 1mm

4. External Dimension: 3000*1720*140 (L*W*H)

Automatic Chemical Filling Machine Related Products