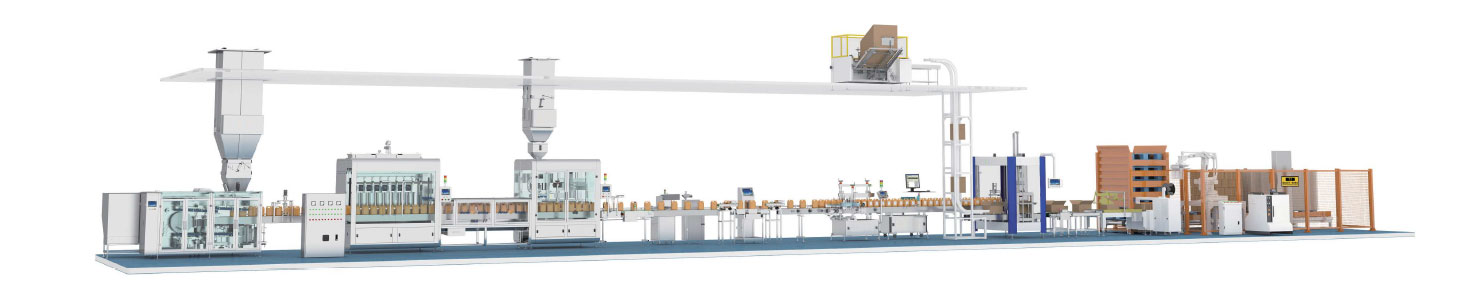

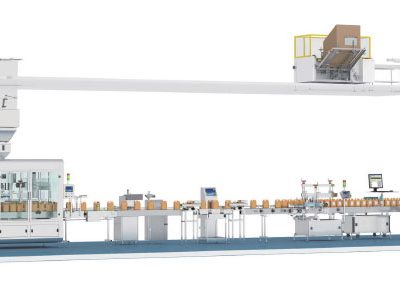

Allpack 1-5L Bullet Train Chemical Filling Machine Automatic Liquid Filling Line

Allpack 1-5L chemical filling machine adopts the metering and filling principle of keeping liquid level constant (constant speed) and timing mode, and realizes the precise filling. With PLC control, touch-type man-machine interface, the chemical filling machine is easy and intuitive to operate. The external frame, material box, feed pipe, conveying frame, filling head, liquid level detection, valve, knife retaining seat, and so on are made of anti-corrosion PP material with good anti-corrosion performance. And suitable for automatic filling of corrosive liquid with good fluidity.

Allpack 1-5L Bullet Train Chemical Filling Machine Features:

1. Independent electrical box design, toughened glass door cover to seal the machine body, and the air exhaust system above the filling head. Its interface can be connected with the factory's induced air system to discharge waste gas generated during the filling process, which is safer and environmentally friendly.

2. The filling head uses the air cylinder diving filling method, which can reduce the foam of the foaming material and prevent the contamination of the bottle mouth caused by the overflow of the material.

3. The Electric Control System adopts the Schneider configuration, an Integrated Electric Control System, which is more stable and reliable, safe and green, and low energy consumption.

4. The name of the Trachea and photoelectricity mark on the equipment, which is convenient for maintenance and repair.

5. In addition to normal working liquid level control, high and low liquid level detection and sound and light alarm devices are added to prevent abnormal liquid levels.

6. The air pressure of SMC in Japan is tested. When the air pressure is lower than the set value, the equipment alarms and stops automatically.

Allpack 1-5L Bullet Train Chemical Filling Machine Technical Specification:

P-D70 Automatic Bottle Unscrambler

1. Applicable Bottle Size: L: 120-230mm, W: 70-120mm, H:250-350mm

2. Speed: ≤3000 Bottles/hour (5L)

3. External Dimension: 3300*2310*1950mm (L*W*H)

CCG5000-8TS Chemical Filling Machine

1. Applicable Bottle Size: Round Bottle: φ80-140mm, H: 140-340mm

Flat/Square Bottle: L: 80-200mm, W: 80-140mm, H: 230-340mm

2. Capacity: 800 BPH (5L)

3. Filling Precision: ±5g (1L), ±8g (5L)

4. External Dimension: 2365*1600*2750mm (L*W*H)

FXG-1H Follow Type Capping Machine

1. Applicable Bottle Size: Min: 140*60*180mm, Max: 260*145*330mm

2. Capacity: 2500BPH (1000ml)

3. Cap Size: φ25-60mm, Cap Height: 20-40mm

4. External Dimension: 2000*1450*2400mm (L*W*H)

TS-150B Self-Adhesive Labeling Machine

1. Label Size: L: 20-260mm, Max Height: 140mm (Round Bottle)

L: 20-150mm, H: 20-160mm (Flat/Square Bottles)

2. Capacity: ≤2400 Bottles/hour

3. Labeling Precision: ±1mm

4. External Dimension: 3000*1500*1850mm (L*W*H)

KZ-1D Carton Packing Machine

1. Applicable Bottle Size:φ 40-95mm, Height: 80-230mm

2. Capacity: 4-8 cartons/min

3. Carton Size: L: 280-500mm, W: 200-400mm, H: 100-300mm

4. External Dimension: 2240*2250*2780mm (L*W*H)

ABB Mechanical Arm Palletizing Machine

1. Loading Weight: 110Kg

2. Positioning Precision: 0.1mm

3. Reaching Distance: 2.4m

4. Base Size: 1136*850*320mm

Automatic Chemical Filling Machine Related Products