Multi-Functional Pharmaceutical R&D Machine

- Rotated Frame

- Uniform Blending

- Multi-dimensional Movement

Multi-Functional Pharmaceutical R&D Machine

Multi-Functional Pharmaceutical R&D Machine is a new generation of equipment designed for the development of pharmaceuticals in the laboratory. The machine is designed and developed by this company in reference to the R & D pharmaceutical machines available domestically and internationally through absorption and optimization of their features. Our machine is complete in a functional, compact, and aesthetic structure with a small area to be occupied. It is suitable for research, development, and pilot production in industries such as pharmaceutical, chemical, foodstuff, and cosmetics. R&D machines are very accurate and efficient machines that precisely measure different parameters for investigating various metrics and properties.It is advanced in technology, stable in performance,easy to operate,clean and maintain.

Multi-Functional Pharmaceutical R&D Machine

U&M-ll Multi-functional Pharmaceutical R&D Machine-MainDrive Unit

Allpack multifunctional pharmaceutical R&D machine is designed for the development of pharmaceuticals in the laboratory. Equipped with some accessory devices (total volume 10L) to meet variety of experimental laboratory perparations, Main drive unit provides touch screen control and PLC control system that makes control more simple and convenient. Including: oscillating granulator, trough mixer, V-Mixer, coating ball, double cone mixer, single-cone mixer, oscillating sifter, agitator, cube mixer, multi-directional mixer. Accessory devices are made of 316L stainless steel and all items totally meet GMP standard.

High quality&efficient

Compliance with GMP requirements

Can be used to mix all bulk materials

The Buyer's Guide

R&D Machine: The Complete Buying Guide In 2024

Most of the research centers and laboratories when target a disease they prepare different sorts of medicines for it and it is not possible to do this manually.

R&D machine helps the pharmaceutical experts to develop different medicines for different kinds of diseases in an easy way providing all the medicine processing automatically.

You will learn all the different scenarios in which R&D machine is used and what is the purpose of it & how it is used not only that, you will get complete guidance about this machine in a step by step guide.

1.What is R&D Machine?

The R&D Machine

The term R & D stands for research and development. Therefore, R & D machine refers to research and development machine.

R&D machines are very accurate and efficient machines that precisely measure different parameters for investigating various metrics and properties.

They are usually smaller in size and are used in laboratories or research centers for the purpose of studying different properties and characteristics of various substances.

2. Explain the different advantages of R&D Machine?

R & D machines are becoming very popular in almost all the industries because of a great number of advantages they provide to the research and development department.

Some of the most significant advantages of R & D machines are described below.

Provision of Knowledge and Insights

By doing a proper and effective research using the R & D machines, you can gain a lot of knowledge that can help you in many different ways.

You may find out new ways that can give your business a great boost. This knowledge can also save you from many financial losses.

Compact Size

The R & D machines usually have a very small size and so they can be easily adjusted in very small places. Therefore, you do not need to worry about arranging a special space for accommodating the R & D machines.

Accurate and Precise

The R & D machines are very accurate and precise. They give almost the same results as the product under study will be given in the larger industries.

The results obtained from the R & D machines are almost perfect and the chances of errors are very low.

3.How R&D machine works?

The working of the R & D machine is very simple. A multipurpose R & D machine is an automated machine which does most of its work on its own without requiring any manual help or supervision.

The R & D machine has a touch screen control panel interface that is very easy to use. The operator can set all the dimensions of the working of the R & D machine and the machine then works according to the instructions given by the operator.

The raw materials are filled in the container of the R & D machine. The maximum capacity of the accessories of the R & D machine is 10L.

The PLC control system is used in the R & D machine for making the control of the R & D machine very easy and simple for the operator.

Once the instructions are set on the control panel, the operator turns ON the R & D machine. The machine then performs the specified function on its own.

The main unit of the R & D machine has rotation centre and different accessory equipment such as the mixers or grinders are attached to it for different purposes.

When the R & D machine is turned ON, the rotation counter rotates with the specified speed set by the operator. In this way, the desired process is completed. The speed of the rotation centre ranges from 0-120 rotations per minute.

After the process is completed, the R & D machine is turned OFF and the product is then discharged and collected out of the machine.

4.What are the different types of R&D machine in pharmaceutical industry?

The R & D machines are very commonly and extensively used in the pharmaceutical industry. Different types of R & D machines are used in the pharmaceutical industry and all of them have their specified uses.

Some of the most common R & D machines used in the pharmaceutical industry are described below.

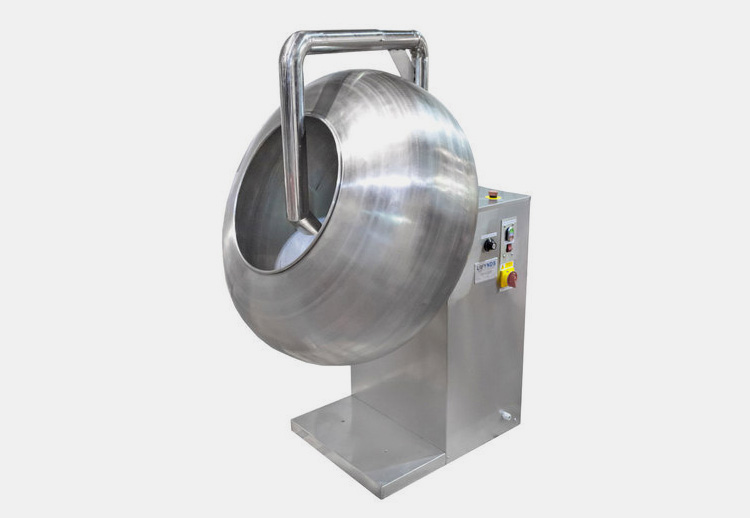

The Coating Pan

The R & D Coating Pan

Coating of a tablet is a very important step in the formation of the tablets because it’s coating greatly affects its pharmacokinetics and pharmacodynamics as well. The coating pan helps in applying the desired coating on the tablets.

The coating pan is available in two forms, perforated and conventional and both of them have their own specified applications.

Working

The working of the coating pan is very simple. The coating pan applies the layer of ingredients to a group of tablets. The ingredients are applied to the tablets in the form of a solution which sticks to the surface of the tablet.

Advantages

- The coating pan is a very fast and efficient device for coating the tablets.

- It can be used for sugar coating as well as film coating.

- The coating done by coating pan is very efficient.

Disadvantages

- There is only one pan for coating and no alternative pan is present.

Working Components

Different components of coating pan include;

Coating Pan Motor

The motor runs the coating pan.

Supply Blower Motor

This motor controls the supply blower.

Exhaust Blower Motor

This motor controls the exhaust.

Spray System

This system spray the coating material on to the tablets.

The coating pan is available in two forms, perforated and conventional and both of them have their own specified applications.

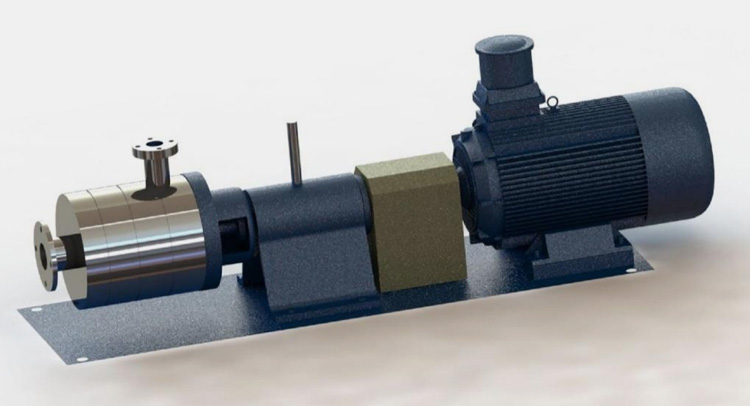

The Batch Reactor

Batch Reactor

The batch reactor is a broad term and is used to refer to a large number of vessels used in the pharmaceutical industry. Batch reactor provides a suitable environment for carrying out different kinds of reactions efficiently.

These are very commonly used for R & D purposes in the pharmaceutical industries.

Working

The batch reactor works by the agitation provided by the agitator. The reaction medium is filled inside the reactor vessel and then the agitator rotates or vibrates.

Advantages

- Easy to use

- Versatile (Can test different parameters at the same time)

Disadvantages

- Expensive Operation

- Variable Product Quality

Working Components

The batch reactor has four key components. These include;

The Reactor Vessel

The part of batch reactor where the operation is performed.

The headspace

This is the empty space which functions to manage the changes in volume of liquid.

The Agitator

Used for mixing the components.

The Reaction Medium

The medium in which reaction occurs

These are very commonly used for R & D purposes in the pharmaceutical industries.

The High Pressure Homogenizer

High Pressure Homogenizer

Many important pharmaceutical products such as emulsions, suspensions, lipids, and dispersions are made very efficiently by the application of the high pressure homogenizer.

The process of homogenization includes a very high pressure forcing of fluid through a very narrow field for reducing the particle size.

The products obtained by the high pressure homogenizer can be used for making antibiotics, inhalants, and vaccines etc.

Working

Homogenized milk

High pressure homogenizer uses very high pressure pump that pumps the prepared slurry through a narrow vessel, resulting in a reduced particle size.

Advantages

- High consistency in composition

- Increased Dissolution Rate

- Final Products have Greater Stability

Disadvantages

- Very Expensive Device

- Very Large and Heavy Machine

Working Components

High Pressure Pump

The high-pressure pump pumps the prepared slurry through a narrow vessel.

Disruption Unit

It is a very important part of the high pressure homogenizer.

Dampers

The dampers keep the working area damp for better consistency of the slurry.

The Mixers

A great variety of R & D mixtures are used in the pharmaceutical industry. These mixers have different uses and are used for their specified applications.These mixers include the following.

Oscillating Granulator

Oscillating Granulator

The oscillating granulator is used for making the granular solids pass through the mesh belt. The maximum capacity of the oscillating granulator is 30kg/h.

Working

The rotor of the oscillating granulator rotates horizontally at a speed of 180 rounds per minute. The product is loaded via the material hopper and the final product is collected from the rotor lades.

Advantages

- Easy to Operate

- Can be used for both wet and dry granulation

Disadvantages

- Very Expensive

- Large Maintenance

- Complex Structure

Working Components

A Rotor

This rotates the granulator.

Feed Hopper

This is the part of the oscillating granulator in which material is fed.

Sieve

It is used to determine the particle sized and letting only finer particle leave.

- Movable Housing

- Fixed Housing

V Mixer

The R & D V Mixer

The V mixer comprises two asymmetrically made cylinders for efficient and thorough mixing of the material for the formation of a uniform product.

A unique and important advantage of the V mixer is that there is almost zero accumulation of material or the product.

Working

The materials are introduced into the cylinders in which they are displaced back and forth. The ultimate result of this process is thorough mixing of the material components.

Advantages

- Minimum Particle Size Reduction

- Suitable for Fragile Materials

- Minimum Chances of Contamination

- A unique and important advantage of the V mixer is that there is almost zero accumulation of material or the product.

Disadvantages

- Not Suitable for Materials of Different Densities

- Difficult to Instal

Working Components

The Mixing Tank

This is the part of V mixer where mixing occurs

The Control Panel System

This part allows the operator to adjust the working of the V mixer according to the needs.

The Plexiglass Door

The Double Cone Mixer

Double Cone Mixer

The double cone mixer is applied for mixing the freely flowing granules and powders. For achieving homogenous and uniform mixing, the double cone mixer rotates in different dimensions.

Working

Two third of the double cone mixer is filled with the powder or the material to be mixed. The rotation rate should be between 30 and 100 RPM. The tumbling motion causes efficient mixing and the final product is collected from the bottom.

Advantages

- Highly Efficient

- Easy to Use

- Versatile Machine

Disadvantages

- Not Suitable for Fine Particulate System

- Difficult to Install

Working Components

The Shell

This is the main body of the machine that covers the other parts of the machine and make a complete body.

The Shaft Drive

It allows flexible rotation or movement.

The Feeding Port

The material is fed in this part.

The Discharge Butterfly Valve

The product is discharged from this part.

5.What are the important components in R&D machine?

The R & D machine is composed of different components that work in complete harmony to ensure the optimal functioning of the R & D machine. Some of these components are described below.

The Control Panel

The control panel of the R & D machine is the most important part as this is the part that interacts with the operator and gives him the access to easily and efficiently control different parameters such as speed of rotation, dimensions of rotation etc.

The Display

The display of the R & D machine shows the parameters such as the rotation speed and the time of mixing etc.

The Power Buttons

The power buttons of the R & D machine are used for switching the machine ON and OFF. These buttons are important because they control the working of the whole machine.

The Rotation Centre

The rotation centre of the R & D machine is very important and basic part. This is the part that rotates for proper and thorough mixing in the R & D machines such as V mixers, double chamber mixers etc.

The speed and dimensions of rotation of the rotation centre can be easily controlled by the control panel.

The Vessels

The R & D Vessel

The vessels of the R & D machine are also very important part as these are the containers in which the mixing of the materials takes place (in case of mixers).

These vessels are made up of stainless steel that makes them resistant to corrosion and rust.

6.Can you tell what type of medicines you can prepare from R&D machine?

The R & D machine is a very versatile machine and can be used for making a variety of medicines of various dosage forms. Some types of medicines that can be prepared by using the R & D machine are described below.

The Solutions

Liquid Dosage Form

The solutions such as syrups or the IV solutions are efficiently made by the R & D machine. High quality mixing of the contents or the materials by the application of the agitator makes the R & D machine a very important equipment for making then pharmaceutical solutions for medicinal purposes.

The Emulsions and Suspensions

Emulsion

The application of the high pressure homogenizers or the agitator is very useful in forming the emulsions and suspensions.

Emulsion is actually an unstable dosage form that is made up by mixing the two immiscible liquids with the help of an emulsifying agent. The high quality agitation by the R & D machine agitator is very helpful in making these emulsions.

Suspension includes the mixing of the particles in the liquid with the help of a suspending agent. Agitation also plays an important role in making these suspensions.

The Tablets

The Tablets

The tablets are made by the R & D machine by the application of the punching machine. Then single punch machine is most commonly used for making tablets. Also the coating of the tablets is effectively done by the R & D machine coating pan.

The Capsules

The medicinal capsules are also made by the R & D machine. The powder to be filled inside the capsules is mixed uniformly by the mixers of the R & D machine.

The Powders and Granules

Powder

The powders and granules intended for oral intake are a very important dosage form. The efficacy of powders and granules depends upon homogenous and uniform mixing of the contents including the active pharmaceutical ingredient and the excipients.

7.Is it possible to use R&D Machine for different laboratories?

The R&D machines are very useful and versatile equipment that can be widely used in different types of laboratories. Different kinds of R&D machines serve different important services in different types of labs. Some of the common laboratories in which the R&D machines are extensively used are discussed below.

Medical R&D Labs

Research and development is the most important department in the field of medical science. In every field of medical, research about advanced knowledge and development of new technologies is very important. Besides the pharmaceutical industry, the R&D machines are very important in other labs too. These labs are described below.

Botanical Sciences R&D Labs

For the research and development in the field of botany, different R&D equipment such as incubator, laminar flow hood, weighing balance, autoclave and plant growth chamber etc are widely used.

These equipment helps the botanists working in the lab in doing the research and development efficiently and effectively.

Zoological Sciences R&D Labs

Weather tracker, microscope, microscope olympus, laser range finder, telephoto zoom lens, digital scale lens and binoculars are some of the most widely used R&D machines in the zoological sciences R&D labs.

Efficient and effective research and development of the zoological department lab is based on the efficient working of these R&D machines. So, these R&D machines are very important for these labs also.

Earth Sciences R&D Labs

The earth sciences R&D labs also need efficiently working R&D machines for properly carrying out the research and development.

Different R&D machines used in the earth sciences R&D labs include polarising microscopes, jaw crusher, electric oven, ultra-sonic cleaner, and rock or tile cutter etc.

Ultrasonic Cleaner

Chemical R&D Labs

In the chemical R&D labs, different R&D machines are used for testing different chemicals to identify their chemical and physical properties for research and developmental purposes.

The services provided by these specialised R&D machines are very helpful for the chemical industries to manufacture new products after getting enough knowledge about the chemicals.

Material R&D Labs

The material R&D labs use different R&D machines to carry out research and development about different kinds of material for their more efficient usage in different ways in the future.

Other Types of R&D Labs

Many other types of R&D labs for the research and development purposes in the field of AI, computers, mobiles, algorithms and transmission technology are widely using the R&D machines.

The effective and efficient working of R&D machines in all of these labs is very important for efficient, effective and productive research and development.

8.What are the things to avoid while working with R&D machine?

Even though R&D machines have proved to be a blessing for many industries in recent times because of their efficient and effective working, proper planning and utilization is the key factor for getting the best of the R&D machines.

There are some things that must be avoided while using the R&D machines.

Poor Planning

Planning is the key whenever doing any task. If not properly planned, the task is destined to fail. While using the R&D machines, you should be fully prepared and then use the R&D machines according to the devised plan.

If the process of buying and using the R&D machines is planned poorly, the company suffers financial losses. Therefore, in order to avoid any such loss, proper planning must be done.

Using the R&D machinefor Purposes Other Than its Intended Use

Each R&D machine is designed for a specialised function and that must be used for doing only that specialised function.

You should never use a R&D machine for a purpose other than its intended use. For example, you should never use tablet hardness tester for crushing the tablets.

Over Loading the R&D machines

Always remember that the R&D machines are made for research and developmental purposes and should be used only for that.

You should never use the R&D machines for manufacturing purposes because it may overload the machine and you may end up damaging the R&D machine.

Conclusion

In conclusion, the ALLPACK R&D machine is very efficient, easy to use, and versatile equipment that can be effectively used in many different industries such as pharmaceutical, cosmetic, food, and chemical industries. The compact size and wide range of applications make the ALLPACK R&D machine a very healthy investment for your business. Please reach us anytime for handy solutions.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours