Auger Filler: The Complete Buying Guide In 2025

Auger Filler: The Complete Buying Guide In 2025

Whether is it pharmaceutical industry, food industry, or chemical industry, the manufacturing of powders and granules is carried out in one way or another. But at the same time, it has been found that the conventional tactics employed for processing these products are now out of fashion and their use can only cause the waste of material as well as time. So, producers are looking for an alternative.

In this way, auger filler has been introduced to extricate these complexities. Its advanced technology, excellent design, and compatible components greatly help in achieving the precise filling of all kinds of powders and non-powders. Hence, this guide will be covering Auger Filler from its definition to the benefits which it provides followed by its versatility, maintenance, troubleshooting and much more. So, be ready to know these all!

1.What Is An Auger Filler?

Allpack Single Head Automatic Powder Filling Machine

An auger filler is a type of filling machine peculiarly designed to fill different types of dry powders and granules. As most of the powders like talc powder, custard powder and milk powder are sort of adhesive and get stacked, obstructing the way for smooth filling, an auger filler is used to swirl the stainless-steel auger shaft inside the powder and dispense them into containers.

This machine does not only perform the function of product filling but also accounts for their accurate weighing. It supports quick modification of setting by providing easy-to-use machine interface and allows you to integrate it with multiple other machines to achieve high throughput in your respective fields whether of food, pharmaceutical, cosmetics, or chemical.

2.Explain The Advantages Of An Auger Filler?

An auger filler comes with substantial benefits both for your material safety as well as productivity growth. These are enumerated below:

Enhance Production

Improve production icon- Picture Courtesy: dribbble.com

Auger filler perform the functioning of products metering as well as filling automatically at once. This ultimately proves the machine’s high efficiency which results in filling more containers in an hour.

Flexibility

Different types of powered, granulated, and flaky eatables in jars

The machine is highly resilient and flexible in terms of processing different types of products like powders, granules, and flakes etc. Moreover, it is also adaptable to changes such as its filling head height, the speed of conveyor, and frequency of auger shaft can be adjusted.

Precision

Precise filling of tea into bottles- Picture Courtesy: All-Fill Inc

Auger filler ensures the accurate weighing and dosing of material to each container thus high precision and consistency in product filling is realized. In addition, the machine has a flawless filling rate by reducing over and underdosing.

Cost Effective

You will find an auger filler a cost-effective solution due to multiple reasons encompassing its low maintenance costs, low operating costs, and minimal parts changeover for conducting operation.

Product Safety

Zero waste of eatables- Picture Courtesy: meetgreen.com

An Auger filler is designed to maintain a hygienic and safe environment for processing goods like food and drugs etc. It gives high levels of safety against bacteria and environmental elements due to the enclosed design. Along with that, the machine has a photoelectric sensor which enable it to not release product until the container is placed right under the filling nozzle.

3.What Products Can Be Filled By An Auger Filler?

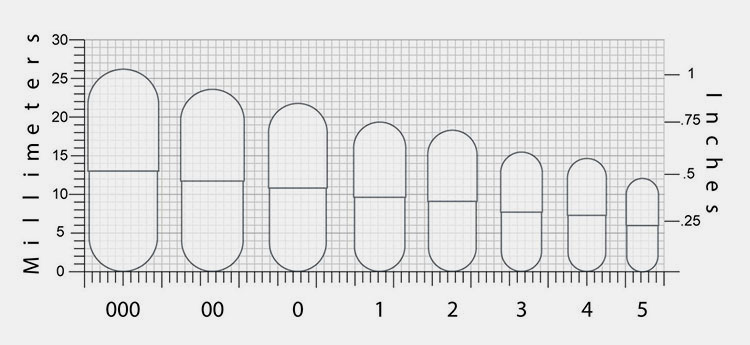

An auger filler is always suitable for all kinds of dry powders whether free-flowing, non-free-flowing, granules, and particulates etc. Let's know some of the prominent ones!

Free Flowing Powders

Powdered milk in bowl- Picture Courtesy: livestrong.com

Free flowing powders are form of powders which do not stick together and have high proclivity to flowing. Its particles are frequently of large size, thus flows freely. The common examples include table salt, milk powder, and glucose etc., which can be filled by an auger filler.

Adhesive Powders

Talcum powder- Picture Courtesy: pratibharefractory.com

Auger filler is also suitable for extremely fluffy and adhesive powders like that of custard powder, talc powder, starch powder, and some seasoning powders whose weighing and filling is one of the difficult tasks. But here it is performed with much ease.

Grains

Multiple types of rice- Picture Courtesy: theveganatlas.com

Grains, some kinds of pulses, and seeds are other products which are counted in the list of materials which can be processed by this machine.

Flakes

bowl of cornflakes- Picture Courtesy: Behance

Apart from powders and grains, here is another form of material usually called flakes and pellets for whose measuring and packaging into containers an auger filler can be utilized.

Granules

White granulated sugar

Small to large granules starting from sugar to plastic granules, and food granules can be processed by an auger filler.

4.What Type Of Containers Does An Auger Filler Support?

Different types of containers can be filled by an auger filler due to its flexibility through which it can be conveniently adjusted to meet various specifications. Following are the popular containers:

Bottles

Multiple spice powder bottles- Picture Courtesy: cleaneatingmag.com

All kinds of plastic and glass bottles with varying shapes and sizes can be easily processed by an auger filler due to the machine’s high adaptability and structural adjustment.

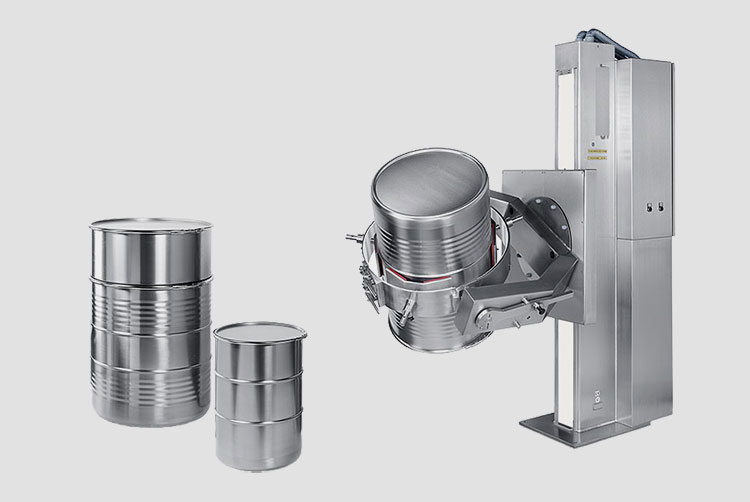

Cans

Milk powder can- Picture Courtesy: redirect.viglink.com

Metallic cans are often big in size compared to bottles, but they too are eligible to be processed by an auger filler. In fact, most of the products including milk powder, coffee powder, juice powder, and chocolate powder are often filled in durable tin cans.

Jars

Coffee powder jar- Picture Courtesy: yellowimages.com

Jars are glass containers with extremely high safety for products against moisture and bacteria. Therefore, most of the dry products like flakes, granules, and powders are stored in jars which are easily supported by an auger filler.

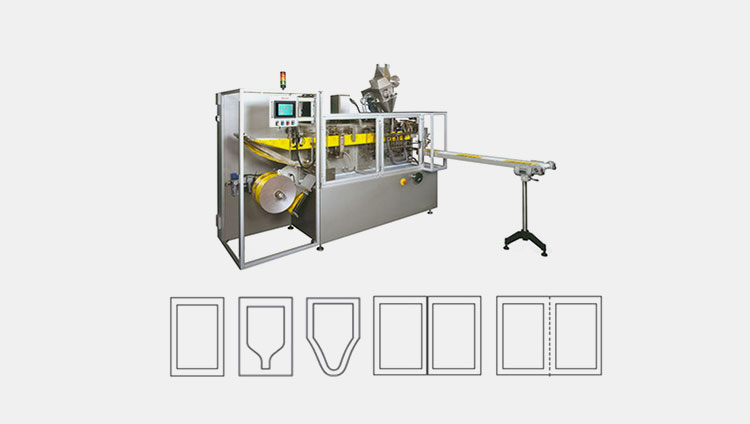

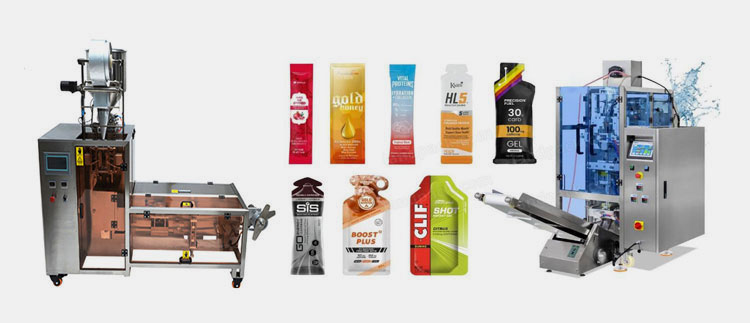

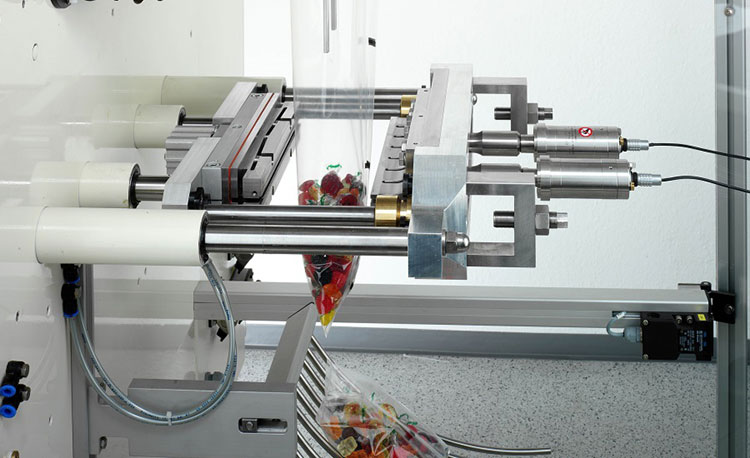

Pouches

Multiple seeds standup pouches- Picture Courtesy: packagingoftheworld.com

You might be surprised after seeing the term pouches here but yes! Pouches can also be used to filled by an auger filler. Even there are some types of auger fillers which can form pouches and supply them with precise amount of material.

Sacks

Wheat grains filled sack- Picture Courtesy: freepik.com

Sacks are large bags often made from polymers, compostable materials, and other plastics. These are popularly used for packing bulk sugar, flour, and grains etc. Hence, they can be processed by an auger filler.

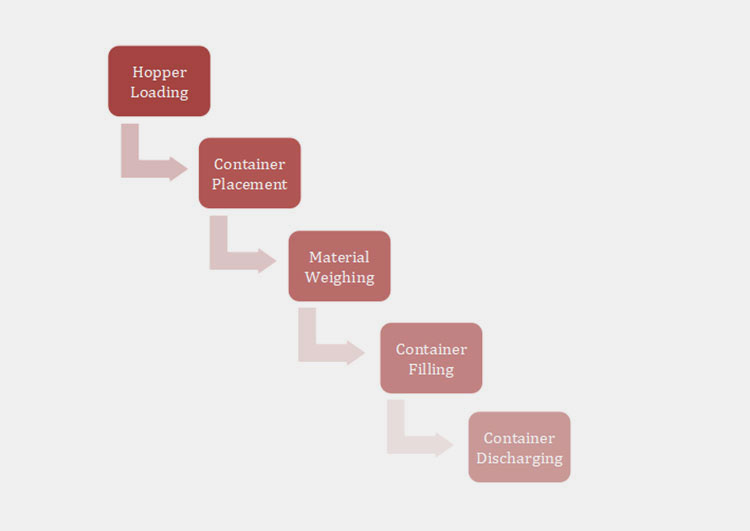

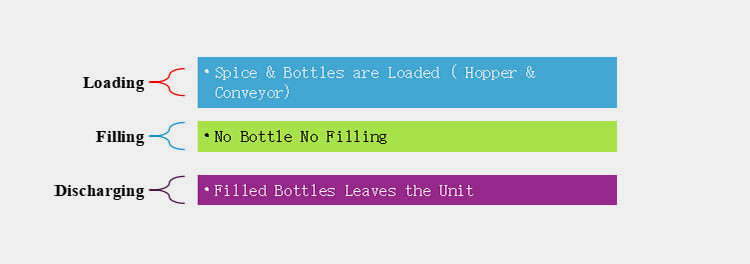

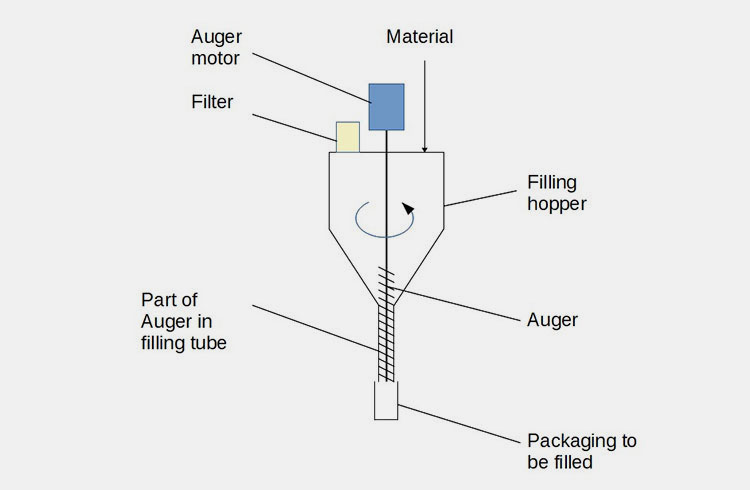

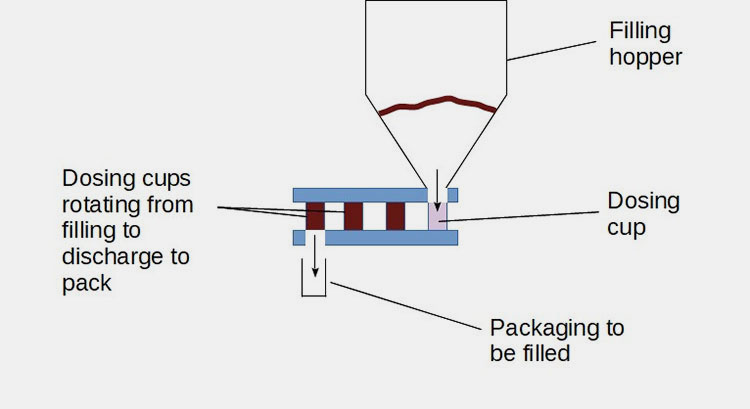

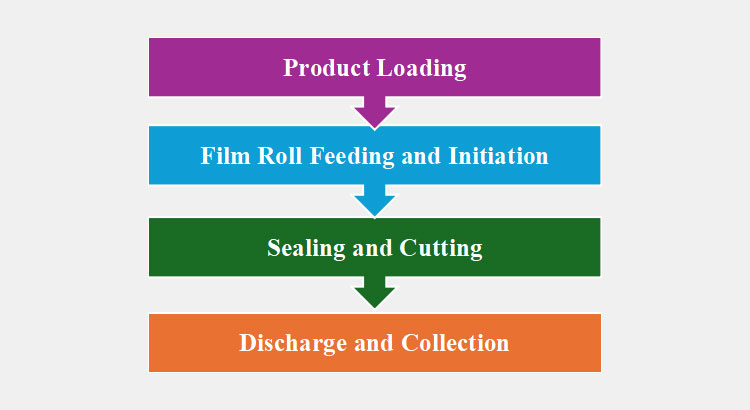

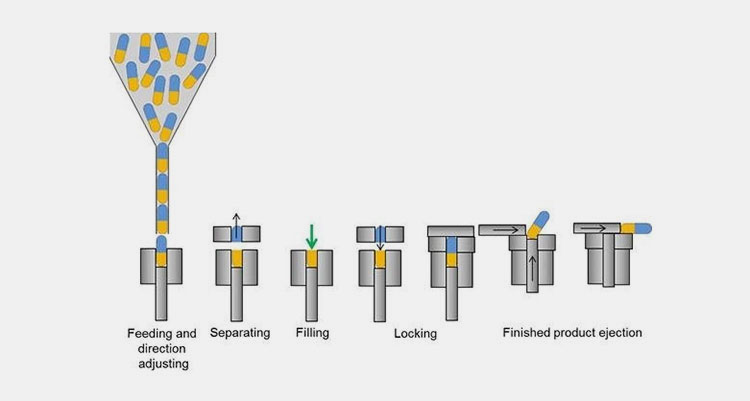

5.Elucidate The Working Principles Of An Auger Filler?

The working process of an auger filler is generally based on few principles which are explained below:

Hopper Loading

Auger filler hopper loaded with spices- Picture Courtesy: JDA Progress

Firstly, the hopper of an auger filler is loaded with sufficient volume of material. Commonly, the capacity of an auger filler hopper varies from 15L to 100L. However, small place inside the hopper must be left free for enabling the auger to process material freely.

Container Placement

Empty containers placement- Picture Courtesy: JDA Progress

Secondly, containers like bag, bottle, can, or sack etc., are placed under the filling head. In fully automatic auger fillers, this task is carried out by the machine independently, however, in semi-automatic auger filler an operater manually place the bottles.

Material Weighing

Auger filler measuring principle- Picture Courtesy: ipharmachine.com

In third step, the machine is powered on once the demands regarding material processing is communicated to the machine. Here, the motor energizes auger which in turn start rotating in the middle of hopper. The rotation of auger draws the material from the hopper and conveys it to the bottom. The material reaches to the end place of an auger where it encounters a valve mechanism which is responsible for regulating and controlling the flow of product. Thus, weighing step is carried out.

Container Filling

Bottles filling with spices- Picture Courtesy: JDA Progress

In fourth step, precise amount of product is allowed to leave the funnel and dispensed into the container after valve gets open. Here, the speed of an auger can be synchronized with container movement to ensure accurate filling.

Container Discharging

Filled bottles discharging- Picture Courtesy: JDA Progress

Finally, the filled containers are discharged from the machine through a conveyor and their place is taken by other empty containers. The process is repeated untill desired number of containers are filled.

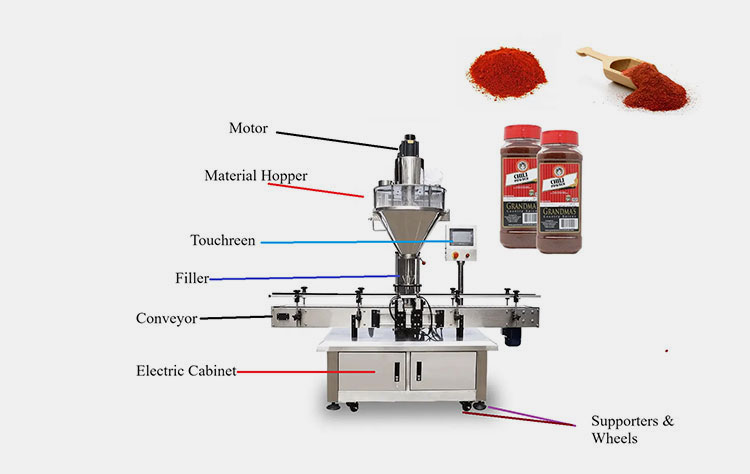

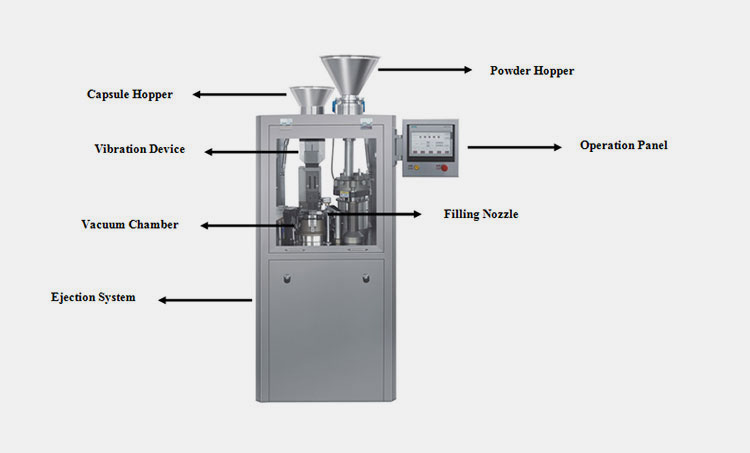

6.Describe The Various Components Of An Auger Filler?

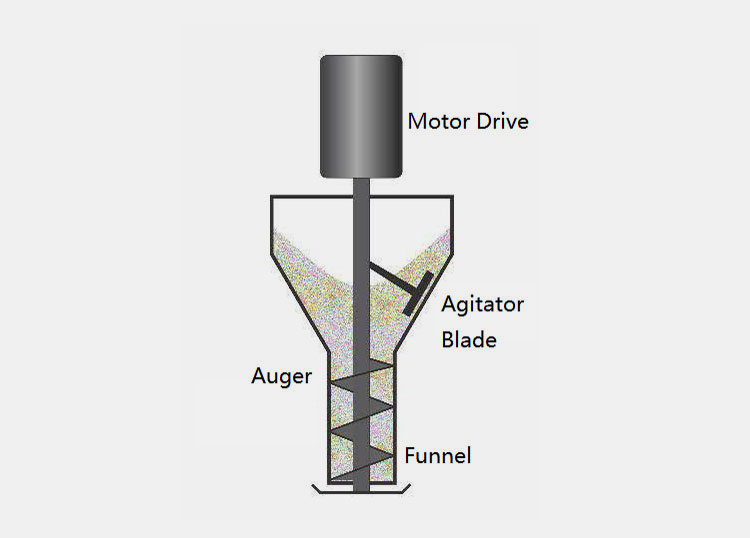

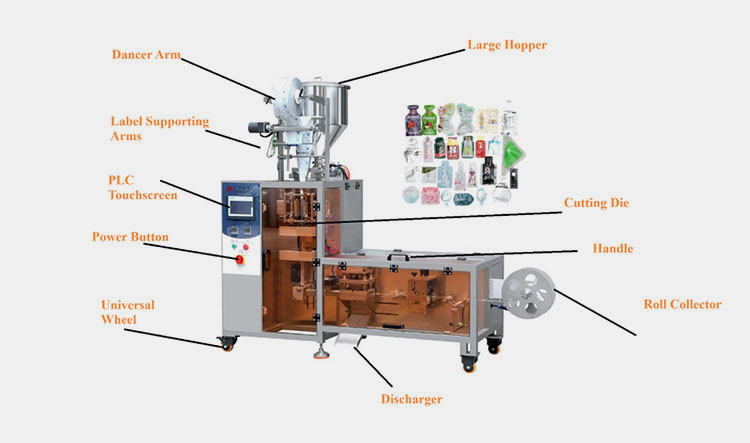

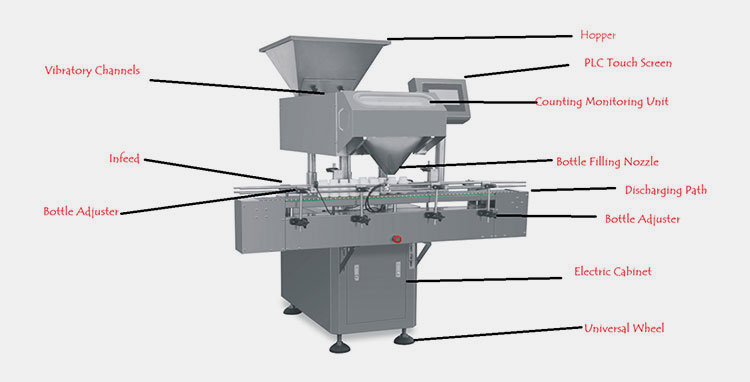

An auger filler typically consists of the following components:

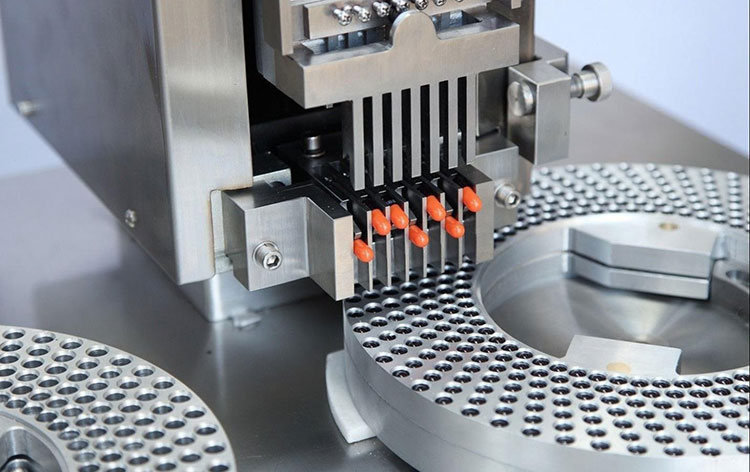

Components of an auger filler -Picture Courtesy: ipharmachine.com

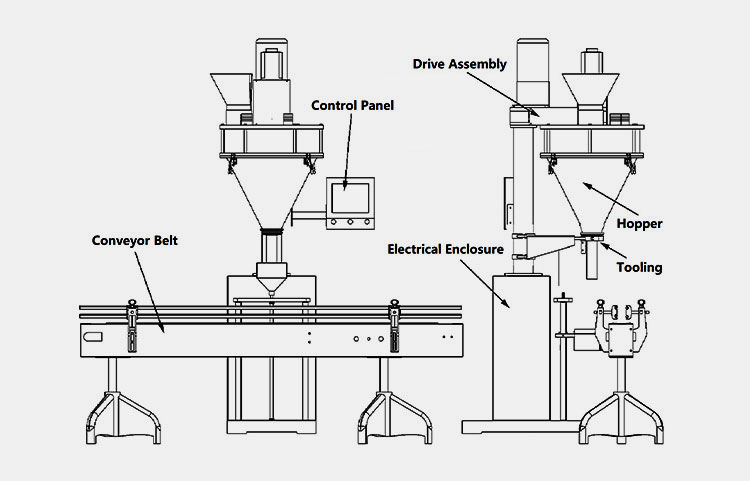

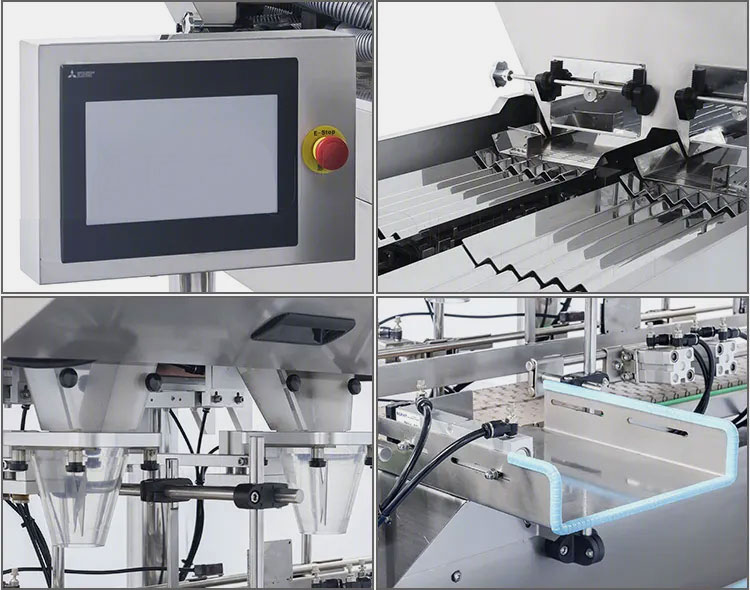

Control Panel

Control panel is the most important part of an auger filler that mainly consists of a touch screen panel along with certain knobs and buttons for switching machine. It is user-friendly through which operator set the commands in machine such as the the auger speed, product volume, and filling speed etc. It is located on the top front of machine.

Conveyor

Conveyor is another crucial part of automated auger fillers which is made up of certain components including photoelectric sensors, adjustable guide rails, speed system, and side tools for supporting containers. It performs the function of mobilizing bottles, cups, and bags from one station to another efficiently.

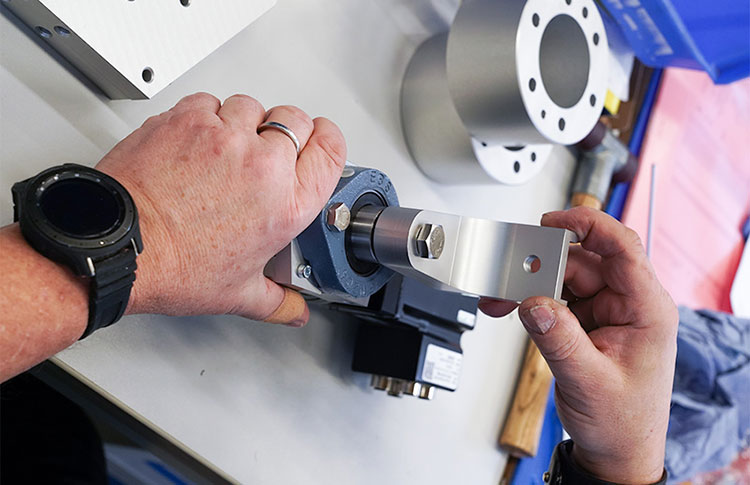

Drive Assembly

As the name denotes, drive assembly is a complex system of dual motors responsible for regulating the machine as well as controlling the speed of an auger. Depending on the type of auger filler, this drive assembly may be electric, hydraulic, or pneumatic.

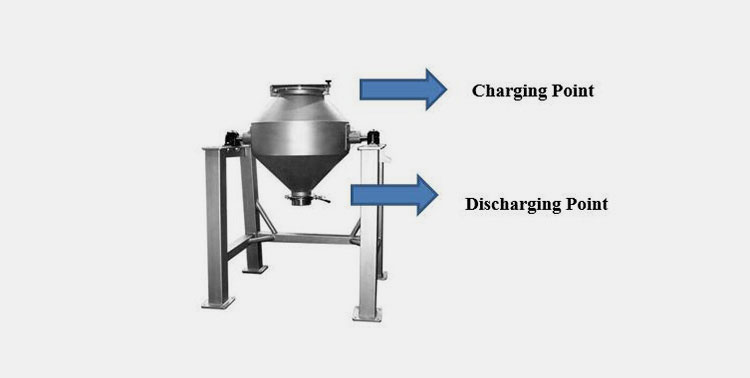

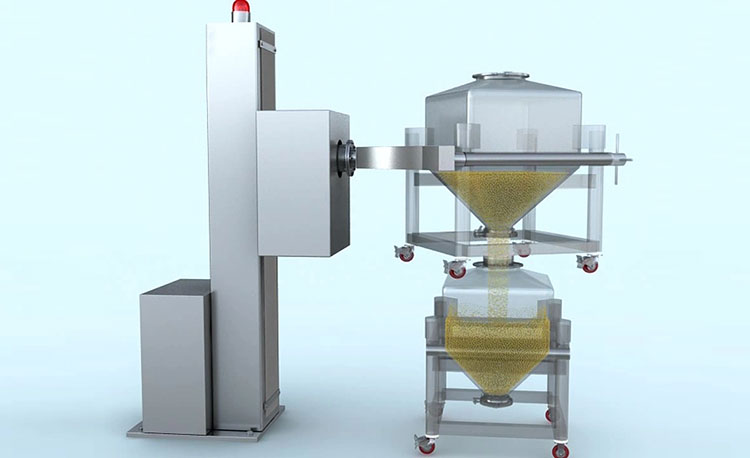

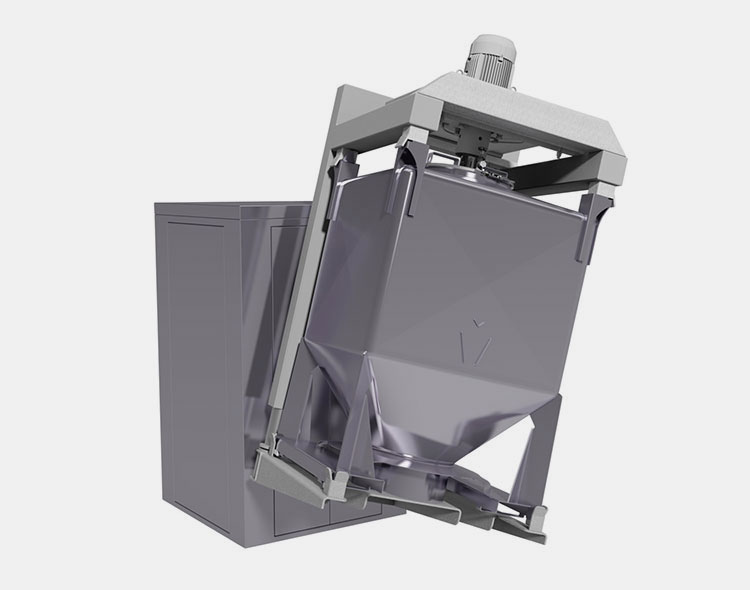

Hopper

It is the storage area where product is placed before its processing. The hopper is constructed with sanitary stainless steel, built-in agitator and shaking mechanism. The overall purpose of hopper is to keep the product inside and process it further with the help of tooling parts.

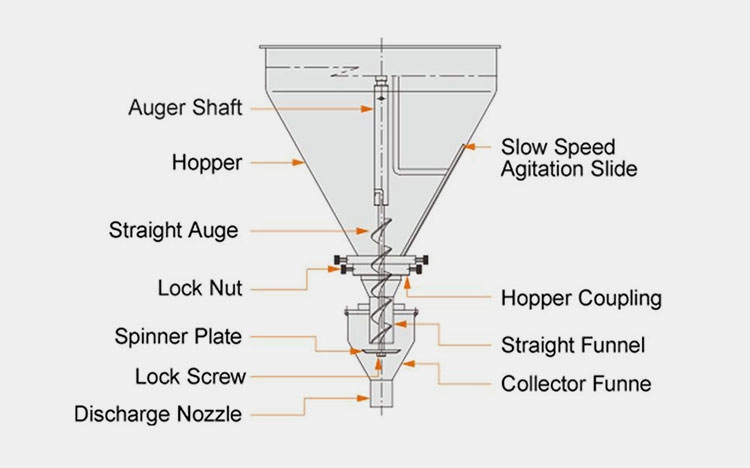

Tooling

Auger filler hopper flow chart- Picture Courtesy: auger-filling.com

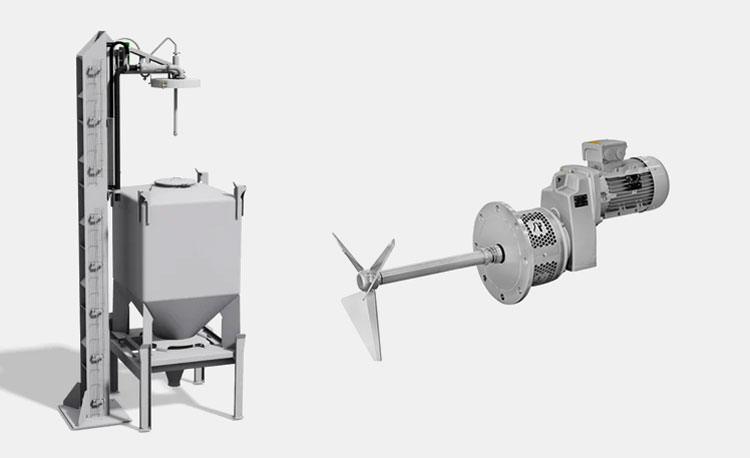

The tooling part of an auger filler is located at the center of hopper from top to the bottom down in a straight line. It consists of the underlying components:

Auger Shaft:Auger shaft is a stainless-steel tool attached with straight auger at the end while motor regulator at the top. It helps in moving the auger.

Slow Speed Agitation Slide:It is the agitator blade that circulates on the corners of hopper to stir the material for homogeneous blending. It greatly helps in reducing overfills. This agitator blade is driven by a motor and its speed and direction of rotation can be modified.

Straight Auger:It is a screw-like tool that persistently move in a circular motion to keep the flow of product at desirable condition. Its movement and speed can be adjusted as per the flow rate requirement of ingredients.

Other Parts:The tooling section also include a funnel through which material is precisely dispensed into containers, a lock nut, lock screw, and hopper coupling etc., for the attachment of filling nozzle with hopper.

Electric Enclosure

The electric enclosure is found at the base of machine where all electric components are fitted in form of wires, switches, and circuits etc. Collectively, electric enclosure is responsible to provide safe heaven for electrical components including sensors, fuses, and knobs etc.

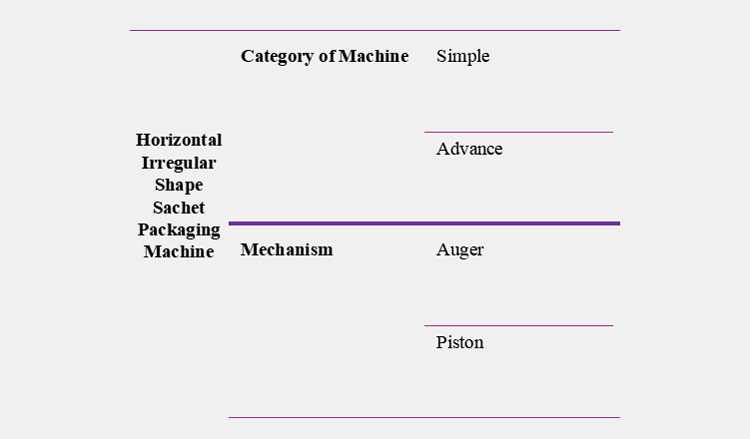

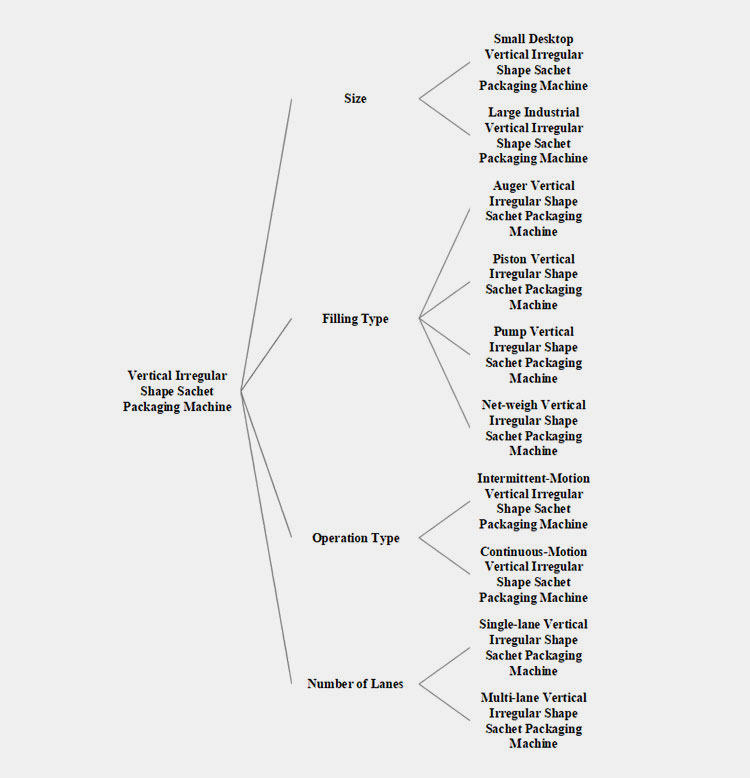

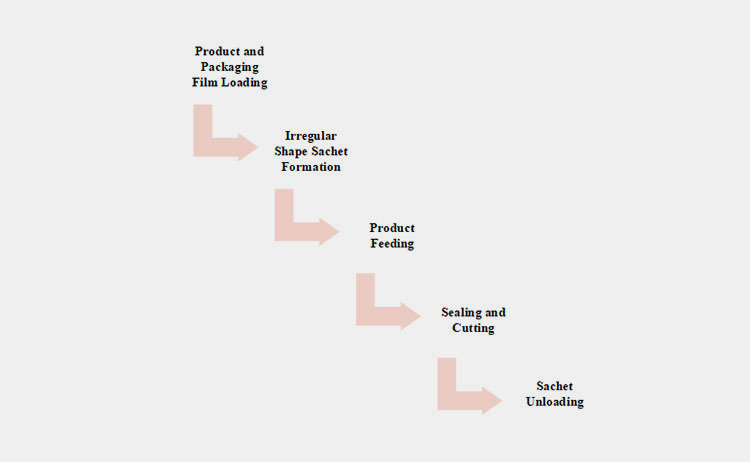

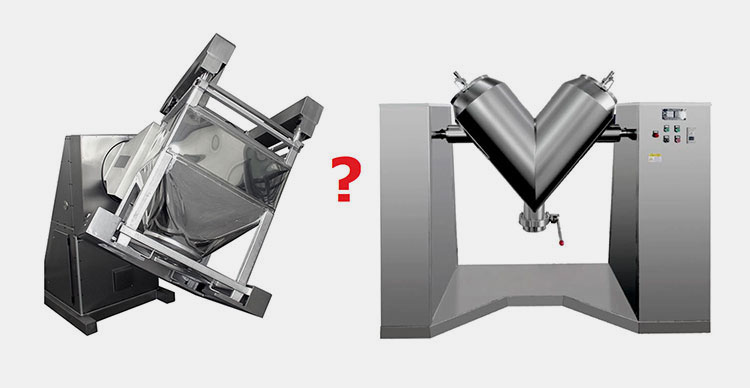

7.Can You Explain The Classification Of An Auger Filler?

An auger filler can be classified into different types on several basis. This classification is the result of diversities in industrial uses of auger filler like automatic, semi-automatic, and many other types of auger filler. Let's explore these types one by one!

According to Automation

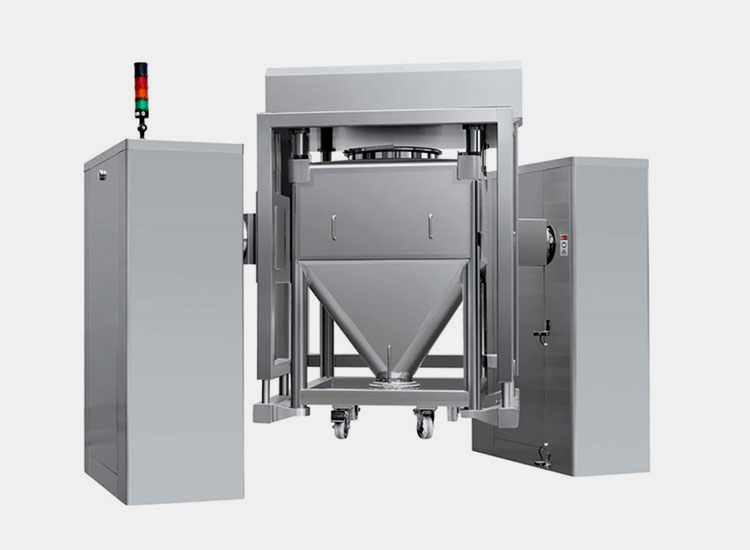

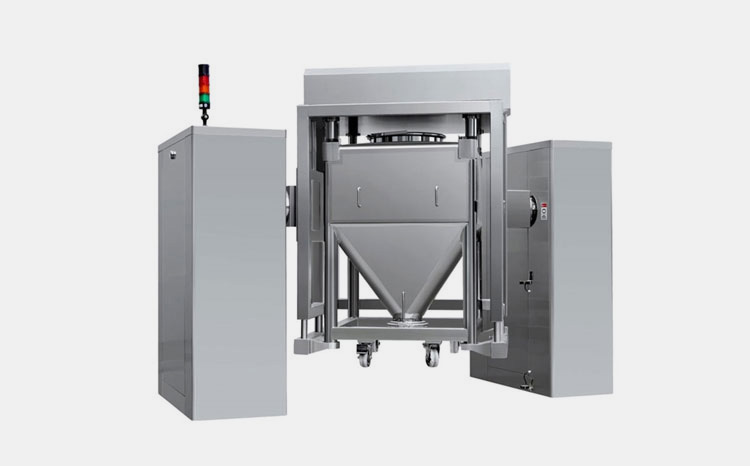

Fully Automatic Auger Filling Machine

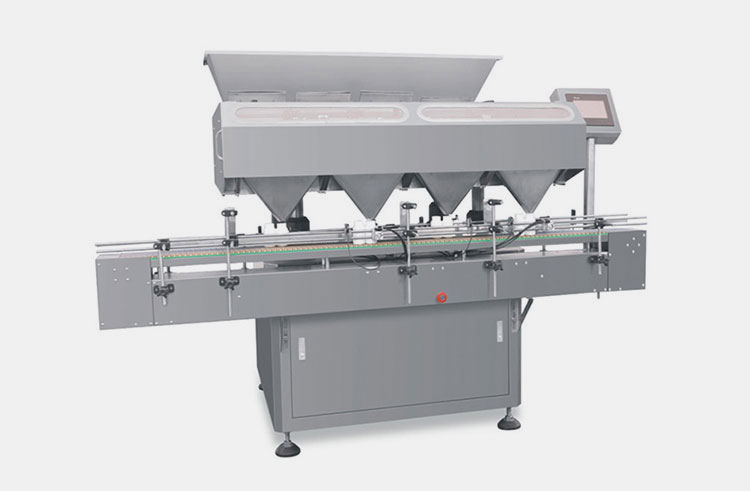

Fully automatic auger filling machine

Fully automatic auger filler is a compact machine built on sturdy stainless-steel frame designed to meet the exceptional production targets with efficiency rate of filling up to 90 bottles in a single minute.

Structure

Several components make the body of a fully automatic auger filler including a conveying mechanism, electrical enclosure, hopper, auger system, and motors for machine regulation.

Process

Its working process is independent with machine automatically loading the material from attached feeding station to the hopper. Here, the material is well processed and accurately weighed. Once, the precise metering of product gets done, it is dispensed into bottles without wasting any particle. These bottles are then automatically discharged from the machine.

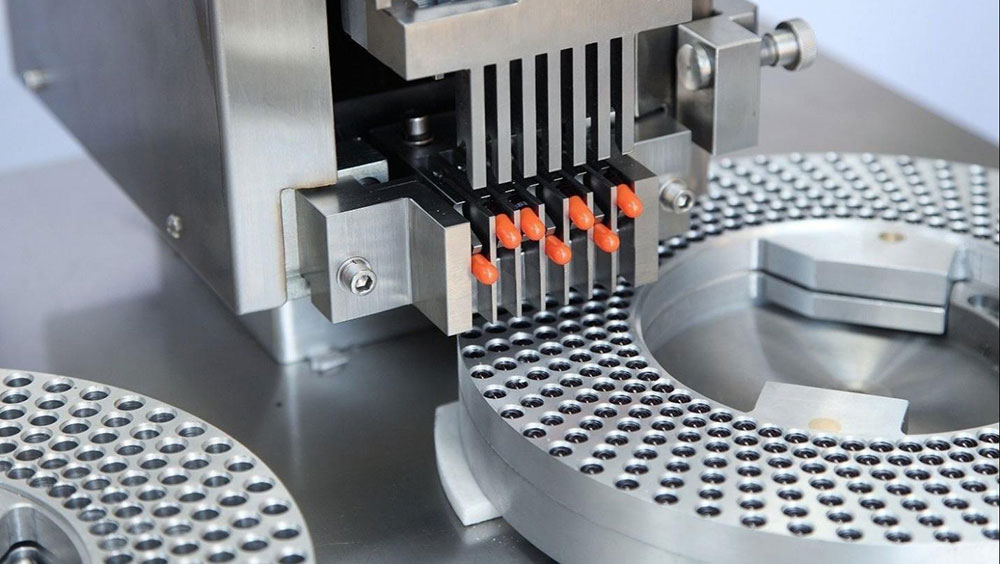

Semi-Automatic Auger Filler

1-10kg Semi Automatic High Accurancy Auger Filler Machine

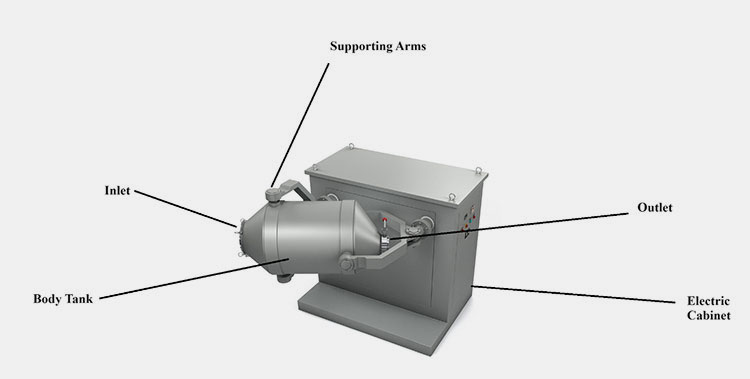

Semi-automatic auger filler is structured with stainless steel body and high accuracy capabilities in terms of weighing and filling various types of powders and granules. The machine can fill up to 30 bags and bottles per minute.

Structure

It consists of a drive assembly, a hopper with transparent glass for clear observation during operation, control panel, internal tooling system, foot switch, adjustable filling nozzle, stainless steel tray for containers holding, and a stable base with 360° movable casters.

Operation

Its operation is simple and can be carried out with one user. The operator manually load hopper with material and place a container under the filling nozzle. Once, the setting is done, the operator presses the foot pedal and machine start weighing the material and discharge accurate volume of product into container. Afterwards, the operator manually takes the container and place an empty one.

According to Filling Heads

Single Head Powder Filling Machine

Allpack Single Head Automatic Powder Filling Machine

This automatic single head automatic auger type power filling machine adopts screw dosing mechanism for filling powders with efficacy. It is compatible with all kinds of powders and granules and can be combined with other machines to make a production line. You will easily get the output ratio of 50 bottles per minute by using this machine.

Structure

The machine has comparably robust and compact structure with one auger filler head, HMI, guide rail, detectors, hopper, drive motor, and control cabinet etc.

Process

Its process is extremely simple with one bottle being filled at a time. Hence, the task of filling material into containers is carried out flawlessly.

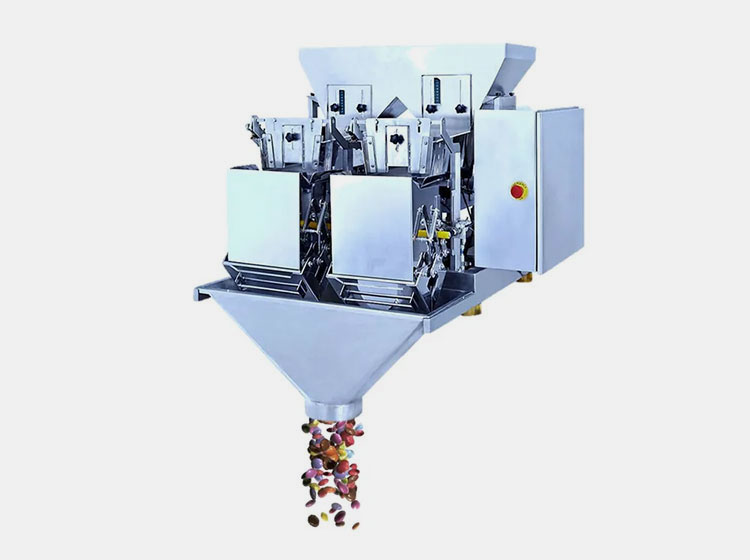

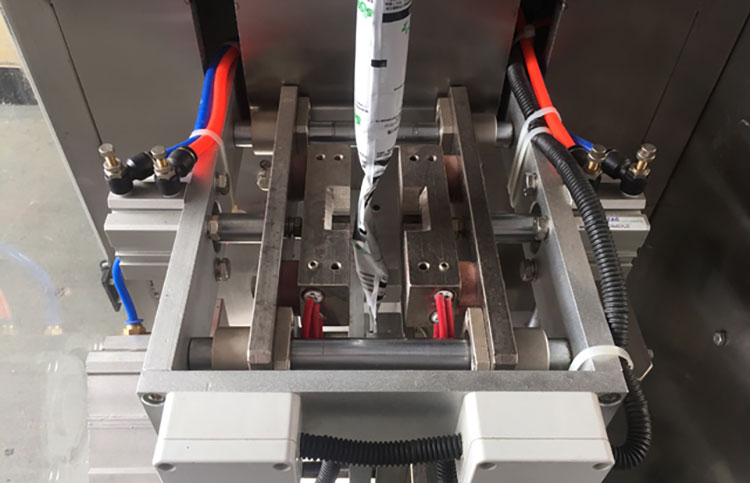

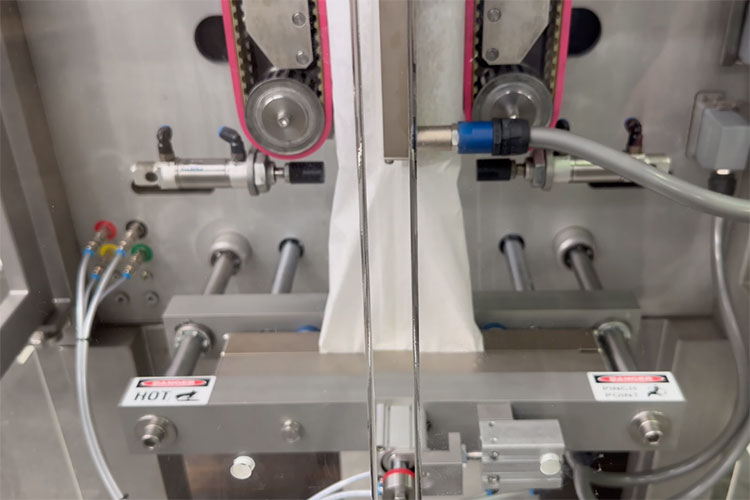

Double Head Auger Filling Machine

Automatic Double Head Auger Filling Machine

Double head auger filling machine is a resilient machine suitable for filling all kinds of dry, fluffy, and sticky powders and granules in various sizes of bottles and containers. Depending on the fill volume and type of product, the machine can fill 40 to 60 bottles in a minute.

Structure

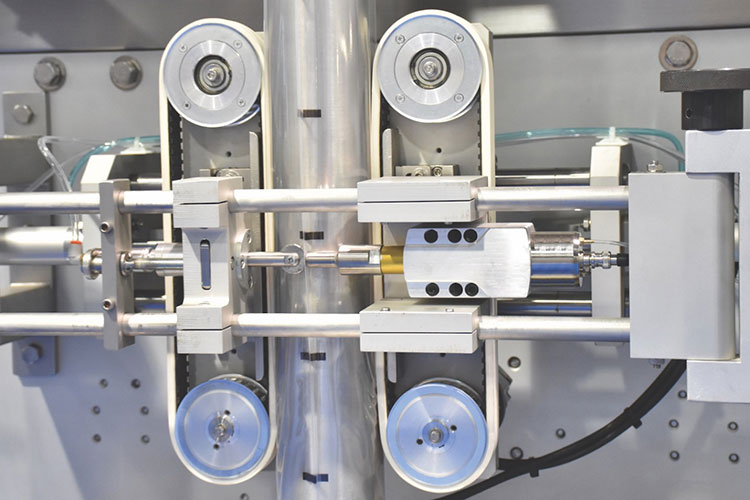

It is composed of a stainless-steel compact body, dual auger fillers, control system, photoelectric sensors, conveyor, and pneumatic system.

Process

The process of double head auger filler is somehow unconventional where two bottles are moved at the same time towards filling heads. The sensors located on conveyor detect the presence and signals it to the machine. The first bottle is filled with precise amount of material and then moved forward where another empty bottle is filled with same amount of material. Finally, both are conveyed for discharging.

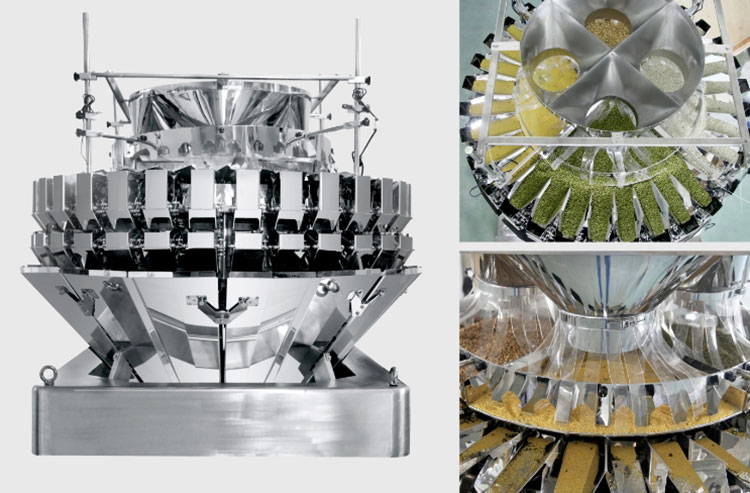

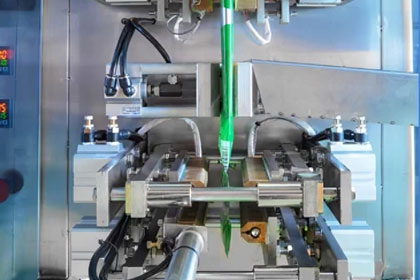

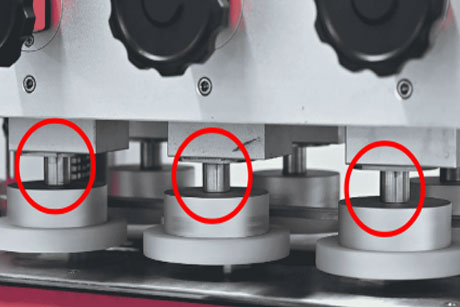

Multihead Auger Filling Machine

Automatic 4 Head Auger Base Powder Filling Machine

This multihead auger filling machine is an outstanding equipment tailored with unique features and robust design to beat the complexities regarding targeted production rate. It can be used for all types of materials as well as containers.

Structure

The structure of machine is stable, comprehensive and at times compact. Overall, the major components accounts for its body include the four auger filling heads, double conveyor belts, heavy-duty electric system, stainless steel rigid body, and multiple regulator motors, each attached to the respective auger filling head.

Process

Here, the bunch of bottles are mobilized towards the machine through separate but adjoined conveyors simultaneously. Similarly, the pair of two containers stop under one filling head where one container is filled and the other remain empty. Moving forward, the empty container is filled and loaded one is stopped by a pneumatic holder. The same process is continued for the back heads of auger filler until desired number of bottles are filled.

According to Structure

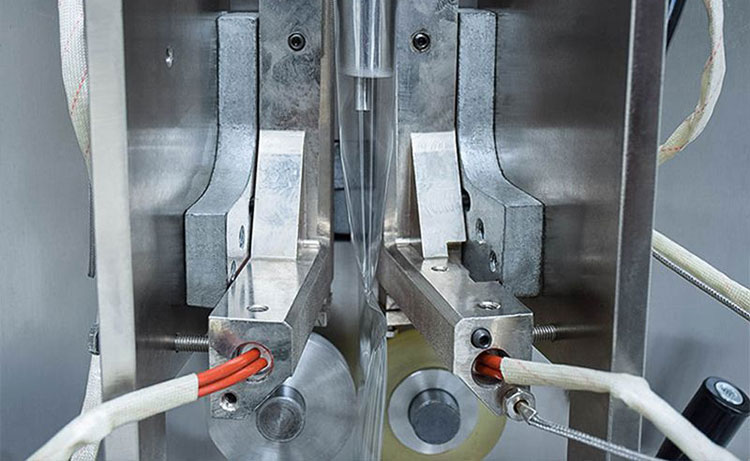

Linear Auger Filler

Single Head Linear Type Automatic Auger Filler- Picture Courtesy: vtops.com

Linear auger filler is an inline type of machine suitable for all kinds of plastic, glass, and metal containers and cans. The machine adopts extremely convenient and straight forward mechanism for filling material into containers.

Structure

It has a linear body comprised of several constituents encompassing linear positioning device, LCD touch screen, adjustable height and diameter for bottles, split hopper, conveying system, and a servo motor.

Process

It processes the containers in a straight way where machine meters the specific volume of product and dispense it into a container after detecting its presence. Similarly, all the bottles get filled and transported to discharged station through guide rail.

Rotary Auger Filler

Rotary Type Single Head Automatic Auger Filler- Picture Courtesy: vtops.com

This rotary type of auger filler is an innovative design machine constructed with unique features to ensure high positioning accuracy with a star wheel. The fitted system of skipped container perfectly helps in dealing with missing bottles by reducing possible material waste.

Structure

It is made up of an auger filler, PLC control panel, a rotary star wheel, conveyor belt, servo motor for filling, and a composite assembly to stand upright with stable feet.

Process

The working process of machine follows a rotary direction where containers are fed onto the conveyor which are then adjusted to the star rotary wheel. The wheel rotates in a circular direction and take a pause when each bottle arrives under the filling head. At this point, the machine load weighed volume of material into bottle, the wheel start rotating by discharging the filled bottles on one side while as taking an empty bottle to the filling head on the other.

8.What Are The Applications Of An Auger Filler?

When talking about the uses or applications of an auger filler you will always find diverse sectors on the list. Some of these are highlighted as under:

Food Sector- For Productivity

Chocolate power box packaging idea- Picture Courtesy: underconsideration.com

No doubt, food industry is the busiest field where manufacturing and packaging of products like milk powder, condiments, tea, coffee powder, custard powder, sugar, and grains take place. Therefore, to meet such a large scale processing the help of an auger filler is taken.

Medical Sector- For Hygiene

Women horlicks bottle- Picture Courtesy: mirchimasaly.com

Medical sector is another important area where the implementation of an auger filler is realized. It is because the sensitive nature of powered drugs like calcium powder, nutraceutical powders, herbal products, and syrup powder require safe environment for packaging which is provided by this machine.

Daily Chemical Sector- For Safety

Various detergent powder pouches- Picture Courtesy: www.behance.net

Daily chemical sector is commonly engaged in the production of materials like detergent powder, dish washing powder, and floor cleaning agents etc. These objects often contain chemical substances which if dispersed in air can get into the eyes and nose causing hazards to health. Hence, this enclosed auger filler is employed here to ensure the safety of operator as well as product itself.

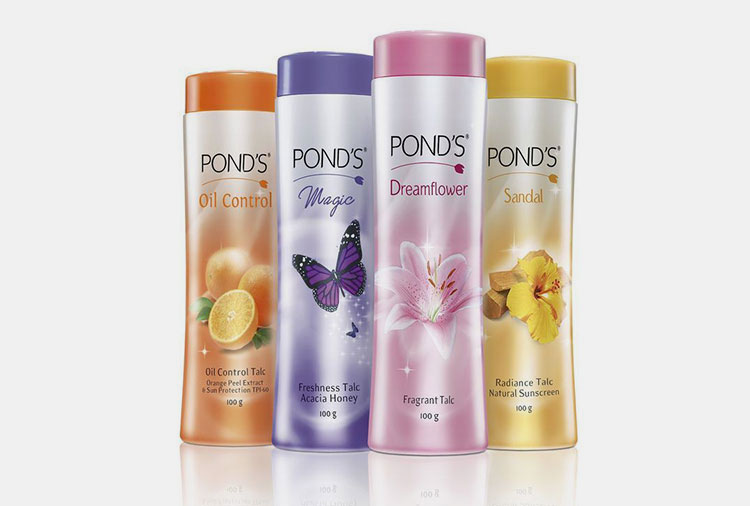

Beauty Care Sector- For Precision

Various talc powder bottles

Cosmetic industry is the most prominent sector continuously striving for producing beautiful and effective products for beauty care such as face powder, talc powder, and other facial powders etc. For their precise weighing and dosing the industry takes help of an auger filler.

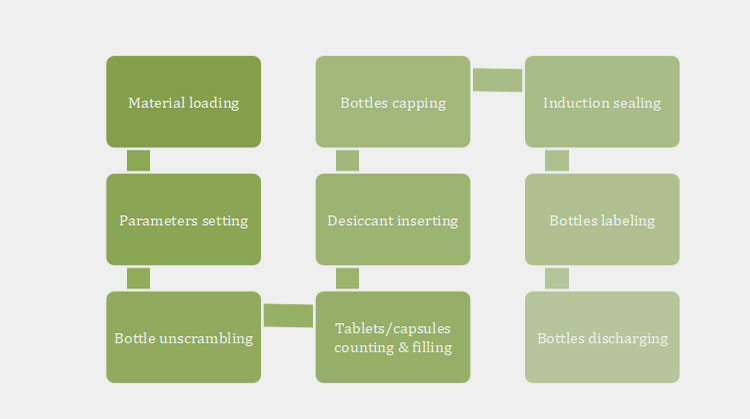

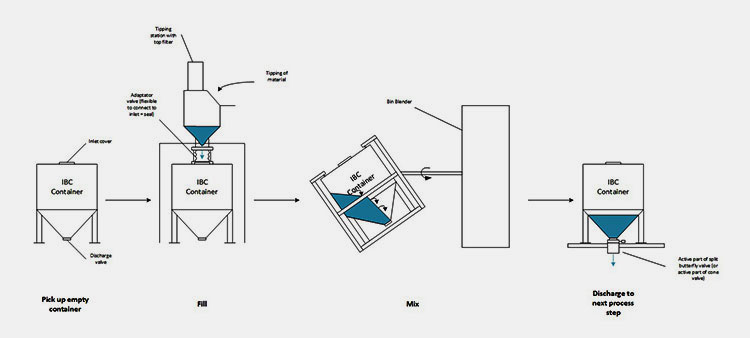

9.What Is The Production Line For An Auger Filler?

An auger filler can be integrated with other machines to make a production line and carry out the entire function of bottling powders and granules from filling to capping, sealing, and labeling etc. These machines are described below:

Bottle Unscrambler

Allpack APC-A160 Bottle Unscrambler

Bottle unscrambler is an automatic machine used to process the bulk scrambled bottles and orient them in a right position so, that these bottles or containers can be easily filled with material. It is made up of a corrosion resistant stainless-steel body, a rotary plate, electric system, transparent enclosed window for clear observation and stable feet. It functions through automatic process and supply the production line with unscrambled bottles through conveyor.

Automatic Auger Filler

Auger powder filling machine- Picture Courtesy: weighpack.com

An automatic auger filler can be employed to integrate with other machines. It has fully automated system for bottles moving in form of a conveyor, a feed hopper, alarm detection system, auger filling hopper, and control system etc. Together these components enable the machine to perform material weighing and filling in one run without wasting time.

Bottle Capping Machine

Allpack APC-D903 High Speed Capping machine

Bottle capping machine is another machine you will need for making the production line for your auger filler. It consists of a hopper for holding caps, a chuck station, conveyor belt, control panel, main frame, and gripper disc etc. It carries out the function of capping by first applying the caps over bottles or containers and then tightly screwing them to achieve rigid sealing.

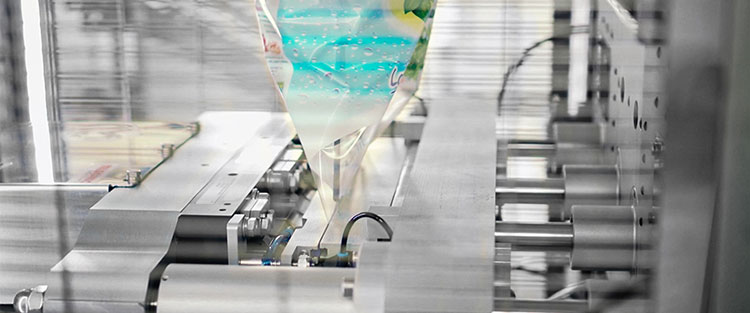

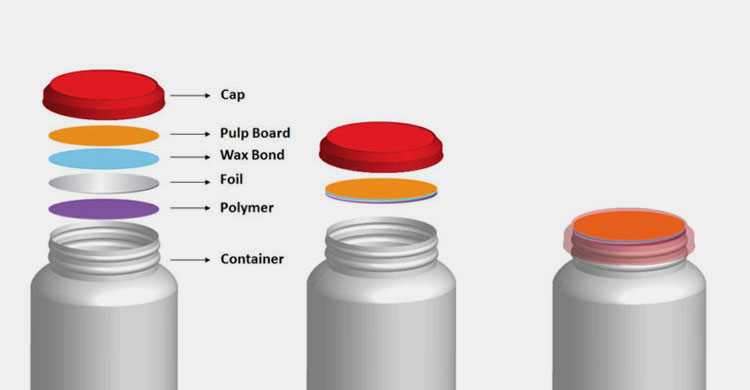

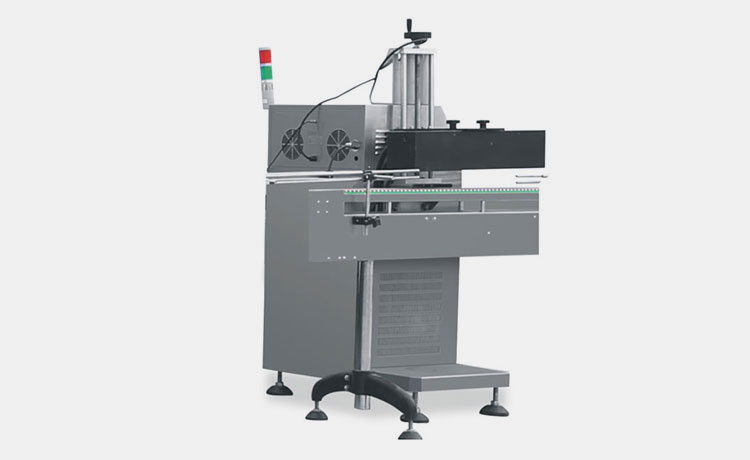

Induction Sealing Machine

Allpack APC-M1 Induction Sealer

An induction sealing machine is one of the most important machines that must be integrated to the production line of an auger filler. It is made with an advanced technology to ensure stringent sealing of foil that is located inside the cap through electromagnetic field. It creates the heat through electromagnetic radiation to foil which in turn get stick to the lip of the bottle and ultimately a strong airproof stringent sealing is realized.

Automatic Labeling Machine

Allpack APC-T1 Round Bottle Side Face Labeler

As labeling is the most crucial part of any business, automatic labeling machine will be attached to the main line for performing this task. It is composed of a label plate, label pulling mechanism, screw adjust device, label applicator, and a fur brush. The process gets started with label plate releasing the label from roll and delivering it to shafts.

These shafts pull the label and supply it to the label applicator. Finally, the label applicator applies the label to passing bottles and press the labels around them via fur brush to make sure label is fully adhered to the bottles’ surrounding.

10.How To Maintain An Auger Filler?

Maintenance presented through digital form- Picture Courtesy: 3group.com.au

Maintenance of an auger filler is the key to its successful functioning. By properly maintaining your auger filler you can extend its working life and working efficiency. Follow the following steps:

- Keep the setting of machine’s parameters all time adjusted before starting operation.

- Adjust the tools of machine as per the size of containers such as the width of conveyor and height of the filling head.

- Add a little oil, grease, or lubricants to the moving parts once every 2-3 months for smooth functioning.

- Tight all the nuts and screws each time when you are about to operate the machine.

- Keep checking the sealing strip on both sides of material hopper as it gets worn after a year so, replace it timely.

- Wash those parts of machine which are in contact with material after daily task gets ended such as the hopper, agitator, auger, and funnel etc., to remove out the residues and debris.

- Apply anti-rust oil on machine to prevent it from corrosion and properly seal the machine to keep it safe against impurities.

11.What Are The Main Quality Specifications For An Auger Filler?

Quality standards components- Picture Courtesy: oceanproperty.com

Quality specifications refer to those rules and regulations which are established by international organizations in order to make sure that safe products as well as machines are being produced. Hence, different quality specifications are being followed for ensuring the protection of an auger filler. These are as follows:

International Organization for Standardization (ISO)

ISO provides set of quality standards for auger filler in terms of quality management system to make it compatible to the customer expectations.

Good Manufacturing Practices (GMP)

Good manufacturing practices is another platform carrying the goal of regulating quality manufacturing and processing of machines. Hence, an auger filler also comes under the GMP regulations and must adhere to its policies.

Food and Drugs Administration (FDA)

Food and Drugs Administration is a USA based agency with prime focus on the protection of public health. Therefore, the organization has settled certain criteria to control the drugs manufacturing as well as the machines associated with it. Ergo, an auger filler must comply FDA rules.

Conformité Européenne (CE)

CE is abbreviation for European Conformity which indicates that all the goods and machines with this mark are complying the European Union health, safety, and environment protection prerequisites. Thus, it is another quality specification for an auger filler.

12.How Do You Troubleshoot An Auger Filler?

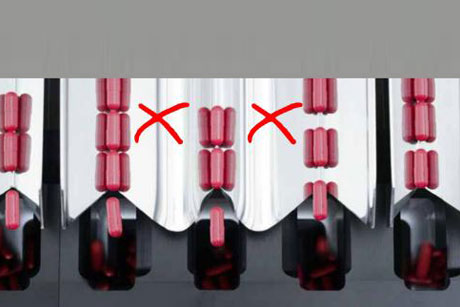

When operating an auger filler you might encounter few predictable problems. So, we have provided for your ease an advance solutions which will indeed help you out. These are described below in the table:

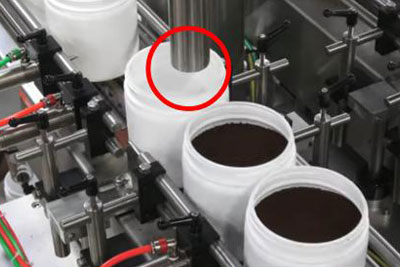

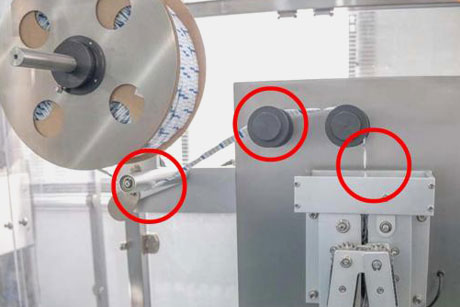

| No | Issue | Causes | Solution | Picture |

| 1 | Filling accuracy issue | It is due to the inaccurate calibration of machine | You need to recalibrate the machine according to the specifications of material |

Encircled filling nozzle- Picture Courtesy: All-Fill Inc |

| 2 | Material blockage in nozzle | It happens when the filling speed is excessive which results in the accumulation of material in funnel | Reduce the filling machine to keep the flow of material at normal condition |

Encircled blocked filling nozzle- Picture Courtesy: All-Fill Inc |

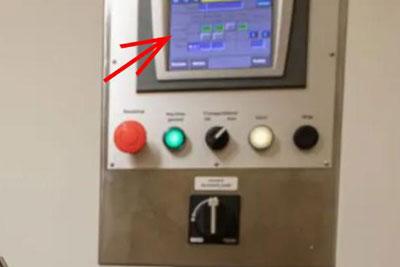

| 3 | HMI gets blur and has performance issues | Sometimes the outdated software, hardware, and incomplete starting of machine results in blurry display and its performance malfunctions | Hence, it is important to keep the software of HMI upgraded along with hardware. Also, restart the machine when you face difficulty in parameters appearance on HMI |

Indicating blur HMI- Picture Courtesy: altrimex.nl |

| 4 | Excessive noise during operation | This occurs due to the worn bearings, loose parts, and insufficient belt tension | Resolve it by replacing the wear bearings, tight loose parts, and adjust the belt tension. |

Stopping noise- Picture Courtesy: seekpng.com |

13.What Should You Consider When Choosing An Auger Filler?

When choosing an auger filler, certain factors must be kept in mind to avoid making unsuitable decisions. These are explained below:

Production Scale

The very first thing you need to look for is the sphere of your production. For instance, if you are running small batch production then semi-automatic auger filler will be a good choice which can give you output of 30 bottles per minute. In contrast, if your manufacturing is large enough then you must go for a fully automatic auger filler and consider the adjoining machines for efficiency.

Specifications

Specifications for machine- Picture Courtesy: apifirst.in

The second and most important factor is to examine the specifications of an auger filler. It is because some machines despite being less automated in nature come with brilliant features for safety, accuracy, and structural adjustment. Therefore, if a machine is adaptable and support quick changeover, ultimately, it will have positive prospects for your business.

Type of Product

Various powered and whole spices

As we have discussed earlier that an auger filler is capable to process all kinds of dry powders and granules, yet there are auger fillers who are particularly designed for specific materials. Hence, it is pertinent to opt for the machine that perfectly handle your specific products.

Supplier Reputation

Find a reputable supplier- Picture Courtesy: customsclearance.com

Buying an auger filler is something that must be done carefully as it will determine the future of your production. So, looking for a reputable vendor who has a good history in manufacturing and supplying quality machines, who consider customer expectations and provide you with a warranty policy will indeed become a helpful partner.

Conclusion

To put in a nutshell, this buying guide about an auger filler aims at enabling you with its every facet. It is because the need of an auger filler is realized in almost every field. It can give you extremely suitable results in form if precise filling, reducing product waste, processing multiple products and containers, ensuring high throughput and much more. So, be ready to avail these all benefits for your lucrative business by opting for an outstanding auger filler manufactured by Allpack with one year of warranty. Contact us for further information!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Auger Filler: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours