Bin Mixing: The Complete FAQ Guide In 2025

Want to attain even mixing to your formulation? A bin mixing is a key answer that offers you unlimited mixing benefits that every manufacturer dreamt for. An amazing thing about bin mixing is that you can find them in market with various shapes, sizes, and prices. The question arises which one is the best for you? Our expert advice is to read this informative blog to know important points about ‘Bin Mixing’. We promise, by the end of this article, you will be pretty sure about choosing the right machine for you. So, Sit Back and Enjoy the article!

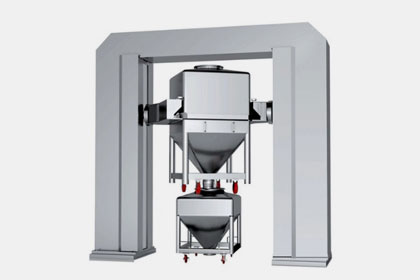

1.What is Bin Mixing?

Allpack Bin Mixing

Bin mixing can be understood by knowing what actually is bin mixing or IBC blender, whose other names include ‘Pharmaceutical Blender or even Pharmaceutical Powder Blender’ is an equipment that runs following mechanical, electrical, and optical power controlled by PLC technology.

It can easily carry out all the tasks of a mixer hopper such as clamping, elevating, dispersing and lowering the material into the bin. It assists free falling and is suitable for utilizing in applications where container volume requires to be in bulk capacity or where the required working procedure needs a fixed clamp blender. Bin Mixing can also be customized or changed in specifications according to customer needs.

2.How Is Bin Mixing Significant?

The significance of bin mixing is discussed below:

Time Saver

Bin Mixing, a Time Saving Equipment

One quality that needs to be appreciated of a bin mixer is its time saver characteristic ! Any powders or granules can be added to this equipment and it ultimately makes sure that each particles are perfectly collided and well blended. This gives a consistent texture to your mix material that enables good quality medicines or general items.

Contamination Bodyguards

Bin Mixing offers Pure and Original Mixing of Substances

Bin mixing has a safeguarding feature for your particle mix that provides hygiene and prevents it from getting contaminated by any outside agent. This is done by keeping each batch of material in its own zone.

Cleaning Made Easy

Bin Mixing Easy to Clean Machine- Picture Courtesy: Cos.mec

To make the cleanliness measures less tiring and problem-free, the parts of this equipment are designed in such a way that makes this task super easy.

GMP Compliant

A bin mixing provides GMP Compliant Properties

The structural and functional diameter of the running parts of this mixer are manufactured to follow the rules of GMP: Good Manufacturing Practices. This ensures that your batch production stays quality assured and controlled.

3.What are the Major Uses of Bin Mixing?

The industrial applications of bin mixing are mentioned in below discussion:

Pharmaceutical Industry

Bin Mixing Uses in Pharmaceuticals

Pharmaceutical industry is nothing without the involvement of bin mixing machine as it is frequently used equipment for utilization in making of medicines available in either solid semi-solid, or liquid formulations, such as capsules, tablets, powders, suspensions, and so much more. A bin mixing is safe and compact machine that can bring these sensitive task in a hygienic environment.

Chemicals Industry

Bin Mixing uses in Chemical Industry- Hover Australia

You must have heard about chemicals tablets, capsules, solutions, such as buffers, pH, titrimetric indicators, and other analytical substances. All of these compounds require a bin mixing machine for the creation of specialized products without stress for health hazards or other unintended consequences.

Cosmetics Industry

Bin Mixing uses in Cosmetics

The preparation of cosmetics requires bin mixing for perfect blending of cosmetical products such as foundations, mascaras, face powder, dusting powders, eye shades, and other pigment formations. All these products require promising distribution of substances to achieve an even results, for that a bin mixing is an ideal machine.

Food and Beverage Industry

Bin Mixing Application in Food and Beverage Industry

Say thanks to bin mixing which brings an easy blending of food and beverage products like sugar coffee, instant powders, drinking sodas etc.

Metals, Construction, and Alloys Industry

Bin Mixing significant role in the construction, metal and alloy industry

For the manufacturing of various material belonging to the metals and alloy industry such as iron, copper, aluminium and other minute compounds that require combination mixing require a bin mixing for attaining required characteristics. Moreover, the construction departments needs a bin mixing for combining substances such as cements, paints, gypsum, limestones etc.,

Agriculture Industry

Bin Mixing in Agriculture Industry

A bin mixing is used in agricultural industries for making and mixing of animal feeds to bring more nutrients into cattle’s well-being and obtain good crops. Moreover, the formation of substances like pesticides, insecticides, and related items needs a bin mixing for proper distribution of molecules.

4.How to Classify Bin Mixing?

Classifying bin mixing can be a little complex so for you to grasp it easily we have outlined a flowchart and its explanation. It can be categorized as per its size of use, design of equipment, shape of in mixing container, dimension, and it’s column type. Read on further to know:

According to Size

Laboratory Bin Mixing

| Laboratory bin mixing is only suitable for small scale of manufacturing, for processing lesser quantity of feeding material. The structural design is firm having a mini sized mixing container and is usually chosen for laboratories of smaller factories. It comes cost effective for such factories which do not need bulk amount of blended material. |

Allpack Laboratory Series Bin Mixing |

Industrial Bin Mixing

| Industrial bin mixing has the ability to process large quantities of blending material in bulk amount such as 200-5000 liters. It is appropriate for large scale production factories manufacturing in quick speed and precise quantity, therefore equipped with highly modernized computerized and technological controlling parameters. |

Allpack Industrial Bin Mixing |

According to Design

One Arm Bin Mixing

| In its structural configuration, the machine has a conjoined arm that is connected with the major supporting column. One arm bin mixing is favourable for less production capacity of batch materials. It is suited to elevate, hold and turn the blending container. This design supports cost-effective feature , although it is less efficient requiring operator interference in loading and discharging processes of materials. |

One Arm Bin Mixing |

Two-Arm Bin Mixing

| Two arm bin mixing can be seen as having two fixated arms which are connected with opposite sides of each supporting stand respectively. It is said to be more stable in terms of balancing the equipment and is suitable for the process of large size batches as per its huge structure. This equipment can turn and blend the materials in a more complicated pattern as it allows two sided rotation. |

Allpack Two-Arm Bin Mixing |

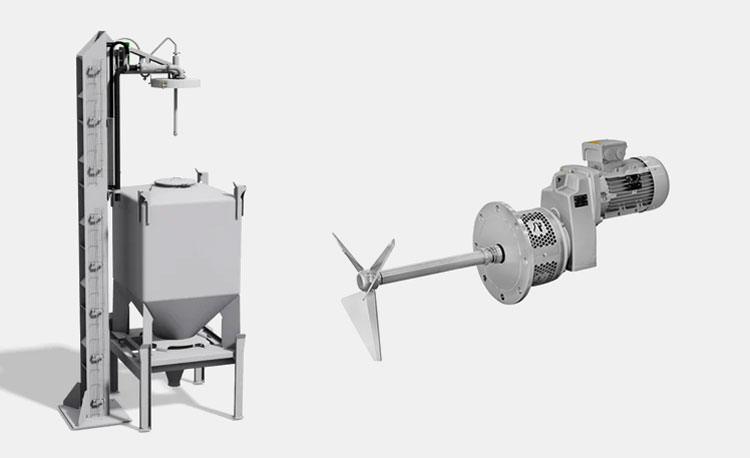

Fixed Bin Mixing

| Fixed bin mixing has a container that is placed fixed in its position persistently and so it does not turn. The blending process is carried out via agitators or paddles in this type of bin Mixing, the mixing vessel does not rotate, instead it is permanently fixed on the main frame of the bin Mixing. The mixing in this machine is carried out with the agitators or paddles; hence, in contrast with other types of bin mixing, it is ideal for aggressive mixing. |

Allpack Fixed Bin Mixing |

According to Shape of Vessel

Cylindrical Bin Mixing

| There are various kinds of bin mixing, cylindrical -shaped is an important container that shows similitude to a drum. It’s a straight-end cylindrical blending container that permits for quality efficient blending because of its reliable stumbling.

However, products that stick to one another can cause problems here as they are released from the cylindrical bin mixer in a messy form. |

Allpack Cylindrical Bin Mixing |

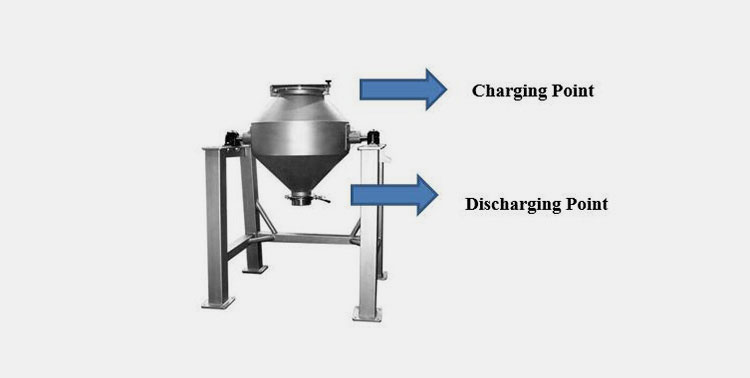

Cone Bin Mixing

| The cylindrical blending container of this machine is tapered in such a way to form an inverted cone. The tumbling action directing substances to the centre, leads to greatest mixing efficiency compared to cylindrical bin mixing. The items which are sticky as well are effortlessly discharged from the bottom, because of how the conical bin mixing is configured. |

Allpack Cone Bin Mixing |

Octagonal Bin Mixing

| It appears to be an eight-sided polygon because of its straight lines and angled design. The octagonal bin blending equipment produces more efficient mixing because of its slanted walls, which also makes it easier to unload these items. There are no mixing dead zones as a result of these angled walls and so it mixes the particles with both elegance and rapidness. |

Allpack Octagonal Bin Mixing |

Irregular or Ribbon Bin Mixing

| This category of container blending features a personalized form that is better suited to distinct mixing requirements and space constraints. It can be customized to facilitate stirrers or helical ribbon for blending challenging-to-mix substances. |

Allpack Irregular or Ribbon Bin Mixing |

According to Dimension

3-D Dimension Bin Mixer

| A collective mixture of different products can also be obtained by a three-dimensional mixer. This machine is utilized by many manufacturing sites for blending processes. Three dimensions mixer can rotate in three different directions to result in an exact form of blend.

This blending machine is constructed of stainless steel, giving it a plus point that when one or more reactions are carried out by this machine the substances won’t be sticking to the container walls. |

Allpack 3 D Bin Mixing |

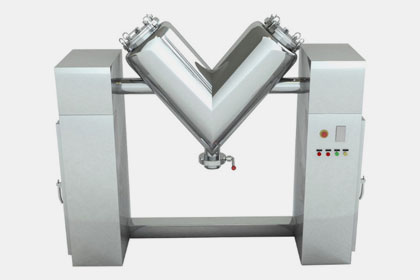

2-D Bin Mixer

| Two dimension mixers can blend the substances in two directions for getting a consistent mixture. 2-D Mixer is carried out by the following parts which work in the process such as: rotary barrel, swing frame supported with 4 rollers, transmission system crank shaft. |

Allpack 2 D Bin Mixing |

According to Column Type

Single Column

| A single-column bin mixing is commonly denoted by a repository or a container arrangement crafted with a single vertical column for containing substances. This terminology is frequently utilized in relation to storage containers across diverse sectors. The configuration may be differently based on the specific application and necessities.

Single column bins are constantly used in industrial sites or production setups to store and arrange substances such as parts, ingredients, or basic materials. Because they are usually designed as stackable, these bins make impactful use of the vertical space in the storage section. |

Single Column Bin Mixing |

Double Column

| Double column bin mixing is related to a blending configuration that uses two vertical columns to combine or evenly distribute components.

This type of blending arrangement is commonly used in industrial processes where careful material integration is necessary for producing items such as chemicals, food, pharmaceuticals, or other related uses. The system features two separate storage boxes or columns where the substances designated for blending are deposited. Every column may incorporate its unique blending mechanism. |

Double Column Bin Mixing- Picture Courtesy: Aipak |

5.How Bin Mixing Works?

The working process of bin mixing is very simple and precise. For your understanding we have categorized them into three broad stages. A description about following stages is discussed below:

Stage 1: Introduction of Product

Introduction of Product begins the process- Picture Courtesy: Freud Vector

The first step of bin mixing begins with addition of product into the hopper of the machine which is an enclosed structure with an opening. The outlet assist you feed the product inside effectively and secure the bin with a valve to close the structure.

Stage 2: Mixing of Formulation

Mixing of Formulation

The second stage of the mixing bin accompanied by lifting of clamping arm or gyrator which simultaneously induce the rotation of mixing bin vessel for smooth mixing procedure and gently blending of your formulation. This process is crucial in order to achieve an even mixing task with variation of velocities which is depending on the production cycle or manufacturer choice. An agitator facilitates the fast mixing action and rotation of bin allow tumbling of the product. The combine action allows greater interblending and even mixing output.

Stage 3: Formulation Discharge

Unloading of Bin Blender Pharmaceutical

The mixing process time is based on the manufacturer or product’s demand. Some products need shorter mixing time while other needs more.

The mixing time is mostly fed in the machine, once it is completed, the machine stops itself. A bin mixing is featured with discharge port which is designed as butterfly valve. This is helpful in the opening and unloading of the charged material inside the bin. Operator has turn down the machine for unloading or this process can be taken place via availing automatic features.

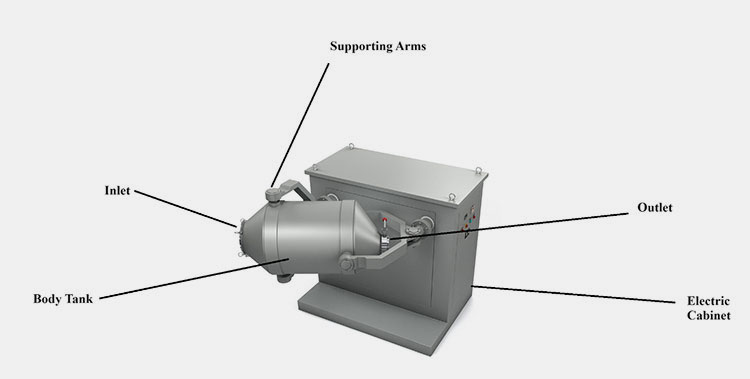

6.What is Structure of Bin Mixing?

Allpack Bin Mixing Parts

| Supporting Arms | As it names shows, these parts of the machine helps bin mixing to move flexibly in different positions or dimensions. The supporting arms are strong and stable structures which is meant to hold the overall structure of the tank and ensure integrity and stability of the machine to maintain its balance and operational procedure in a compliant way. |

| Inlet | The inlet of the bin mixing is the point that allows introduction of raw material which is meant to mix with this machine. This point serves as a entry or opener of the machine ensuring that mixing substances enters the apparatus. |

| Outlet | This is the point allowing you to discharge the mixed material out of the machine. Upon completion of mixing time, the bin mixing machine stops its activity and allow the outlet unit to regulate the evacuation of mixed substances from the equipment. |

| Body Tank | This is the machine chamber that enables you to attain mechanical mixing. This is a hollow and large cylinder that is composed of agitator and blending blades which is helpful in proper mixing of material and giving you an even and homogenous mixture. |

| Electric Cabinet | The regulation of bin mixing is controlled by an electric cabinet which is composed of plugs, wiring, connections, with 100% safety regulation. This section is responsible for regulating various tasks such as switching on, off, and other important tasks. |

7.What Product Can Be Produced by Bin Mixing?

Bin mixing is a useful equipment utilized in different industries because of its both gentle and aggressive mixing. Here are some examples of products formed by bin mixing:

| Solid Dosage Forms

Bin mixing can create the blends for tablet compression and capsule encapsulation. It is readily utilized to form pharmaceutical formulations. |

Pharmaceuticals Ingredients |

| Spice and Herbs Mix

Chillies, garlic powder, ginger, cloves, nutmeg, black pepper, turmeric, oregano, thyme, basil, etc are mixed in the bin mixing to spice up culinary experience. |

Spice and Herbs Mix |

| Bakery Blends

Flour, cocoa, sugar, sweeteners, dry milk are mixed in bin mixing to form a dough for bakery products. |

Bakery Blends |

| Cosmetics Fusions

Sparkling eye shades, tantalizing tints, blush powders, foundations, whitening powders, to name a few are produced in the bin mixing. |

Cosmetics Fusions |

| Paints

Various chemical pigments and additives are mixed in the bin mixing to create vibrant and colourful blends of paints. |

Paints |

| Cleaning Agents

Surfactants, detergents, baking soda, toilet cleaner, and other disinfectants are products that are produced by the bin blender. |

Cleaning Agents |

| Agriculture Products

Bin mixing creates dry and wet mixtures of fertilizers, animal feed, organic manure, humus, herbicides, pest controls. |

Agriculture Products |

| Ceramics

Bin mixing is popular due to its speedy mixing and creating ceramics mixes like clay, silica, feldspar, and cement. |

Ceramics |

8.How is Bin Mixing Different from Traditional Mixing?

A Bin Mixing VS Traditional Mixing

Talking about mixing brings just simple blending in our minds. But, if you go in depth of this term, you can find various variation depending on various perspectives. Similarly, Bin mixing is also different from Traditional mixing encompasses these variations.

Bin mixing is indeed a modern way of mixing that holds material inside a chamber featuring an agitator and blades giving you consistent results on a larger scale. Whereas traditional mixing including very simple hand mixing or paddle mixing which is basically used on a very small scale to produce short or limited production capacities.

Bin mixing is based on a modern way of mixing whereas traditional mixing which is a less efficient method of mixing is based on manual mixing or operation.

Bin mixing is a fast method of mixing that almost nullifies various challenges that occur in mixing of difficult substances, but traditional mixing is less effective in mixing of difficult substances such as semi-solid mixing of compounds that required a high degree of technician’s expertise.

The cleaning of bin mixing is comparatively more easier and reliable due to no chances of cross-contamination whereas a traditional mixing is difficult to clean as the entire method has to take place using manual handling.

9.How to Maintain Bin Mixing?

Maintenance of Bin Mixing

A bin mixing is proven to be a reliable machine in any industrial setup as it is efficient solution that facilitates your production processes. But the quality of your production line become always stable when it comes to taking care of the machine as today this factor is becoming increasingly significant in order to achieve a hygienic and compliant products.

The process of maintenance involved with removal of sticky residues and debris build up over the wall of bin mixing that should be flushed out the unit by using water and cleaning liquid such as IPA 70% to make your unit extremely cleared.

Use lubricants around the entire movable components of the machine to get a smooth movement without chances of vibration and noise.

Remember to replace damaged components, and above mention tips would be proven useful to bin mixing.

10.How to Solve Problems during Bin Mixing?

Yes, even though, bin mixing is a high-tech equipment, still occasional problems arise in it which affect the product and could lead to loss of money. But here are some tips for solving these problems in bin mixing:

| Reason | Solution | Picture |

| Build-up of Static Charges | ||

| Bin is not properly ground.

Dry operational settings. Improper bin materials. Poor material formulation. |

Properly ground the machine.

Use humidifier. Use bin with conductive materials. Add anti-static ingredients in the blending mixture |

Build-up of Static Charges- Picture Courtesy: Hayward Gordon |

| Bridging of Materials | ||

| Improper design of the bin.

Improper flow of materials. |

Utilize live bottom bin vessel.

Use baffles to aid in the fluidity of materials. |

Bridging of Materials- Picture Courtesy: Matcon |

| Segregation of Materials | ||

| Differences in the particle sizes of ingredients.

High fill levels Low mixing time. |

Use materials with uniform particle sizes.

Determine working volume of the bin and fill it to required level. Increase the mixing time. |

Segregation of Materials- Picture Courtesy: Matcon |

| Poor Blending | ||

| Decreased mixing speed.

Inadequate fill levels. Inaccurate mixing duration. Irregularity in material loading. |

Increase the mixing speed.

Load the materials to the accurate levels. Increase mixing duration. Load the materials after fixed intervals in the bin. |

Poor Blending- Picture Courtesy: The National Provisioner |

| Clumping of the Materials | ||

| High moisture content in mixing ingredients.

Poor mixing intensity. |

Lower the moisture content during mixing.

Increase mixing intensity using baffles and vibration. |

Clumping of the Materials- Picture Courtesy: AZoM |

| Degradation of the Bin | ||

| High mixing time.

Heat production during mixing. Incompatibility between materials and mixing vessel. Poor mixing environment. |

Lower the mixing time.

Operate the machine at low temperature. Use materials that are compatible with the machine. Operate the machine in an inert atmosphere. |

Degradation of the Bin |

Conclusion

After reading the ‘Bin Mixing’ buying guide, we assume that you will be well versed in this machine. Yes, that’s what our aim is! We Allpack is a Team of experts belonging to machine services and purchases. Our motto is to offer an amazing series of ‘Bin Mixing’ and provide essential information you need to skyrocketing your business. If you’ve any queries or need to buy a machine with a friendly budget- Don’t worry! Just send a message; our representative will contact you shortly. Happy Shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide