Bottle Counter Machine: The Complete Buying Guide In 2025

Looking for bottle counter machine? Welcome readers! You’re possibly at the right place where you can find A to Z and Basic to Deep streamline guidance about bottle counter processes, integration, machine types, pricing, and much more.

This guide provides you with comprehensive detail about its significance and how it can unlock the journey of success for tugging your time and money. Our experts have provided tailored information for you to explore the knowledge about bottle counter machine.

So, Familiarize yourself with What’s inside!

1.What is a Bottle Counter Machine?

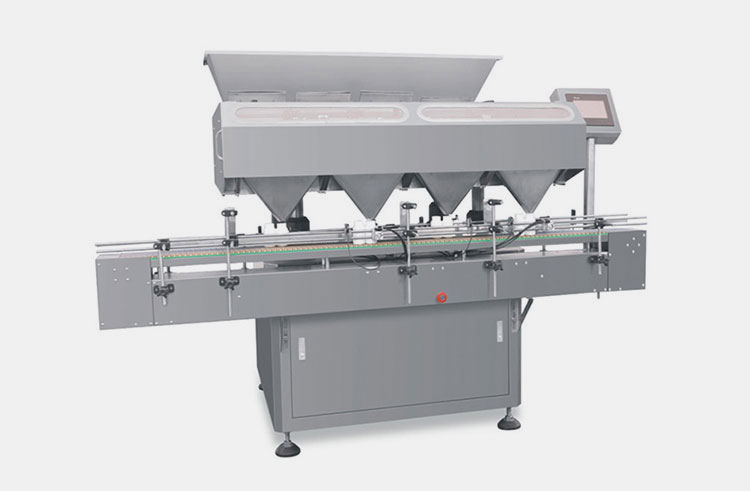

Allpack Bottle Counter Machine

The bottle counter machine is a remarkable equipment of technology that simplifies the bottle-counter process in industries such as beverage production and pharmaceuticals. You can consider it to be an exceptionally smart helper seamlessly integrated into your production line. Utilizing advanced sensors and specific parameters, this machine precisely tallies the bottles in movement, ensuring you always have an accurate count.

From a technical perspective, it provides a high degree counting mechanism and a user-friendly collaboration, making customisation seamless. Its flexibility is a game-changer, effortlessly handling various bottle shapes and sizes. Think of it as the supervisor of your production process, guaranteeing precision, efficiency, and a problem-free counting experience. Whether dealing with small batches or large-scale productions, this gadget has you covered, making bottle counter a straightforward task.

2.Where is the Bottle Counter Machine Used?

A bottle counter machine has a wide dimension of it’s applications across several industries. This is due to it’s great amount of precision, reliability, and speedy output. Here are few important industries that generally bring use of this equipment.

Pharmaceutical Industry

Applications in Pharma Industry

A bottle counter machine is a phenomenal machinery that is of due importance for the rapid and correct dosage delivery e.g., tablets, capsules, pills, and caplets. This machine assures you that individually counted and filled tablets are accurately packaged and processed for further sale without any mistakes or risk of contamination.

Nutraceutical Industry

Applications in Nutraceutical Industry

Similar to the benefit of use taken by the pharmaceutical industry, the nutraceutical industry as well require the role of this machine for packaging department to enable accurate and precise, error free delivery of products such as vitamins, supplements, and probiotics, in the dosage form of gelatinous capsules, tablets or any others.

Food and Beverage Industry

Applications in Food and Beverage Industry

A bottle counter machine is not only limited to the above two industries, it is also found in the food and beverage industry. This machine is employed by manufacturers for counting and filling of products like chewing gums, toffees , chocolate beans, gummies or jellies, etc.,

Cosmetics Industry

Applications in Cosmetics Industry

Interestingly a bottle counter machine can be found in cosmetics industry too, where it is utilized to enumerate and package products such as serums, waxing beads, and hair products present in powderous or granular form, that are usually filled in gelatin capsules or other dosage forms. The machine makes sure that it’s packaging is carried out perfectly accurate and reliable .

Chemical Industry

Applications in chemical industry

Chemical industry is the production setups where precise and accurate products are considered mandatory. For this purpose, you will need a bottle counter machine for quick and proper dose measurements in the filling of chemical products such as buffer pellets, tablets, and some other chemicals in the form of solid tablets, granules, or pellets form.

Veterinary Medicine

Applications in Pet Industry

Veterinary industry also requires the use of bottle counter machine for the dispensing of their pet medicines such a as tablets, capsules or other animal based products like pet food etc re supposedly counted and filled using this equipment.

Herbal Industry

Application in Herbal Industry- Picture Courtesy: life botanics

Alike other industrial uses of this machine, herbal industry have also employed this equipment for counting, filling and packaging it’s herbal based ingredients or medicines such a as herbal supplements, capsules, tablets, pellets or granules .

Research and Development (R&D)

R&D Applications

The research and development departments across many industries are the one that utilizes this bottle counter machine primarily for test and trial studies on the tablets. Therefore each task is conducted with great monitoring and extreme finesse .The bottle counter machine has highlighted importance in R&D sectors.

Electronics Industry

Bottle counter machine uses in electric department

This industry manufactures hardware items that are needed for engineering, construction and automobile services and projects, and also in some other construction industries. Examples of the items are: nails, screws, screw bolts, buttons, electronic chips, and other mechanical small parts can also be enumerated using bottle counter machine.

Stationery Industry

Bottle counter machine application in stationery Industry

The stationery industry is also essential sector for production of items like pencils, erasers, sharpeners, staple pins, thumb pins, clips etc that finds its purpose for proper counting of these things with the use of bottle counter machine.

3.How Beneficial a Bottle Counter Machine?

Frankly speaking! Your business would be in loss if you are running it without adding a bottle counter machine. The reason behind this point is that it offers number of significant benefits to you. Some of very important benefits are jotted down.

Numerous sectors depend on bottle counter machines as they provide significant advantages for any customer choosing this option in manufacturing procedures, such as:

Precision in Dosage

Bottle Counter Machine with high Accuracy Percentage

Utilizing advanced technology, the machine ensures accurate counter and filling methods.

Avoiding Contamination

Pure and Original Product with Bottle Counter Machine

It aids in prevention of cross-contamination by facilitating the filling and packaging of medication with minimal physical exposure. The machine is composed of high-quality stainless steel and equipped with safety characteristics, ensuring product safety and eliminating the risk of any microbial or dirt invasion.

Streamlined Detection

Digital Detector with Ultra Finest Scanners

Equipped with electronic and digital features, including scanners and detectors, the machine identifies errors or malfunctions in tablets or the machine itself, addressing issues through notifications.

Enhanced Efficiency

Fast Touch Screen System with enhanced Efficiency

By automating the assembling, calculating and filling of pills, tablets and capsules, the bottle counter machine streamlines the production leading to enhanced efficiency by flexibility in process without the necessity of manual intervention.

Cost-Efficiency

Cost Effective Addition to your Business!

Industries, pharmacies, and various sectors experience cost savings by avoiding the need for technicians to manually monitor and package tablets. Additionally, the machine cuts down on time and energy too, contributing to increased productivity and throughput.

4.What products can be Counter in Bottle Counting Machine?

Now you can enjoy dispensing various products in bottles with high accuracy, rapidness, and precision ratio with bottle counter machine. Some of commonly used products are mentioned below:

| Sweet Candies |

Whether gummies candies, chocolate beans, gummy bears, gummy dragon, or colorful enticing confectionery. They’re filled with bottle counter machine without worry for cross-contamination. |

| Laundry Pods |

In laundry and dishwashing tablets counting, the bottle counter machine is of worthwhile invention for separating, counting, and filling of these products with promising outcomes. |

| Pills |

Small or large pills with various shapes or sizes can be counted and filled into each bottle with bottle counter machine. The machine is significant in dispensing small or bulk quantities. |

| Tablets |

In delivering and packaging of medicinal or general tablets can be counted and filled by using a bottle counter machine. |

| Capsules |

You can count softgel, hard gel, animal based or plant-based capsule into individual bottle using this reliable and robust machine. |

| Chewing Gum |

You can find bottle of chewing with precise quantity of product in market. This is all because of bottle counter machine that helps in the packaging of these products. |

| Biscuits |

The biscuits in bottles are counted and packed using bottle counter machine. |

5.What is the Composition of the Bottle Counter Machine?

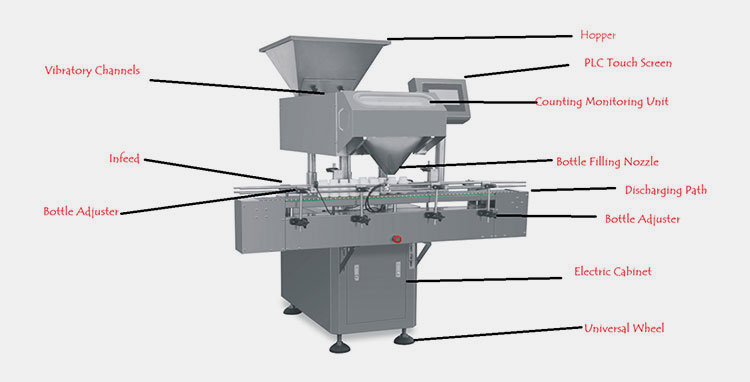

The structure of the bottle counter machine is almost very basic and easy to understand. Some of the basic parts of the machine are illustrated in the figure with descriptions.

Allpack Bottle Counter Machine

| Part | Description |

| Hopper | The topmost position of the bottle counter machine is equipped with a flat and hollow tank known as a hopper. This property allows flexible control on releasing counter items from the hopper to further units of the machine via force of gravity. |

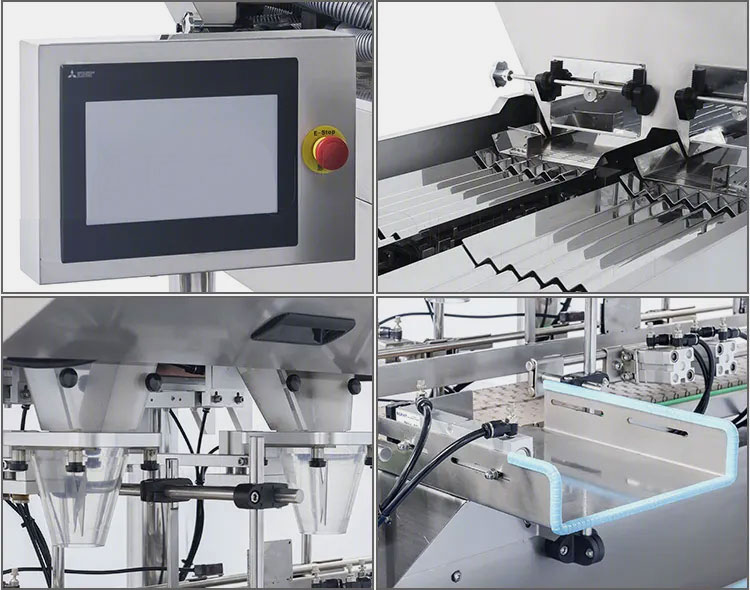

| PLC Touch Screen | This is also known as the brain of the machine. A programmable logic controller is basically a digital manager of the equipment that regulates various parameters such as the speed of counting items, vibratory channel movement, run time, memory, processing, and so on. |

| Vibratory Channels | To run and supply counting items into the bottle, vibratory channels facilitate a smooth pathway to move and pass through items from sensors where detection of correct and faulty products can also be caught. The movement of these channels allows items to transfer from the hopper to the filling nozzle for accurate counting. |

| Counter Monitoring Unit | The bottle counter machine offers an amazing feature where you can monitor the movement of counting material via a transparent sheet of glass or plastic. The passing of items or in case of any problem one can easily troubleshoot by opening the passage. |

| Bottle Filling Nozzle | This is the main component of a bottle counter machine where a narrow passage known as a filling nozzle accompanies the filling bottle directly. Once the bottle reaches the site, it senses and allows precise and accurate counting of items and directly pours onto each bottle. upon filling, the nozzle detects and stops further filling and sends the bottle to further steps which is of course discharging unit. |

| Infeed | A predetermined number of bottles enters the machine using an infeed passage which is guided by supporter units. This passage is also known as a conveyor which moves whether continuously or intermittently depending upon the type of machine or manufacturer choice. |

| Discharging Path | Once bottles are filled with a predetermined amount of items such as capsules/tablets/pills/etc., then it is time to leave the machine; a discharging path is a connection where bottle filling machine is attached to other machines of the production line such as capping machine, or other units of the system. |

| Bottle Adjuster | A proper spacing between each bottle as well as an aligned number is followed and maintained by the bottle adjuster. This unit supports the bottles of various shapes and sizes. |

| Electric Cabinet | An electric cabinet is meant for the safe enclosure of all electrical components, plugs, connections, motors, etc in a cabinet that ensures 100% safety and lesser chances of short circuits or heating up of the machine. so this machine is safe to use. |

| Universal Wheel | The mobility, installation, and fixation of the machine are easier when comes to using a universal wheel. These wheels are of prime importance when it comes to moving your machine from one place to another. |

6.What is Step by Step Working of Bottle Counter Machine?

Step 1: Starting & Bottle Feeding

Illustration of step 1

The procedure starts by switching on the power button of the bottle counter machine and adding information on PLC Touchscreen. This begins the inside mechanisms and working of gears, getting the equipment ready for the counting operation.

Bottles are supposed to be fed into the conveyor system, which is suited for perfect bottle motion so that they’re consistently and methodically aligned to ensure precise counting.

Step 2: Algorithmic Counter Ballet

This process is designed with extreme finesse, as the algorithmic tallying of bottles takes place via highly advanced sensors. The sensors are fitted in the machine to identify the presence of each bottle with definiteness, playing the role of gatekeeper of counting process.

The counting procedure is mechanized by high-tech algorithms that defines a collaboration of calculations. As bottles swiftly move through, this mechanism uninterruptedly tallies up the numbers, showcasing its aptitude in high-speed arithmetic.

Step 3: Live Bottle Counter Display & Discharging

Bottle Counter Machine- Final Step of counter and discharging

As the machine is equipped with a smart PLC screen device, it allows for super friendly operator interface by which operator can set parameters and functions for controlling the machine easily. The whole bottle counting session can be visualized as the screen displays the count of different items that are counted via the machine.

7.What are the Types of Bottle Counter Machine?

A bottle counter machine can be divided into broad category of types which relies on different technical aspects of the machinery. The major purpose of laying out this categorisation is for you to decipher the possible features of the machine in the market for helping out in better selection.

BOTTLE COUNTER MACHINE WITH AUTOMATION

In this type, the machine can be sub-classified into three broad categories:

Manual Bottle Counter Machine

Manual Bottle Counter Machine

A manual bottle counter machine indicates the presence and need of a user operating to count and fill medicines such as tablets and capsules. The mechanism is driven by manually placing the required medication on the counter tray where each tablet is counted using the aid of spatula and later separated to be dispensed into the filling container.

As the size of the machine clearly shows its conveyance for small scale industries it is not required in large areas for application. As each tablets are tallied by human hands individually, chances of error or contamination are minimized, helping in accurate results.

Semi-Automatic Bottle Counter Machine

Allpack Semi-Automatic Bottle counter machine

If compared with a manual bottle counter machine, the semi automatic bottle counter machine is developed technologically advanced as it can count and fill many tablets per hour, more than the former machine. However it does require some human interference too. The containers to be filled or the packaging material are manually loaded and discharged too. This machine finds it’s best purpose for medium scale production setups as it is cheaper than the fully automatic one, enabling new businesses to thrive and prosper taking it’s help effectively.

Automatic Bottle counter machine

Automatic Bottle Counter Machine

An automatic bottle counter machine is the most efficient working of them all. This equipment is reliably appropriate for large scale production setups where processes run around the clock without any probability for errors. Each step from bottle feeding, counter of tablets, filling the container and it’s discharge by conveyor belt is carried out automatically.

An operator is only required to input parameters into PLC system and the whole working doesn’t need to be supervised by any technician. This equipment can give hundreds and thousands of precise products filled and packaged per hour.

BOTTLE COUNTER MACHINE WITH COUNTING TECHNOLOGY

Based upon functional technologies, a bottle counter machine is further subdivided into rotary wheel, vibratory and slat procedures of counting. Although the basic structure and mechanism of these types are in contrast, but the major objective of counting is stayed similar.

Rotary Wheels Bottle Counter Machine

Allpack Bottle counter machine

This technology can be found to be inculcated in semi-automatic and automatic versions of bottle counter machines. The important advantage of this technology is that it’s easily maneuvered and convenience in change over is possible for many shapes and sizes of tablets, capsules or other medicines. The most important characteristic of this machine is swift mobility of rotary wheel that lets the tablets to fall down into filling nozzle section where the detector senses the presence of tablet and tallies or counts them and dispenses into their respective containers. The whole working mechanism is precise and convenient . This machine is found in comparatively cheaper rate and is not considered suitable for large production industries as its output volume is relatively lower than other machines.

Vibratory Bottle Counter Machine

Allpack Vibratory Bottle Counter Machine

This machine provides a more rapid approach than a rotary bottle counter machine in which tablets undergo feeding compartment for formatting; by inducing vibrations each tablet moves from a scanning device individually and falls down to the feeding nozzle for further counting and filling process.

This machine is applicable for operations of large-scale manufacturing sectors where the necessity of packaging is almost higher. Moreover, this equipment is further categorized in the availability of number of compartments such as single, eight, sixteen or twenty-four vibratory compartments ensuring counting and filling task in huge quantities without any probability of mistakes.

Slat Bottle Counter Machine

Slat Bottle Counter Machine

Comparatively seen this is a rapid version of rotary wheel and vibratory bottle counter machine. The slat system takes advantage of specialized partitions where individual tablets or pills are counted and moved towards containers that are to be filled with them.

This allows quick filling of many tablets per hour. These cavities enable certain shapes of pills to fix accordingly in it for further operation, without the slightest chance of leaving any empty or double filled. In this method, it gives almost precise results. However, a drawback lies in this machine having a limitation of continuously changing parts for accommodating different sizes or shapes of tablets where required.

BOTTLE COUNTER MACHINE WITH DIFFERENT COUNTER HEADS

Bottle counter machine can be found in two general types, categorized according to the number of filling head they have. Single head and multiple head bottle counter machine are two of them. Now you’ll be reading about these types below:

Single Head Bottle Counter Machine

Allpack Single Head Bottle counter machine

This equipment has the most convenient structural design and is cheaper in costs for achieving automatic tablet counting and filling purposes. A single head bottle counter machine is like an advanced facility for those who prefer to work at small setups. However it only has one counting and filling nozzle, alongside all other essential features that are present in multi-head counter machine such s sensors, PLC system, camera etc.

Multi- Head Bottle Counter Machine

Allpack Multi- Head Bottle counter machine

A Multi head bottle counter machine has many numbers of filling and counting nozzles that are placed adjacent to each other. Due to it’s structural design it allows high speed of counting and filling enabling greater production capacity every time. Hence it perfectly collaborates with large industries providing them with flexible bulk quantity of production.

BOTTLE COUNTER MACHINE WITH DIFFERENT COUNTER CHANNELS

Counting channel of a bottle counter machine is considered to be an essential characteristic as it facilitates convenient orientation and movement of tablets. These channels are also fitted with scanning device that can judge the tablet structure and analyse if it is to be approved or discarded from the batch. There are single or multiple channels that will be classified according to it’s usage per production output required. These are:

Single Channel Bottle Counter Machine

Single Channel Bottle Counter Machine

Single channel bottle counter machine can be perfect for a small industry as it has only single section indicated for lower volume production, hence ensuring it’s precise counting and filling for a limited capacity . As the name says it has only one unit that is responsible for filling of tablets or pills by the feeding mechanism.

Multi- Channel Bottle Counting Machine

Multi- Channel Bottle Counter Machine

This machine has the capability feature that has multiple units that processes tablets for counting and their filling in containers simultaneously. Both functions work and move adjacent to each other with greater rate of counting and filling of those tablets. Each section for counting is incorporated with detection sensors that can identify any damage or issue present. This equipment is suitable for large scale industrial setups as it can handle bulk sized products efficiently.

8.What is the Complete Production line of Bottle Counter Machine?

Bottle Unscrambler

This is an important machine that initiate the process line of bottle counter machine. Imagine a process of bottle counting without an alignment and proper orientation of bottle can be hectic and full of errors with huge costs.

But using this machine can simply bring bottles in a uniform way. Overall process can take place by using of movement of base with speedy blower which helps in acquiring an upright position of bottles. Once bottles are perfectly in position, they’re sent to the next machine which is of course a counter machine.

Bottle counter machine

This machine is the second part of the production process where the counting of products takes place and send the bottle to the next machine.

Desiccant Inserter

This is the next phase once bottles are filled. You know this, due to weather conditions humidity may develop inside the bottles or jars. To avoid the progression of moisture inside the bottles. Various manufacturing companies prefer inserting a desiccant inside each individual bottle. yes, this is done by using a desiccant inserter, the machine is featured with a roller cutter that cuts each strip prior to dropping it inside each bottle. once it is introduced in bottles, the conveyor helps in discharging bottles to the next machine.

Bottle Capping Machine

You can’t market bottles without properly enclosing them. For that, a bottle capping machine is of prime importance as it helps in the placement and twisting of caps to secure the present content inside the bottles. The machine is equipped with auto-grippers that facilitate picking and twisting caps around the bottle neck and sending the bottles to the next machine of the production line.

Bottle Induction Sealing Machine

Now tampering is difficult as bottle induction sealing machine is here in the markets. Today, every manufacturing company must have this machine in order to sustain integrity of brand and security of their products. An induction sealing machine by the help of electromagnetic radiation melts the placement of the inner lining of the caps. These melting upon cooling solidify and form a tough bond with bottles known as seals. This seal can only be opened by customers ensuring that they get an original product.

Labeler Machine

For better presentation and conveying important information, a labeler machine is used which is also known an essential marketing tool. A labeler machine is meant to stick a label with informative messages such as doses, manufacturing date, expiry date, etc. The machine works by unfolding a label coil with the help of attached roller feeders; the presence of roller presser ensure fixation of each label over bottle evenly and firmly.

9.Is Bottle Counter Machine and Tablet Counter Machine Same?

A Bottle Counter Machine

Yes, a bottle counter machine & a tablet counter machine almost serves similar responsibilities in the filling and packaging processes.

Both apparatuses are designed to sense and notify the presence of dropping items over detecting channels such as tablets, capsules, pills, or any products that we discussed above.

The machine is featured with same properties such as hoppers, vibratory channels, filling nozzles that cumulatively offering identical operations.

So, you should be confused when it comes to purchasing or requiring bottle counter machine or tablet counter machines.

10.What is Maintenance & Cleaning of Bottle Counter Machine?

Maintenance & Cleaning of Bottle Counter Machine

The maintenance and cleaning tips of bottle counter machine are discussed below:

- It is recommended that a bottle counter machine should be operated in a room temperature and avoid operating in high temperature or humid environment.

- The presence of dust or debris over vibratory or rotary plate or channel should be cleaned regularly.

- The monitoring or connecting bolts must be inspect on regular basis.

- After completing each batch, the surface of the bottle counter machine should be cleaned using 70% IPA spraying and wiping with light cloth to bring polishing and finishing over surface and minimizing chance of microbial growth.

- Regularly monitor and clean the surface of the sensor.

11.What are the Problems & Troubleshooting of Bottle Counter Machine?

After reading above description, this is understood that a bottle counter machine is promising machine in the term of technical and mechanical complexities. But every machine sometime encounter problem. The ideal thing is that user must be aware of solving the technical problems. The few and major problems and solution of bottle counter machine are described below.

Blockage of Items

A Bottle Counter Machine

The flow of counting products becomes jammed or interrupted.

Solution

Schedule the cleaning and maintenance program of the machine, including proper oiling of movable parts of the machine, the smooth movement of the plates allows seamless flow of the particles/items so no chances of jamming or blockade.

Double Counting of Items

Bottle Counter Machine

This is commonly occurring problem where a bottle counter machine addressing counting items twice and affecting overall accuracy of the product and making batch toward rejection phase.

Solution

This problem is mostly occurred when you ignore frequent or regular cleaning and maintenance of the machine. It is suggested that after running each batch clean the machine with duster and re-calibrate units such as scanner, vibratory channels, sensors. This would help in fast and sharp counting of each falling object over detector.

Vibration More than You Expect

Bottle Counter Machine

The machine vibrates more during the working process.

Solution

Monitor and correct the alignment of the machine by checking its universal wheel system. Check and calibrate the vibratory parts and lubricate them. Check the flooring or installation surface of the machine; try installing it on a smooth surface.

Conclusion

Dear readers! We hope you have found this blog up to your expectations. A bottle counter machine is a worthwhile investment that can bring success to your business. Thinking of buying Now? Allpack Team welcomes you to contact them to unlock the horizon of unlimited bottle counter machine types. If you’re having very specified budget! Then we also have a solution for you. For Product Purchases or Any Queries please Message us. We promise to offer tremendous customer services Free of Cost.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide