Automatic Capsule Machine: The Complete Buying Guide In 2025

Are you interested in buying an automatic capsule machine and getting its related information? Does your facility involve capsule making process? Is an automatic capsule machining a part of your production line? Do you want proper guidance regarding the working principle and types of automatic capsule machines available globally? So, you are at the right place that will help resolving all your queries related to automatic capsule machine and will support you in selecting the best type. Please read the complete buying guide to get much possible knowledge from it.

1.What Is An Automatic Capsule Machine?

Allpack Automatic Capsule Machine

An automatic capsule machine is a highly specialized type of machine that is used to fill and encapsulate different types of particles, powders into capsules in an efficient manner. These machines fill various types of substances in capsules and then are consumed for various reasons. Complete processes in an automatic capsule machine are carried out in an aligned sequence that makes the production precise and uniform.

2.What Are The Industrial Applications Of An Automatic Capsule Machine?

Automatic capsule machines are currently present in all types of small and large scale industries. These industries have optimal usage of automatic capsule machine to enhance their productivity. Some of the industries using automatic capsule machines are

Pharmaceutical Industry

Pharma Capsules - Picture Courtesy: Pharma Franchise Company

Pharmaceutical industry is the largest consumer of an automatic capsule machine as capsules are one of the orally consumed medications globally. These capsules of different sizes and shapes are filled and sealed using automatic capsule machines in an efficient manner. Machines ensure that the ratio of dosage inserted is according to the standards and is approved by different clinical trials.

Food Industry

Nutrient Supplements

Food industry is also a consumer of an automatic capsule machine as it also produces products that are in the form of capsule. Ingredients like chocolates, jellies, vitamins and supplements are filled in these capsules that make consumption easier and also attract adults towards them.

Cosmetics Industry

Cosmetics Hyaluronic Acid Capsules - Picture Courtesy: Republic Cosmetics

Some of the vitamins and protein health care products that are used as cosmetic products are also present in the form of capsule. These capsules are filled and sealed using an automatic capsule machine. It makes the product look presentable and attracts number of customers towards it.

Agricultural Industry

Nutrient Capsules For Agriculture

Capsules having organic fertilizers and nutrients that are useful for agricultural land are also manufactured using an automatic capsule machine. These capsules generally contain products that are essential for agricultural land and to improve its internal strength.

3.What Are The Advantages Of An Automatic Capsule Machine?

Some of the advantages of an automatic capsule machine are

Productivity

Capsules Productivity

The designing of an automatic capsule machine is done in a way that it helps the manufacturer to produce large volume of capsule in limited time. The procedure is done to keep the system remain efficient in each of the capsule and to keep complete similarity in them.

Efficiency

Efficient Manufacturing Of Capsules

Efficiency is another benefit that can be gained using an automatic capsule machine. It is taken in the context of chemical composition that each of the capsules has equal dosage formulation to work effectively. The mechanism ensures consistent flow to keep the medication dosage filled in an efficient manner using an automatic capsule machine.

Formulation Flexibility

Flexible Formulation Of Capsules

One of the leading advantages of an automatic capsule machine is that it allows wide range of capsule filling in a single machine. Whether it is powder, pellets or granules that has to be filled in capsules, a single automatic capsule machine can accommodate each of the formulation in it in an efficient and precise manner.

Consistency

Elongated Consistent Capsules Making

Quality is a factor that helps to check the consistency of an automatic capsule machine. It provides flexibility in producing capsule by using highly accurate sensors and actuators. These components help to fill accurate amount of formulation in capsules and maintain consistency in them.

4.What Is The Steps Involved In Working Of An Automatic Capsule Machine?

Automatic Capsule Filling - Picture Courtesy: grupobsg

The working of an automatic capsule machine follows several series of steps. These are internally coordinated with each other to maintain the system run efficiently .These steps are

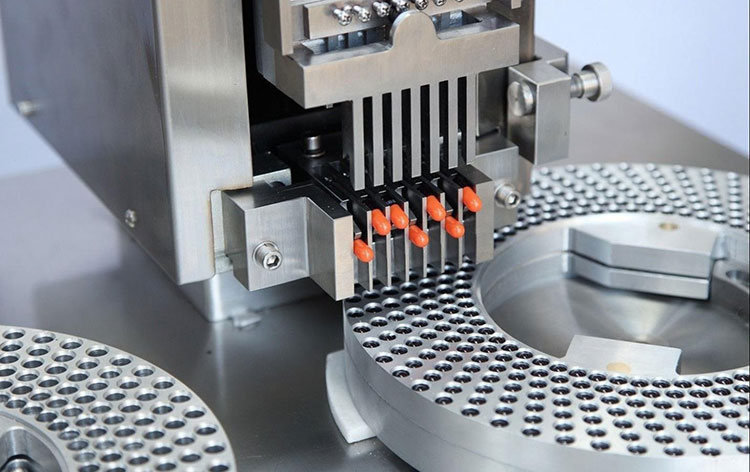

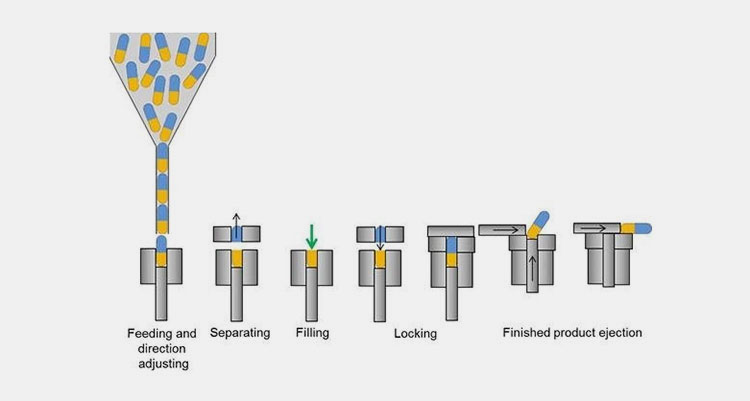

In the first step, both the empty capsules and powder in inserted into their respective hoppers present at the top of machine. Both the object s is delivered in an automatic sequence to the filling stations where they are blocked by highly advanced mechanism.

In the block-shelf, the capsule direction is using guide slots that adjust the capsules both upward and downward for proper filling. Both of portions of capsules are separately adjusted into the lower and upper molds and stick by vacuum suck so that chances of falling can be eliminated.

In the third step the filling of capsules placed in die mold is carried out. The material released from the powder hopper enters into these capsules cap by filling nozzles in an accurate amount.

After the completion of filling process, both the cases of capsules are locked together by a dose plate so that no spillage can occur.

As the capsules are ready, they are discharged from the system through a proper ejection system that continuously pushes them out from the mold surface. The mold gets cleaned after each capsule formation by a vacuum chamber to maintain consistency in the system.

5.What Are The Main Components Of An Automatic Capsule Machine?

Components In An Automatic Capsule Machine

The main components of an automatic capsule machine are

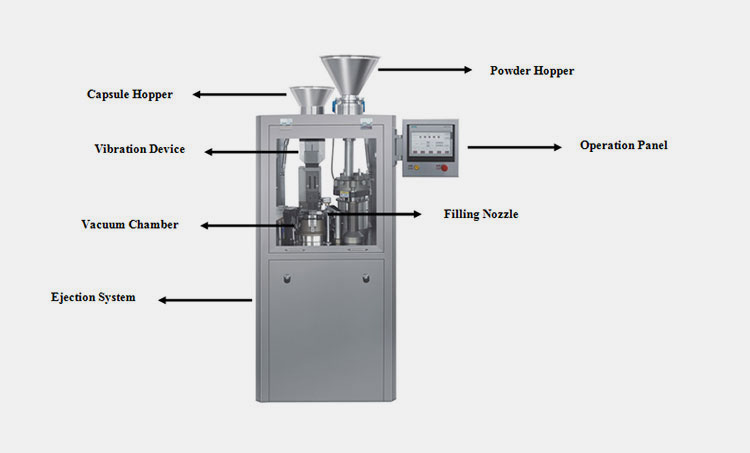

Hoppers

Both of the powder and capsule hoppers are present in an automatic capsule machine that is used for holder of filling material and capsules respectively. A capsule hopper is mostly with a vibration support that ensures segregation of capsules and to allow their free flow.

Operation Panel

An operation panel of an automatic capsule machine contains all the options involved in product processing. The productivity is controlled by increasing and decreasing of speed controller present on this operation panel. Other options like start on and off button, emergency buttons and others are also present in this panel.

Vibration Device

As capsules are attached altogether in a hopper it is always necessary to segregate them and separate each of them to maintain efficiency and consistency in system.It minimizes the risk of error and keeps capsule flowing individually to fill and get sealed.

Vacuum Chamber

Vacuum chamber in an automatic capsule machine has dual functions to perform. Initially it helps in capsule segregation and then also supports in cleaning the machines to maintain hygienic environment. These are mostly present at the bottom side of an automatic capsule machine where it can perform both of the tasks efficiently.

Filling Nozzle

The capsule material is dispensed into the capsules through a highly systematic filling nozzle that helps in its release and also in an accurate manner. The specific limit of material is dispensed so that consistency is maintained in each of the capsule.

Ejection System

Once the capsules are filled and sealed properly, they are taken out of the system through this ejection system. An ejection system works an offloading channel from where all the capsules are collected and moved forward for their packaging and transportation.

6.How Does An Automatic Capsule Machine Improve The Efficiency Of A Process As Compared To Other Types Of Capsule Machines?

Automatic Capsule Filling Machine

An automatic capsule machine has an ability to perform at a high speed and makes rapid production in a very short interval of time. It processes thousands of capsules filling and sealing procedures in a single day with its highly automatic system and maintains the quality in each single capsule.

Further improving the efficiency of any system is also due to its compatibility with different sizes of capsules. Each capsule is filled with an accurate amount of dosage as defined standard and filling duration allowed to it. The machine remains user friendly and gives an access to reach out all its working parameters that can help in improving the systems efficiency.

7.How Different Sizes Of Capsules Are Produced In A Single Automatic Capsule Machine?

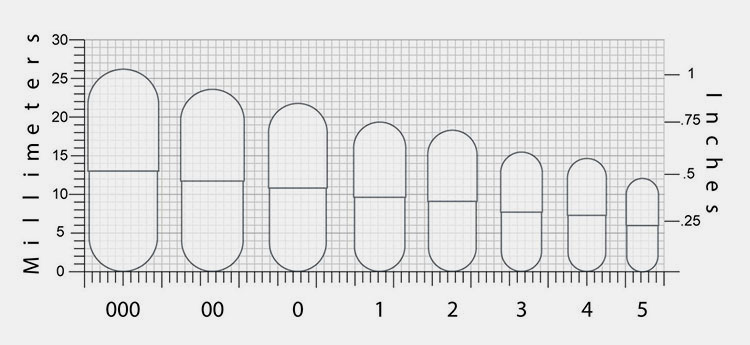

Capsule SizeChart- Picture Courtesy: LFA Capsule Fillers

Flexibility with different sizes of capsules and their filling is one of the most important benefits an automatic capsule machine can offer. It can easily accommodate various sizes of capsules in it as it holds an adjustable filling station and nozzle that varies according to the size of capsule. These can easily be changed and modified according to their sizes in just a fraction of time.

The parts of an automatic capsule machine are interchangeable that can be replaced easily by the operator. This makes efficient filling and sealing of different types of capsules in a single machine to make the system economical.

8.What Are The Major Differences Between A Manual Capsule Machine And An Automatic Capsule Machine?

Some of the differences between a manual capsule machine and an automatic capsule machine are

Productivity

Improved Productivity

A manual capsule machine is mostly used in small scale or cottage industry where the productivity is in low volume. It has a capacity of producing few hundreds of capsules in a hundred or depends upon the working efficiency of the operator.

Mostly high and medium scale industries use automatic capsule machines to make their run in a faster way. Thousands of capsules of different sizes and shapes can easily be produced in a single automatic capsule machine.

Structure

A manual capsule machine has a simple structure and handed completely by manual operations. A hopper is present in it with manual placing of capsules.

Whereas in an automatic capsule machine has a highly systematic processes for filling, sealing and feeding of capsules. It has a complex structure and sometimes include conveying system too that helps in movement of capsules within the system.

Application

Both of the machines are applied in pharmaceutical, food, cosmetics, agricultural and chemical industries depending upon their requirements and productivity.

Precision And Accuracy

Capsule Filling Machine Tool

Manual capsule machines are low in precision and accuracy due to manual involvement and slow process.The machines precision and accuracy solely depends on the performance of operator.

On the other hand an automatic capsule machine has a high precision and accuracy levels to maintain consistency in the system. Each of the capsule formed show similarity in structure and composition both.

9.What Are The Process Line MachinesAssociated With An Automatic Capsule Machine?

Auxiliary machine are associate with an automatic capsule machines to enhance its productivity and to produce highly quality products that can attract more and more customers towards it. Some of them are

Capsule Counting Machine

Capsule Counting Machine

To accurately count the number of capsules present in a batch, capsule counting machine is one of the advanced modes to do so. The process of a capsule counting machine saves a lot of time and does it with greater efficiency as compare to manual counting.

Blister Packaging Machine

Blister Packing Machine

For packaging of completely processed capsules, blister packaging machines are used in many of the industries that make their packaging easier. Blister packaging machines work in a highly efficient manner and packages capsule according to the shape of packaging and the number defined to them.

Conclusion

For high productivity of capsules in an efficient and precise manner, an automatic capsule machine is the most reliable thing to select. It can be used for filling and sealing of capsules that are different in size and shape. But you need complete machine related information to select the right type of automatic capsule machine for your setup. For this All pack is always here to provide you complete machine related information and help you in buying the best product. For any query contact our customer representatives that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide