Vertical Irregular Shape Sachet Packaging Machine: The Complete Buying Guide In 2025

Have you seen an irregular-shaped sachet in the market and wondered what machine such a creative shape sachet? The answer is a vertical irregular shape sachet packaging machine. It is a sophisticated unit that fabricates and assembles irregular-shaped sachet with its specialized cutting and sealing components.

A vertical irregular shape sachet packaging machine uses diverse packaging materials to form, fill, weigh, seal, and cut irregular shape sachet. It is a compact unit that is composed of high-tech components that create irregular sachets at much higher speeds.

This blog post is specially designed for readers interested in learning about the vertical irregular shape sachet packaging machine like its components, functioning, uses, benefits, and types.

Let’s get started!

1.What is Meant by a Vertical Irregular Shape Sachet Packaging Machine?

Vertical Irregular Shape Sachet Packaging Machine-Picture Courtesy: SED Pharma

A vertical irregular shape sachet packaging machine fills a wide range of products in a compact sachet, whose shape differs from typical regular rectangular or square sachet. This machine loads a single-serve of a variety of products like grainy, dry powders, gels, granules, pastes, oils, and liquids into irregular-shaped sachets.

It is high in demand because of the popularity of one-time serve irregular-shaped sachet and their affordability. Brands use this machine because it creates unique irregular-shaped sachets that stand out on retail shelves and boost impulse buying.

2.What are the Important Advantages of a Vertical Irregular Shape Sachet Packaging Machine?

Vertical irregular shape sachet packaging machine has a long list of benefits that increase productivity and generate tons of revenue. Some of the useful benefits of this manufacturing unit are discussed below:

Automation

Automation by Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Packaging Technology Today

This machine adopts the latest technology and advanced sensing gadgets due to which, this machine is automated and increases the packaging efficiency of the industries. There is no need for human involvement; hence, it has more speed than simple hand-filling and packaging.

Budget-Friendly

Budget-friendliness of Vertical Irregular Shape Sachet Packaging Machine

This machine forms single-serve irregular-shaped sachets that are easily made with fewer packaging materials. Hence, this machine is a budget-friendly option, as it utilizes less packaging film, which lowers the necessity to buy more packaging film. Moreover, due to less human intervention, it also reduces labour wages.

Accuracy and Precision

Accuracy by Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Packaging Insights

Real-time weighing components and electronic sensors in a vertical irregular shape sachet packaging machine measure the volume and weight of products during the filling step, which lowers the filling error. Moreover, technology advanced forming stations, sealing jaws, and cutters form consistent shape sachets every time. These features allow this equipment to achieve packaging precision.

Marketability and Branding

Branding by Vertical Irregular Shape Sachet Packaging Machine

This machine creates different uniquely shaped sachets that offer brands an edge over their competitors because irregular-shaped sachet stands out among the crowd of typical rectangular and square-shaped sachets. These unique shapes are retained in the memory of end-users and are a sure way to have a place in the shopping trolley on the next visit.

Flexibility and Versatility

Flexibility of Vertical Irregular Shape Sachet Packaging Machine

Due to the quick change of parts, this machine can create diverse kinds of irregular-shaped sachets, differing in their design, size, seal pattern, and cut type. In this way, a vertical irregular shape sachet packaging machine can accommodate both the present and future needs of the businesses. Furthermore, this machine is an adaptable unit that loads a variety of products into the irregular shape sachet.

3.Where Vertical Irregular Shape Sachet Packaging Machine Is Used?

Due to its speed, efficiency, and flexibility, a vertical irregular shape sachet packaging machine is utilized in almost every industry. A few industrial applications of this equipment are listed below:

Food Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Food Industry- Picture Courtesy: World Packaging

Due to the traction of irregular-shaped sachets because of their portability and affordability, the vertical irregular shape sachet packaging machine is employed in the food industry. This machine packs diverse kinds of food products like honey, jams, condiments, ketchup, spices, herbs, dressings, pastes, etc in irregular shape sachets.

Beverage Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Beverage Industry- Picture Courtesy: SHANGHAI FUBO PACKAGING MACHINERY

The beverage industry utilizes this machine because of its ability to create stylish bottle-shaped sachet for packing energy drinks, juices, soft drinks, smoothies, and various other beverages. It uses specialized and custom-based sealing jaws to fabricate irregular-shaped sachets.

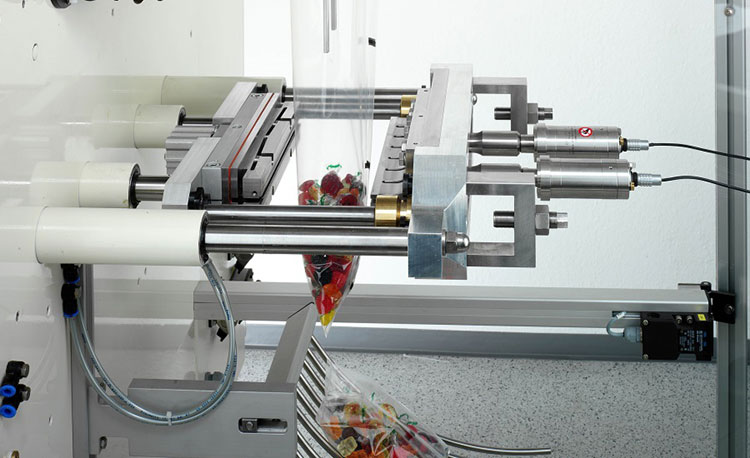

Confectionery Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Confectionery Industry

Different kinds of sweet beans, Choco balls, gummies, chewing gums, sweet candies, toffees, and chocolates are packed in the trendy and tailor-made sachet by vertical irregular shape sachet packaging machine. These unique-shaped confectionery sachets tempt both grownups and children to buy these products.

Pharmaceutical and Nutraceutical Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Pharmaceutical and Nutraceutical Industry

Different kinds of pharmaceutical and nutraceutical products like energy boosters, vitamin supplements, sports gel, trail mixes, and protein shakes are packed in irregular-shaped sachets such as bottles or circular by the vertical irregular-shaped sachet packaging machine. It fabricates different-shaped sachets with high speed and accuracy.

Cosmetic Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Cosmetic Industry- Picture Courtesy: Hehu Packaging

Yes, the cosmetic industry also uses this machine to load different kinds of lotions, face creams, dyes, foundation, etc in small irregular shape sachet. This machine also loads sample cosmetic products, for instance, liquid blush, gels, and fragrances in irregular shape sachet.

Personal Care Industry

Use of Vertical Irregular Shape Sachet Packaging Machine in Personal Care Industry

Vertical irregular shape sachet packaging machine feeds single-use personal care products like shampoo, liquid soap, body mists, hair conditioners, aseptic wipes, hand sanitisers, and sanitary products in the irregular shape sachet. These products are used while travelling and are also found in hotel amenity kits.

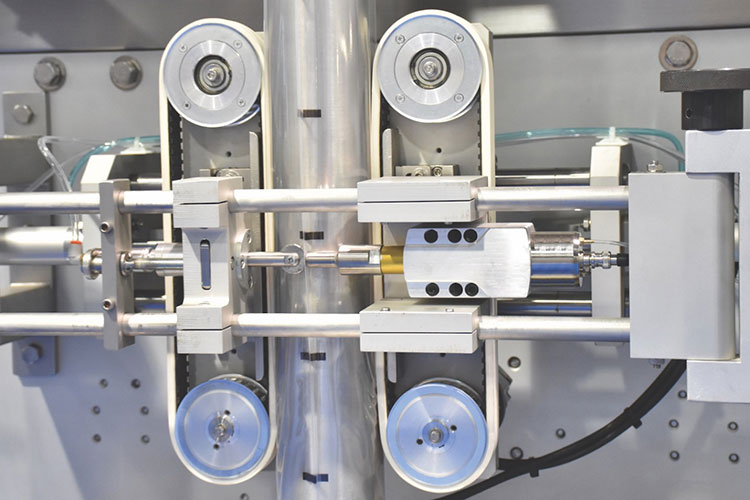

4.What are the Primary Parts of a Vertical Irregular Shape Sachet Packaging Machine?

Vertical irregular shape sachet packaging machine consists of high-tech, electronic, and power-driven components that work in perfect harmony to form, fill, and seal irregular shape sachets. Here is a list of primary parts present in the vertical irregular sachet packaging machine.

Parts of Vertical Irregular Shape Sachet Packaging Machine

| Film Roll Holder | It is a cylindrical stand on which large packaging film is placed before the start of the operation. |

| Product Hopper | It is a square, rectangular, and conical product hopper. It stores huge quantities of products for uninterrupted operations. |

| Forming Station | This station is essential in folding and transforming packaging film into an irregular-shaped sachet. |

| Alarm System | It is a safety feature present in some models of the vertical irregular-shaped sachet packaging machine. It lights and voice alarm for notifying users about technical faults or fire and electric hazards in the machine. |

| HMI | It is an intelligent touchscreen panel that aids in programming and adjusting operational parameters. It also helps to diagnose machine faults and troubleshoot them. Operators can also view the progress of packaging operations by interacting with HMI. |

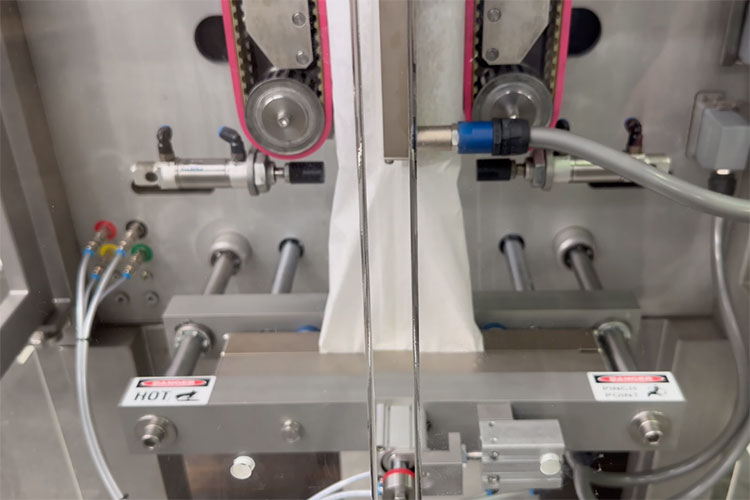

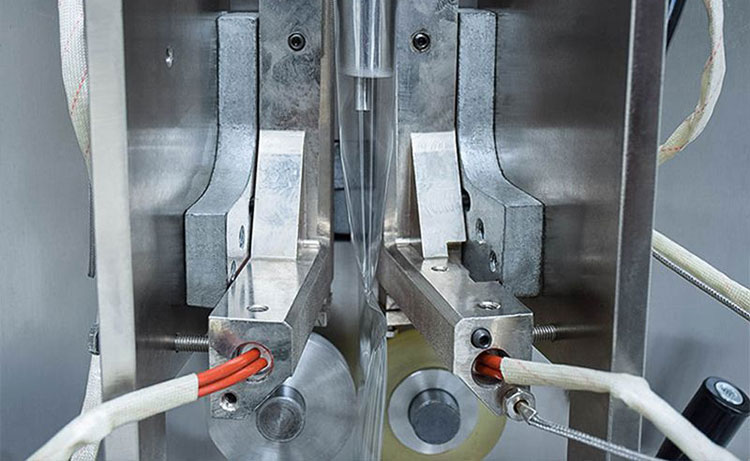

| Vertical Sealing Jaws | This type of heated sealing bar seals the middle and side edges of the irregular-shaped sachet. |

| Horizontal Sealing Jaws | These heated sealing bars melt and fuse the top and bottom edges of the irregular shape sachet |

| Cutter | It is a sharp blade located in the middle of horizontal sealing jaws and trims the edges of two consecutive irregular-shaped sachets. |

| Outfeed Chute | It is a small chute where irregular-shaped sachets are collected after packaging operations. |

| Caster Wheel | These are the caster wheels that move the equipment by their rotation. |

| Electric Cabinet | This component powers up the machine. It is a sturdy and fire-proof structure where different types of cables, relays, switches, breakers, etc. are present. |

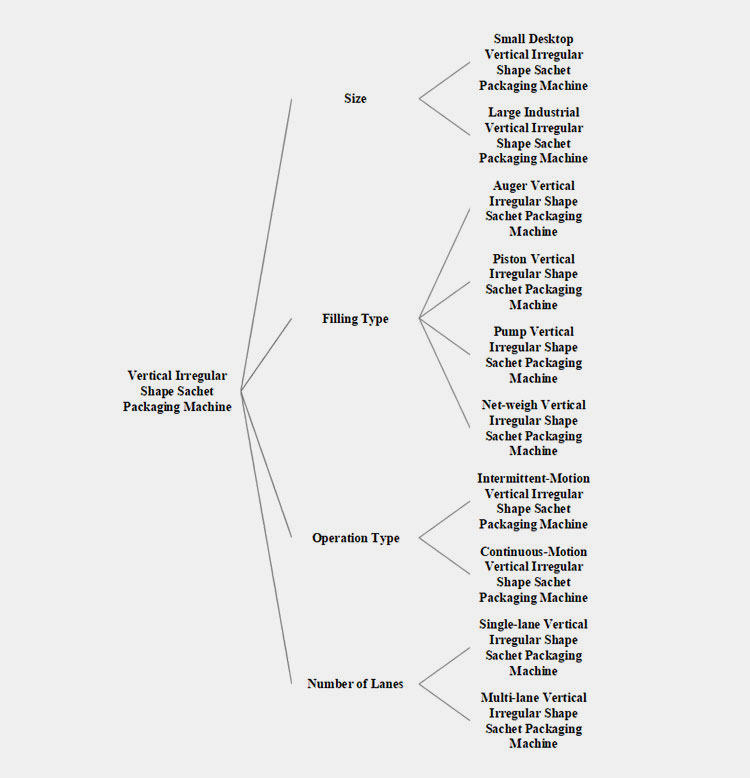

5.What are the Types of Vertical Irregular Shape Sachet Packaging Machines?

This machine is classified into different models based on size, filling device, and operation type. The complete detail of the classification of the vertical irregular shape sachet packaging machine is penned below:

According to Size

Small Desktop Vertical Irregular Shape Sachet Packaging Machine

Small Desktop Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Xiamen Link Machinery Technology Co. Ltd

It is a small-sized machine best for small and medium businesses. It is cost-effective but has a limited output rate. Some functionalities are automated, for instance, forming, filling, and sealing. Other functionalities like loading and unloading are carried out by the operator.

It requires minimal room for installation and working.

Large Industrial Vertical Irregular Shape Sachet Packaging Machine

Large Industrial Vertical Irregular Shape Sachet Packaging Machine

It is a large-sized machine requiring heavy initial investment. It needs more floor space, so it is ideal for large productions with more room and budget. It has the latest technologies like PLC system, HMI, and sensors that improve its output rate; it packs more irregular shape sachet per hour.

According to the Filling Type

Auger Vertical Irregular Shape Sachet Packaging Machine

Auger Vertical Irregular Shape Sachet Packaging Machine Picture Courtesy: Heyi-pack.com

It is the most commonly utilized type of vertical irregular-shaped sachet packaging machine. It fills dry powders, grains, granules, and pellets into irregular shape sachets. It has a closed auger filling device, thus is best for contamination-free filling of products.

It feeds an accurate volume of the products into a sachet by the rotation of auger screws. This rotation aids in the fluidity of products from the hopper to the auger plates, from where the products load inside sachets.

Piston Vertical Irregular Shape Sachet Packaging Machine

Piston Vertical Irregular Shape Sachet Packaging Machine

This type of vertical irregular shaped sachet packaging machine fills semi-sold, viscous, and free-flowing liquids into the irregular-shaped sachet. The products flow from the hopper to the sachet by the movement of the piston inside the cylinder.

The piston vertical irregular shape sachet packaging machine is popular in various industries due to its accurate volumetric fill.

Pump Vertical Irregular Shape Sachet Packaging Machine

Pump Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Heyi-pack.com

This machine comes with various types of pumps like gear, lobe, and cavity pumps that rotate and enforce chunky and viscous liquids from the hopper into a sachet. This machine works on the principle of time-based and pulse-based filling.

It is an excellent volumetric dosing machine and is a budget-friendly option for businesses.

Net-weigh Vertical Irregular Shape Sachet Packaging Machine

Net-weigh Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Glopak

It is the only type of vertical irregular shape sachet packaging machine that fills the products inside the irregular-shaped sachet by weight instead of volume. It feeds liquids and solid items into the sachet by calculating their weight during fill. The load cells present in this machine estimate the weight of the products.

According to Operation Type

Intermittent-Motion Vertical Irregular Shape Sachet Packaging Machine

Intermittent-Motion Vertical Irregular Shape Sachet Packaging Machine - Picture Courtesy: Marchesini Group

As the name suggests, this machine stops when it fills the products inside the sachet. Due to this, it has less packaging speed than its continuous-type counterpart. It is usually found in enterprises with medium-sized processivity.

It has minute filling errors as the machine pauses during the filling steps.

Continuous-Motion Vertical Irregular Shape Sachet Packaging Machine

Continuous-Motion Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Mentpack

It has continuous packaging operation, as the machine does not pause during product filling stages. It has more packaging capacity due to its continuous cycle. Continuous-motion vertical irregular shape sachet packaging machine has more accuracy in its product loading but it comes at a higher price due to its complicated set-up.

According to the Number of Lanes

Single-lane Vertical Irregular Shape Sachet Packaging Machine

Single-lane Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Multiko Packaging

This machine has one lane that forms, fills, and seals one irregular-shaped sachet during one cycle. Because of the presence of only one lane, its output rate is lower. This machine is routinely seen in medium-sized business ventures, where high packaging volume is not required.

Multi-lane Vertical Irregular Shape Sachet Packaging Machine

Multi-lane Vertical Irregular Shape Sachet Packaging Machine- Picture Courtesy: Heyi-pack.com

This machine has 2-820 lanes due to which, it can pack multiple irregular-shaped sachets during one cycle. Each lane has its hopper, forming station, cutter, and sealing jaws. It is speedier and has high packaging efficiency. It is added in large production plants that process a higher volume of products.

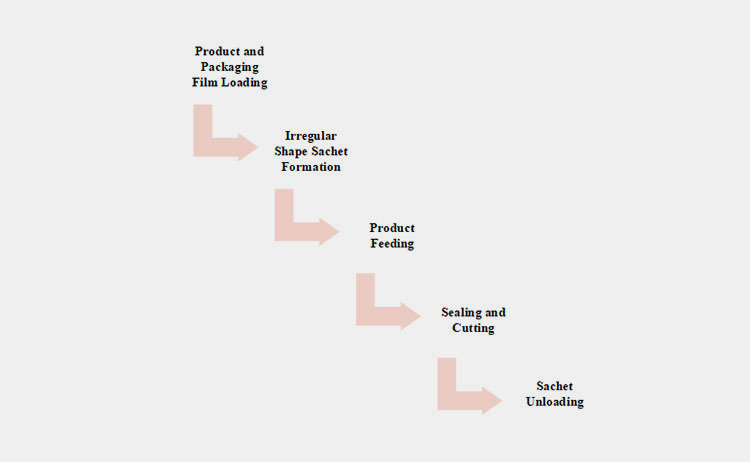

6.How Does a Vertical Irregular Shape Sachet Packaging Machine Work?

Vertical irregular shape sachet packaging machine has complex yet seamless working. The operates on the same principle that is seen in vertical form, fill, and seal machine, A detailed description of working steps is given below for your information.

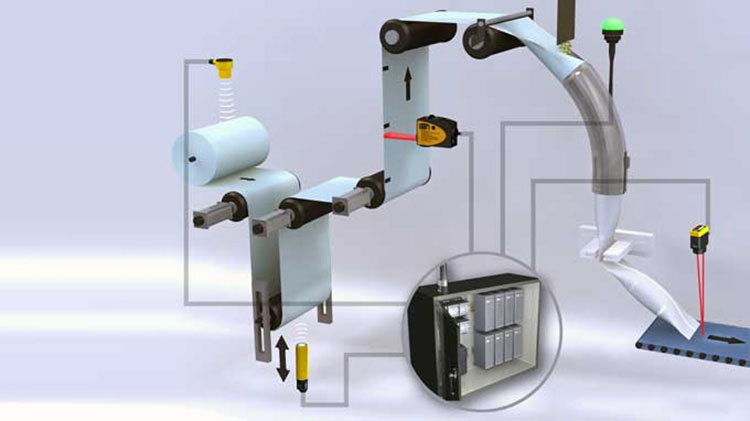

Product and Packaging Film Loading

Product and Packaging Film Loading- Picture Courtesy: Turk Banner

At first, the packaging film for forming the sachet is placed on the cylindrical film holder that is found at the top or bottom part of the vertical irregular sachet packaging machine. The product is also loaded in the product hopper found at the top of the machine.

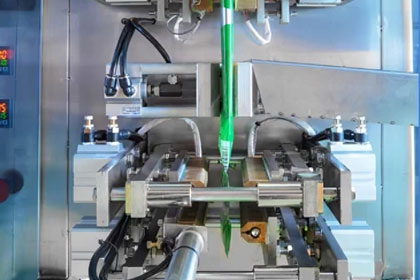

Irregular Shape Sachet Formation

Irregular Shape Sachet Formation

With the unwinding of the film, it goes over the roller and reaches the forming part of the machine. here, it is folded and wrapped around the forming collar and sealed by vertical sealers to create an irregular shape sachet.

Product Feeding

Product Feeding- Picture Courtesy: rotarypack.com

Afterwards, this newly formed irregular shape sachet is filled by the filling nozzles. The product from the hopper flows into the filling nozzles through the rotation, vibration, and to-and-fro motion of the filling devices.

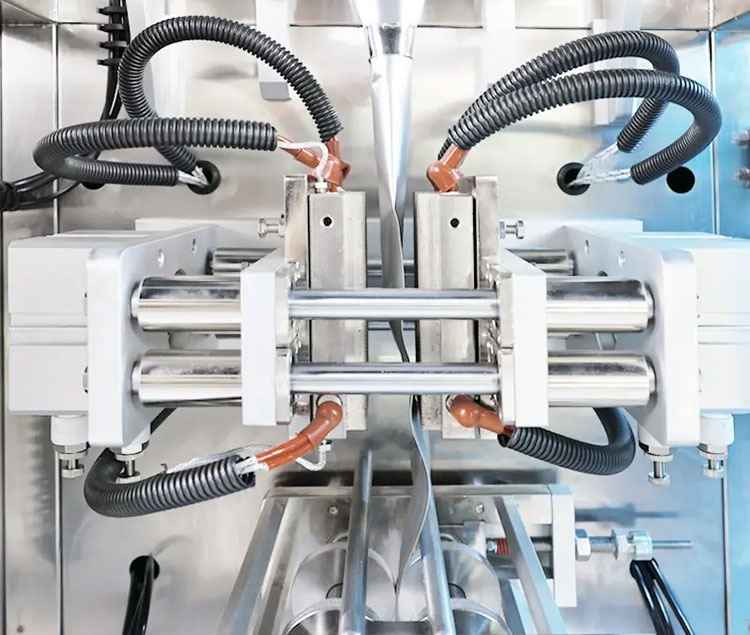

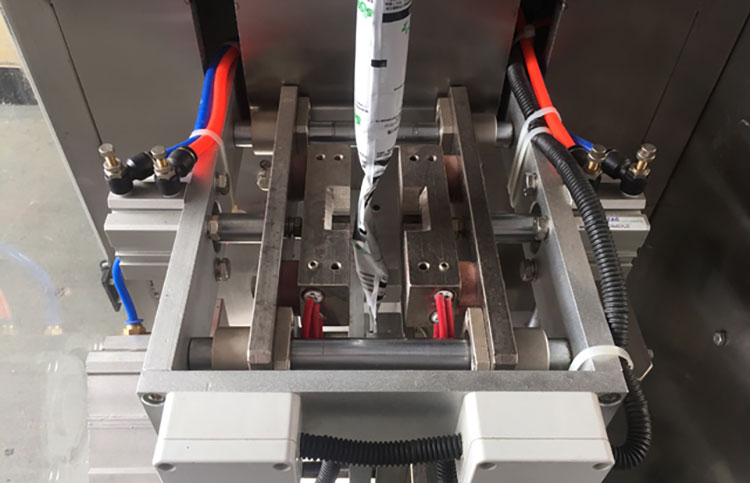

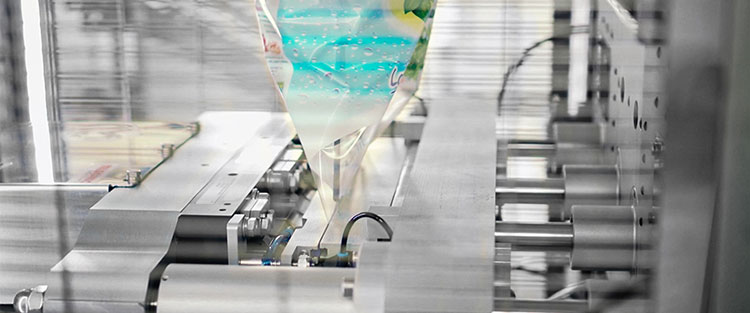

Sealing and Cutting

Sealing and Cutting- Picture Courtesy: SHENZHEN PENGLAI Industrial Corporation

After the product feeding, the irregular-shaped sachet is sealed on the top side. Then, a sharp cutter trims the top and bottom edges of two successive irregular sachets. These sealing jaws and cutters have diverse designs to form irregular-shaped sachets.

Sachet Unloading

Sachet Unloading- Picture Courtesy: Packaging Strategies

In the last, the finished irregular-shaped sachets are ejected into the outfeed chute from where they are collected for secondary packaging.

7.What are the Shapes of Irregular Sachets Produced by Vertical Irregular Shape Sachet Packaging Machine?

Vertical irregular shape sachet packaging machine is tailored to form a wide variety of sachet differing in their shapes, for example:

| Bottle Shape Sachet

Bottle Shape Sachet- Picture Courtesy: World Pack |

These sachets have a wide base and taper off at the top just like the bottle. These have narrow centres and a wide cap-like outline. It is the most common irregular shape sachet. |

| Tube shape Sachet

Tube shape Sachet |

It is a cylindrical sachet with a cap-like figure at the top. It is usually utilized for packing honey, jam, ketchup, condiments, etc. |

| Eye Drop Shaped Sachet

Eye Drop Shaped Sachet |

It has a rectangular base just like a normal-shaped sachet but has a pointed tip. |

| Heart Shaped Sachet

Heart-Shaped Sachet |

It resembles a heart shape and is used for packing cosmetic products. It is also employed for storing promotional items for Valentine’s Day. |

| Circular Shape Sachets

Round Shape Sachets- Picture Courtesy: World Pack |

These are round-shaped sachets, mostly used for storing cosmetic products like lotions, creams, gels, etc. |

| Triangular Shape Sachet

Triangular Shape Sachets- Picture Courtesy: Doypack Machine |

It resembles a triangle or prism with its three edges and it stores honey and other condiments. |

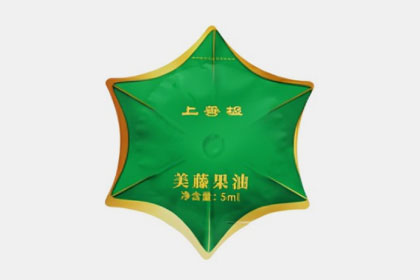

| Star Shape Sachet

Star Shape Sachets- Picture Courtesy: World Pack |

It has a shape like a star and this irregular shape sachet stores cosmetic products. |

| Jar Shape Sachet

Jar Shape Sachets- Picture Courtesy: World Pack |

It has a jar shape with a wide base that tapers off at the top. Cosmetic and food brands use such irregular-shaped sachets. |

| Custom Shape Sachet

Custom Shape Sachet |

On special occasions like Halloween and winter holidays, brands introduce custom-shaped sachets like hand, ghost, leaf, and fruits to name a few in the market to attract end-users. |

8.What are the Sealing Methods Utilized in Vertical Irregular Shape Sachet Packaging Machine?

For hermetic and leakage-proof sealing of irregular shape sachet, there are multiple sealing approaches. These are discussed one by one below:

Heat Sealing Method

Heat Sealing- Picture Courtesy: Sew-Eurodrive

This is one of the most common sealing methods employed in vertical irregular shape sachet packaging machines. High-temperature sealing jaws melt the edges of packaging film and fuse them, creating a strong bond.

Ultrasonic Sealing Method

Ultra-sonic Sealing- Picture Courtesy: Products - Ultrasonic Machines

It is the other widely utilized approach for sealing the edges of packaging film. High-frequency sonic radiation heats and melts the area for fusion. It is applied for films that are heat-sensitive and deteriorate upon high temperature.

Cold Sealing Method

Cold Sealing- Picture Courtesy: Propac Industrial

This method of sealing is not widely used. The cold sealing method is used for the packaging films that activate at low temperatures. Upon activation, they exert high pressure and join two film seams. The cold sealing method is also termed as pressure sealing method and is typically utilized for materials that need sterile sealing.

9.How Are Technical Problems Troubleshooted in Vertical Irregular Shape Sachet Packaging Machine?

Technical failures in the vertical irregular sachet packaging machine are part of machine operation but they could cost production some serious downtimes. However, you can troubleshoot these problems by following some tips such as:

| Cause | Solution | Image |

| Film Stick to Sealing Jaws | ||

| High temperature during the sealing process

Extreme sealing pressure Coarse surface of sealing jaws Sealing jaws are not cleaned |

Adjust the temperature, it should be according to the manufacturer's recommendation

Adjust the settings of the sealing pressure Replace damaged sealing jaws Properly wipe the surface of the sealing jaws with a damp cloth |

Film Stick to Sealing Jaws |

| Uneven Cutting of Irregular Shape Sachet | ||

| The cutting knife is not aligned accurately in the sealing jaws

Blunt cutter |

Align the cutting knife accurately in the sealing jaws

Sharpen the blunt cutter and if not possible then replace it |

Uneven Cutting of Irregular Shape Sachet |

| Jamming of Packaging Film | ||

| Inaccurate alignment of the inclination roller

Obstruction in the path of film |

Realign inclination rollers

Remove the hindrances in the path of the film |

Jamming of Packaging Film |

| Differences in the Length of Irregular-Shaped Sachets | ||

| Incorrect film tension at the dancer’s arm

Unclean film belts |

Adjust the film tension at the dancer’s arm

Properly clean the film belts using a clean and damp cloth |

Differences in the Length of Irregular-Shaped Sachets |

| Ripping of Packaging Film | ||

| During the unwinding of the film, it faces high tension | Fix the brake part of the machine so that it delivers consistent tension to the film |

Ripping of Packaging Film- Picture Courtesy: Justdial |

| Machine Get Over Heated | ||

| Poor air ventilation

Old or faulty motor Clogged and dirty air filters |

Properly ventilate the room in which the machine is set up.

Replace old motors Clean thoroughly the air filters |

Machine Get Over Heated- Picture Courtesy: Coretamp |

10.How to Choose an Ideal Vertical Irregular Shape Sachet Packaging Machine for Business?

Buying of vertical irregular shape sachet packaging machine is a single-time investment and consequently, businesses make this selection after great consideration and planning. Here are some buying tips that will aid you in selecting a vertical irregular shape sachet packaging machine:

Go with Reputable Manufactures

Reputable Manufactures

First jot down a list of reputable manufacturers, after looking on their website for their machine listing, industrial standing and lists of positive reviews. A list of positive reviews indicates that manufacturers sell superb quality machines that last long and they also provide the best customer care.

Plan Your Budget

Budget

Secondly, before buying estimate your required budget. The automated large industrial vertical irregular shape sachet packaging machine needs heavy initial investment while the smaller vertical irregular shape sachet packaging machine is a more cost-friendly option.

Determine Your Product Type

Product Type

In the next step, determine your product characteristics like viscosity, temperature sensitivity, etc. It is important because filling devices like pumps, augers, etc in a vertical irregular shape sachet packaging machine only fills a particular product type.

Decide Your Sachet Shape

Sachet Shape- Picture Courtesy: www.amanal-petros.de

Before going to the market to purchase a vertical irregular shape sachet packaging machine, select your sachet type, because forming tubes, sealing jaws, and cutters create a specific kind of sachet shape, otherwise you will not be able to form your required sachet shape.

Compare Key Features

Key Features of Vertical Irregular Shape Sachet Packaging Machine

Look and compare filling methods like auger, pump, piston, and sealing methods like ultrasonic, heat, and cold to determine which vertical irregular shape sachet packaging machine is well-aligned with your production requirements.

Conclusion

Vertical irregular shape sachet packaging machine has prominence in the packaging industries because of its ability to fabricate irregular shape sachets for marketability and branding purposes. It creates dynamic shapes of sachets like stars, round, triangular, bottles, and so many more to attract and engage customers. One of the biggest advantages of a vertical irregular shape sachet packaging machine is its flexibility and versatility because it can handle diverse products and packaging film. Hopefully, by reading this guide, you have learnt about different elements that make vertical irregular shape sachet packaging machines in industries. If you have any further queries or want to purchase machine, message Allpack customer care team right now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide