Bottling Line: The Complete Buying Guide In 2025

The complexities of product packaging especially in bottles has compelled the manufacturers to look for an alternative that perform each and every task for perfect bottling. This ultimately resulted in the creation of bottling line which holds in it the vary machines to facilitate the precise bottle processing from cleaning to filling, capping, and labeling.

Are you planning to invest in a bottling line? Or intending to make your own bottling line by combining together multiple sophisticated machines? If yes, you are at the right place. As this buying guide is particularly made to facilitate you in exploring bottling line and getting every information related to it. So, make sure to read it thoroughly!

1.What Is Bottling Line?

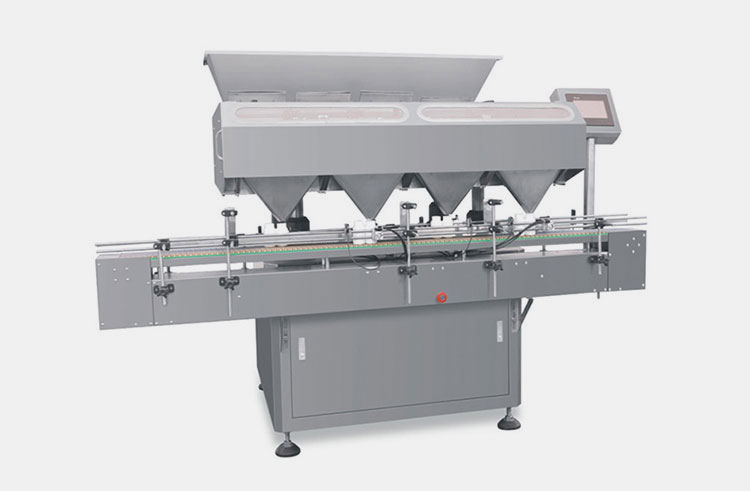

Allpack Medium Speed Automatic Multifunction Capsule & Tablet and Pill Counting Line

A bottling line is the collection of multiple interconnected automatic machines who are systematically arranged in order to perform various tasks in a single run. These machines typically involve a bottle unscrambler, tablet counting machine, desiccant inserting machine, bottle capping machine, induction sealing machine, and labeling machine etc.

At Allpack, the bottling line is manifesting a unified packaging line that administer the bottles processing by filling inside them precisely counted capsules/ tablets and undergoing them through stringent sealing and packaging process. Hence, you can employ it for enhancing the efficiency of your relevant industries.

2.Explain The Benefits Of Bottling Line?

Bottling line is highly advantageous for all the infants and experienced experts in the realms of bottle packaging. Some of the significant benefits of bottling line are highlighted as under:

Exceptional Efficiency

Excellent efficiency indicator- Picture Courtesy: berkonomics.com

As bottling line is a composite whole of cutting edge machines, it supports the non-stop functioning and resulting in giving exceptional production output. In addition, high speed bottling line by Allpack is capable of filling up to 50-90 bottles in a single minute.

Enhanced Precision

Process of bottling- Picture Courtesy: Parle Global

Manually bottling your tablets and capsules is a tiresome task and bring with it multiple challenges of inaccurate counting, the proclivity of getting contaminated or inconsistent packaging like sealing and labeling issues. On the other hand, bottling line perform this task with high degree of responsibility via advance detection system which ultimately provide you with precise bottling.

Easy-to-use

Operator using HMI- Picture Courtesy: kitamura-machinery.com

Bottling line is extremely convenient to use. There is no need of technical specialists or trained staff to operate it. Instead, one trained operator is enough to run the batch by simply communicating commands in it through intuitive Human Machine Interface.

Product Versatility

Pills presentation idea

Bottling line is not just used for tablets and capsules of particular specifications as well as the bottles of same size. But, if setting is adjusted, it supports different sizes and shapes of tablets, pills, candies, and containers, including bottles, jars, and cans etc.

Long-term Use

Bottling line is built with innovative features to last for longer production without wearing out. It enables you to grow your business and keep it under operation for years by simply ensuring the weekly and monthly maintenance checks.

3.What Products You Can Process Through Bottling Line?

Bottling Line can be used for wide range of products from tablets to candies and laundry pods. Some of the popular objects are as follows:

Tablets

Bulk tablets

You can process tablets of different sizes, shapes and nature by bottling line. In fact, our bottling line is known as tablet counting line.

Capsules

Various softgel capsules- Picture Courtesy: creativemarket.com

Counting capsules is a difficult task due to their sensitivity to moisture, contamination, and light. Therefore, bottling line is best suitable not only to count but also pack both types of hard gelatin and soft gelatin capsules in bottles.

Candies

Multicolor candies filled jar- Picture Courtesy: foodnetwork.com

Confectioneries like candies are hard in form but at the same time their sugar rich nature make their texture sticky. So, they are meant to be well counted and packed through systematic process. Hence, they are easily processed by a bottling line.

Laundry Pods

Laundry pods in bottle- Picture Courtesy: parents.com

Laundry pods are small detergent pods filled with liquid cleaning agents. These laundry pods can be perfectly processed by a bottling line and packed in bottles, jars, and containers.

Chocolate Balls

Multihead chocolate balls bottles- Picture Courtesy: packaginginspiration.com

Likewise, candies, chocolate balls are also heat sensitive and require safe environment to be counted and welll packed. Thus, chocolate balls are also suitable to processed by a bottling line.

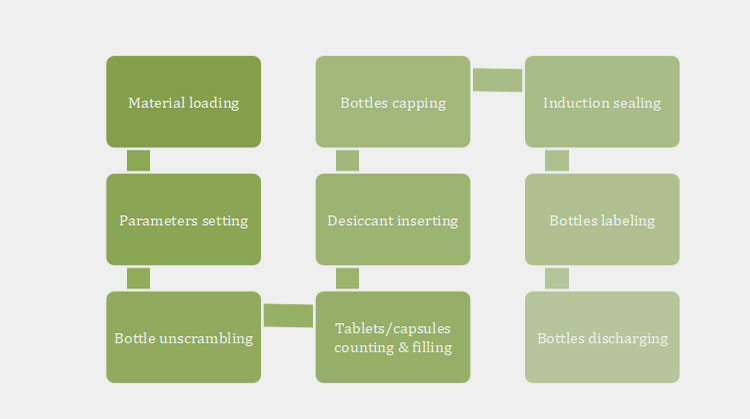

4.What Are The Working Principles Of Bottling Line?

Bottling line follows a sequential order to carry out the function of bottling. This process is based on few steps which will be explained in the upcoming paragraphs. Make sure to understand them thoroughly!

Material Loading

Tablets feeding in machine hopper

In order to operate the bottling line, the first step you need to take is loading the various materials or objects into their respective places. For instance, load the empty bottles in bottle unscrambler disc, pour bulk tablets or capsules in hopper, place the film roller and silica gel in desiccant inserting machine. In same manner, you have to load the capping machine with bottle caps and labeling machine with rolls of labels.

Parameters Setting

Once the loading of material gets done, the next and most crucial step is to set the parameters of respective machines. It is important to perform this task responsibly and fix the speed of conveyor belt, quantity of tablets to be filled in each bottle, the temperature of induction sealer and adjustment of tools with respect to the height and size of bottles. After accomplishing parameters setting, just start the bottling line.a

Bottle Unscrambling

Bottle unscrambling process

Now, the process of bottling line starts with bottle unscrambler processing disoriented bottles through a rotary disc. Here, the randomly positioned bottles are aligned in such a way that their neck or mouth is upward and the body is standing on lower side. These oriented bottles are then moved forward towards bottling line via conveyor belt.

Tablets/ Capsules Counting & Filling

Tablets bottle filling

At this point, the tablets or capsules are gradually released from the hopper onto vibratory trays. These vibratory trays, when vibrate, result in the segregation of tablets and align them in a serialized way. At the same time, these tablets or capsules get into the counting channel where counting phase is taken place. Afterwards, the counted tablets or capsules are discharged into bottles through the filling head.

Desiccant Bag Inserting

Desiccant inserting into bottles

Proceeding further, desiccant inserting machine create bags from film, load the bags with precise amount of silica gel and seal them tightly. When the presence of bottles is detected by the machine, it cuts the desiccant bags and deliver the bags into bottles by following the principle of one bottle one bag.

Bottles Capping

Bottle capping process- Picture Courtesy: ipharmachine.com

The bottles, when receive a desiccant bag, move forward through conveyor belt for capping. Firstly, the machine drops caps over bottles and then push the bottles for screwing. Hence, the tight closure of bottles is realized here.

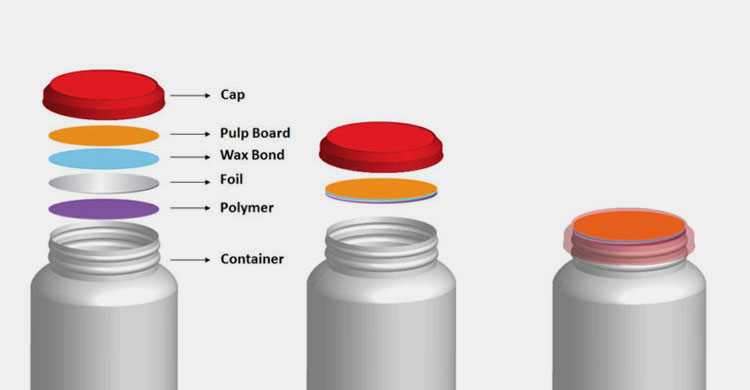

Induction Sealing

Working principles of induction cap sealing- Picture Courtesy: inductioncapsealing.com

This step involves the induction sealing of capped bottles. The machine generates heat through electromagnetic radiation which leads the foil, a linear located inside caps, to tightly stick to the bottle neck. In this way, an airtight and moisture proof sealing of tablets filled bottles is achieved.

Bottles Labeling

Tablets bottle labeling- Picture Courtesy: EPI

Last but not least, the sealed bottles are assembled to be labeled. This function is carried out in a systematic way where the label is pulled by labeling wheel and applied around the bottles. These labeled bottles are then passed through a fur brush to stick the labels tightly around bottles.

Bottles Discharging

Finally, all the processed and finished bottles are discharged by the bottling line. Here, a collection chamber is attached to the line for assembling bottles.

5.What Machines Make Up The Bottling Line?

Bottling line is made up of several automatic machines. These are described below in detail:

Bottle Unscrambler

Allpack APC-A160 Bottle Unscrambler

Bottle unscrambler is machine that constitute the very first unit of bottling line. It is made up 304 stainless steel body and equipped with advance technology to orient scrambled bottles. The machine is composed of a hopper, taper plate, aligner, mould, blower, and turntable tooling channel. Together these components enable the machine to pick randomly positioned bottles and align them in a straight direction towards conveyor.

Automatic Tablets Counting Machine

Allpack APC-32 auto counter 32 channel tablets counting machine

As the name shows, this machine is an electronic equipment tailored with unique features to facilitate the counting of various types of tablets, capsules, and candies etc. It is generally made up of hygienic and corrosion resistant material that provides safe environment for the counting of tablets and capsules. Moreover, the vibratory channel, detection system, and automatic counting enable the machine to precisely count and dispense the tablets or capsules into different bottles.

Desiccant Inserting Machine

APC-C120 Automatic desiccant inserting machine- Allpack

The desiccant inserting machine is another important machine found in the bottling line. It is used to create the bags out of film strips, fill these bags with silica gel and insert these small desiccant bags into tablets filled bottles. The machine is an assembly of certain small to large components including bottle feed screw, bottle rejection mechanism, feeding supplier, fix guide, support roller, jog belt screws and others.

Capping Machine

Allpack APC-D902 Capping Screwing machine

Capping machine is an equipment that is included in the bottling line to stably perform the capping of filled bottles. It is strongly compatible to different sizes and shapes of bottles caps. The machine is made up of three pairs of friction wheels, intuitive PLC control panel, cap dropping and wearing device, stepper motor, photoelectric sensor, and other components. It performs the capping of bottles when they are taken by conveyor belt where caps are applied and tightly screwed.

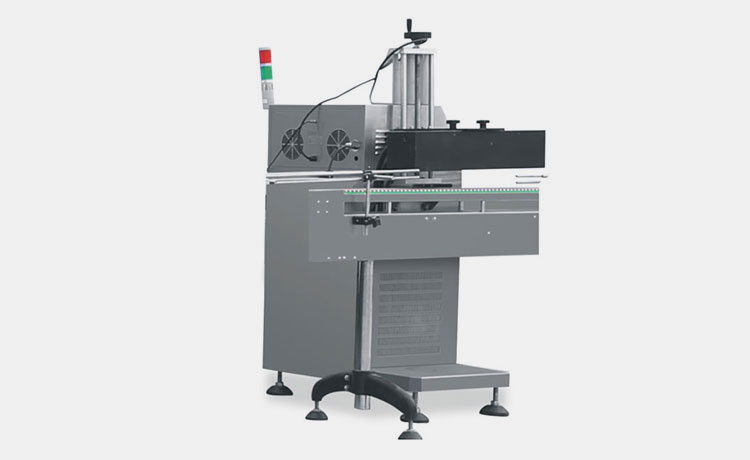

Induction Sealer

Allpack APC-M2 Induction Sealer(water cooler)

An induction sealer is another important machine present in bottling line. It uses electromagnetic field to generate a strong sealing over tablets filled bottles through which the foil get stick to bottles' neck and keep the content intact until opened. The machine is an assembly of several parts including a stainless steel main frame, an emergency alarm, power supply, sealing head, controller and conveyor.

Labeling Machine

Allpack APC-T2 Multi-function labeler

Labeling machine constitute the last part of bottling line. It has been made with an astonishing features to apply multiple types of labels over square, round, oval, and flat bottles at the same time.

Its synchronization chain mechanism enable the machine to pull labels from roller and precisely apply around the bottles efficiently. This ultrafast performance is the result of integration of various small to large components including stable body, screw adjust device, label applicator, and coder etc.

6.Describe The Multiple Types Of Bottling Line?

Bottling line can be divided into three basic types on the basis of speed. These are described below in detail:

Low Speed Automatic Bottling Line

Allpack Low Speed Automatic Bottling Line For Capsule/Tablet

This low speed automatic bottling line by Allpack is an intelligent assembly of various machines encompassing round bottle unscrambler, electronic counting machine, automatic desiccant inserter, automatic capping machine, induction sealer, and round bottle side face labeler.

The bottling line is having small size body, compared to other types of bottling line, and consume low power. Despite being smaller, the line fulfill all essential attributes of automatic detection, alarming system, and precision of operation.

Hence, you can employ this low speed automatic bottling line for your small to medium size batch production which is capable of finishing up to 50 bottles in a single minute.

Medium Speed Automatic Bottling Line

Allpack Medium Speed Automatic Multifunction Capsule & Tablet and Pill Counting Line

The second type of bottling line is medium speed automatic bottling line which is composed of a bottle unscrambler, electronic counting machine, automatic desiccant inserter, capping screwing machine, induction sealer, and round bottle side face labeler.

This bottling line has higher speed with output ratio reaching out the figure of 90 bottles per minute. Along with that, it supports multiple languages and has the capacity to save up to 20 different settings. So, you can simply switch the setting instead of resetting it from start.

Moreover, this bottling line is best suitable for eclectic sizes and shapes of tablets, softgels, and hardgels etc. Hence, you can use it for your medium to large scale production facilities.

High Speed Automatic Bottling Line

Allpack High Speed Automatic Multifunction Capsule Tablet Pill Counting Line

High speed automatic bottling line is the cutting edge unit of several machines including bottle unscrambler, electronic counting machine, automatic desiccantnserter, high speedcapping screwing machine, water-cooled inductionsealer, and high speed round bottle side face labler

It has a large complex body that proficiently carry out the bottling of hundreds of bottles in an hour. Its bottling output frequency stood at 90 bottles per minute with excellence in processing various shapes and sizes of bottles.

This bottling line is the best ever choice for your large to extra large manufacturing industries of pharmaceutical, chemical, and cosmetics.

7.What Are The Applications Of Bottling Line?

When it comes to count the applications of bottling line, you will always find diverse sectors on the list. Let's discover some of these!

Pharmaceutical Industry

Doctor in pharmacy store- Picture Courtesy: techbullion.com

Pharmaceutical industry is always on the top where the use of bottling line is realized. It is because hundreds and thousands of tablets and capsules are produced everyday to meet the growing demand for medicines to cure ills.

Nutraceucal Industry

Multiple nutraceucal pills & capsules- Picture Courtesy: icontentmart.com

Similar to pharmaceutical industry, nutraceucal industry is also expanding rapidly. Now, this sector has been involved in providing patients with essential nutrients and minerals filled pills across the globe, for which definitely bottling line is the dire need.

Veterinary Industry

Veterinary doctor treating cat- Picture Courtesy: urbansplatter.com

Pet and animal care now go side by side with that of human care. In this way, veterinary industry is on the front line to produce and process tablets and capsules for animals. To achieve this end, bottling line is the prime solution to be employed.

Cosmetic Industry

Cosmetic softgels- Picture Courtesy: honestlyjamie.com

As we know that beauty care is an undeniable step for almost all of us, cosmetic industry is running in same direction and trialblazing new methods for fulfilling our demands. Consequently, the manufacturing and processing of capsules like vitamin E, Omega-3, and vitamin C is the practice adopted in cosmetic industry. Ergo, bottling line becomes eligible here.

Confectionery Industry

Multicolor gummies- Picture Courtesy: candyclub.com

Confectioneries are all time favorite of kids, adults, and older people in all its forms including candies, gummies, chocolate, and jellies. Therefore, the industry is taking help of bottling line to accurately count these confectioneries, fill them in bottles, and pass them through further packaging steps.

Chemical Industry

Chlorine tablets bottle- Picture Courtesy: dennyshop.co.uk

Chemical industry is yet another area where different kinds of tablets are produced and packed. Hence, medium to large scale chemical industries can use bottling line.

8.How To Maintain A Bottling Line?

Maintenance plays a key role in the successful functioning of your bottling line it is the only means through which you can improve the work efficiency as well as working life of your bottling line. Let's discover some of the prominent steps that must be carefully taken for maintaining a bottling line!

Adjusting Specifications

Adjustment of the bottling line is first and foremost step that must be carried out on daily basis. It simply involves the modification of external parts of bottling line in accordance with changing objects like the width of conveyor, the heads of various units including tablet counting machine, capping machine, and induction sealing machine. The purpose of specification adjustment is to ensure that your bottling line is fit for initiating new task.

Lubrication

Lubrication of movable parts- Picture Courtesy: nexxis.com.au

Keep in mind that poor lubrication decreases the efficacy of bottling line and ultimately leave you with insufficient output. Hence, make sure to regularly inspect the moving parts of bottling line and add new lubrication oil to each point on weekly basis.

Cleaning

The bottling line must be kept clean in order to undertake safe and hygienic processing. So, you need to strictly follow the daily and weekly cleaning of all its parts especially those where product is directly placed such as the hopper, counting channel, and label applicator etc. Different means can be used for disinfecting bottling line including washing, rinsing, and use of compressed air.

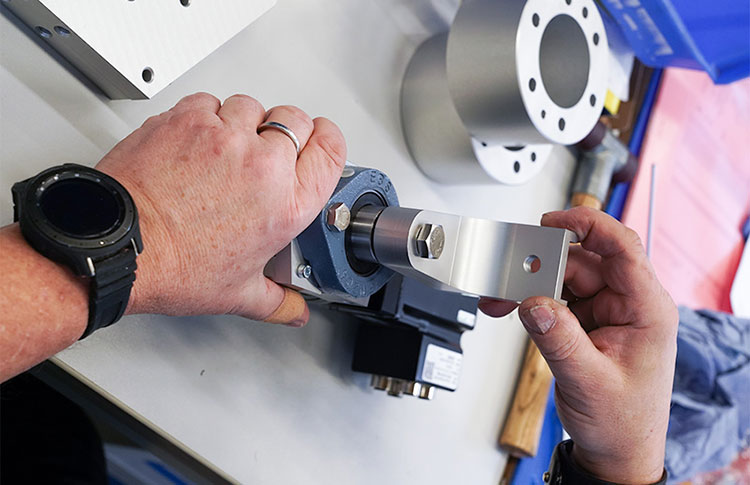

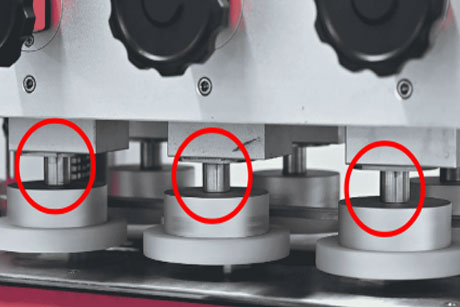

Parts Changeover

Parts changeover of knob

It is obvious that at any point the unit or part of your bottling line may initiate abnormality. First, you need to examine the cause. Secondly, if found that any part or tool has been damaged you should replace it timely or it will lead to create further problems in functioning.

9.What Quality Standards Should Bottling Line Meet With?

ISO quality standard icon- Picture Courtesy: qualitymag.com

Tablets and capsules are highly sterile and sensitive in their nature that they are meant to be processed in a protected environment with zero bacterial presence, which can otherwise badly affect their quality. To meet this end, international community has established certain quality standards which every bottling line must meet with. These include:

Good Manufacturing Practices (GMP)

GMP or cGMP is the most notable quality standards formulated to promote safe regulation of goods and machines in pharmaceutical, biotechnology, and chemical sectors. Therefore, a bottling line must adhere to the principles of GMP.

International Organization for Standardization (ISO)

ISO is another quality standards which is often issued by the state authority to concerned industries related to food and gods manufacturing. Hence, bottling line is supposed to be on the list of ISO rules followers.

Food and Drug Administration (FDA)

FDA is US based quality standards which every bottling line must meet with in order to be eligible for tablets and capsules processing.

Conformite Europeenne (CE)

Bottling line must also be certified by CE which confirms its eligibility in European Union.

10.Common Operational Errors Of Bottling Line?

It is a matter of fact that despite being made up of quality tools, at any point the machine will cause malfunctions. Similar is the case with bottling line not because its essence is lost but because of the constant working which result in minor issues. You will be able to tackle these problems simply by getting information about them which is provided below:

| No | Error | Cause | Solution | Picture |

| Bottle Unscrambler | ||||

| 1 | Jamming of unscrambler disc | The issue is caused by the failure of transmission gears and friction plate | It can be adjusted by replacing friction plate and modifying the specifications of transmission gear |

Jammed unscrambler disc |

| 2 | Incorrect unscrambling of bottles | Sometimes bottles get jammed and disoriented bottles move towards conveyor | You are required to reset the machine, check sensors, and blowers to make sure bottles are properly aligned |

Operator setting bottle unscrambler |

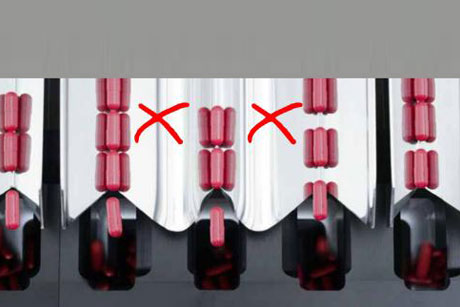

| Electronic Counting Machine | ||||

| 3 | Tablets and capsules counting error | This is a common problem often have roots in the false setting of counting amount or the error in sensor | It can be corrected by adjusting the counting amount in machine through control panel and removing dust from sensor |

False capsules counting- Picture Courtesy: pharmacompass.com |

| 4 | Vibratory channel creating noise | It happens when the vibratory tray is disconnected to discharging channel | Resolve the issue by tightening the screws and making both the components attach to each other |

Noisy capsules counting vibratory channel- Picture Courtesy: pharmacompass.com |

| 5 | Tablets spilling out of bottles | The gap between tablets filling head and bottle result in tablets scattering around bottle | You need to reduce the distance between filling head and bottle to the size of tablet diameter |

Encircled distance between bottle & filling head- Picture Courtesy: maharshi.com |

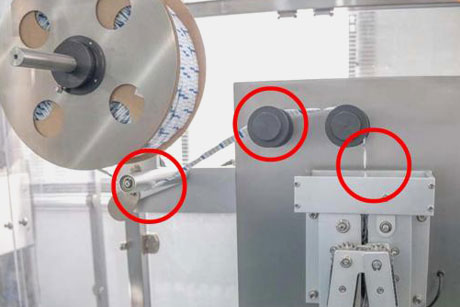

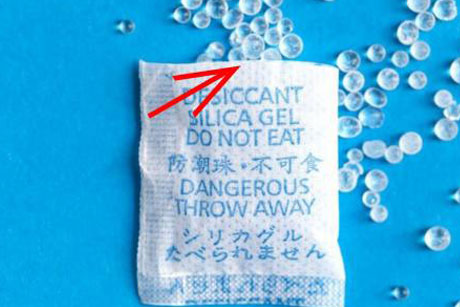

| Desiccant Inserting Machine | ||||

| 6 | Desiccant strips get jam in the machine during operation | The fault is common but serious which can ruin the entire processing. It occurs due to multiple factors associated with machine setting | Here, you are supposed to reset the machine including the adjustment of film pulling speed, the placement of film over feeding roller and its connection to various pulling shafts |

Jamming of desiccant strip in machine |

| 7 | False cutting of desiccant bag | This is one of the major issues caused by the incorrect sensor functionality | You need to calibrate the machine with right bag specification, so that, the cutting of bags will be done on right place |

Falsely cutted desiccant bag- Picture Courtesy: healthline.com |

| 8 | Feeding of two desiccant bags in bottles instead of one | Sometimes, two desiccant bags enter in one bottle while few bottles have no bags. It happens when the speed of feeder supplier is too much, and sensor is contaminated to detect presence of bottles | The problem can be resolved by adjusting the speed of feeder supplier to make it compatible to that of conveyor belt. Along with that, you need to clean the sensor for effective performance |

Absent desiccant bag in capsule bottle |

| Capping Machine | ||||

| 9 | Cap is too loose on bottle | Either the cap is not applied on right direction or false capping technique has been used | Remove the cap and reposition it. Use right capping method by allowing even pressure for application |

Faulty adjusted cap screwing heads |

| 10 | The cap get deform or crack | The size of cap is not compatible to that of bottle or the pressure of cap applicator is excessive | Use correct size of caps and adjust the cap applying pressure of machine by decreasing |

Bottle with broken cap- Picture Courtesy: reddit.com |

| Induction Sealer | ||||

| 11 | Burned pulp-board liner | This issue is the result of slow conveyor speed and excessive sealing power | Adjust the speed of conveyor belt and that of sealing power to maintain equilibrium |

Burned aluminum foil- Picture Courtesy: technopackcorp.com |

| 12 | Bad sealing | It may be due to insufficient or excessive sealing temperature and the incorrect application of torque | Make sure the temperature of sealing head is neither too high nor too slow. Also, check the torque for proper closure of bottles caps |

Poorly sealed capsules bottle- Picture Courtesy: technopackcorp.com |

| Labeling Machine | ||||

| 13 | Label pulling shafts do not function properly | The issue lies in substrate motor which is in static condition or the driving belts are loose | You need to lubricate the substrate motor for proper functioning and tight the driving belts |

Jammed labeling pulling wheels- Picture Courtesy: directindustry.com |

| 14 | The label is creased | It is because the speed of label delivery wheel is to fast which create wrinkles over label | Reduce the speed of label application wheel to suitable level |

Labeled bottle with wrinkles over it |

11.Factors To Consider When Choosing A Bottling Line?

Purchasing a bottling line is one of the responsible tasks you will do for determining the fate of your business. Hence, you must be cautious and have considered some of the essential factors which we have provided below. These include:

Speed

Speed indicator

While bottling line is in itself provides an automatic production line, there are still different types of bottling line available in market with varying speed specifications. So, by keeping in mind the length of your production, like medium scale, large scale, or extra-large scale, you need to set the desired speed and opt for compatible bottling line.

Budget & Scalability

Another factor is to take your current budget in your mind and look for the upfront cost that will occur on buying a bottling line. Along with that, the most paramount aspects is to evaluate the productivity gains and bottling line's potential for your business expansion.

Space & Layout

Tablets counting Line- Picture Courtesy: countec

It is obvious that a bottling line is comprehensive enough in its structure whether it is low speed or high speed. What significant here is to examine your facility of placing the bottling line. It will enable you to alter the layout drawing like installing the bottling line in a swing positive than in linear way, if place is small.

Spare Parts Availability

Spare parts placement- Picture Courtesy: ett.de

The unavailability of spare parts has been the major issues most of new buyers confront especially the overseas. Therefore, make sure to have the supplier who provides remote services for replacement parts or at least have available alternative.

Supplier Reputation

Quality assurance icon- Picture Courtesy: Open Library

When investing in a bottling line it is pertinent to establish long-term contact with your vender. It is only possible if the supplier is trustable, having been recognized by international quality standards, and most importantly care for customers by providing technical support and warranty policy etc.

Conclusion

The bottom line is that bottling line is one of the best creation to support all kinds of small to medium and large size tablets/ capsules/ grains production facilities. By employing bottling line into your firm, you will determine the brighter future for your lucrative business. It is because opting for individual machines might cost you more both in price and trust. But here, Allpack is offering you broad range of choices with approved machines along with one year of warranty. So don't make delay and save your time, money, and future of your business by contacting us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide