Canning Machine: The Complete Buying Guide In 2025

Canning Machine: The Complete Buying Guide In 2025

The packaging industry is on its way towards rapid advancement. More importance is now given to the preservation of food items and safety of other materials like chemicals, engine oil and paint etc.

Among different other ways of packaging, canning is the most significant and cost-effective way. In this respect, manufacturers are constantly looking for getting the best canning machine, so their brands could be distinguished for providing goods with effective packaging. This canning machine is featured with lots of qualities that can perfectly help you in making your business more lucrative. For knowing in depth the purpose, uses and process of canning machine go through this article!

1.What Is A Canning Machine?

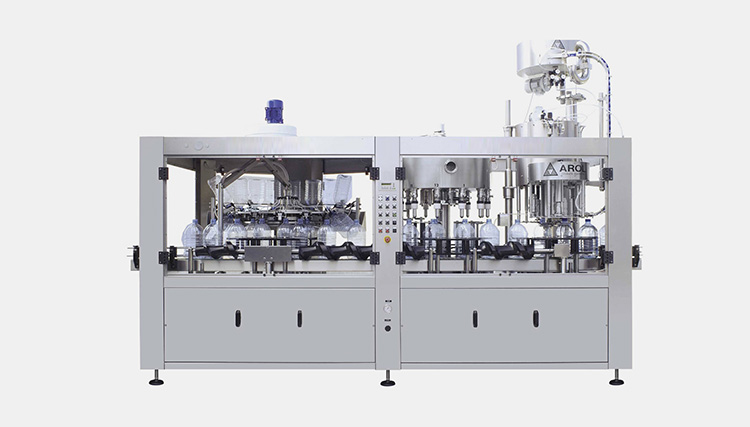

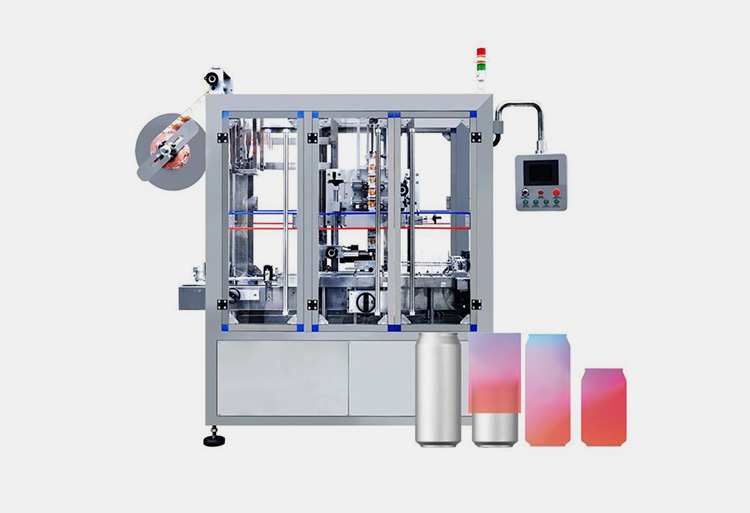

The term “Canning” refers to the method of processing cans through series of steps such as can rinsing, filling, carbonating, seaming and printing. The machine which performs the entire mechanism of canning is known as canning machine. It works through automatic system and have various types to accomplish the canning task.

The reason that, number of functions are performed by using this single equipment, demand for canning machine is increasing day by day. Its significance is more in beverage industry, brewery industry and food industries. The machine’s quick and reliable functioning has greatly increased its relevance.

2.Why Is A Canning Machine Important For Packaging?

A canning machine is a crucial piece of equipment that performs every step of can production, which would otherwise require multiple machines. It is essential because by giving your items excellent processing, it aids in their preservation.

Before the product is put into a can made of tin, aluminum, or thin steel, it is thoroughly sanitized. This shows that a canning equipment complies with all the hygiene requirements needed to ensure the safety of your products. Furthermore, cans are the most convenient and portable form of packaging now available thanks to advances in modern packaging technology. Because of this, a canning machine is always necessary and important.

3.For Which Purpose A Canning Machine Is Used?

A canning machine serves a very clear purpose because it processes distinct can type by putting them through different phases. By entirely removing oxygen from cans, it reduces the potential for product waste and lowers the danger of quality degradation. A lot of brands are undoubtedly benefiting from this machine’s level of efficiency and precision as they build their reputations in the marketplace.

4.What Are The Essential Features Of A Canning Machine?

Every company wants to add a canning machine to the production line since they have many advantageous characteristics that come with them. Check out the information below to learn more about these crucial features:

Comprehensive Whole

This canning machine is extensive in a way that it includes every component you possibly need to process cans, such as a can rinsing station, a filling unit, a lidding, seaming, and printing unit.

Exceptional Performance

This machine performs at an incredibly high level of speed and accuracy. It is possible to precisely fill a certain number of cans without wasting any goods. You can increase both your productivity and level of perfection with such a quick and effective performance.

Durability

Despite being used for numerous tasks, the equipment is incredibly sturdy and compact. You can easily change its place of operation through wheels.

High Degree of Automation

Due to its high level of automation, a canning machine is the only one without a manual type. Once the operator gives the machine the necessary commands, it completes all the jobs.

Customizable

Due to the machine’s high degree of adaptability, it can fill cans of any size and form. It implies that this device is adaptable.

Complying Quality Standards

The machine is built of stainless steel and has a bacterial-fighting anti-acidic chemical. It complies with all hygiene requirements necessary for material processing.

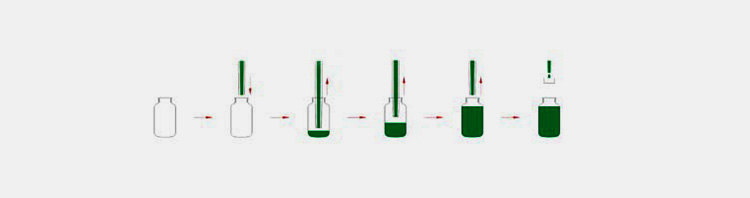

5.How Would You Bring A Canning Machine Into Operation?

A canning machine’s control panel is totally automatic. But how exactly is this device operated? Is what we’ve covered below:

Material Loading

Material is placed into large tank which is attached to the main machine before the machine get started.

Can Loading

Like filling material, cans are also loaded in bulk form, so they can be delivered to machine quickly through automatic system.

Setting Parameters

The process starts here, when operator fixes the necessary measurements required for the execution of cans processing. When machine is turned on, a series of cans either in single lane or dual lane start moving towards the main machine through conveyor belt.

Can Rinsing

When cans arrived to the machine, first thing which is done is their rinsing with water and then these cans are nitrogen flushed.

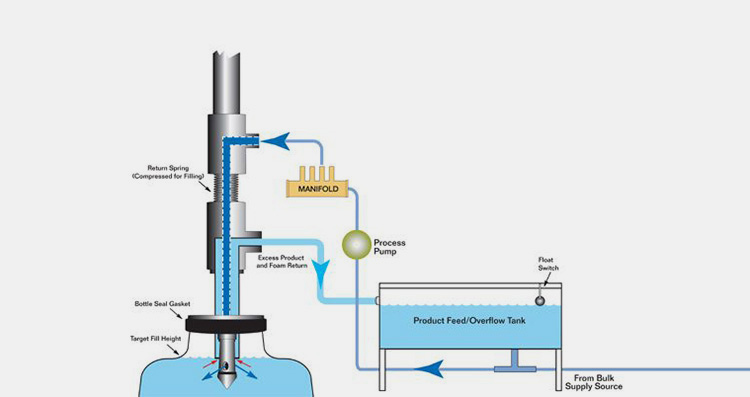

Can Filling

These cans then moved forward and are filled with the desired material till the final level is reached. After filling, in case of soda water or wine, cans are carbonized and pass out for further processing.

Lid Application

After every step, cans are passed through different processing units among which lid application unit is also included. In this step, a lid is delivered over the cans which cover their opening.

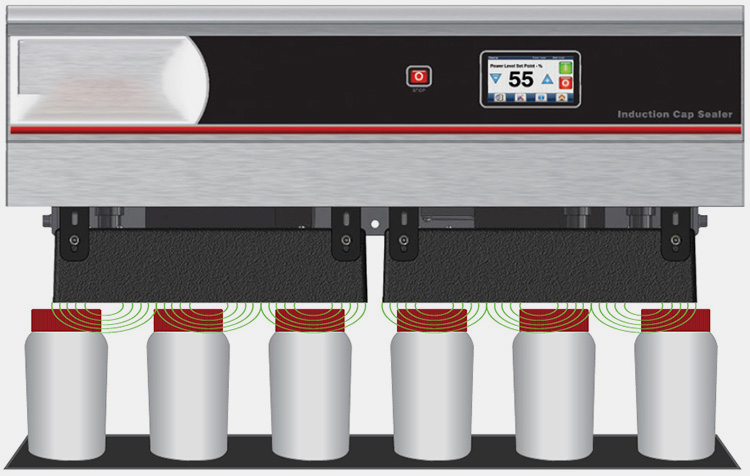

Can Seaming

Quickly after lid application, the can seamer seams all the covered cans tightly and deliver them forward.

Can Printing

After the completion of all necessary steps, in last, cans are printed through two devices which holds each can and move it quickly to create desired design.

Can Discharging

Finally, all the processed cans are discharged by the machine and collected in can accumulator.

6.What Type Of Products You Can Fill With A Canning Machine?

The nature and type of products vary which you can fill while using a canning machine. Below is the brief description of these products:

Free flowing liquids

A canning machine can be used on large scale to fill the beer and other carbonated drinks in cans such as pepsi, coca cola, sprite, soda water and even milk.

Thick Liquids

You might have observed, that cans are also used for storing wide variety of juices extracted from fruits and vegetables. No doubt, these beverages are thick in nature, but a canning machine can easily fill them in cans.

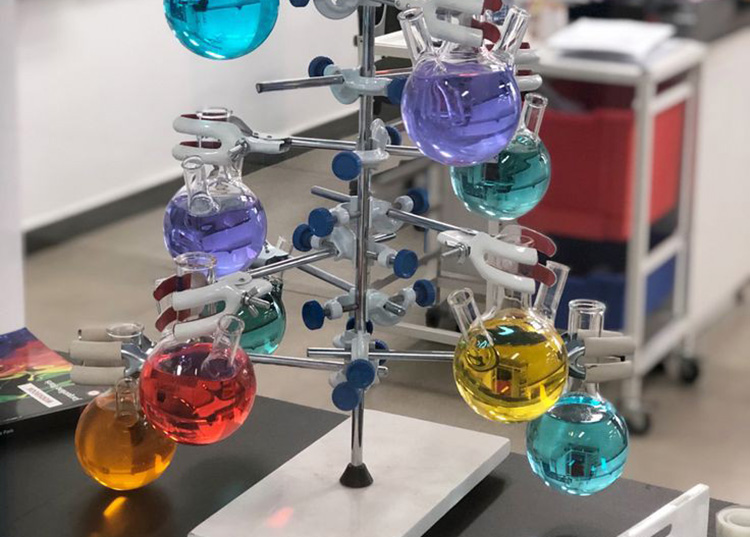

Viscous Liquids

Thick and sticky liquids like viscous can also be processed while using a canning machine. For instance, paint, honey and sausages can be conveniently filled by this machine.

7.Describe The Key Components Of A Canning Machine?

A canning machine is highly complex machine with so many part’s availability in a single machine. To know its structure and function of each component consider the information provided as under:

Material Tank

The liquid which is supposed to be filled in cans is poured into the material tank that is attached to the main machine.

Cans Holder

This device holds the bulk of cans together from where cans are conveyed for the process in an orderly manner.

Conveyor Belt

It is the guide rail, through which these cans are passed through different stages of processing.

In-feed Table

Through in-feed table, cans enter to the main machine and their process begin here.

Can Rinsing Station

Can rinsing station is responsible for the cleaning of each and every can.

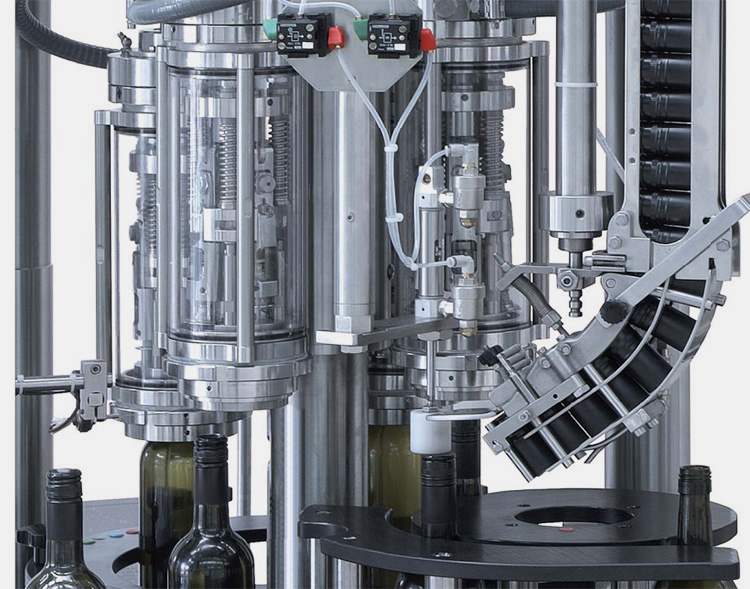

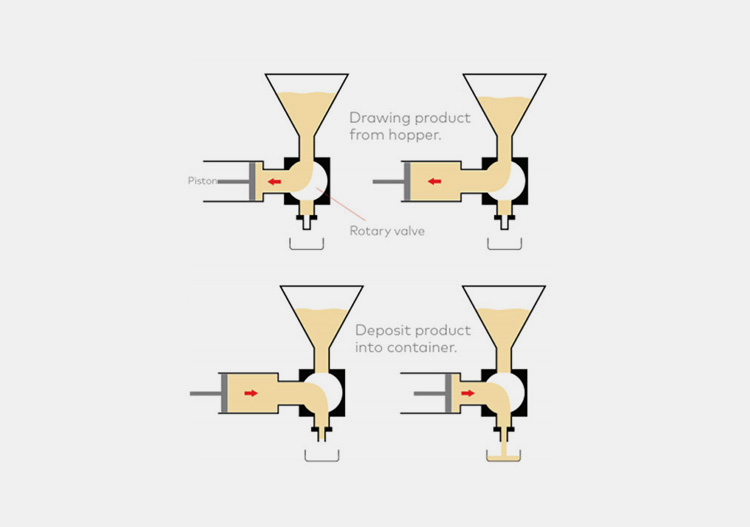

Can Filling Station

It is an essential component, who performs the filling of cans. It consists of filling tubes and valves through which liquid is dispensed into cans.

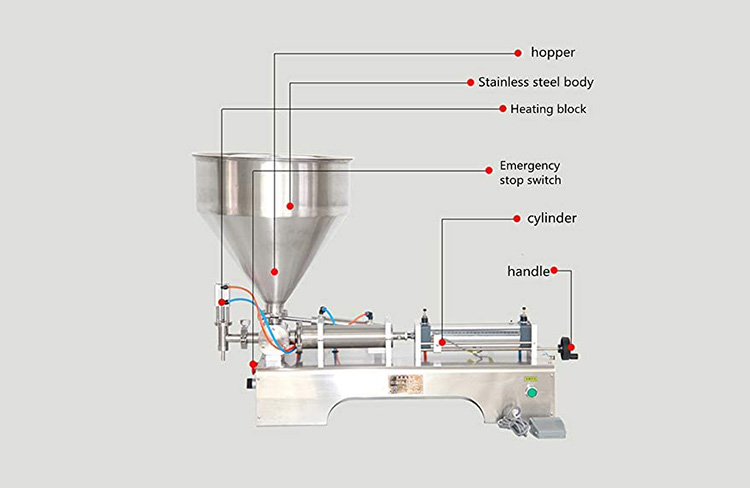

Lidding System

The lidding system involves a hopper which carries the lids and gradually deliver them through a narrow lane where lids are accurately positioned over the cans mouth.

Can Seamer

Can seamer seal tightly seals the lid of cans over cans body by quickly moving the rollers around them.

Can Printer

It is located in the end of machine before discharging unit. The printing system is composed of device on both side of conveyor belt which come close to the cans which they are passed through and holds these cans moving them in circular direction for creating perfect printing design.

Outfeed Table

It is the last part of machine which is also known as the can accumulator where all cans are collectively gathered after they are completely processed.

8.Which Material Is Used For Producing Cans Which Are Processed By A Canning Machine?

Different type of cans can be processed by a canning machine. They are as follows:

Aluminum

Aluminum is the most popular element used in the production of cans. Most of the cans are prepared from thin layer of aluminum and further processed through other steps. The reason that aluminum is cost-effective, light weighted and sustainable, most of the cans you will ever find would be made of aluminum. Different liquids like beverages, beer and milk are stored in aluminum cans.

Tin

Tin is thin metal which is also used for preparing different types of cans. It is cheaper than aluminum, however the durability ratio is less than aluminum. Most of the food products are packed in tin cans.

Steel

Steel is durable metal with corrosion resistant surface that provides your products better and safe environment for long survival. It is expensive than aluminum and tin due to the high degree of compactness it possesses, however, mot of the reputable brands use steel cans for packing there products as their is no chance of material or cans degradation especially during transit.

Plastic

There is another type of cans which is prepared from plastic. As plastic is cheap and flexible that it can be easily drawn into any shape or design, most industries prefer using plastic cans for distribution of their goods.

9.Explain The Various Types Of A Canning Machine?

There are only two types of a canning machine due to the fact, that canning is a long way process, the machinery used to carry this operation runs automatically. The types of a canning machine include the following:

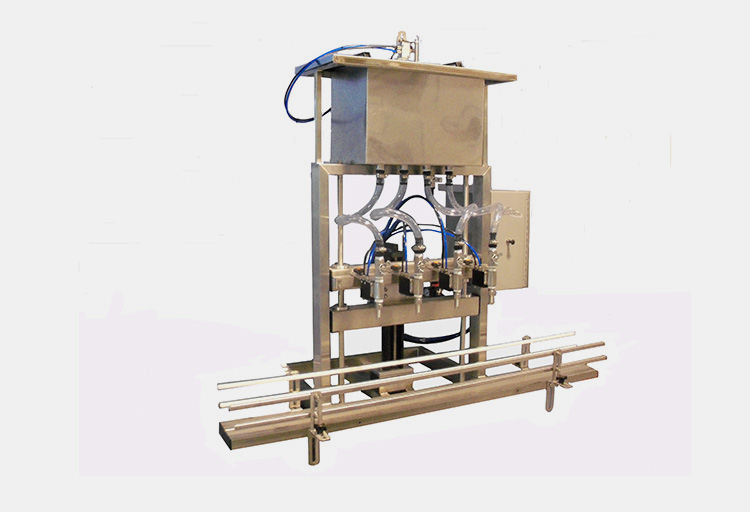

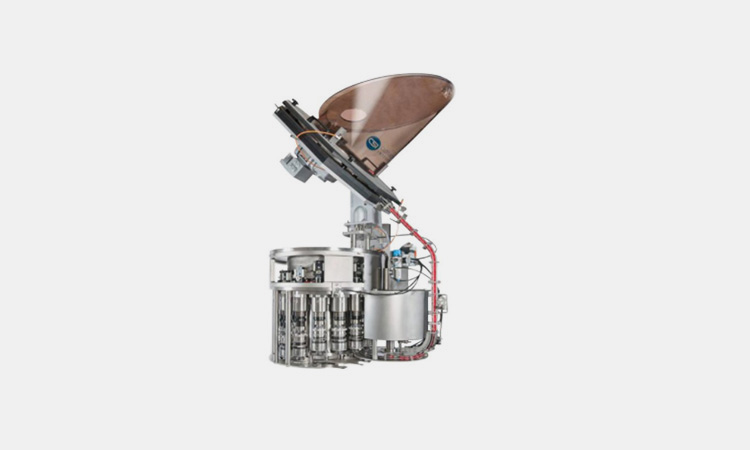

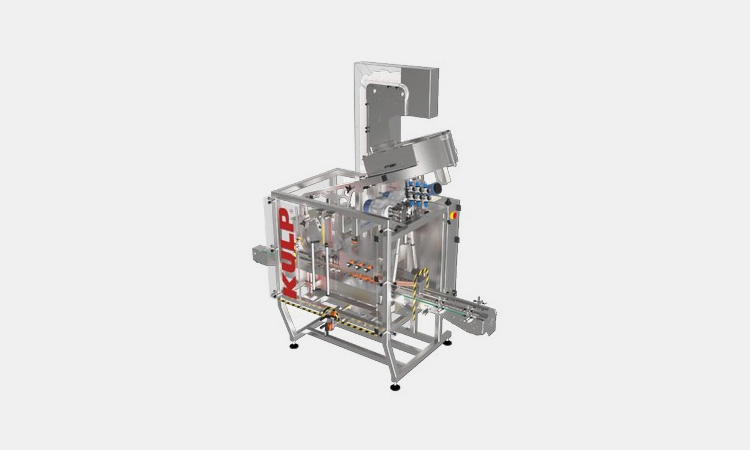

Single Lane Canning Machine

Single lane canning machine is fully automatic and also available in semi-automatic form. In this type of machine, cans are processed in single line, but its performance and efficiency remains the outstanding and provide perfect packaging for your successful business.

Components

The machine is composed of control system, movable wheels, conveyor belt, filling material, can cleaning station, filling nozzles, lidding unit, can seamer, printer and outfeed table.

Working Principles

In automatic form, the entire process is simply run by machine. However, in semi-automatic form, operator manually load the cans into machine where they are well flushed, filled with product, capped with lid and sealed by the can seamer. Finally, all these cans are discharged and picked up by user.

Application

This machine is suitable for medium to large scale industries who want to process their products with a machine having reasonable price.

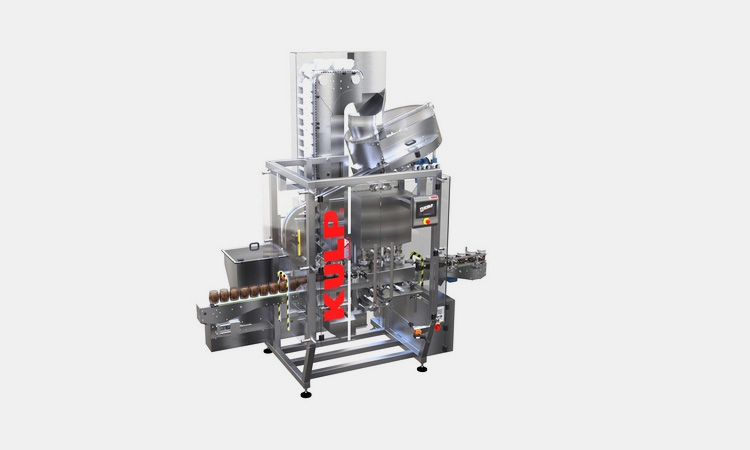

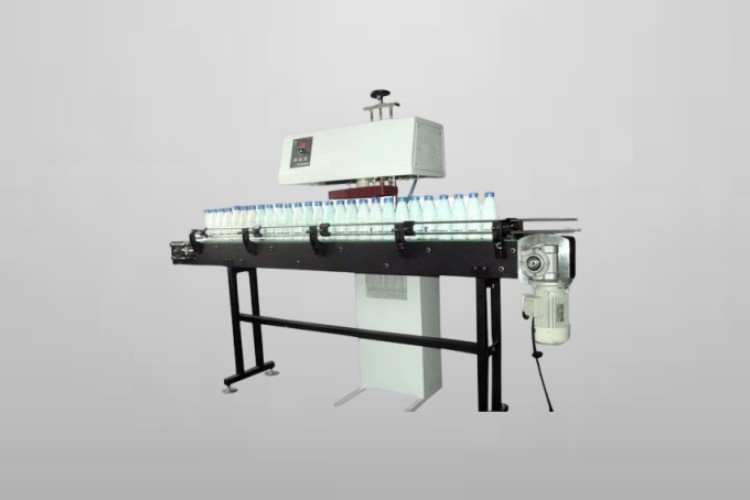

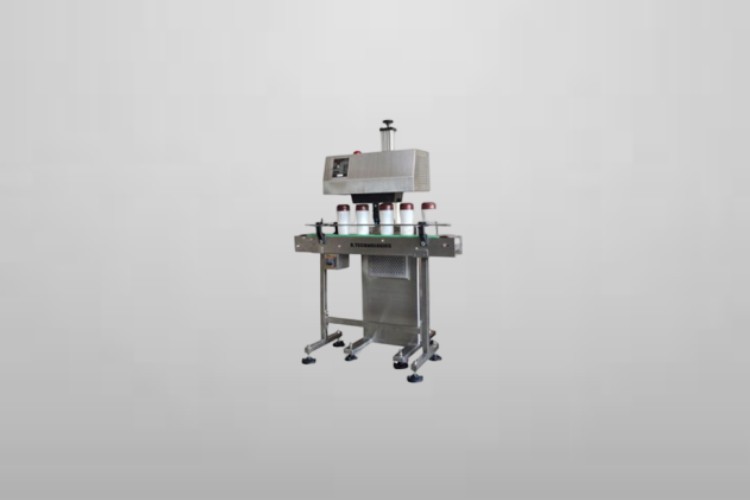

Dual Lane Canning Machine

Dual lane canning machine is fully automatic that gives you exceptional results in terms of efficiency and packaging. It is capable of dealing with large number of cans while allowing dual lanes for cans. The entire process is automatic.

Components

It consists of lidding hopper, material tank, can holder, can cleaning station, can filling unit, conveyor belt, speed regulator, casters, stainless steel main frame, control panel, can seamer, can printer and can accumulator etc.

Working Principles

This machine works through automatic system, once the operator complete the necessary setting. Cans are moved in proper way towards processing and passed through the units of can rinsing, filling, lidding, seaming, printing and discharging respectively.

Application

Commercial industries on national and international level who are engaged in large scale production are perfectly eligible for using this machine.

10.Which Industries Tend To Incorporate A Canning Machine Into Their Manufacturing?

The application of canning machine is vast enough due to its precise performance. Following are few areas, where presence of this machine can be found:

Carbonated Drinks

All these drinks which contains water, carbon dioxide, high amount of sugar and artificial flavors can be termed as carbonated drinks. Industries who process such type of drinks are the most popular for using canning machine as it provides them a single platform for running the whole process of packaging. Examples of carbonated drinks include soft drinks, soda water and beer etc.

Paints

Paint is viscous and thick liquid used for coloring and decorations. The industries involved in processing paints used to pack it in airtight containers so that external elements could be prevented from getting into the content. For this purpose they use a canning machine.

Cosmetics

Cosmetic industry is also on the list for using this machine. For instance, body spray, fragrance and other cosmetics are packed in aluminum and steel cans which are processed by this machine.

Food Products

Different types of food items including ketchup, sauces, seafood and honey are mostly packed in cans for which this machine can be easily undertaken.

11.What Is The Environmental Impact Of Using Cans?

The environmental impact of using cans for packaging food and beverages can vary depending on a number of factors, such as the materials used to make the cans, the methods used to recycle or dispose of them, and the distance they must be transported.

One of the main environmental concerns associated with cans is the production process. The production of aluminum cans requires a significant amount of energy and generates greenhouse gas emissions. Additionally, the mining and refining of the bauxite ore used to make aluminum generates toxic waste and contributes to deforestation.

Another concern is the disposal of cans. Cans that are not properly recycled can end up in landfills, where they can take hundreds of years to decompose. Even when cans are recycled, the process of recycling them also consumes energy and generates emissions.

On the other hand, cans are relatively lightweight and take up less space than other types of packaging, which can reduce the energy required to transport them. Additionally, cans can be recycled multiple times, which reduces the need to extract new raw materials.

It can be said that the environmental impact of using cans depends on the recycling rate of the cans, the energy consumption of the production process, and the source of the energy used. It’s important to consider these factors when evaluating the environmental impact of using cans.

12.What Is The Production Line For A Canning Machine?

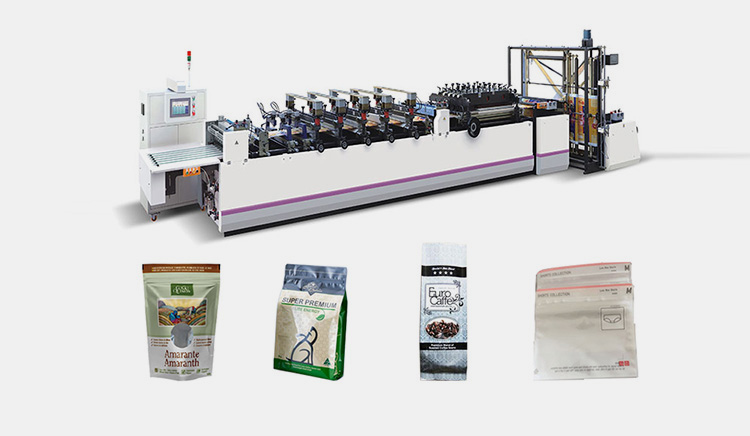

A canning machine is itself a production line for your can packaging. However, few machines you can further add for your packaging are as follows:

Can Making Machine

Can making machine is used to form cans of different shapes and sizes from think sheets of aluminum, tin or steel. During the can making process, the machine strictly follows providing safe and hygienic environment for cans and pass them through series of washing stations to ensure full cleaning.

Shrink Wrapping Machine

Shrink wrapping machine is helpful when you have prepared cans for distribution. By using this machine you can pack your cans in form of six-pack or twelve-pack by wrapping them in a plastic film shrunk through this machine.

Stretch Wrapping Machine

Stretch wrapping machine is employed to pack the products which are already integrated in cartons. This machine uses a flexible plastic in the surrounding of cartons so that they can be well knitted for easy shipping.

13.How To Solve The Problems Caused By A Canning Machine?

To counter the common problems faced during operating a canning machine look into the table below:

| No | Problems | Causes | Solutions |

| 1 | Cans do not transfer into machine | There is problem in the conveyor belt or in-feed table which cause blockage | Examine the guide rail and correct it in case can is stuck into it |

| 2 | Inconsistent filling | There might be problem in filling nozzle which result in improper filling | Accurately check the filling tubes and valves for cleaning and removing debris |

| 3 | The seaming of can is broken | It is either due to excess filling compound or the sealing is too tight | Reduce the quantity of sealing compound and also reduce the pressure of sealing |

| 4 | The sealing of lid is false | It happens if the lid is assembled in incorrect way or the flange of can is inflicted | Make sure that lid delivering unit is on right direction for putting lids over cans and also adjust the sealing pressure to moderate level |

| 5 | The seaming rollers do not move around cans | There may be something stuck into rollers or the connection of seaming station is interrupted | Well clean the rollers and also check the power connection and control panel for accurately running the station |

14.What Tips Should You Follow For Getting The Best Canning Machine?

- Look for a machine with a high-quality construction that is built to last.

- Consider the size and capacity of the machine to ensure it meets your needs.

- Look for a machine with a wide range of adjustable settings to accommodate different types of jars and food items.

- Look for a machine with easy-to-use controls and a clear display.

- Check for safety features such as overheat protection and automatic shut-off.

- Consider the cost and ensure it fits within your budget.

- Read reviews from other users to get an idea of the machine’s performance and reliability.

- Look for a machine with a warranty and good customer service.

- Consider the additional accessories that come with the machine, such as jars and lids, to ensure they are of good quality.

- Consider the space you have available to store the machine.

Conclusion

The cans are processed completely autonomously by canning machines, which are highly adaptable and cutting-edge pieces of machinery. Enterprises aspire to utilize the canning method for their beverages and goods as the packaging sector develops. A canning machine can tremendously help in this area. Additionally, you can get in touch with us through the provided link if you want more details about a canning machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Canning Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours