Gravity Bottle Filler: The Complete Buying Guide In 2025

Gravity Bottle Filler: The Complete Buying Guide In 2025

Gravity bottle fillers are used to fill bottles with liquid or viscous substances using gravity as a source of pull. The filling nozzle releases the product by the effect of gravitational pull. Industries like food, pharmaceutics, beverages, and chemicals are widely applying gravity bottle fillers in their processes to increase productivity in an efficient manner.

Gravity bottle fillers are now widely used in small and medium-scale industries and their demand is increasing drastically. For this many manufacturers in the global are producing gravity bottle fillers. Allpack is also one of the world's leading process machine manufacturers and provides the best machines globally. The buying guide will help you select a gravity bottle filler with all its related information. So let’s go!

1. What Is A Gravity Bottle Filler?

Gravity bottle fillers are mostly used for filling liquid materials in bottles, jars and containers using gravitational pull. The filler can easily fill materials like juices, chemicals, beverages, syrups and others in the food, beverages, chemical and pharmaceutical industries. The gravitational pull flows liquid and also dispenses an accurate amount of material in these bottles.

A valve is present at the opening of the filling nozzle which cut the flow once it reaches its maximum level. The flow of liquid can be controlled through flow rates and it allows accurate and precise filling of bottles. These bottles or containers are usually moved by manual support throughout the process. Mostly small and medium-scale industries prefer to use gravity bottle fillers.

2. What Are The Applications Of A Gravity Bottle Filler?

Gravity bottle filler are mostly used in small-scale industries to perform highly precise filling of bottles and containers. Some of the applications of gravity bottle filler are

- Food Industry

Food industry is the major sector where gravity bottle fillers are used for filling of bottles with different types of material. These materials include oil, liquid sauces, syrups and etc. The bottles are filled with these materials in a highly precise manner.

- Beverages Industry

Else of the food, and beverages industry also applied gravity bottle fillers that are used for filling juices, shakes, drinks, milk flavors, wines, and other sodas in different sizes of bottles. The filling mechanism only depends on the viscosity of liquid material and controls the filling levels throughout the system.

- Chemical Industry

Chemicals like detergents, shampoos, acids and other types of solvents are filled in bottles using gravity bottle filler. The machine incorporates several materials depending on their solubility and chemical composition.

- Pharmaceutical Industry

Lastly, the pharmaceutical industry also applied gravity bottle fillers in its different stages. For filling of medicines, supplements and solutions, gravity bottle fillers can always be helpful in filling these materials and maintaining its expiration life,

3. What Type Of Bottles Are Filled Using A Gravity Bottle Filler?

Different sizes and types of bottles, containers, and jars are filled using gravity bottle filler. The opening of a filling nozzle can be adjusted according to the required filling material. Following are some of the bottle materials that are used for filling of gravity bottle fillers.

- Plastic Bottles

Bottles that are made up of Polyethylene Terephthalate (PET), HDPE, Polyethylene and other are too high to decompose. The material is highly recommended due to its easy handling and availability. The bottles can also be traveled easily.

- Metal Bottles

Other than plastic bottles, metal bottles are famous and common for filling liquid material using gravity bottle fillers. Many shapes of bottles and materials including thin aluminum and stainless steel are used for filling purposes in gravity bottle fillers.

- Glass Bottles

Finally, glass bottles are also used in gravity bottle fillers for maintaining an equal amount of liquid filling. As it is mostly hot in temperature, and transparent but there was losing in the junction of the transformer and is the reason that caused the smoke.

4. What Are The Advantages Of A Gravity Bottle Filler?

Some of the advantages of gravity bottle filler are

- Precision and Accuracy

Gravity bottle filler are the source for filling liquid materials in an efficient, precise and accurate manner. The machines are designed in a way that the valves gets shut after completing its filling cycle and do not allow the material to overflow or turn into waste.

- Versatility

Gravity bottle filler has an option that it can dispense material into different size and shapes of bottles. Irrespective of its shape, the level of distribution of material is done by only changing the dimensions of bottle neck and adjusted accordingly.

- Zero Material Loss

The material directed flows once the bottle or container is detected onto the system and then filled with various types of liquids. This type of filling avoids any type of wastage, spillage or overflow material and becomes much more effective to the filling system.

- Ease In Operation

The bottle fillers are much easier to operate as it includes maximum human efforts in their operation. The concerned worker is responsible for placing the bottle in the final packaging steps. There are also various safety measures in the machine that secures both material strength and human safety.

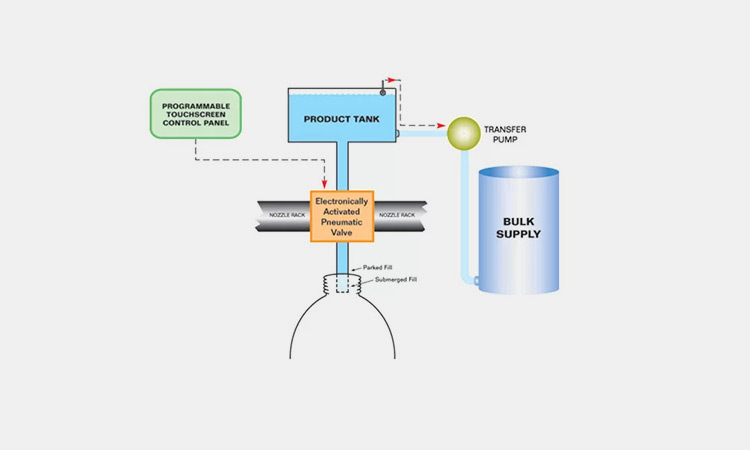

5. What Is The Working Principle Of Gravity Bottle Filler?

Gravity bottle fillers are easy to operate and involve only gravitational pull and filling levels. The steps involved in its operation are

- In the first step the hoppers or containers are cleaned properly to avoid contamination and clean if any residual of previous production is left.

- Once the container gets cleaned it is then filled with filling material that is then packaged in different sizes and shapes of bottles.

- Afterwards, in the second step the filling bottles or containers are placed manually or automatically kept under the filling nozzle and adjusted accordingly.

- The filling packaging once detected by the sensors present in gravity bottle filler directs the system to start its operation.

- As the system gets its signal, it opens the valve of filling nozzle and with a gravitational pulling mechanism it allows the continuous flow of material.

- The system automatically shuts the valve and stops the flow once the desired level of filling is achieved.

- Accurate filling is carried out in this way into different types of packing material. The final bottles are packaged by sending it further for capping, labeling and coding processes.

- The final completed products are moved onto the same conveying system and at the end they are packaged in their respective packaging form.

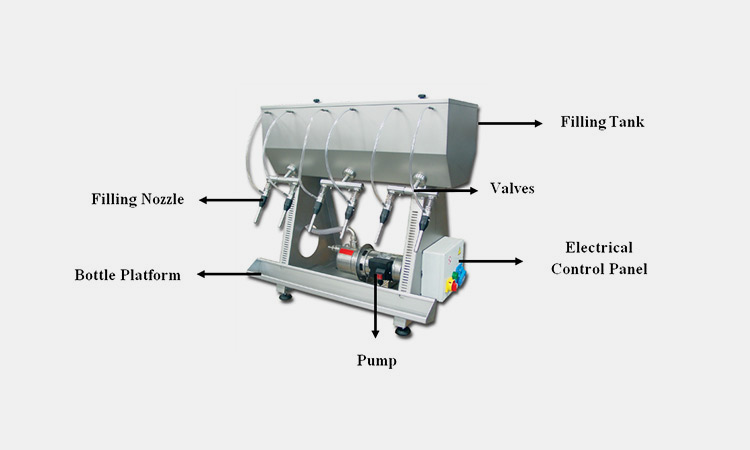

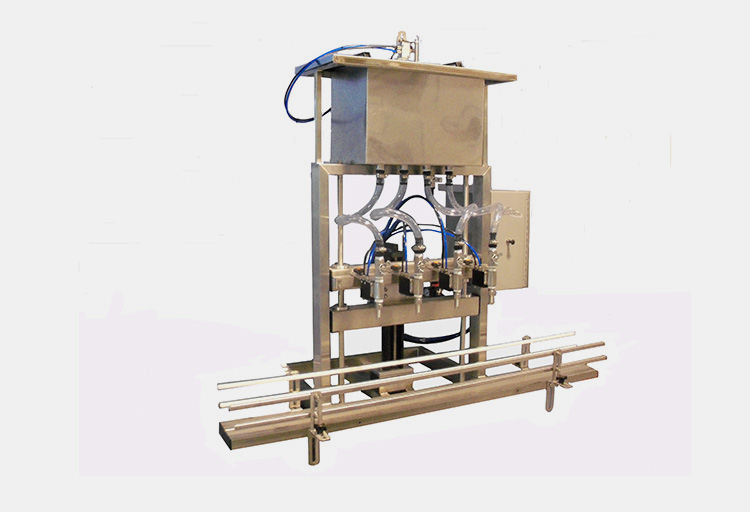

6. What Are The Main Components Of Gravity Bottle Fillers?

A gravity bottle filler has no complex structure and is manufactured in a way that handling of process is done in an easy way. Following are the important components that are available in gravity bottle filler

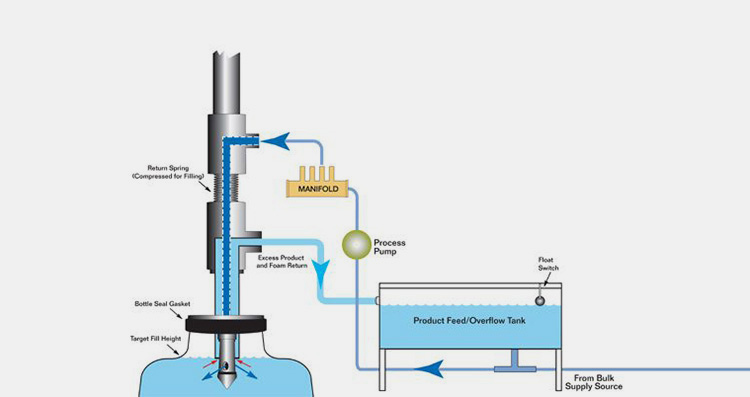

- Filling Tank

This is the place where the material that has to be filled is placed and can be found at the top of the gravity bottle filler. Various types of tubes and valves are further attached to this feeding tank that support inflow of liquid material out of the feeding tank. The size of the feeding tank varies according to that of the gravity bottle filler size and shape.

- Pump

Electric pumps are attached with a gravity bottle filler that is responsible for the efficient flow of liquid within the system. The pump circulates the liquid from huge containers to the feeding tank and then in further processes. The power of these processing pumps is less due to the small and compact size of the fillers.

- Valves

Valves are the most important part of gravity bottle fillers that are responsible for the accurate filling of liquid material. These valves are electro-mechanically controlled and perform both tasks. The electrical system generates signals when to close and when to open for filling purpose. Whereas, when the signal is received the valves open and close its gate accordingly. The weight and gravitational pull is also controlled by these valves.

- Filling Nozzles

The area from where the liquid gets dispensed out of the system is its filling nozzles. The nozzles are usually made up of stainless steel so that it may be prevented from corrosion and rust.

- Bottle Platform

In gravity bottle filler most of the tasks are performed manually. This is why the filler uses bottle platforms instead of conveyor belts. The bottles are place on these platforms and then the filling work is done.

- Electrical Control Panel

This is the source for interaction of operator and machine. From here are the parameters including temperature, pressure, sleep, timers and others are set according to the requirement of system. It also displays all the ongoing operation and indicates if any hazard occurs

7. What Are The Types Of Gravity Bottle Fillers?

The important types of gravity bottle filler according to the filling mechanism are

- Manual Gravity Bottle Filler

A manual gravity bottle is the simplest type of gravity bottle filler that is applied in small-scale production setups. The productivity of this type of machine completely depends upon the operator and has no automation. The operator fills and packs the bottle or container by himself and using his hands. These are ideal where productivity is less and no burden is applied.

- Semi-automatic Gravity Bottle Filler

Semi-automatic gravity bottle filler is an intermediate level that involves both manual and automatic operations in it. The operator completely gets involved from placing to picking but the bottles are filled automatically by the machine. Machines are partially automated and are best suitable for small and medium-scale industries.

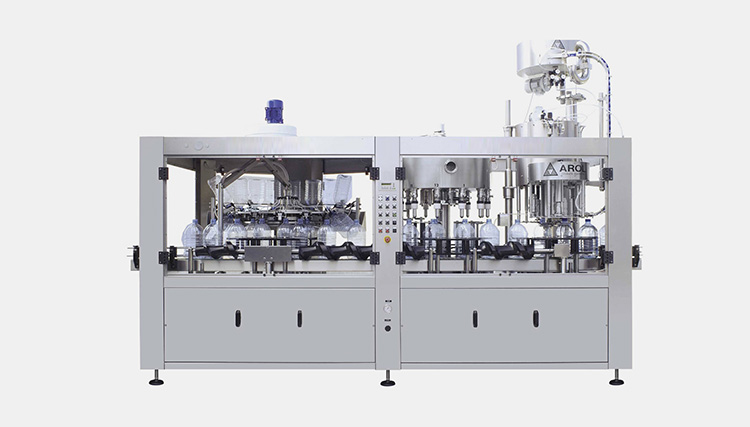

- Fully Automatic Gravity Bottle Filler

The most advanced and automated type of gravity bottle filler is its fully automatic gravity bottle filler. It completely relies on automation and from the bottle moving to its filling and then final packaging; all of are performed by the machine. It does not require any operator influence and is ideal to be used in high-scale industries where greater productivity is to be achieved.

- Rotary Gravity Bottle Filler

The fourth type is rotary gravity bottle filler. The bottles are placed in a rotational cycle where a number of bottles are continuously moved and filled in a single step. The output results of this type of gravity bottle filler are much higher as its speed is greater than any of the others.

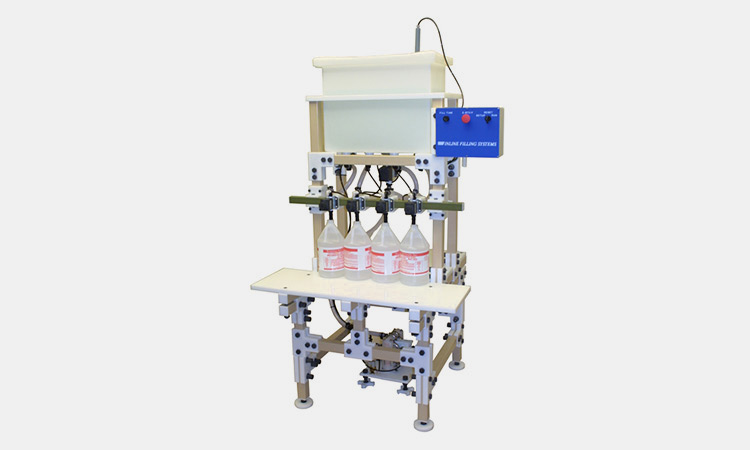

- Inline Gravity Bottle Filler

This type of gravity bottle filler is counted only because it shows complete support toward lining bulk quantities of bottles that are then efficiently filled with material. It saves a lot of segregation time and improves the quality of the product.

8. What Are The Differences Between Manual, Semi-automatic And Fully Automatic Gravity Bottle Fillers?

All three types of gravity bottle fillers are merged into each other and are distinguished on the basis of automatic level, productivity, operator involvement and structure design. Some of the major differences are

- Automation Level

Manual gravity bottle filler completely involves the operator in its operation and is responsible to perform each of the tasks.

The operator and machine both have an intermediate level while performing tasks in semi-automatic gravity bottler filler.

Whereas fully automatic gravity bottle fillers are solely depending upon the machine's automation level and perform each of the tasks in a perfect manner. Uniqueness is the leading benefit that one can get using a fully automatic gravity bottle filler.

- Working Principles

The bottles or containers are placed by the operator in manual gravity bottle filler and then he pushes the button to operate the solenoid and release of liquid. When the level is gained the work removes the bottle and applies cap on its top.

Once the bottle is placed by the operator, the semi-automatic gravity bottle filler detects its presence and dispenses the required amount of material to fill it.

From product placing to picking, all the performance is gained by the machine. The bottle travels through the conveyor belts and gets filled when come under the filling nozzle. The final product after labeling, stamping, capping and coding is received in a fully automatic gravity bottle filler.

9. What Are The Controlled Parameters To Fill Bottles Using Gravity Bottle Filler?

For consistent and precise filling of bottles, few important controlling parameters are there in gravity bottle filler that are to be maintained throughout the system. These controlling parameters are

- Filling Pressure

The most important parameter in gravity bottle filler is its filling pressure. As the pressure directly affects the level of filling and also the product quality, it is important to maintain standard pressure according to the size of the bottle and the material's chemical strength.

- Filling Temperature

The other parameter stands for is its filling temperature. The temperature in the container and filling tubes can directly affect the composition of the material which is why it is important to set specific temperatures so that smooth and accurate results can be gained.

- Filling Speed

The dispensing speed of liquid can be controlled by adjusting the flow rate that is attached to the valves of the gravity bottle filler. The speed can affect the filling quantity of material so for this it is important to maintain this parameter.

- Bottle Placement

For gravity bottle fillers, it is always important to calibrate the sensors in a way that the accurate position of the bottle can be confirmed. It is usually important because accurate filling can get affected by the irregular placement of the bottle and can also cause material wastage.

- Filling Accuracy

Further to maintain systems accuracy and consistency, it is important to verify filling accuracy after every interval of time. This gives a high level of consistent filling options even in bulk quantity production setups.

- Filling Volume

Auto-shut valves are set in a way that they close once the set filling volume is gained. For identical packaging, it is important gravity bottle filler gains its filling volume in each of the cycles.

10. What Are The Differences Between Piston Bottle Filler And Gravity Bottle Filler?

Both of the bottle fillers are responsible for filling accurate amounts of material in their specified filling products but are distinguished on a few important parameters. These parameters are

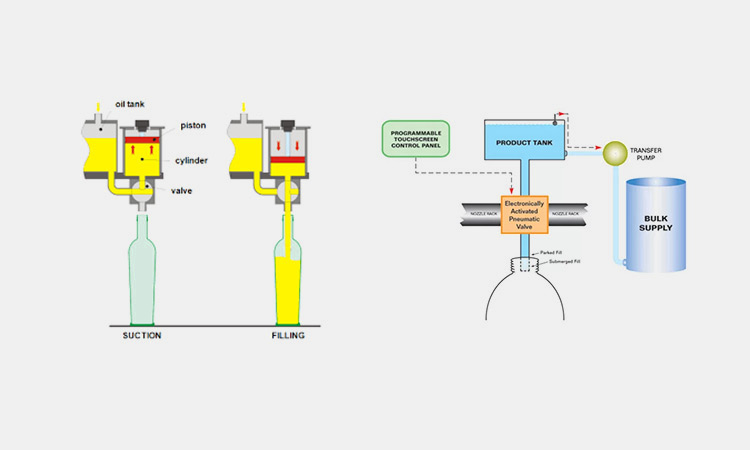

- Filling Mechanism

Piston bottle filler has a complete cylinder and piston mechanism incorporated in its construction that is responsible for filling of bottles. The material is supplied from the tank to the filling nozzle through the process pump and from there onwards it is dispensed by the to and fro movement of the piston.

In contradiction to it, gravity bottle fillers also follow that same procedure till the material reached the filling nozzle. Once the material is to be dispensed there are valves present that release material directly by gravitational pull. No electrical or mechanical supply is required at this step.

- Product Types

Piston bottle fillers are best suitable for materials that are viscous and thick in their existing nature. These can be pastes, creams, sauces and other viscous materials.

On the other hand, materials like juices, beverages, water, syrups and chemicals that are thin in nature are ideally filled using a gravity bottle filler.

- Productivity

As compared to gravity bottle fillers, piston bottle fillers are fast in the filling procedure as they can produce a large number of bottles as filling results. Gravity bottle filler is a bit slow and cannot produce a large number of bottles in a short interval of time.

- Construction

Piston bottle fillers are usually compact in size that they can be adjusted on simple tables. Pistons and cylinders are present in it to perform filling tasks.

Gravity bottle fillers are made up of stainless steel and have no complex structure. Simple tubes, valves, pumps and frames are present in it.

11. What Should Be Considered Before Purchasing A Gravity Bottle Filler?

Some of the important factors that should be considered before purchasing gravity bottle filler are

- Bottle Dimensions

It is the most important factor while considering gravity bottle filler that what type of bottle size and shape needs to be filled. The level of platform, distance of platform from filling nozzle, size of bottle and its shape are the most important things that are to be considered keeping the internal production requirement in view.

- Filling Product Type

The second most important thing to find what type of product is to be filled using gravity bottle filler. Whether its viscosity, volume, internal composition and temperature; are to be kept in mind before its purchasing. Wrong selection can cause a lot of economical loss to the buyer.

- Machine Automation

The level of automation or speed is also another important factor. How much bottles are to be filled in a minute or an hour supports the buyer to select the right type of bottle filler.

- Spare Parts Availability

Availability of spares is yet another important factor as it intimates to the buyer whether they will be getting spares in the future or not. Bottle fillers that get obsolete in a minimum time are never good to buy.

- Manufactures Assistance

The support that a manufacturer provides through its experience is always important for the customers. This factor along with the reviews of previous customers is important to consider so that no wrong decision may be taken.

Conclusion

Gravity bottle fillers are simple and economical to fill bottles with liquid material. Their demand is drastically increasing and is more popular in small-scale industries. But due to the variety of manufacturers, it is always a tough decision to take from which manufacturer the filler can be purchased. Allpack in this regard is here to provide you a bulk quantity of gravity bottle fillers and their components. If there is any question in your mind you can call our representative or visit our website https://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Gravity Bottle Filler: The Complete Buying Guide In 2025 Read More »