Double Seam: The Complete FAQ Guide In 2025

Double Seam: The Complete FAQ Guide In 2025

Double seam is a crucial aspect of canning and packaging, as it provides a secure and reliable seal that helps preserve the freshness and flavor of the contents. Whether you are a seasoned canner or just starting out, choosing the right double seam equipment can be a challenge. With so many options available in the market, it can be difficult to know where to start. This buying guide will help you navigate through the maze of double seam options and find the right one that fits your specific needs and requirements.

It is important to note that this process is not only used for cans, but it is also used in the production of other packaging materials such as plastic bags and paperboard boxes.

Let’s delve deeper into the Double Seam!

1.What is double seam?

A double seam is a type of canning process used to seal canned goods. It involves folding the top of the can over the lip of the bottom of the can, and then welding the two together using heat and pressure. This creates a secure seal that helps to preserve the contents of the can and prevent contamination. Double seams are commonly used for canned food products such as vegetables, fruits, and meats.

2.What are the primary objectives of double seam?

The primary objectives of using double seaming include creating an airtight seal to preserve the product inside the can, ensuring the product is safe for consumption, and providing a tamper-evident seal to protect the product from contamination.

Examples of products that are commonly sealed using double seaming include canned fruits, vegetables, soups, and meats. These products have a long shelf life and need to be preserved in order to maintain their quality and safety for consumption.

Additionally, double seaming also provides tamper-evident feature, which is a mechanism that provides visible indication to consumer if the can has been opened before or not. This helps to ensure that the product inside the can is safe for consumption and has not been tampered with.

3.How the Double Seam is developed?

This method was first developed in the late 19th century, around the same time that canned food was becoming popular. The first cans were sealed with a single seam, but it was found that this method was not always reliable, and the cans could sometimes leak or break open.

The double seam was developed as a solution to this problem, and it quickly became the standard method for sealing cans. It involves folding the top and bottom edges of the can over and then crimping them together to create a tight seal. This method is still used today and is considered to be one of the most effective ways to seal cans.

4.What are the various beneficial aspects of double seam?

The process involves folding the edges of the can or jar lid and body together, creating a secure seal. There are several benefits to double seaming, including:

- Airtight Seal:Double seaming creates an airtight seal that helps to preserve the quality and freshness of the food or beverage inside the can or jar. This is particularly important for products that are sensitive to air and light, such as canned fruits, vegetables, and meats.

- Leak-Proof:Double seaming ensures that the can or jar is leak-proof, which is essential for products that are sensitive to moisture, such as powdered mixes or dry goods.

- Sterilization: The double seaming process can also be used as a means of sterilizing the contents of the can or jar. The high heat and pressure applied during the double seaming process can kill bacteria and other microorganisms, making the product safe for consumption.

- Durability: The double seam provides a strong, durable seal that can withstand the rigors of transportation, storage, and handling. This can help to prevent damage to the product and reduce spoilage.

- Cost-Effective:Double seaming is a cost-effective method of packaging, as it requires minimal equipment and labor compared to other sealing methods.

- Efficient: Double seaming is a high-speed process, which allows for large volumes of cans or jars to be sealed quickly and efficiently.

- Versatility: Double seaming is suitable for a wide range of products and can be used with a variety of can or jar sizes and materials, including metal, glass, and plastic.

5.Enlist significant applications of double seaming?

Double seaming is used in a variety of applications, including:

Food packaging:

Double seaming is commonly used to package a wide range of food products, including fruits, vegetables, meats, and soups. The process ensures that the food remains fresh and uncontaminated during storage and transport.

Beverage packaging:

Double seaming is also widely used in the packaging of beverages, including beer, soda, and juice. The process ensures that the beverage remains fresh and carbonated, while also preventing contamination.

Industrial packaging:

Double seaming is also used in the packaging of industrial products, such as chemicals and lubricants. The process ensures that the contents remain uncontaminated and that there are no leaks, which can be dangerous in the case of some industrial products.

Canning of fruits and vegetables:

Canning of fruits and vegetables is common application of double seaming. The process involves heating the canned product, which kills bacteria and creates a vacuum seal that prevents contamination and spoilage.

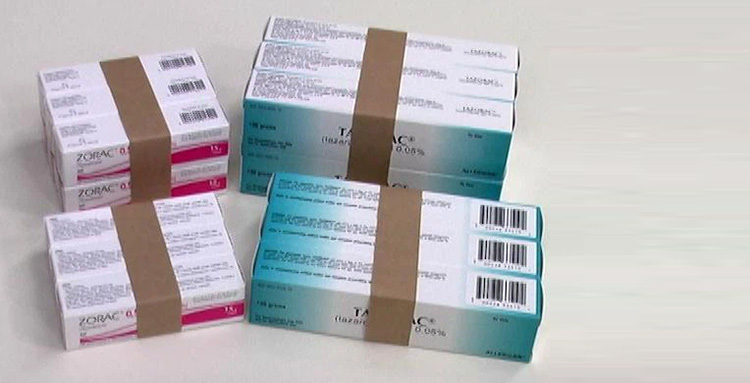

Medical packaging: Double seaming is also used in the packaging of medical products, such as vaccines and injectable drugs. The process ensures that the contents remain uncontaminated and that there are no leaks, which can be dangerous in the case of some medical products.

Overall, double seaming is a critical process in the packaging of a wide range of products, as it helps to ensure that the contents remain fresh, uncontaminated, and safe for consumption or use.

6.How Double Seam is formed?

A double seam is a type of closure used for canned goods. It is used to seal the top and bottom of a can together, creating an airtight and secure seal that helps to preserve the contents of the can and prevent contamination.

The double seam is created by the combination of two layers of metal that are folded over the top of the can, creating a hermetic seal.

- The first step in the double seam process is to form the can body, typically made of tinplate or aluminium, and then the can ends, which are made of the same material.

- The can body is then filled with the desired product, such as vegetables, fruits, or meats.

- The can end is then placed on top of the can body and a flange or curl is formed around the edge of the can end.

- This flange or curl is then folded over the top edge of the can body and the two layers of metal are crimped together.

- Next, the can is heated and pressurized, which causes the metal to expand and form a tight bond. The process typically includes several stages of heating and pressurizing to ensure that the bond is secure and airtight.

- The final step is to inspect the cans to ensure that the seams are properly formed and that there are no leaks or defects.

- Double seams provide a high level of protection against contamination and spoilage, which is why they are commonly used for canned food products. They are also used in other industries, such as chemical and paint manufacturing, where airtight seals are essential to the preservation of the product.

7.What are the equipmentused for Double Seam?

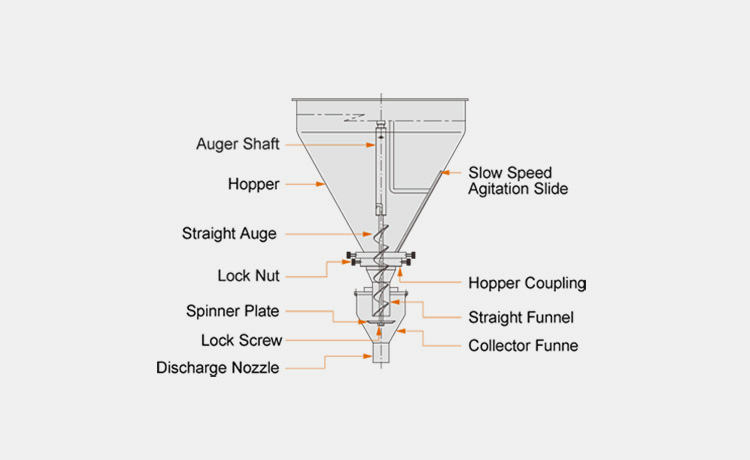

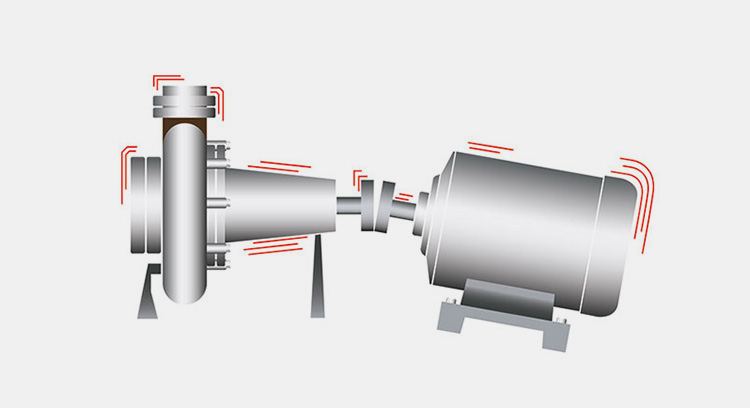

- Can Seamer:

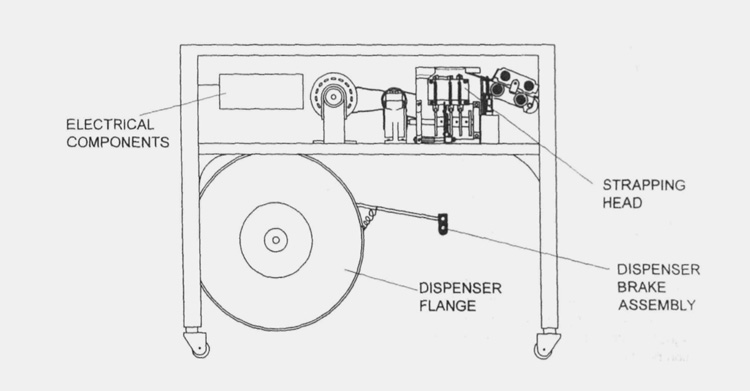

The double seam is created by a machine called a can seamer, which uses a series of rollers and other mechanical components to precisely control the folding and rolling of the lid onto the can.The rollers apply pressure to the lid and can body, compressing the metal and creating a strong, airtight seal.

The can seamer also has a precise mechanism to control the overlap between the two seams, ensuring a perfect seal every time.The can seamer is essential part of packaging line for food and beverage, chemical, and other industries. The machine is designed to be easy to operate and maintain, and it can be adjusted to accommodate different can sizes and lid types.

- Can Sealing Machine

A can sealing machine that is used for double seam typically consists of seaming chuck, seaming rollers, seaming head and drive system. The machine is to apply caps to cans and then add pressure, until the double seam is completed.

8.Are there any specific types of products that are best suited for double seam?

Double seam is a method of sealing cans that is commonly used in the food and beverage industry. It is particularly well-suited for products that are acidic or have a high sugar content, as the double seam provides a secure seal that can withstand the pressure and corrosive effects of these types of products.

Some examples of products that are commonly packaged using double seaming include canned fruits, vegetables, and soups, as well as carbonated beverages. The process of double seaming involves creating two overlapping seams on the can lid and the can body, which creates a secure seal that is resistant to leaks and contamination.

9.What material is the Double Seam compatible with?

The most commonly used materials for Double Seam applications are tinplate and aluminium. Tinplate is a thin steel sheet coated with tin and is known for its corrosion resistance, making it suitable for use in food packaging. Aluminium, on the other hand, offers excellent barrier properties and is lighter in weight compared to tinplate, which makes it more cost-effective for larger containers.

It is important to note that the suitability of a material for use in Double Seam applications is dependent on a number of factors, such as the type of product being packaged, the end-use environment, and the desired shelf life. The choice of material may also be influenced by regulatory requirements and sustainability considerations.

In summary, the Double Seam is typically used for metal containers made from tinplate or aluminium, but the suitability of a material for use in Double Seam applications should be evaluated based on the specific requirements of the product and packaging.

10.What are the prominent elements of double seam?

A double seam is a type of canning technique used to seal food in cans. It consists of several components, including the following:

Can body – The can body is the main container that holds the food. It is typically made of tin-plated steel or aluminium.

End – The end is a circular piece of metal that is placed on top of the can body to create the sealed top of the can. It is typically made of tin-plated steel or aluminium.

Seam – The seam is the joint between the can body and the end. It is created by folding the edge of the can body over the end and then crimping it tightly to create a secure seal.

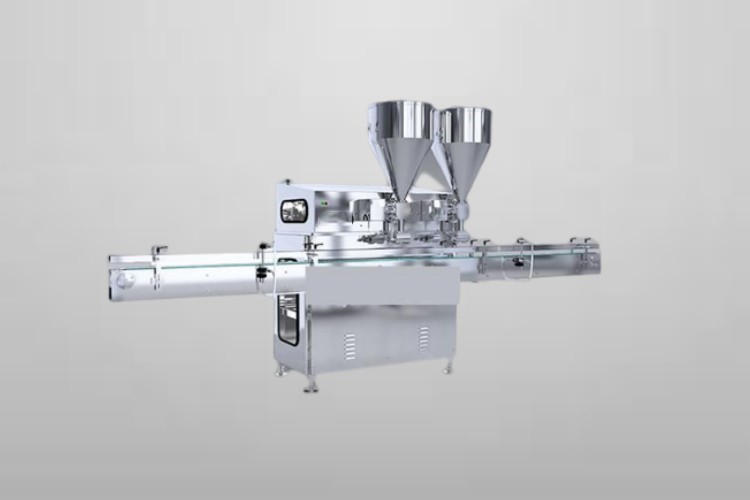

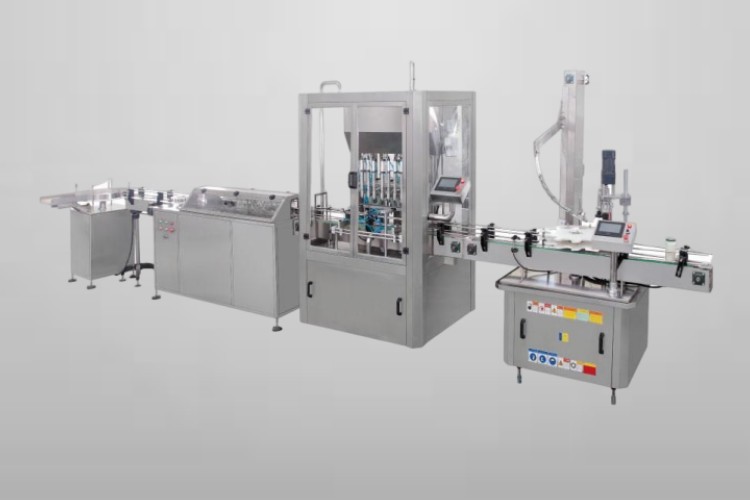

Filler – The filler is the machine used to fill the can with food. It is typically a high-speed machine that can fill hundreds of cans per minute.

Seamer – The seamer is the machine used to create the double seam. It is typically a high-speed machine that can create the double seam on hundreds of cans per minute.

Can inspection – The can inspection is the process of inspecting the cans for any defects or issues. This includes checking for leaks, dents, or other issues that could compromise the safety or quality of the food.

Can labeling – The can labeling is the process of applying labels to the cans, including information such as the product name, weight, and expiration date.

11.What are the essential parametersin assessing the double seam?

The essential parameter in evaluating the double seam is the “seam tightness.” Seam tightness refers to the degree to which the edges of the can lid and can body are joined together, and it is measured in terms of the amount of air that can pass through the seam. A tight seam will have very little air leakage, while a loose seam will have significant air leakage.

Examples of tight seam: A tight seam will have little or no visible light passing through it, when held up against a light source.

Examples of Loose seam: A loose seam will have visible light passing through it, when held up against a light source.

Tightness is determined by measuring the amount of air that can pass through the seam when a pressure difference is applied. This is done by using a device called a seam gauge, which applies a specific amount of pressure to the seam and measures the amount of air that leaks through. The tighter the seam, the less air that will pass through, and the higher the rating on the seam gauge.

It is important that the seam tightness is within the specified range, as it is one of the factors that ensures the safety and shelf life of the packaged product. A loose seam can cause product spoilage, leakage, and other problems that can affect the product’s quality and safety. Additionally, a tight seam is one of the important factors in maintaining the vacuum inside the can which is crucial for the preservation of the product.

12.How Double Seam is measured?

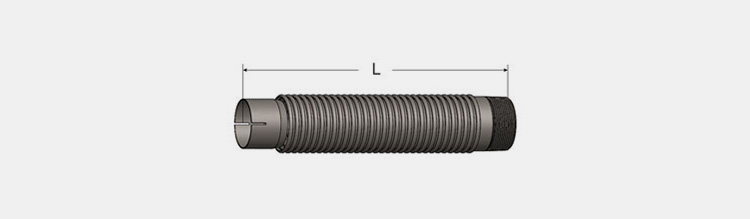

The measurement of double seam refers to the thickness of the seam between the two pieces of metal, as well as the overall quality of the seam.

Double seam measurement is typically done using specialized equipment, such as a micrometre or seam gauge. These tools measure the thickness of the seam at specific points along the length of the can. The measurements are then compared to industry standards to determine if the seam is within acceptable tolerances.

Double seam measurement is important because it ensures the integrity of the can, and that it is able to withstand the pressure of the contents, and to prevent leakage. A poorly formed double seam can lead to leaks, or even the failure of the can, which can be dangerous and cause product spoilage.

Double seam measurement should be done at various stages of the can-making process, including after the can body has been formed, after the can has been filled, and after the can has been sealed. This allows for any issues with the double seam to be identified and addressed early on, before the can is sent to the customer.

13.Are there any specific safety precautions or certifications required when using the Double Seam?

The safety precautions and certifications required for using double seam technology may vary depending on the industry and the country in which it is being used. Here are some general safety measures that may be taken:

- Equipment maintenance: Regular maintenance of the canning equipment, including the double seam machine, is important to ensure that it is functioning properly and to avoid any potential safety hazards.

- Operator training: Operators must be trained on the proper use of the double seam machine and must follow all safety procedures and guidelines.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, such as gloves and eye protection, to minimize the risk of injury.

- Hazard assessment: The workplace must be regularly assessed for potential hazards and steps must be taken to minimize or eliminate these risks.

- Quality control: Quality control measures must be in place to ensure that the cans produced using the double seam technology are safe and meet the relevant industry standards.

In terms of certifications, it is recommended to check the specific industry standards and regulations in your country or region. For example, in the food industry, the cans may need to be certified by a third-party organization to meet food safety standards such as the Global Food Safety Initiative (GFSI).

Conclusion:

In conclusion, double seam is a crucial process in the canning industry that ensures a secure and airtight seal for canned goods. This process is essential for maintaining the safety and shelf life of canned products. With the information provided in this FAQ guide, you should now have a comprehensive understanding of the double seam process and its importance in the canning industry. In case you have any further questions, please refer to the specific section in the guide or consult with a canning expert.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Double Seam: The Complete FAQ Guide In 2025 Read More »

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

A vegetable canning machine typically has several major components, including:

A vegetable canning machine typically has several major components, including:

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours