Box Strapper Machine:The Complete Buying Guide in 2025

In the industrial world, box strapper machines are an essential piece of equipment for many applications. From packaging to transportation, the ability to securely and effectively hold together a package for traveling can be invaluable. But with so many variations available, it’s important to make sure you choose the right machine that suits your needs and budget when looking into buying one- but where do you even start?

This comprehensive guide will help break down what a box strapper is and give insight on which type of machines would best suit your business or project. Be sure to read all the way through so you know exactly what kind of machine is right for you in 2025!

1.What Is A Box Strapper Machine?

A box strapper machine is a type of automated packaging equipment used to secure boxes and products for shipping or storage. It does this by applying straps around the box, which are then tightened in order to create a tight seal. This helps prevent movement during transport and can help keep contents safe from tampering or damage.

Box strappers come in many different sizes and can be used to secure boxes of all shapes and sizes. They are typically used in warehouses and distribution centers, but they can also be a vital part of any packaging or shipping operation. When using a box strapper machine, it’s important to understand the process so that you can properly use the equipment, as well as troubleshoot any issues that may arise. This can help ensure that your products arrive safely and securely to their destination.

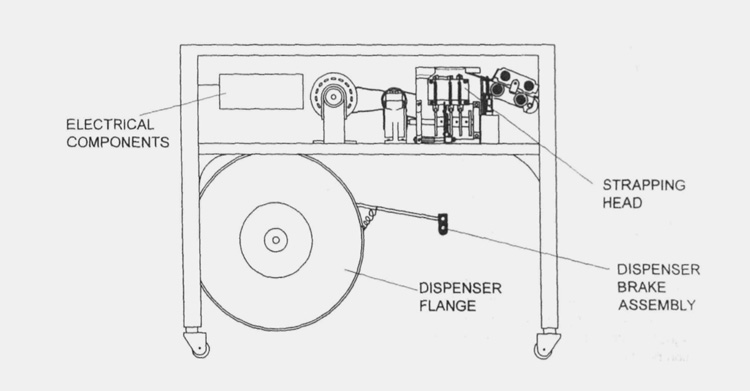

2.What Are The Different Components Of A Box Strapper Machine?

Box strapping machines are essential for safely and securely packaging and shipping boxes. They use a combination of components to assist in the process, including tensioners, sealers, reels, and conveyors. Here’s a breakdown of each component:

Tensioner

This is a device used to apply tension to the strapping material, allowing it to be tightened around the box for a secure hold. The tensioner has adjustable knobs that can be used to adjust the amount of tension applied and help ensure the strapping is held securely in place.

Sealer

A sealer is used to create seals on both ends of the strapping material, ensuring it is held together firmly and will not come loose during shipment. This component ensures the box stays closed and secure until it arrives at its destination.

Reel

The reel holds the strapping material in place so that it can be easily fed into the machine for use. It also helps to keep excess strapping from getting tangled up and making it difficult to work with.

Conveyor

The conveyor is used to facilitate the movement of the box and strapping material through the machine so that it can be quickly and easily strapped in place. This component helps to speed up the process and ensure that each package is securely sealed before shipment.

Control Panel

The control panel is responsible for controlling the strapping process. It will allow you to select which type of straps to use, how many straps per box and other settings that are necessary for an efficient and effective strapping process.

These components, working together, are essential for efficiently and securely packaging boxes for shipment. By understanding how each component works, you can ensure that your boxes arrive safely and without damage.

3.How Does A Box Strapper Machine Work?

In operation, the box strapper works by taking a continuous roll of plastic or metal strapping and applying it around the package. The strapping is fed into the machine, then cut to the desired length and placed in position on the box. A motorized head is used to tension, or pull tight, the strap before it is sealed with a heat sealing device.

The motorized head not only tensions the strap but also positions it around the box. This ensures that the strapping is properly aligned and will create a tight fit on the package when secured. Once the strap has been tensioned, heat is applied to seal the ends of the strap together. The heat seals are what hold the strapping securely in place and make sure that packages stay secure during transport.

The entire process of strapping with a box strapper is automated and requires no manual intervention. This makes it ideal for high-volume applications where time is of the essence. Box strappers are also highly reliable and durable, meaning they can be used in heavy-duty industrial environments without fear of breakdowns or malfunctions. However, if manual straps are used, the operator will need to cut and pre-measure each piece according to the size of the package. The strap then needs to be fed through a small hole in the machine and pulled tight around the box using a lever or crank. Once the strap is secure, it will be sealed to keep it in place.

4.What Are The Applications Of A Box Strapper Machine?

The box strapper machine is an essential tool for a variety of industries. It can be used to quickly and efficiently finish packing tasks, with precision and speed. Here are some common applications of the box strapper machine:

Food and beverage industry

The box strapper machine is used to keep together cardboard boxes filled with food and beverages. It helps to ensure that the contents remain safe while in transit or storage, reducing the chance of contamination or damage.

Retail

For retail, the box strapper machine can be used for a variety of tasks. It is perfect for bundling clothing or other products that are not fragile or breakable, which makes it much faster and more efficient to transport them.

Construction

Box strapper machines can also be used to bundle building materials together. This helps make transportation easier and prevents items from becoming damaged during construction projects.

Pharmaceutical industry

Box strapping machines are used to package medical supplies and equipment for safe transportation. The machine can be used to bind items together securely, preventing them from becoming loose and damaged during transit.

Shipping industry

The shipping industry requires secure and reliable packaging solutions that can handle the rigors of transportation. Box strapper machines help to create packages with strong seals that will hold up during transit, ensuring items reach their destination in pristine condition.

5.What Are The Advantages Of Using A Box Strapper Machine?

When it comes to the packing and shipping of goods, a box strapper machine is a great tool to have in your arsenal. These machines offer several benefits that make them invaluable for businesses ranging from small mom-and-pop shops to large warehouses. Here are seven advantages of using a box strapper machine:

Increased Efficiency

Using a box strapper machine to secure boxes for shipment can be significantly faster than manually fastening them with tape or other materials. Additionally, many machines are designed to produce uniform straps that are consistently tight and secure, meaning you won’t have to worry about over- or under-tightening them during the process.

Improved Safety

Box strapper machines reduce the risk of injury by eliminating the need to manually pull tight straps or tape around boxes. This helps to eliminate back injuries and repetitive stress injuries that are common when completing this task manually.

6.What Are The Different Types Of Box Strapper Machines Available On The Market?

There are a variety of box strapping machines available on the market for various tasks. Depending on your needs, you may require one type over another. Here is a look at some of the different types of box strapper machines that are available to use:

Automatic Box Strapper Machine

An automatic box strapper is a more advanced type of machine that can efficiently and quickly strap boxes with straps. It has an automated system that allows it to automatically measure the size and shape of boxes, adjust the tension, and apply the straps in one swift motion. This type of machine is perfect for companies that have high volumes of boxes to strap.

Manual Box Strapper Machine

A manual box strapper is a traditional type of machine that uses hand-operated tensioners to manually secure straps around the boxes. It’s an ideal solution for small businesses or those who don’t need to consistently strap large quantities of boxes.

Semi-Automatic Box Strapper

A semi-automatic box strapper is a combination of the manual and automatic box strapping machines. It features both manual tensioners and an automated system to measure boxes and strap them with straps quickly. This type of machine is perfect for companies that have moderate volumes of boxes to strap.

Portable Box Strapper Machine

This type of machine is powered by an internal battery and can be used in remote locations where a power source is not available. This machine is ideal for applications that require quick and easy strapping of boxes on the go.

7.What Is The Difference Between Manual And Automatic Box Strapper Machines?

The difference between manual and automatic box strapper machines lies mainly in their operation. Manual machines require an operator to operate the machine, manually feed the straps through the box and activate the machine by pressing a button. Automatic box strapping machines are much more automated, using motors, sensors and other technologies to automatically strap boxes with minimal human intervention.

Manual box strapping machines are more cost-effective but require a larger amount of human labor and time to operate. Automatic box strappers, on the other hand, are much faster and more efficient than manual machines, but they can be expensive upfront due to the technology involved. Ultimately it depends on your needs when deciding which type of machine is best for you.

Manual box strappers are ideal for small businesses with a low number of boxes to be strapped, while automatic machines are suitable for larger businesses that process high volumes of packages and need to save time and costs. Manual machines are also more reliable because they don’t require any additional technology or power supply and can be used in any environment or location.

8.What Types Of Products Can Be Strapped Using A Box Strapper Machine?

A box strapper machine can be used to strap a range of different items. The most common products that are strapped by these machines are boxes and packages, include:

Food Items

Bulk food items such as cans, bottles, cartons and boxes of food can be strapped with a box strapper machine. This is often used in the grocery industry to keep products securely packaged before shipping.

Mail and Paper Products

Post office boxes or packages of mail are usually secured with straps for easy transport. Strapping is also used on cardboard products like paper, envelopes and folders to prevent them from spilling out of their packaging during transit.

Electronic Goods

Items such as computers, electronics and other delicate products can be strapped with a box strapper machine for extra protection against damage. This ensures that the goods arrive safely to their destination without any damage.

Furniture

Many pieces of furniture, such as chairs and tables, require strapping for secure transportation. A box strapper machine can help to ensure that furniture pieces remain securely strapped together and in place during transport.

Clothing

Garments and clothing items are often strapped together with a box strapper machine for easy transport. It also helps to keep them from getting mixed up when being shipped or stored.

Toys

Toys, such as dolls and action figures, can be secured with a box strapper machine. This keeps them safe and secure during shipping or storage, reducing the risk of breakage.

Syrup

Large containers of syrup and other liquids can be strapped with a box strapper machine to keep them securely sealed and protected against spills or leaks.

Capsules

Small capsules, such as pills, vitamins and medicines, can be strapped together with a box strapper machine for easier transport and storage. This keeps them from getting mixed up or damaged during transit.

9.What Are The Different Types Of Packaging Materials That Can Be Used With A Box Strapper Machine?

When using a box strapper machine, you need to choose the right type of strap material for the job. There are a few different types of straps that can be used with a box strapping machine depending on what kind of job you want it to do.

Polypropylene (PP) Straps

Polypropylene is the most commonly used type of strap for box strapping machines. It’s a strong, lightweight and durable material that can be heat-sealed or crimped. It also has excellent resistance to weathering, chemicals, UV radiation and abrasion. It’s widely used for general packaging applications.

Polyester Straps

Polyester is a strong and lightweight material that’s highly resistant to wear, tear and chemicals. It also offers excellent elongation properties, allowing it to stretch slightly when tensioned. Polyester is often used for heavy-duty applications such as palletizing or bundling large items.

Steel Straps

Steel straps provide superior strength and are ideal for use in harsh environments where other materials may not be suitable. Steel is also highly resistant to corrosion and abrasion, making it a great choice for outdoor applications.

Fabric Straps

Fabric straps are also used in some applications, but they are not as common. They provide a higher level of security than plastic straps and can be found in various colors, designs, sizes and strengths. Fabric straps should only be used with manual strapping machines.

10.How Do You Troubleshoot Common Problems With Box Strapper Machines?

The first step in troubleshooting any issue with a box strapper machine is to ensure that the straps and film are loaded correctly. Check the tension on the strap and the size of the strap to make sure they meet the manufacturer’s specifications. If not, adjust accordingly. Another common issue is when straps do not get fed or are cut off. Ensure the feed mechanisms are working properly and that no foreign objects, such as dirt or dust, are blocking the movement of parts. Make sure all components of the machine, including rollers and strapping units, are adjusted correctly.

If you’re still having trouble after making these adjustments, it’s time to inspect the machine for more serious issues. Check for worn or damaged parts, and look for jammed straps in the strapping unit. If you suspect a mechanical issue, contact the manufacturer to get it resolved as soon as possible.

Finally, if you’re still having trouble, you may need to call a technician for further troubleshooting. The technician can help determine the cause of the problem and help you make repairs.

11.Are There Any Tips On How To Maximize The Efficiency Of A Box Strapper Machine?

Make sure the machine is level

Before you use your box strapper machine, it’s important to make sure that it is properly leveled on the floor or surface. This helps ensure that the straps are applied with good tension and will help prevent any issues with misaligned boxes and unequal tension.

Check the strap tension

Regularly check the tension of your straps to make sure they’re not too tight or too loose. This will help ensure that your boxes are securely fastened without damaging any of the goods inside.

Adjust box size accordingly

If you have different sized packages, adjust the machine settings so that it can accommodate the different sizes. This will save you time and help you to maximize the efficiency of your machine.

Regularly clean your machine

Keep your box strapper machine clean and lubricated by regularly wiping it down and applying a good quality lubricant. This will make sure that any dirt or dust doesn’t interfere with the machine’s operation and will ensure it works at maximum efficiency.

Use quality parts

Make sure that you use quality parts when it comes to replacing any components on your box strapper machine. Genuine manufacturer parts are usually preferable, as they are designed specifically for the machine and will often last longer than third-party parts.

Monitor your straps

Make sure to monitor the straps regularly, as they are prone to wear and tear. If you notice any fraying or thinning of the material, replace them as soon as possible for maximum efficiency.

Properly store strapping materials

Make sure that you store all of your strapping materials properly, as they are susceptible to damage if exposed to moisture or extreme temperatures. This will help you maximize the efficiency of your box strapper machine and ensure that you don’t have any problems with straps coming loose in transit.

Conclusion

Box strapper machines have changed the way we package materials with increasing speed and accuracy, making them an essential part of any company’s production in 2025. From selecting the right size machine to understanding innovative labeling technologies, this buying guide has provided a 360-degree view of purchasing a box strapper machine. With this knowledge in hand, you can find a strapper that meets your business needs without having to compromise on quality. If you’re still undecided after reading this guide, reach out to Allpack for a consultation and get personalized advice about what box strapper machine is right for you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide