Commercial Vacuum Sealing Machine:The Complete Buying Guide in 2025

With the ever-evolving food processing industry, new solutions are emerging to help businesses improve their productivity and efficiency. One of these powerful solutions is a commercial vacuum sealing machine. This innovative piece of equipment can help companies preserve and protect their products for longer periods of time by creating an airtight seal that eliminates oxygen from the package. Not only does this allow for increased shelf life and flavor retention, but it also has numerous other benefits that contribute to organizations’ success!

In this comprehensive guide, we will be delving into everything you need to know about purchasing a commercial vacuum sealing machine—from advantages and product types to features you should look out for when shopping around. Ready? Let’s get started!

1.What Is A Commercial Vacuum Sealing Machine?

A commercial vacuum sealing machine is a specialized device used to securely seal food items and other objects in airtight plastic packaging. The process of vacuum sealing is achieved by extracting all the air from the bag or container, which effectively eliminates the chances of spoilage due to oxidation.

Commercial Vacuum Sealing Machines are designed for heavy-duty use and are capable of quickly and efficiently sealing bags or containers of various sizes. These machines come in a variety of models, ranging from manual to electric-powered, and can handle the needs of commercial businesses with ease. With their wide range of features and options, these machines are essential for any business looking to preserve food items or other products for longer periods of time. If you’re looking for an efficient and reliable way to preserve your food or products, investing in a commercial vacuum sealing machine is the way to go.

2.What Are The Different Components Of A Commercial Vacuum Sealing Machine?

A commercial vacuum sealing machine consists of three main components that work together to effectively seal food items. These components include:

Vacuum Chamber

This is the inner part of the machine where the bag and product are inserted. It contains a powerful, yet quiet vacuum pump that works to reduce oxygen levels within the chamber and create an airtight seal for your product. The size and shape of the vacuum chamber will vary depending on the size and type of product that needs to be sealed.

Film Roll Holder

This is a bracket or track system designed to hold the plastic film rolls for your machine. The holder also helps position and feed the film into the sealer’s heating bar so it can create an airtight seal.

Sealing Bar

This is the part of the machine that applies heat to the plastic film in order to create an airtight seal. The length and position of your sealing bar will also depend on the size and type of product that needs to be sealed.

Control Panel

The control panel is where all the settings for the machine are regulated. It allows you to adjust parameters such as heat and vacuum levels, seal time, and other functions.

Safety Pressure Release Valve

This is a safety feature that prevents over-pressurizing within the chamber. If too much pressure builds up inside the chamber, this valve will open and release it from the chamber, preventing any damage to the product or equipment.

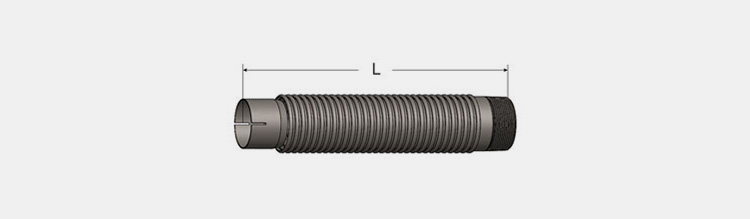

Exhaust Hose

This is a flexible hose that connects the vacuum sealing machine to an exhaust port or outlet. It helps remove air and excess pressure from within the chamber during the sealing process, ensuring a clean and consistent seal every time.

3.How Does A Commercial Vacuum Sealing Machine Work?

A commercial vacuum sealing machine works by removing air from a sealed pouch or container, which helps preserve food for longer periods of time. The process begins with the item to be vacuum sealed and placed into a pouch or special container. Then, the pouch is loaded into the vacuum sealing machine and the lid is closed.

Once the lid is closed, the vacuum chamber is sealed and a vacuum pump is activated. The pump works to remove the air from inside of the pouch or container. As pressure builds up in the chamber, it forces the air out of the pouch or container through a one-way valve which does not let any new air enter back into the system. This creates an air-tight seal that keeps food fresh for a longer period of time.

At the end of the process, the machine releases the vacuum and automatically opens its lid, allowing you to remove your sealed pouch or container with your food items preserved inside. With a commercial vacuum sealing machine, you can extend the shelf life of food products by up to five times the original amount of time.

The process makes it easier to store and preserve food products in restaurants, catering, and other food service establishments. Vacuum sealing machines are also used for packaging and sending out items such as documents or tools that need to be protected from moisture or dust.

4.What Are The Applications Of A Commercial Vacuum Sealing Machine?

A commercial vacuum sealing machine can be used for a wide range of applications, from food packaging and preserving to medical equipment storage. Here are some of the main uses of a vacuum sealing machine:

Food Packaging and Preservation

Vacuum sealing is an efficient way to store perishable food items such as meat and vegetables for extended periods of time. By removing the oxygen from the package, it inhibits bacterial growth and preserves the flavor and nutrition of the food. It also prevents freezer burn caused by dehydration.

Medical Equipment Packaging

A commercial vacuum sealing machine is often used to store and protect delicate medical equipment such as IV bags, surgical gowns, and gloves in sterile environments.

Dry Goods Packaging

Vacuum sealing is also used to store and protect dry goods such as electronics, documents, and pharmaceuticals from environmental factors such as humidity, moisture, dust and dirt. This ensures they remain in a pristine condition while in storage or transit.

Automotive Parts Storage

Vacuum sealing is also ideal to store and protect automotive parts such as brakes, filters, spark plugs, and accessories for extended periods of time. This helps maintain the quality and integrity of the parts until they are needed in a repair or replacement.

Cosmetic Packaging

Another application for commercial vacuum sealing machines is to store and protect cosmetics such as creams, lotions, and perfumes. By keeping these products sealed in a dry environment, it helps prevent them from spoiling and ensures they remain fresh for longer.

Household Use

When it comes to household use, vacuum sealing can be used to store and protect items such as clothing, blankets, and linens from dust and moths. This helps protect the item from moisture, dust, dirt and insects.

Artwork Preservation

Vacuum sealing is also used for preserving valuable artwork such as paintings, photographs, and other collectibles from the elements. It helps maintain the integrity of the item over time.

5.What Are The Advantages Of Using A Commercial Vacuum Sealing Machine?

The use of a commercial vacuum sealing machine comes with a variety of advantages. It can be used to extend the shelf life of food products, store items in an airtight and moisture-free environment and protect delicate items from damage.

Extending Shelf Life

By removing air and moisture from the packaging, it significantly extends the shelf life of food products such as meat, cheese, fruits and vegetables. The lack of oxygen in the package helps to prevent oxidation, bacterial growth and dehydration. This increases the amount of time that perishables can stay fresh and safe for consumption.

Airtight and Moisture-Free Environment

As commercial vacuum sealing machines create an airtight and moisture-free environment, they are ideal for storing items in a variety of ways. This is beneficial for different industries such as the medical industry where sterile conditions are necessary to maintain safety standards or in the food industry where airtight and moisture-free packaging ensures food safety.

Cost Reduction

Vacuum packing also helps to reduce costs associated with shipping and storage of goods. By removing the air from a package, it reduces its size and weight, allowing for more products to be shipped at one time and with less packaging materials.

Space Saving

Vacuum packing save space, as items can be stacked more easily in a smaller package. This helps to reduce the amount of storage space needed for products and makes it easier to transport them from one place to another. With less packaging materials being used, this also reduces waste.

Improved Quality

Vacuum packing also helps to improve the quality of products by eliminating air and moisture from the packaging. This helps to ensure that food products stay fresher for longer, making them more appetizing and enjoyable for customers.

Versatility

Vacuum packing machines are also versatile, and can be used to package a variety of products. This makes them an ideal choice for many different industries, including the food industry, medical industry, cosmetics industry and more.

Safety

Vacuum packing helps to ensure the safety of food products by eliminating contaminants from the packaging. This reduces the risk of food-borne illnesses, helping to keep customers safe while they consume food products packed in this manner.

Efficiency

Vacuum packing improves the efficiency of food production by allowing for more products to be packed in a shorter amount of time. This helps to increase productivity and minimize downtime, resulting in greater profits for businesses.

6.What Are The Different Types Of Commercial Vacuum Sealing Machines Available?

Chamber Commercial Vacuum Sealing Machines

Chamber vacuum sealers are the most commonly used type of commercial vacuum sealing machines due to their ability to consistently seal products in an airtight environment. The chamber is filled with air and then sealed shut, creating a vacuum inside while removing all the air from the outside of the product being sealed. These machines offer superior performance and can be used to seal a variety of products, including food, medical supplies, and other items.

Handheld Commercial Vacuum Sealing Machines

Portable vacuum sealers are beneficial in cases where portability is more important than volume production capabilities. These machines are lightweight and compact, making them ideal for sealing products in the field or during travel. While these machines may not offer the same performance as their larger chamber-style counterparts, they are a great option for those who need to seal items on-the-go.

Double Chamber Commercial Vacuum Sealing Machines

Double chamber vacuum sealers are similar to chamber vacuum sealers, but they offer an extra layer of protection by sealing two sides of the bag at once. These machines are designed for larger and heavier products that require additional air tightness, such as frozen foods or medical supplies.

7.What Types Of Products Can Be Sealed With A Commercial Vacuum Sealing Machine?

Vacuum sealing machines are becoming increasingly popular as a method of food preservation, as they can keep food items fresh for longer. But that isn’t the only type of product which can be sealed with a commercial vacuum sealing machine. In fact, there are many other products that benefit from being vacuum sealed in order to extend their life and maintain their quality.

Here are some of the types of products which can be sealed with a commercial vacuum sealing machine:

Meat

Vacuum sealing machines are great for preserving red and white meats, including beef, pork, chicken, fish and game. Meat sealed in a vacuum bag reduces the amount of oxygen that is present which slows down spoilage and helps to keep it fresh for longer.

Herbs

Herbs such as sage, oregano and thyme are often dried and stored in jars or containers. However, vacuum sealing them instead will keep all the flavor and aroma of the herbs intact until they are ready to be used.

Cheese

Cheeses can also benefit from being vacuum sealed. Cheese is a living product which continues to ripen over time, so vacuum sealing it can help to slow down the ripening process and keep it fresh for longer.

Fruits & Vegetables

Fruits and vegetables also degrade quickly as they start to rot. Vacuum sealing them helps to reduce oxygen levels, slowing down the rotting process so they stay fresher for longer.

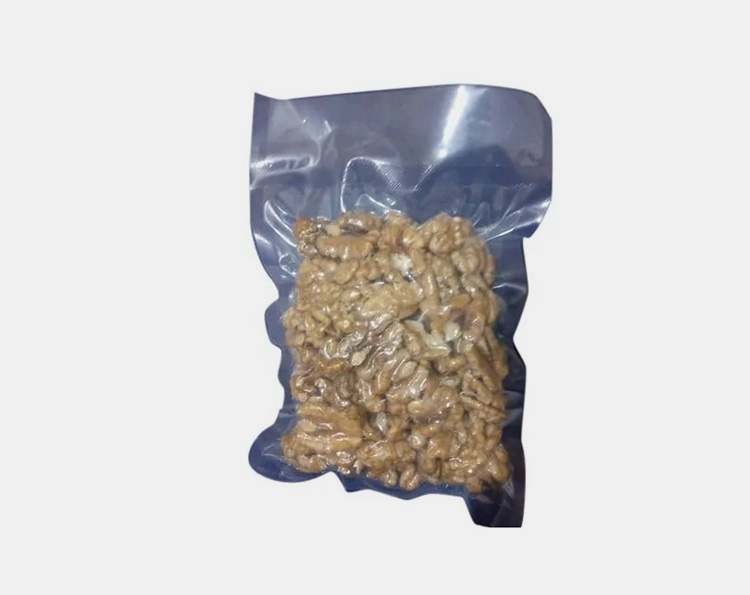

Nuts & Seeds

Nuts and seeds can also be vacuum sealed to help them stay fresh for longer. This is especially important for nuts such as almonds and walnuts, which are high in fat and therefore more prone to going rancid quickly.

Coffee Beans

Coffee beans are another product which can benefit from being vacuum sealed. This will keep them fresher for longer, as it prevents air and moisture from getting into the bag and causing the beans to become stale.

Electronics

Vacuum sealing electronics can help protect them from water damage, dust, and corrosion while they are stored or transported. This is especially important if you are transporting fragile items over long distances.

Documents

Documents such as birth certificates, passports, and other valuable papers can be vacuum sealed in order to protect them from water damage or accidental destruction. This is also especially important for documents which are frequently transported or handled by multiple people.

Clothing

Vacuum sealing clothing can help keep them clean and free of dust, dirt, and other debris which can damage the fabric over time. It also helps protect delicate items such as lace or silk from being damaged while in storage or transport.

8.Are There Different Types Of Bags That Can Be Used With A Commercial Vacuum Sealing Machine?

When selecting a commercial vacuum sealing machine, it’s important to know the types of bags material that can be used. The most commonly used materials include:

Polyethylene (PE)

PE is the most commonly used bag material for vacuum sealing machines. It is an economical choice and provides excellent airtightness, moisture resistance, and a long shelf life for your food. It is also FDA-approved for direct contact with food.

Mylar

Mylar is a more expensive option that provides superior airtightness and moisture resistance, making it ideal for products such as coffee beans or herbs that need to be stored in an oxygen-free environment.

Polypropylene (PP)

PP is the most heat-resistant bag material and can withstand temperatures of up to 200°C. This makes it ideal for sous vide cooking, as well as food packaging and medical device sterilization.

Polyvinylidene chloride (PVCD)

PVCD is a durable and flexible material that provides excellent airtightness and moisture resistance, making it suitable for products such as vacuum-sealed meats.

Nylon

Nylon is a strong and flexible bag material that is popular for storing products such as nuts and dried fruits. It provides good airtightness, moisture resistance, and puncture resistance.

9.What Size Of Bags Can Be Used In A Commercial Vacuum Sealing Machine?

When it comes to vacuum sealing, size matters. You need the right size bag in order to make sure your food stays fresh and that your seal is airtight. So what sizes of bags can you use in a commercial vacuum sealing machine?

The most common bag sizes used in commercial machines are 8×10 inches, 11×14 inches, and 12×20 inches. These sizes are perfect for sealing bulk items like fruits and vegetables, meats, cheeses, and more.

The 8×10 inch option is ideal for small items like nuts or jerky. The 11×14 inch bag is good for larger items such as steaks or batches of cooked casseroles. And the 12×20 inch bag is perfect for storing larger amounts of food, like a whole roaster chicken or an entire tray of lasagna.

If you need to seal something larger than these sizes, you can also purchase special oversized bags. These are designed to fit in standard machines but are large enough to hold larger items, like a whole turkey or a side of salmon.

No matter what size bag you need, there is an option that will fit perfectly in your commercial vacuum sealing machine. Just make sure to check the size of your machine before purchasing any bags. That way, you can have peace of mind knowing that everything will fit perfectly and all your food will stay fresh and sealed.

10.Are There Any Tips To Make Using A Commercial Vacuum Sealing Machine Easier And More Effective?

Yes, there are a few tips that you can use to make using a commercial vacuum sealing machine easier and more effective.

First, before you start any vacuum sealing process, take the time to read through your machine’s owner manual so you have an understanding of how it works and what its capabilities are. This will help ensure that you are using your machine to its full potential.

Second, use high-quality bags and rolls when vacuum sealing your food items. Low-quality bags can be torn during the process, resulting in a weakened seal or even a compromised package. Look for quality packaging materials that are specifically designed to work with your machine’s settings and capabilities.

Finally, if you’re having difficulty getting a good seal, check the settings on your machine. You may need to adjust the temperature or pressure settings in order to achieve the desired result. Additionally, make sure that no air is being trapped in the bag before sealing it by pressing out any air bubbles with your hands.

11.What Is The Expected Shelf Life Of A Product Sealed In A Commercial Vacuum Sealing Machine?

When using a commercial vacuum sealing machine on your products, the shelf life can vary depending on the exact product that you are sealing. Generally speaking, vacuum sealed food products will last around two to three times longer than their non-vacuum sealed counterparts.

Other items such as documents and fabrics may last significantly longer when vacuum sealed due to the lack of oxygen and the protective barrier created. Vacuum sealed items should always be stored in cool, dry conditions to ensure maximum shelf life is achieved. However, if you have any questions about the expected shelf life of a particular product sealed in a commercial vacuum sealing machine, it’s best to consult with your local packaging supplier or industry expert for accurate information.

12.Are There Any Common Issues With Commercial Vacuum Sealing Machines And How Can They Be Fixed?

Malfunctioning Gaskets

A malfunctioning gasket is one of the most common issues to be found in commercial vacuum sealing machines. This issue can easily prevent the machine from achieving a proper airtight seal, and it can also cause leaks or other irregularities when attempting to use the vacuum function.

Solution: To fix this issue, you should replace the gasket if it is worn or damaged. If that doesn’t solve the problem then it could be a blockage in your vacuum system and you may need to take apart and clean all of the components.

Clogged Vacuum Hose

A clogged vacuum hose can cause a wide range of problems in your commercial vacuum sealing machine. It can prevent the machine from achieving a proper seal or complete the vacuuming process at all.

Solution: You should take apart your vacuum hose and clear out any blockage that is preventing air flow. You may need to use a brush or other cleaning tool to get rid of any built-up debris.

Poor Power Supply

If your commercial vacuum sealing machine isn’t receiving enough power, it won’t be able to complete the vacuuming or sealing process properly. This can lead to weak seals and other issues that prevent your food from being properly stored in a vacuum sealed bag.

Solution: Make sure that you are providing the machine with enough power by checking the voltage and ensuring that all of your wiring is in good condition. If there appears to be an issue, then you may need to replace any faulty wires or components before attempting to use the machine again.

Mechanical Problems

Sometimes mechanical issues can prevent your vacuum sealing machine from working properly. This could be anything from a worn-out belt to a malfunctioning valve or switch.

Solution: Depending on the issue, you may need to check and adjust all of the mechanical components in order to get your machine back up and running again. If all else fails then it might be time for a replacement part.

Conclusion

No matter the business you are in, a quality commercial vacuum sealing machine is an excellent investment. With this tool, you can preserve your product’s shelf life and ensure its freshness for customers. In this guide, we went over all the features to consider before making your purchase. We also reviewed some of the best machines on the market. Allpack has a wide selection of high-quality machines that will suit any business need. If you have any questions or would like help choosing the right machine for your business, please contact us today. Our experts would be happy to assist you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide