Auger Filling Machine:The Complete Buying Guide in 2025

Auger filling machines are used in today’s automated industries to provide consistent and efficient distribution of powdered-based products such as spices, chemicals, and even coffee. The process not only improves the overall production time but also provides a much higher level of accuracy, making them ideal for high-volume applications.

So, if you are looking to invest in an auger filler machine this year, then you have come to the right place. In this complete buying guide, we will provide you with all the necessary information and considerations you need to make when selecting an auger filler appropriate for your individual needs in 2025. Let’s get started!

1.What Is an Auger Filling Machine?

An Auger Filling machine is a type of automated filling equipment that uses precision augers to fill containers with precise amounts of product. This type of machine offers accurate and consistent dosing with low material wastage, making it an ideal choice for production lines where accuracy and efficiency are essential. The Auger Filler can also be programmed to fill containers with a variety of different materials, from powders and granules to liquids and creams.

With its user-friendly interface and easy setup, the Auger Filler is an excellent choice for businesses that need reliable automated filling solutions. This equipment can also be used in combination with other machines, allowing for a more efficient production process. If you are looking for an effective way to fill containers quickly and accurately, then an Auger Filling machine is the perfect solution. With its precise dosing capabilities and easy setup, it can make all your production needs smoother and faster.

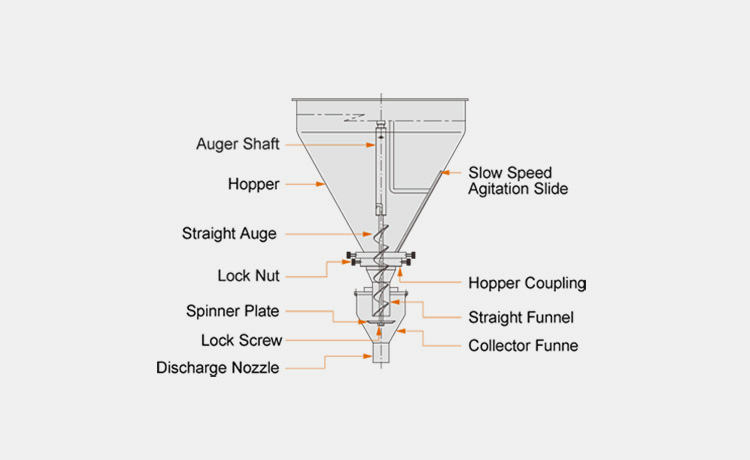

2.What Are The Components Of An Auger Filling Machine?

An Auger Filling Machine consists of several key components that work together to get the job done. The main parts include:

Dispensing Hopper

This is where your product or ingredients are placed before being inserted into the machine. It is typically made of stainless steel and designed with a built-in agitator or shaking mechanism to ensure that the ingredients are properly mixed for accurate filling.

Auger System

This is the main part of the machine, consisting of a rotating screw that pushes products down into the spout and out of the machine. The speed and number of revolutions can be controlled by adjusting the speed settings on the auger motor or by changing the auger’s pitch.

Filling Nozzle

A nozzle at the bottom of the auger is used to deposit a precise amount of product into each container or packaging. This is the spout where products are dispensed from the machine. It can be adjusted to different sizes, depending on what you’re filling and how much product you need to fill in a single cycle.

Pneumatic System

The pneumatic system is used to control the speed of the auger. This ensures that the material is evenly and accurately distributed into the container during filling.

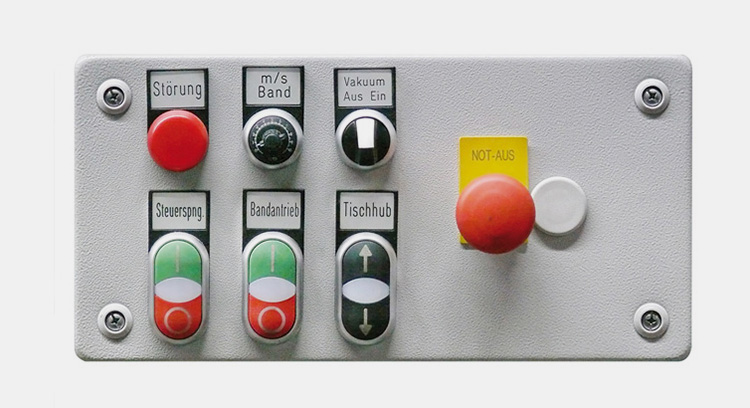

Control Panel

This is where all of the settings and controls for the machine are located so that you can adjust things like auger speed, fill head size, and product control settings. It also houses the safety features for the machine so that it will shut down if something goes wrong.

3.How Does An Auger Filling Machine Work?

An auger filling machine works by using a rotating screw-like device, called an auger, to accurately measure and dispense powder or granular materials. The auger rotates at high speeds to force the material into a container below it. You can control the quantity of material that is dispensed and ensure consistent dosing with an auger filling machine.

The auger itself is typically made of stainless steel and comes in a variety of shapes and sizes, depending on the application. The length and diameter of the auger are determined by the type of material being used, as well as the size of the container that will be filled. The teeth on the auger can also be adjusted to control the density of the material being dispensed.

Once the auger is in position, a container or hopper is placed below it. The hopper can be filled with powder or granular materials, depending on what the machine is set up to do. As the auger rotates, it forces measured amounts of material into the container below it.

Once the desired amount of material has been dispensed, a mechanical arm is used to move the container out of the way and prepare for the next filling operation. The auger continues to rotate until all material has been transferred from the hopper into containers. This process can be repeated multiple times in order to quickly fill multiple containers.

4.What Are The Different Types Of Auger Filling Machines?

Auger filling machines are incredibly versatile and can be used to fill a wide variety of products. Different types of auger filling machines offer various advantages depending on the type of product being filled. Here is a list of the different types of auger filling machines and what they are best suited for:

Volumetric Auger Filling Machines

Volumetric auger filling machines are ideal for products that require an accurate fill weight, such as food items, chemicals, and pharmaceuticals. These machines use a spinning auger to quickly and precisely load the product into containers. They can be further customized with features like scales, air sensors, and vacuum systems to ensure accuracy and consistency.

Semi-Automatic Auger Filling Machines

Semi-Automatic auger filling machines are ideal for products with a wide range of viscosities, such as lotions and creams. They feature several adjustable parts that allow for the precise filling of different product types. Additionally, these machines have no moving parts, reducing the risk of contamination and the amount of maintenance required.

Continuous Motion Auger Filling Machines

Continuous motion auger filling machines are perfect for high-speed production lines, as they can fill up to 600 containers per minute. They use a continuous motion system that allows for products with a wide range of viscosities to be accurately and quickly filled. Additionally, these machines can be customized with automated inspection systems to ensure accuracy and quality.

Multi-Head Auger Filling Machines

These machines are perfect for filling multiple containers at the same time. They feature several augers that can fill up to 10 containers simultaneously and are capable of accurately controlling the speed, volume, and weight of each container. Additionally, these machines are equipped with a variety of automated features that allow for precise control over the entire process.

5.What Are The Applications Of An Auger Filling Machine?

An auger filling machine has the ability to fill products into containers at a precise rate, ensuring accuracy and consistency every time. Here are some of the key applications for auger filling machines:

Food processing

Auger fillers are commonly used in the food processing industry to accurately portion different types of solid products such as grains, powders, and pastes. That allows for consistent production and packaging of the food product.

Pharmaceuticals

Precision is key when it comes to pharmaceutical products. So, auger fillers are often used to package drugs and supplements due to their precise filling capabilities. This ensures that each product contains the same proportion of ingredients each time.

Cosmetic/Personal-Care Products

Auger fillers are great for filling jars and bottles with liquid cosmetics such as lotions and creams. The machine can accurately dispense the right amount into each product, providing a consistent quality of goods every time.

Veterinary Medicine

Auger fillers are also used in veterinary medicine to dispense medication accurately for animals. This ensures that the animal receives the correct dosage each time.

Agricultural & Gardening Products

Auger filling machines are used to fill containers with dry products such as fertilizers, pesticides, and soil conditioners. This ensures accurate measurement of the product for optimal results.

Automotive Industries

Auger fillers are also used in automotive industries for filling lubricants and other liquids into components. This allows for quick and accurate mass production of products, ensuring efficient operation.

6.What Are The Advantages Of An Auger Filling Machine?

When it comes to filling products, an auger filling machine is the top choice for many businesses. Here are seven of the advantages associated with an auger filling machine:

Efficiency

Auger filling machines are designed to be incredibly efficient, allowing for quick and easy production time that can fill a large number of containers in a short amount of time while still ensuring accuracy. This makes them an ideal choice for larger companies looking to speed up their production processes.

Versatility

Auger filling machines are incredibly versatile, with the ability to be used for a variety of products ranging from food and beverage items to pharmaceuticals and chemicals. This makes them ideal for businesses that may need to produce a wide range of goods.

Reliability

Auger filling machines are designed to last, so you can count on them, providing consistent results for a long time without needing to repair or replace them. This can save your business money and time in the long run.

7.What Kind Of Material Can Be Used In An Auger Filling Machine?

An auger filling machine is a versatile tool for packaging and production lines. You can use it to dispense many different kinds of materials, including powders, granules, pastes, and liquids.

Powders

Powdered products like spices, flours, baby powder, and nutritional supplements are easy to package with an auger filling machine. The auger pushes the powder through a tube, ensuring accurate amounts are dispensed into each container.

Granules

Foods like cereals, grains, and muesli can also be packaged with an auger filling machine. You can also package things like nuts, sugar, and candies.

8.What Types Of Products Can Be Filled By an Auger Filling Machine?

The most common types of products that can be filled with an auger filling machine include:

Spices

Spices, such as table salt and pepper, can be quickly and reliably filled into packaging with an auger filling machine. The accuracy of the machine ensures that each container is filled to the same level.

Flour

Flour is a lightweight, powdery product that requires a precise filling level. An auger-filling machine can quickly and accurately fill containers with flour for bakery or packaged goods purposes.

Rice

Rice, both white and brown varieties, can be quickly filled into packaging with an auger filling machine. The accuracy of the machine ensures a consistent fill level for each container.

Coffee

Ground coffee beans require a precise filling level for each container. An auger-filling machine can quickly and accurately fill containers with ground coffee in an efficient manner.

Oats

Oats can be filled quickly and accurately with an auger-filling machine. The accuracy of the machine helps ensure a consistent fill level for each container.

Sugar

Granulated sugar, powdered sugar, or confectioners’ sugar requires accurate filling levels to maintain product consistency. An auger filling machine can quickly and reliably fill containers with sugar in an efficient manner.

Hair Styling Products

Hair styling products, such as gels, mousses, and waxes can be filled quickly and accurately into packaging with an auger-filling machine. The accuracy of the machine ensures that each container is filled to the same level.

Nuts

Nuts, such as almonds, cashews, and walnuts, require a precise filling level for each container. An auger-filling machine can quickly and accurately fill containers with nuts in an efficient manner.

Fertilizer

Fertilizers can be quickly and accurately filled into packaging with an auger filling machine. The accuracy of the machine ensures that each container is filled to the same level.

9.How Is An Auger Filling Machine Different From Standard Filling Machines?

An auger filling machine is different from standard filling machines in a few key ways. First, an auger filling machine uses a rotating screw-like device to dispense product into containers, whereas standard filling machines use a piston-driven mechanism. This makes auger fillers ideal for free-flowing products that are too thick or viscous for standard filling machines, such as peanut butter, ketchup, and hummus.

Another difference between an auger filler and a standard machine is that the former has faster speeds. Auger filling machines can fill up to 100 containers per minute, whereas standard machines top out at around 60-70 containers per minute. This makes auger fillers a great choice for businesses looking to increase their production speed.

Finally, an auger filling machine is also more accurate than standard machines when it comes to dosing. Auger fillers use digital control systems that allow for precise and consistent product doses, whereas standard filling machines are typically less reliable in this regard. That makes auger fillers the ideal choice for businesses that prioritize accuracy and consistency in their products.

10.How Do You Choose Between Manual And Automatic Auger Filling Machines?

When it comes time to choose between manual and automatic auger filling machines, you have to consider the quantity of product that needs to be filled, the speed at which it needs to be done, and the cost.

If you’re dealing with a large volume of product that needs to be filled quickly and cost-effectively, an automatic auger filling machine might be the best option. Automatic auger filling machines are generally faster and more efficient than manual models, allowing you to fill more product in less time.

On the other hand, if you’re dealing with smaller or varying quantities of product that need to be filled at a slower rate and cost isn’t a major concern, then a manual auger filling machine might be the better option. Manual models are more cost-efficient and offer greater flexibility with product types and quantities.

It’s important to consider your goals when making this decision so that you can make an informed choice about which type of auger filling machine is right for you. Consider the type, quantity and rate at which your product needs to be filled in order to make the best decision.

11.How Can I Maximize The Performance Of An Auger Filling Machine?

When operating an auger filling machine, the key to maximizing its performance is to ensure that you follow the manufacturer’s instructions closely. Make sure all settings are correct, and all components are properly adjusted. Check the machine periodically for wear or damage and replace any necessary parts regularly. Ensure that your environment is clean and free of dust and other debris which may affect the machine’s performance.

Furthermore, ensure that your product is continually monitored to make sure that it meets quality standards and to detect any discrepancies which may signal a problem with the auger filling machine. In addition, be sure to use new and properly stored ingredients when loading material into the machine.

Finally, take steps to ensure proper maintenance so that your machine can perform at peak efficiency. Regularly check for blockages or debris build-up, clean and oil any bearings, and make sure all parts are functioning properly.

12.What Are The Maintenance Requirements For An Auger Filling Machine?

Regular Cleaning

To prevent residues from building up and reducing the efficiency of your machine, regular cleaning is important. Make sure to clean out any debris that builds up in the auger or screw conveyor before it becomes a problem.

Oil Changes

Auger filling machines should be oiled regularly to ensure optimal performance. It’s best to change the oil every few months or as recommended by the manufacturer.

Auger Replacement

Depending on usage and wear, augers should be changed out with new ones once a year or more frequently if necessary. This helps to maintain filling accuracy and reduce downtime due to problems caused by worn parts.

Regular visual inspections

To ensure that the Auger Filling Machine is functioning correctly and that all parts are secure and working properly, conduct regular visual inspections of the machine to scope out any potential problems.

Proper Storage

To prevent damage from occurring, your machine should always be stored in a dry, dust-free environment. If possible, try to store it away from extreme temperature changes as this can cause problems with the seals and other components.

Preventive Maintenance

To avoid unexpected downtime, it is important to have regular preventive maintenance performed. This includes changing out worn parts and checking for any signs of wear or damage that could affect the performance of the machine. Doing this will help keep your production running smoothly and efficiently.

Regular Calibration

Make sure that you are regularly calibrating your auger filling machine in order to maintain accuracy. Doing this will help you avoid overfilling or underfilling and ensure that your products meet quality standards.

13.How Can I Troubleshoot Common Issues With an Auger Filling Machine?

When troubleshooting an auger filling machine, it’s important to identify the source of the issue. To do this, take note of any error messages that may appear on the screen and consult your manual if necessary. Additionally, check all external components connected to the machine, such as hoses and vacuum lines. Make sure they’re securely attached and don’t have any visible damage.

Furthermore, it’s also important to check the auger itself – if it’s not functioning properly, you may need to clean or replace it. You can do this by disassembling the machine and cleaning each component thoroughly with a brush and warm water. Additionally, look for worn-out parts or any signs of damage, and replace them if necessary.

Finally, check the settings on the auger filling machine, such as the speed, pressure, and accuracy. Make sure they’re set to their optimal values, as these can affect how well the machine operates. If you’re still having issues after taking all these steps, it’s best to consult a professional for assistance. They can help identify the problem and provide advice on how to fix it.

Conclusion

Investing in an auger filling machine can be a great and worthwhile venture for businesses. However, taking the time to assess each of the important factors is essential for making sure a business’s specific needs are met. That being said, Allpack offers everything from manual to fully automated systems that can meet the needs of any business dealing with auger filling machines in 2025, helping them to remain safe, efficient, and cost-effective. To secure your long-term success when it comes to auger filling machines needed in 2025, please contact us at Allpack today – we’d love to hear from you!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide