Screw Capping Machine: The Complete Buying Guide In 2025

Screw Capping Machine: The Complete Buying Guide In 2025

Are you looking for the perfect solution to your bottle sealing problems? Are you tired of manually trying to screw-cap bottles and striving for a seamless solution? If so, then a screw capping machine is the ideal choice for you.

This type of equipment automatically caps or seals containers using either plastic, metal or composite lids with an airtight seal. It’s highly efficient and can greatly reduce manual labor costs and delivery timeframes without compromising product quality.

In this blog post, we will dive into all there is to know about screw capping machines: from their simple yet powerful technology behind them to their versatility in use cases as well as how they can provide businesses with additional economic benefits. Keep reading to find out more!

1.What Is A Screw Capping Machine?

A screw capping machine is a device that is used to screw caps onto containers such as bottles and jars quickly, safely, and securely. It can be used for a variety of applications including food and beverage production, pharmaceuticals production, cosmetics production, laboratory use, etc.

The screw capping machine uses the latest technology in closure application systems to screw caps on to containers in a secure and efficient manner. It can apply screw caps of varying sizes and types, from plastic screw caps to metal screw caps with ease.

Also, the screw capping machine offers unparalleled accuracy and speed while ensuring the safety of workers and consumers. This type of machinery is highly reliable, easy to use, and cost-effective.

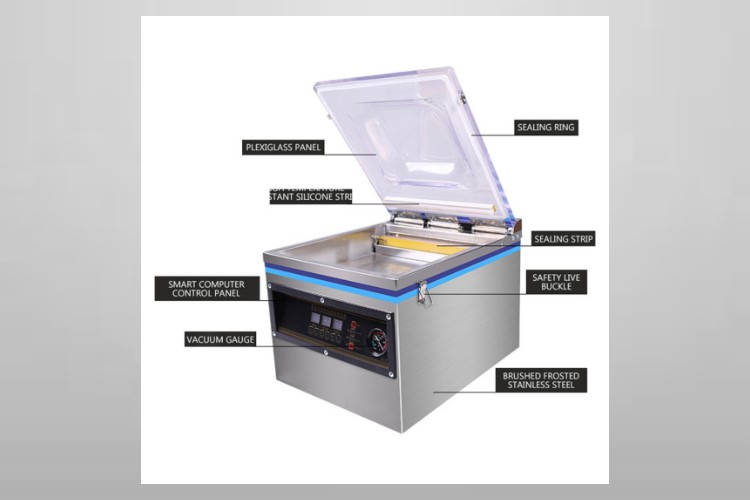

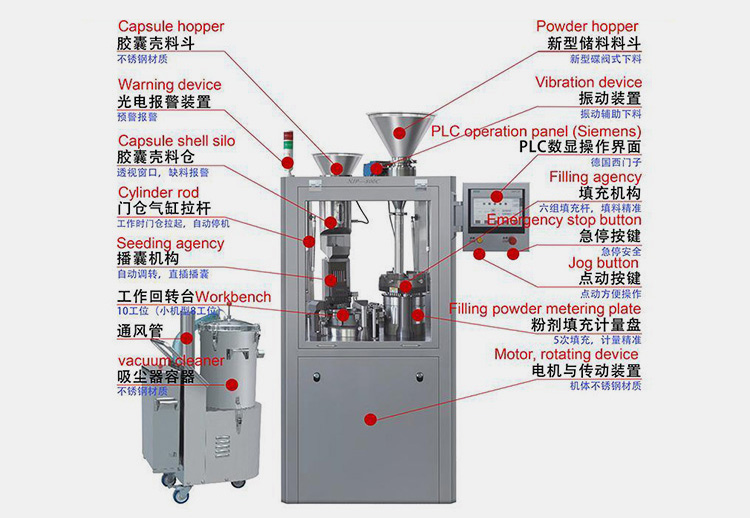

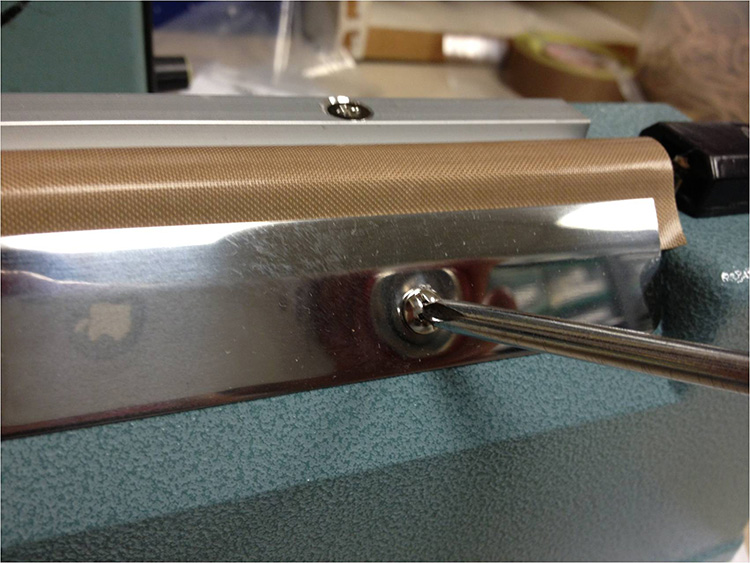

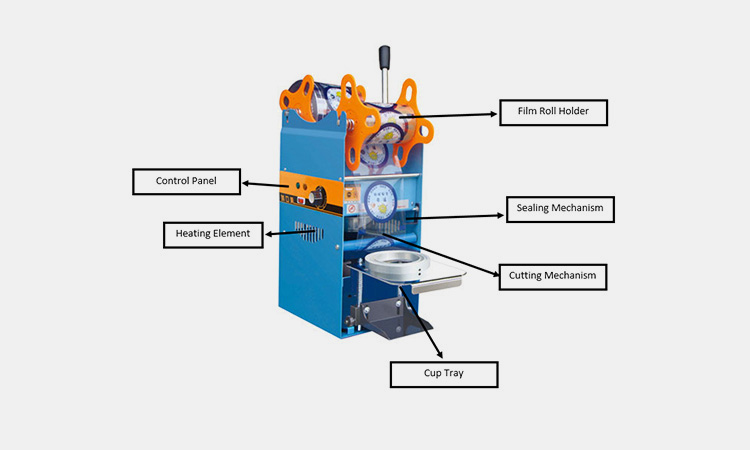

2.What Are The Components Of A Screw Capping Machine?

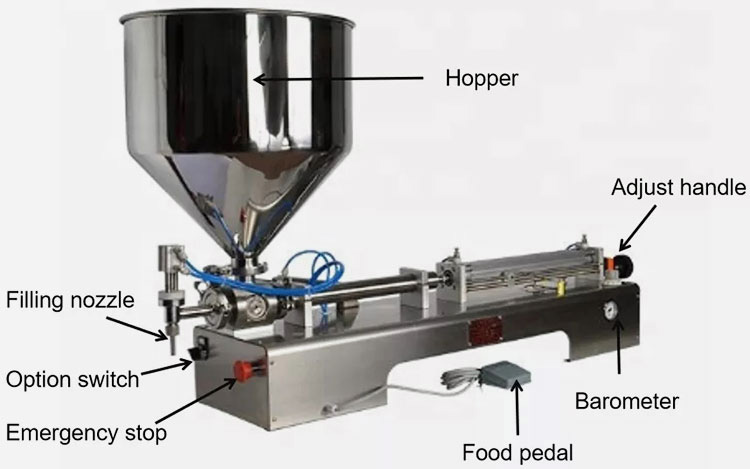

Capping head: The screw capping machine has a capping head which holds the cap and screws it onto the container with a chucking motion.

Container handling system: The screw capping machine also has a container handling system which is used to move containers into position for the screwing process.

Chucks: The screw capping machine has a set of chucks which are used to hold the containers in place while it is being screw capped.

Adjustable speed control: The screw capping machine also has an adjustable speed control, allowing you to adjust the screwing process based on container size and product characteristics.

Cap feeding system: The screw capping machine is also equipped with a cap feeding system which ensures that the right amount of caps are fed into the screwing mechanism.

Torque control system: The screw capping machine has a torque control system which automatically adjusts the screwing process to ensure proper tightening of the screw cap.

Rejection system: The screw capping machine also has a rejection system which kicks out any containers or screw caps that fail to meet quality standards.

3.What Are The Benefits Of A Screw Capping Machine?

Increased Efficiency

Screw capping machines are incredibly efficient, allowing for faster production of capped containers in comparison with manual screwing. This increased efficiency can lead to a significant reduction in labor costs and an overall increase in productivity.

More reliable seals

Screw capping machines create tighter screw caps than manual screwing, which ensures an airtight seal and prevents the contents inside from being exposed to external elements. This makes screw capping machines a more reliable way of sealing containers than manual screwing.

Greater Accuracy

Screw capping machines enable greater accuracy in screw placement and screw tightness than manual screwing, making the process more precise and consistent. This makes screw capping machines a better option for applications where screw placement and screw tightness are particularly important.

Reduced Waste

Screw capping machines reduce waste caused by manual screwing as they require less packaging material to cover the screw cap and protect it from damage before, during, and after screwing. This reduces the cost of packaging materials and helps to improve sustainability.

More Flexibility

Screw capping machines can be easily programmed to accommodate different screw sizes, screw shapes, and screw lengths, making them a versatile option for companies that produce different types of containers with various screw caps. This flexibility can help businesses save time and money as they won’t need to purchase separate screwing equipment for each screw type.

4.What Are The Applications Of A Screw Capping Machine?

A screw capping machine is widely used in a variety of industries, including pharmaceuticals, chemical production, cosmetics and food & beverage. Here are some of the key applications for screw capping machines:

Food Industry

Screw capping machines can be used to seal jars and other containers with products such as sauces, jams, jellies, pickles etc. This ensures that the product is securely sealed and prevents leakage during transport or storage.

Pharmaceutical Industry

Screw capping machines are also used in the pharmaceutical industry for sealing bottles containing medicines, ointments, and other medicines. This helps to ensure that the products remain uncontaminated and secure during transport or storage.

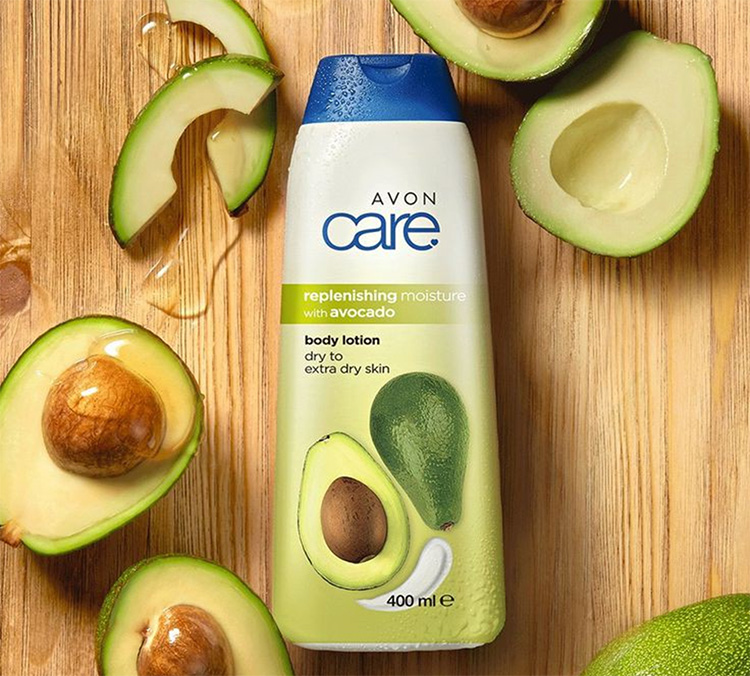

Cosmetics Industry

Screw capping machines can also be used in the cosmetics industry for sealing bottles containing creams, lotions and other cosmetics products, thus preventing leakage during transit.

Chemical Production

screw capping machines are also used in chemical production to seal bottles containing various chemicals, ensuring that the product remains secure during transport and storage.

Beverage Industry

Screw capping machines are also used in the beverage industry for sealing bottles containing carbonated beverages, alcoholic beverages, juices and other drinks. This helps to ensure that the product remains secure during transit or storage.

5.What Are The Working Principles Of A Screw Capping Machine?

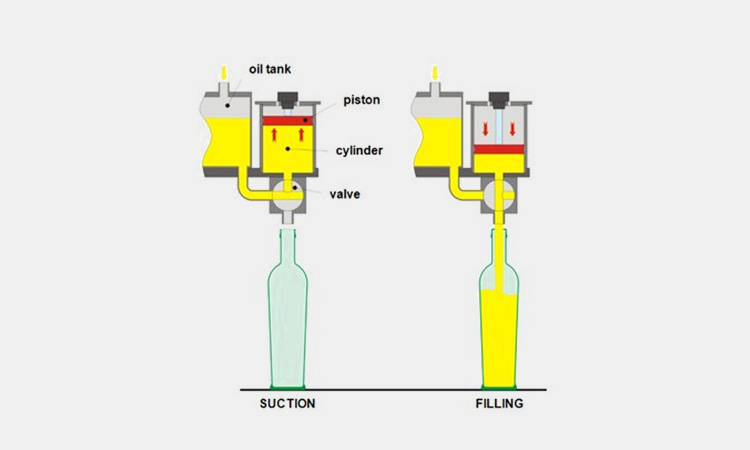

The screw capping process begins by screwing the cap onto a container and then tightening it to ensure that it stays in place. The screw capping machine is designed to automate this process, ensuring accuracy and consistency. This machine uses a screw head to screw the cap on the container, which requires a specific torque setting for each type of cap.

Once the screw head has been applied, the screw capping machine will provide a series of automated screwing and tightening actions to ensure that the cap is in place. The screw capping machine will then check for torque settings to ensure that each container has been properly tightened according to its specifications.

Finally, the screw capping machine will release the screw head from the container to complete the process.

6.What Are The Different Types Of A Screw Capping Machine?

There are a variety of screw capping machines available on the market. These include:

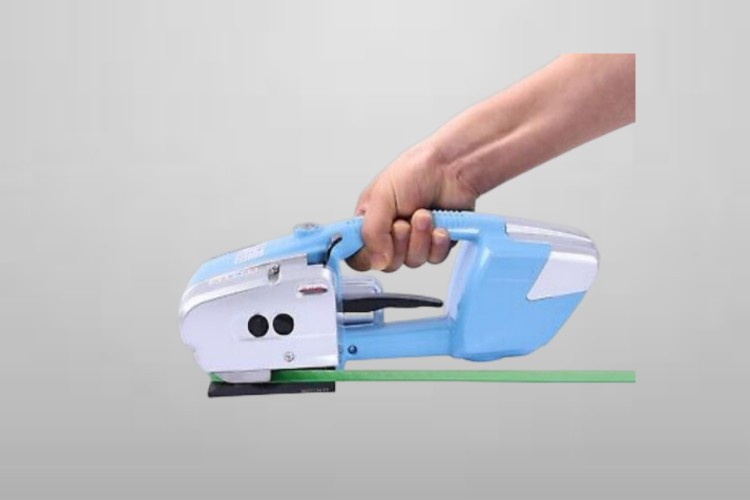

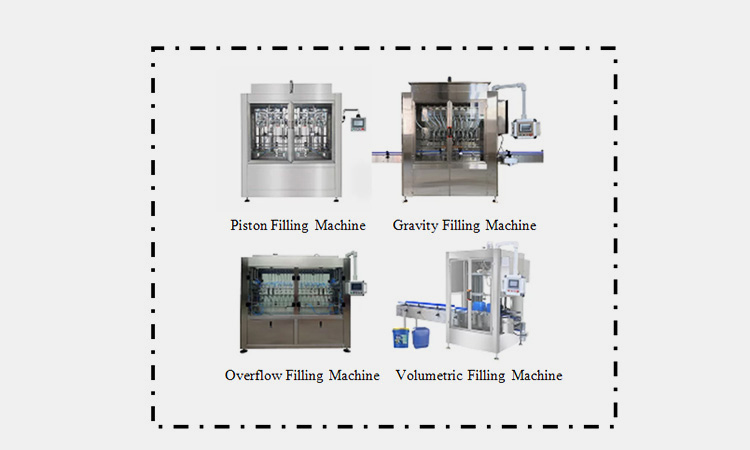

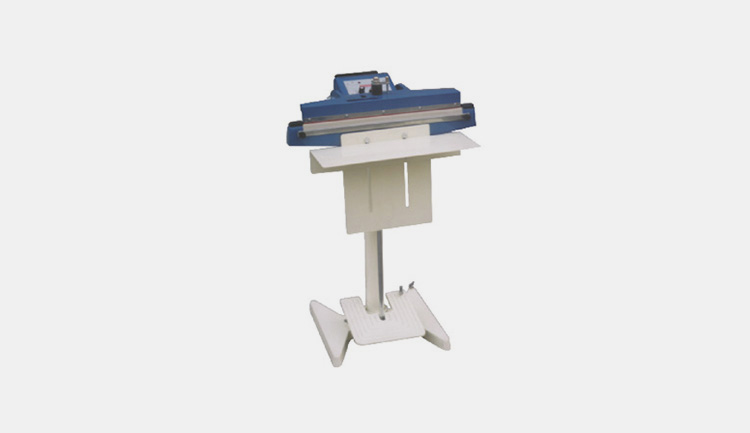

Manual Screw Capping Machine

Manual screw capping machines are typically used in low-quantity production environments, such as small laboratories or research facilities. They feature manual rotation and tightening of screw caps, allowing operators to carefully deal with delicate screw caps.

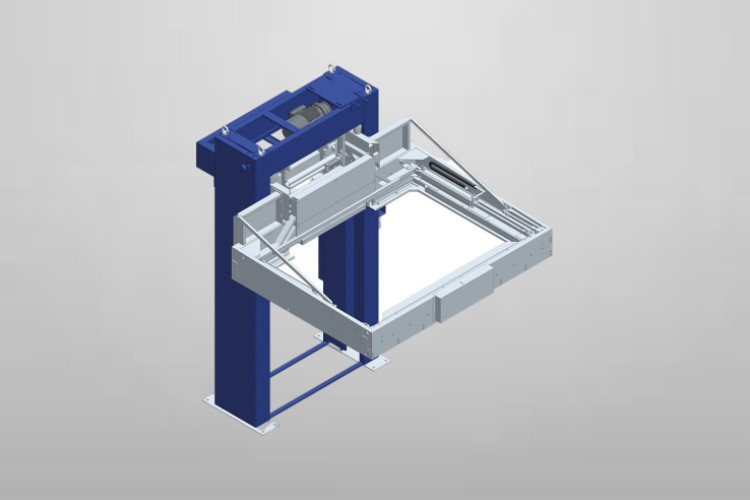

Semi-Automatic Screw Capping Machine

These machines are suitable for mid-capacity production runs, and feature a semi-automatic screw cap tightening process with varying speed and torque settings for precise control. They can also be designed to accommodate various screw caps sizes and shapes.

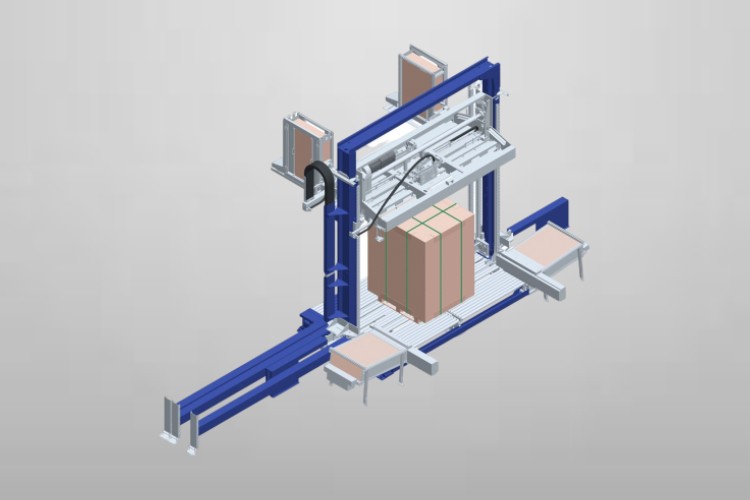

Automatic Screw Capping Machine

These machines are suitable for high-capacity screw capping in industrial production environments. The screw cap tightening process is fully automated, allowing for faster and more efficient screw capping operations. Additionally, these machines can be equipped with advanced features such as automatic screw cap sorting and coding capabilities.

High Speed Screw Capping Machine

High speed screw capping machines are designed to accommodate screw caps with diameters greater than 5 millimeters. This type of screw capping machine is suitable for high-speed production operations, and can achieve speeds of up to 1000 screw caps per minute.

7.What Is The Difference Between Manual Screw Capping Machine And Automatic Screw Capping Machine

a) Manual Screw Capping Machine

b) Automatic Screw Capping Machine

The primary difference between manual and automatic screw capping machines is the level of automation. Manual screw capping machines require manual intervention to secure the cap to the product container while automatic screw capping machines can be programmed to secure caps at a much faster rate.

Manual screw capping machines are manual operated, with an operator manually securing the cap onto the container. This manual approach can provide a low cost option for capping but will generally come with slower production speeds and higher labor costs.

Automatic screw capping machines on the other hand are powered by motors and use servo-driven technology to secure caps onto containers at a much faster rate than manual machines.

Automatic screw capping machines also reduce manual labor costs and improve productivity by eliminating manual intervention. The machines are typically more expensive than manual machines but often times offer a faster return on investment due to their higher production speeds and reduced labor costs.

8.What Is The Difference Between Automatic Screw Capping Machine And Semi-Automatic Screw Capping Machines?

a) automatic screw capping machine

b) semi-automatic screw capping machine

The main difference between automatic and semi-automatic screw capping machines lies in the level of automation.

Automatic screw capping machines are fully automated, meaning that they can operate without any human interference. They have sophisticated programming and sensors to detect when a lid is placed on a container and apply the necessary torque for proper sealing.

Semi-automatic screw capping machines, on the other hand, require manual operation to begin the lid closing process. While automatic machines complete the capping process without any human interference, semi-automatic machines require someone to manually place and tighten the lid onto a container before they can be sealed properly.

Also, while automatic machines can be more expensive upfront, their level of automation makes them ideal for high-volume production lines where accuracy and speed are crucial factors. Semi-automatic machines may be a more cost-effective choice thus suitable for smaller scale production runs.

9.What Type Of Materials Can Be Used With A Screw Capping Machine?

Screw capping machines are versatile tools that can be used with several different types of screw caps to ensure a secure fit. They include:

Plastic Screw Caps

A screw capping machine can be used to tightly fit plastic screw caps onto containers. The screw cap is placed onto the container and then tightened by the screw capping machine.

Metal screw caps

In addition to plastic screw caps, a screw capping machine can also be used to cap metal screw caps onto metal containers. The metal screw caps are placed onto the container and then securely tightened by the screw capping machine.

Aluminum Screw Caps

A screw capping machine is also able to apply aluminum screw caps onto containers. Once again, the aluminum screw cap is put in place and then tightened with the screw capping machine for a secure fit.

Crimp Caps

A screw capping machine can be used to tighten crimp caps onto containers as well. The screw capping machine is able to securely tighten the crimp cap onto the container for a secure fit and seal.

10.What Type Of Containers Can Be Sealed Using A Screw Capping Machine?

Plastic Containers

A screw capping machine can be used to seal plastic containers such as PET bottles and jars. This type of machine applies screw caps or screw lids in a uniform manner, ensuring that they are tightly secured.

Glass Containers

Screw capping machines can also be used to securely close glass containers. These machines are particularly useful when capping jars with screw lids, as they ensure that the lids are tightened in a consistent manner and can guarantee a tight seal.

Metal Containers

Screw capping machines can also be used to secure screw-top lids or caps on metal containers such as cans or tins. This type of machine can help to provide an effective and durable seal for these types of containers, ensuring that the contents are kept safe and secure.

11.Do Screw Capping Machines Have Printing Capability?

The answer is yes – screw capping machines can be equipped with printing capability depending on the specific model and its features. This capability allows for customized product branding or labeling information to be applied, such as expiration dates, lot numbers, and barcodes.

Having this printer integrated into the screw capping machine not only increases efficiency but also provides a reliable and consistent way of labeling products. Furthermore, screw capping machines can be easily integrated with other packaging equipment for a complete automated packaging system to achieve the highest possible production speeds.

12.What Are Some Of The Common Screw Capping Machine Problems And How To Fix Them?

Over-Tightening

This is the most common screw capping machine problem. It can be caused by uneven screw caps, torque settings being too high, or improper screw cap seals.

Solution

To fix this issue, first check to make sure that all screw caps are consistent and properly seated before putting them on the machine. Additionally, reduce torque settings to a level that is suitable for screw caps. Finally, ensure screw cap seals are properly installed and of the right size.

Screw Jamming

This can be caused by worn-out screw heads or damaged screw threads.

Solution

To fix this issue, inspect all screw heads and threads prior to using them in the capping machine, replacing any that are worn or damaged. Additionally, use a screw thread lubricant to ensure smooth screwing and unscrewing of screw caps.

Poor Capping Performance

This can be caused by improper operation of the screw capping machine, such as not tightening screw caps enough or over-tightening them too much.

Solution

To fix this issue, make sure the screw capping machine is properly operated according to the manufacturer’s instructions. Additionally, ensure screw caps are tightened to the correct torque setting for optimal performance.

Leaks

This can be caused by loose or damaged screw cap seals.

Solution

To fix this issue, inspect screw cap seals prior to screwing them onto the screw capping machine, replacing any that are worn or damaged. Additionally, ensure screw caps are tightened to the correct torque setting for optimal performance.

Unscrewing

This can be caused by loose screw threads, improper screw cap seals, and incorrect torque settings.

Solution

To fix this issue, inspect all screw heads and threads prior to screwing them onto the screw capping machine, replacing any that are worn or damaged. Additionally, use a screw thread lubricant to ensure smooth screwing and unscrewing of screw caps. Finally, adjust torque settings to suit screw caps for optimal performance.

13.How Can Screw Capping Machine Production Be Optimized?

The following are some of the best methods for optimizing screw capping machine production:

Regular Maintenance: A well-maintained screw capping machine can operate more efficiently and last longer. Regularly cleaning the screw capping machine, inspecting its parts for wear and tear, and replacing any worn parts will help ensure that it continues to function at its best.

Adjustable Settings: Adjusting the screw capping machine’s settings to match the product being capped can improve its performance. Different screw capping machine models offer adjustable speed and tension, both of which should be adjusted according to the specific products being sealed.

Automation: Automating screw capping machine production can save time and labor costs. Automated screw capping machines can be programmed to cap a variety of products with different screw sizes and configurations, which can significantly reduce downtime.

Quality Control: Regularly testing the quality of screw caps is essential for optimizing screw capping machine production. Poor screw caps can lead to product spoilage and dissatisfaction, so it’s important to ensure that the screw capping machine is producing screw caps of the highest quality.

14.How Can You Choose A Screw Capping Machine That Suits Your Needs?

Choosing the right screw capping machine can be a daunting task. Fortunately, there are several important factors to consider when selecting the best screw capping machine for your needs.

First, consider the scope of your production needs. What size screw caps do you need to close and how many screw caps will you be producing? Do you need a machine that can handle high-volume production or something smaller for low volume needs? Knowing the scope of your needs will help narrow down your options.

Second, consider the type of screw caps the machine needs to accommodate. For example, there are screw capping machines that are designed to work with screw caps of different sizes and shapes. Make sure the machine you choose is compatible with your screw caps.

Third, consider the speed of your screw capping machine needs. How fast do you need your screw caps to be sealed? Faster machines can seal more screw caps in a shorter period of time, so it’s important to make sure the screw capping machine you choose can meet your speed requirements.

Finally, consider the cost of the screw capping machine. Different machines come with different features and capabilities, so they are likely to vary in price. It’s important to find a screw capping machine that fits your budget while also providing the features you need.

Taking these factors into account will help you make an informed decision when choosing a screw capping machine that best suits your needs. With the right screw capping machine, you can ensure quality screw caps are sealed securely and efficiently, helping to keep your production costs low.

CONCLUSION

Overall, the screw capping machine is an invaluable addition to any bottling facility. It is easy to use and can be adapted to fit different types of caps. This functionality makes it one of the best purchases a business in the bottling industry can make. Furthermore, its advanced technology and carefully designed components reduces time spent, preventing unnecessary complications or issues. If you’re looking for quality screw capping machine, then Allpack should be your first resort! We can guarantee that our machines will help you produce the best-capped products around! Don’t just take our word for it; contact Allpack today if you want more information about our services and screw capping machines!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Screw Capping Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours