Commercial Vacuum Packaging Machine: The Complete Buying Guide In 2025

Commercial vacuum packaging machines have emerged as a popular solution for businesses looking to keep their products in top condition for longer periods of time. Whether you’re a small bakery or a large restaurant chain, having reliable commercial vacuum packaging machine can make all the difference in the quality of your offerings.

However, with so many options available, it can be challenging to find the right one for your business needs. In this comprehensive buying guide, we’ll focus on commercial vacuum packaging machines and answer the following questions to help you make an informed decision:

1.What is a commercial vacuum packaging machine?

A commercial vacuum packaging machine is a device used to remove air from a package or container, creating a vacuum seal that helps to preserve the contents inside. The machine removes the air from the bag, sealing it tightly to prevent air from entering.

This vacuum sealing process can help extend the shelf life of food items and other perishable products, as well as protect them from contamination or damage during transport. Commercial vacuum packaging machines are often used in food service, manufacturing, and other industries where preservation and protection of goods is important.

2.What are the benefits of using commercial vacuum packaging machines?

Commercial vacuum packaging machines offer several benefits over traditional packaging methods in a commercial setting. Here are some unique advantages:

Increased shelf life:

Commercial vacuum packaging machine helps to extend the shelf life of products by removing air and oxygen, which can cause spoilage, degradation, and the growth of microorganisms.

Improved product quality:

Commercial vacuum packaging machine helps to preserve the color, flavor, and texture of products by preventing exposure to oxygen and moisture. This can help to maintain the taste and freshness of products.

Cost-effective:

Commercial vacuum packaging machine can help to reduce the cost of packaging materials by using less packaging material, as well as reducing the cost of shipping and storage by reducing the size and weight of the packaged products.

Increased durability:

Commercial vacuum packaging machine helps to make products more durable by protecting them from impact and other types of damage.

Easy to handle and store:

Commercial vacuum packaging machine can help to reduce the volume of the packaged product, making it easier to handle and store in warehouses and on shelves.

Environmental friendly:

Commercial vacuum packaging machine can use biodegradable and recyclable materials, which can help to reduce the impact of packaging on the environment.

3.What are the applications of commercial vacuum packaging machine?

Commercial vacuum packaging machines are versatile tools that have a wide range of applications in various industries. Here are some unique and lesser-known applications of commercial vacuum packaging machines:

Medical and Pharmaceutical Industries:

Commercial vacuum packaging machines is commonly used in the medical and pharmaceutical industries to package and protect delicate items such as medical devices, surgical instruments, and pharmaceutical products. The vacuum sealing helps to prevent contamination, maintain sterility, and increase shelf life.

Food Industry:

Commercial vacuum packaging machines are commonly used in the food industry to preserve food products such as meat, poultry, fish, fruits, and vegetables. Vacuum packaging can extend the shelf life of these products and maintain their freshness and quality, making it a valuable tool for both small and large food businesses.

Environmental Protection Industry:

Commercial vacuum packaging machines can also be used for environmental protection purposes. For example, they can be used to package hazardous waste materials to prevent contamination and exposure to the environment. Vacuum sealing can also be used to package and transport soil or other environmental samples without risking contamination or damage.

Electronic Devices Industry:

Electronic devices such as smartphones, tablets, and laptops can also benefit from vacuum packaging. The vacuum-sealed package can prevent dust and moisture from entering the device, which can cause damage or reduce its lifespan.

4.What are the different commercial vacuum packaging machines available in the market?

- Chambered Commercial Vacuum Packaging Machine

Chambered commercial vacuum packaging machines are essential tools that create an airtight seal around your items, removing all the air from the chamber to prevent spoilage and keep your food fresh for a longer period.

Chambered commercial vacuum packaging machines work by placing the item to be sealed in a vacuum-sealed bag, which is then placed inside the sealing chamber. Once the bag is inside, the machine removes all the air from the chamber, creating a vacuum. Once the vacuum is complete, the machine seals the bag, preventing any air from re-entering.

- External Commercial Vacuum Packaging Machine

Introducing the external commercial vacuum packaging machine, the ultimate kitchen sidekick for sealing your leftovers, meal preps, and even snacks! Say goodbye to soggy sandwiches and stale chips with this trusty tool.

External commercial vacuum packaging machines work by removing the air from the packaging of your food items, creating an airtight seal that preserves freshness and prevents spoilage.

The machine comes with a vacuum sealer bag or roll, where you place your food items and then place the open end into the machine’s sealing area. The machine then removes the air from the bag or roll and seals it shut.

- Automatic Commercial Vacuum Packaging Machine

A new secret weapon: the automatic commercial vacuum packaging machine! This sleek and powerful device will suck the air out of your bags with lightning speed, leaving your food fresh, delicious, and ready to enjoy whenever you want it.

The automatic commercial vacuum packaging machine uses a combination of heat and pressure to remove all the air. First, you place your food in a specially designed bag and insert it into the machine. The machine then seals the bag shut and uses a powerful motor to remove all the air from inside. This creates a vacuum seal.

- Semi-Automatic Commercial Vacuum Packaging Machine

The semi-automatic commercial vacuum packaging machine is here to save your day! With just the push of a button, you can seal your snacks, meats, and leftovers with ease, making you feel like a vacuum sealing superhero.

The semi-automatic commercial vacuum packaging machine uses a combination of heat and pressure. First, you place your food item in the bag and then insert the open end of the bag into the machine. Next, you close the lid and press the vacuum button. The machine will then suck the air out of the bag, leaving your food airtight and free from spoilage.

Once the air is removed, the sealing bar heats up and melts the bag shut, creating a tight seal. And voila, your snacks and leftovers are safe and sound until the next time you’re ready to munch!

5.What are the differences between commercial vacuum packaging machines and industrial vacuum packaging machines?

Both commercial and industrial vacuum packaging machines are designed to accomplish the same goal, but there are several differences between the two that make them suitable for different applications.

Size and Capacity:

One of the most noticeable differences between commercial and industrial vacuum packaging machines is their size and capacity. Commercial vacuum packaging machines are designed for small to medium-sized businesses, such as restaurants, delis, and grocery stores.

They are typically smaller and have a lower capacity than their industrial counterparts, making them more suitable for packaging small quantities of food.

Industrial vacuum packaging machines, on the other hand, are designed for large-scale food production and processing facilities. They are larger and have a higher capacity, which allows them to package larger quantities of food quickly and efficiently. Industrial vacuum packaging machines can handle multiple packages simultaneously, making them ideal for high-volume production.

Durability and Construction:

Industrial vacuum packaging machines are built to withstand the demands of a high-volume production environment. They are typically made of heavy-duty materials such as stainless steel and have a more robust construction than commercial machines.

In contrast, commercial vacuum packaging machines are made of lighter materials and have a less robust construction, making them suitable for lighter use.

Automation and Features:

Industrial vacuum packaging machines often come equipped with more advanced features, such as automatic bag feeders, programmable sealing times, and computerized controls. These features can help improve the efficiency of the packaging process and ensure consistent and high-quality results. Commercial vacuum packaging machines usually have more basic features and may require more manual operation.

Price:

The investment required to purchase an industrial vacuum packaging machine may be prohibitive for smaller businesses, making commercial machines a more practical option for them.

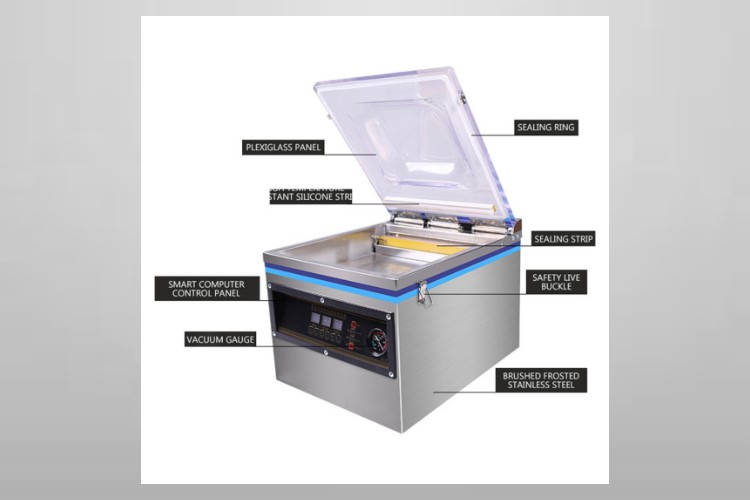

6.What are the major components, a commercial vacuum packaging machine is composed of?

A commercial vacuum packaging machine typically consists of several key components that work together to create a vacuum-sealed package. These components include;

Vacuum pump

The vacuum pump is responsible for removing air from the packaging, which creates a vacuum. It may be a rotary vane pump, a diaphragm pump, or a venturi pump, depending on the model.

Plexiglass panel

A transparent panel made of plexiglass that allows the user to monitor the vacuum sealing process.

Vacuum Gauge

A gauge that measures the level of vacuum in the packaging chamber, allowing the user to ensure proper packaging conditions.

Safety Live Buckle

A safety mechanism that prevents the machine from operating when the packaging chamber is not securely closed.

Sealing Strip

A strip of material (usually Teflon) that is used to provide a strong seal between the packaging material and the sealing bar.

Sealing Ring

A replaceable ring made of silicone or rubber that ensures a tight seal between the packaging chamber and the sealing bar, preventing air from entering during the vacuum sealing process.

Vacuum chamber

The vacuum chamber is where the packaging is placed to be vacuum-sealed. It is usually made of stainless steel and has a clear lid so that the packaging process can be observed.

Control panel

Finally, the control panel is used to operate the machine and set the desired vacuum and sealing times. It may include a digital display, buttons, and other controls to make the machine easy to use.

Together, these components work to create a tightly sealed package that can extend the shelf life of food and other products.

7.What is the working principle of commercial vacuum packaging machine?

The working principle of this machine is as follows:

Place the product in the vacuum bag: The product is placed in the vacuum bag and the open end of the bag is placed in the machine.

Air is removed: The machine removes the air from the bag by creating a vacuum, which can be done in a variety of ways, such as using a vacuum pump or a nozzle that sucks out the air.

Sealing: Once the air is removed, the open end of the bag is sealed. This can be done using heat sealing or impulse sealing, which uses a wire to seal the bag by melting the plastic together.

Gas flush (optional): Some commercial vacuum packaging machines offer a gas flush option, which replaces the air in the package with a gas, such as nitrogen or carbon dioxide, before sealing the bag. This helps to further extend the shelf life of the product.

Cooling: The sealed package is then cooled before being removed from the machine. This helps to ensure that the seal is strong and the product is properly preserved.

8.What are the other devices used in the commercial vacuum packaging production line?

The machines that are commonly used in commercial vacuum packaging production lines:

Labeling Machine

The machine that automatically applies labels to the packaged products, helping to identify them and provide necessary information to the consumers.

Metal Detector

The machine that detects and rejects any metallic contaminants in the packaged products, ensuring that the products are safe to consume.

Cartoning Machine

The machine that automatically folds, inserts, and seals product containers, such as boxes or cartons, to package the products for shipment.

9.Can commercial vacuum packaging machine be used with different types of bags and containers?

Commercial vacuum packaging machines can typically be used with different types of bags and containers, but it depends on the specific machine and the bags or containers being used. Here are some ideas for using different types of bags and containers with a commercial vacuum packaging machine:

Vacuum seal bags

Vacuum seal bags are the most common type of bags used with commercial vacuum packaging machines. These bags come in different sizes and can be used for various types of food items, such as meat, fish, fruits, and vegetables.

Zipper bags

Some commercial vacuum packaging machines can also be used with zipper bags. These bags are more convenient for storing items that need to be accessed frequently, such as snacks or small portions of food.

Three mil vacuum bags

Three mil vacuum bags are commonly used in commercial vacuum packaging machines due to their durability and resistance. These bags are suitable for vacuum sealing a wide range of products, including food, medical supplies, and industrial parts.

Black Vacuum Bags

Black vacuum bags are a popular choice for commercial vacuum packaging machines due to their ability to block out light and UV rays, which can cause degradation and spoilage of food products. These bags are made of multiple layers of material, such as nylon and polyethylene.

Reclosable Foil Barrier Bags

Reclosable foil barrier bags used in commercial vacuum packaging machines, providing airtight and moisture-resistant storage for a wide range of products. These bags are designed with a built-in zipper closure, allowing for convenient access and resealing of the contents.

Meat Vacuum Bags with Black Background

Meat vacuum bags with black background offer superior light blocking properties that help to protect the meat from light-induced oxidation and spoilage. The black background also provides an excellent contrast against the bright colors of meat, making it easier to identify and package different types of meat.

Notched Vacuum Bags

Notched vacuum bags are a common type of packaging material used in commercial vacuum packaging machines. The notched design allows for easy removal of excess air and a tight seal around the contents, ensuring optimal preservation and shelf life.

10.What are the differences between commercial vacuum packaging for short-term and long-term storage?

The main difference between short-term and long-term vacuum packaging is the durability of the packaging materials and the level of vacuum required to ensure the product’s stability and quality over time.

Short-term vacuum packaging is typically used for products that will be consumed within a few days or weeks. These packages may be less sturdy and require a lower level of vacuum because they will not be stored for long periods of time. For short-term storage, it is important to maintain the product’s freshness and quality, but long-term stability is less critical.

On the other hand, long-term vacuum packaging is designed for products that will be stored for months or even years. These packages are typically more robust and require a higher level of vacuum because they need to withstand the rigors of long-term storage. In addition to freshness and quality, long-term stability and resistance to oxidation and freezer burn are crucial factors for success.

11.How to maintain the commercial vacuum packaging machines?

Maintaining commercial vacuum packaging machines is essential to ensure their proper functioning and prevent breakdowns. Below are some tips to help you maintain your vacuum packaging machines:

Clean the Machine: Regular cleaning is necessary to prevent the buildup of debris, dust, or other contaminants that could damage the machine. You should clean the machine after each use and disassemble it every six months for a thorough cleaning.

Lubricate Moving Parts: Lubricating moving parts is an essential maintenance step that helps the machine operate smoothly and prevents it from wearing down prematurely. Use a high-quality lubricant to oil the moving parts, but make sure not to use too much oil.

Use High-Quality Vacuum Bags: High-quality vacuum bags are essential for maintaining the vacuum and ensuring that your packaged items stay fresh for longer. Use vacuum bags that are compatible with your machine and made from high-quality materials.

12.How to choose the best commercial vacuum packaging machine?

When considering the purchase of a commercial vacuum packaging machine, there are several important factors to keep in mind. Here are some key considerations:

Capacity: Choose a machine with the appropriate capacity for your business needs. Consider the volume of product you need to package and the frequency with which you will use the machine.

Bag size and type: Make sure the machine can accommodate the size and type of bags you plan to use. Some machines are designed to work with specific types of bags, so check the specifications carefully.

Automation level: Decide how much automation you need. Some machines have advanced features like programmable settings and sensor technology, while others are more basic.

Durability and reliability: Look for a machine that is built to last and can withstand heavy use. Read reviews and consider the warranty to get a sense of the machine’s reliability.

Maintenance and cleaning: Consider how easy the machine is to clean and maintain. Look for models with removable parts that are dishwasher safe for easy cleaning.

Cost: Determine your budget and choose a machine that offers the features you need within that budget. Keep in mind that a higher-priced machine may offer better durability and advanced features.

Conclusion

In conclusion, a commercial vacuum packaging machine can be a valuable asset for businesses that need to preserve and extend the shelf life of their products. With the right commercial vacuum packaging machine, you can improve your bottom line and provide your customers with high-quality products that they will appreciate.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide