Automatic Tray Sealing Machine: The Complete Buying Guide In 2025

Are you looking for an efficient, cost-effective way to seal and package your products? An automatic tray sealing machine is the perfect solution. This revolutionary innovation ensures that all of your product packaging needs are met quickly and effectively.

Not only does it help protect and preserve food during transport, but it also allows you to customize each individual package with features like printed logos or barcodes. Plus, since it’s entirely automated, you can easily monitor the entire process from start to finish.

So, let’s get started on our journey into discovering how an automatic tray sealing machine could make your packaging process easier and more efficient than ever before!

1.What Is An Automatic Tray Sealing Machine?

Automatic tray sealing machines are machines that are used to automatically seal trays with lids or films. These machines can be adapted to seal a variety of tray sizes and shapes, including round, square, rectangular and even oval-shaped trays.

Automatic tray sealing machines reduce labor costs associated with manually sealing trays by quickly and efficiently sealing multiple trays at once. Automatic tray sealing machines are used in the food industry, packaging industry and many other industries where sealing trays is necessary.

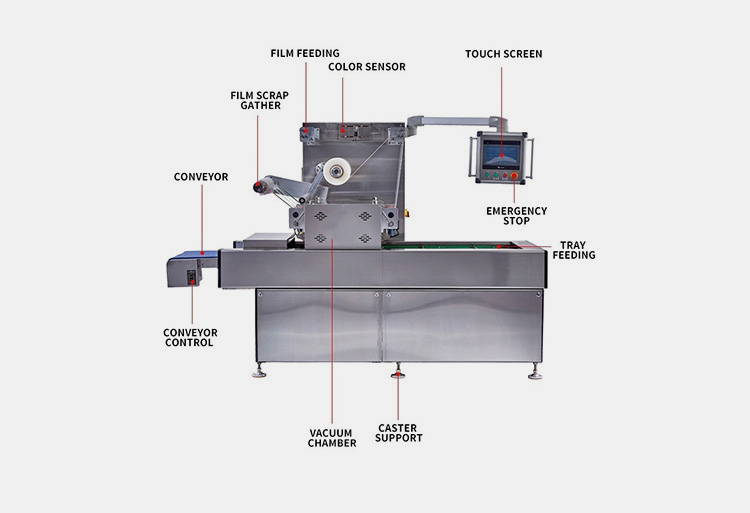

2.What Are The Components Of An Automatic Tray Sealing Machine?

The main components of an automatic tray sealing machine include:

Tray feeding

It is responsible for loading the required tray onto the belt. After the correct number of trays are loaded, they are moved to the next step in the process

Touch screen

The touch screen on automatic tray sealing machines is typically used to control settings, initiate the sealing process and run diagnostics. It also provides status feedback of the machine’s operation.

Vacuum chamber

This is a sealed chamber that creates a vacuum to draw air out of the tray before the top film is sealed.

A Conveyor

Automatic tray sealing machine typically includes a conveyor system, which is used to transport the trays into and out of the sealing process. The conveyor is usually motorized and can be adjusted for different product sizes.

Conveyer control

This is the automated system that drives the automatic tray sealing machine. It operates by using sensors to detect tray size and contents, and then controls the speed of the conveyor belt to ensure accurate sealing.

Film feeding

Automatic tray sealing machines are typically equipped with a film feeding system, which provides the plastic film used to cover and seal the trays. This system can be either manual or automatic depending on the model of machine. The system feeds the film through rollers that pull it over the tray, ensuring an even application of heat for proper sealing.

Film scrap gather

This machine collects the film scrap that is created after sealing a tray. It helps in reducing wastage of films and enhance productivity.

Emergency stop

The emergency stop button is an important safety feature that immediately stops the automatic tray sealing machine in case of any unforeseen emergencies.

Caster support

This is the base of the automatic tray sealing machine. It provides a sturdy platform to mount all other components, as well as helping move it around with ease

Color sensor

This component is used to detect the color of the tray or container. It will then activate a signal to instruct the sealing head on how to seal it depending on its color.

By incorporating these components, automatic tray sealing machines are able to produce consistently high-quality sealed products in an efficient and cost-effective manner. Additionally, automatic tray sealing machines can be used to produce a wide variety of trays in various shapes and sizes, allowing for greater flexibility when it comes to product packaging.

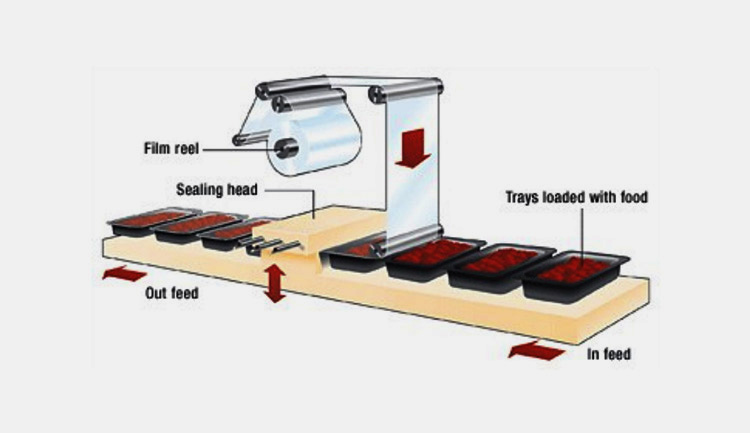

3.How Does An Automatic Tray Sealing Machine Work?

The automatic tray sealing machine works by sealing a pre-filled tray with a heat sealable film, which is then cut to size and sealed around the tray to create an airtight environment. The automatic tray sealing machine utilizes a series of processes that involve;

Heating

The automatic tray sealing machine uses a combination of heat, pressure and time to seal the film layer. This process is done by using two heated plates on either side of the tray that applies heat over the entire surface area in order to evenly distribute the heat so that when it reaches a set temperature, it can be sealed properly.

Cutting

The automatic tray sealing machine also includes a cutting device that can be used to cut the film layer into the correct size and shape for sealing. This is usually done by using a blade or laser, depending on the model of automatic tray sealing machine being used.

Sealing

The automatic tray sealing machine then uses a combination of pressure and heat to seal the film layer around the tray. This process is often done by using a heated roller that applies even pressure over the entire surface area of the tray in order to properly adhere it to the film layer.

The automatic tray sealing machine also often includes additional features such as a product weight detector, which can be used to ensure that all of the products in a batch are sealed evenly and uniformly. This is done by weighing each product before it is sealed, and then recording the weight to make sure that no product is left unsealed or weighted unevenly.

4.What Are The Different Types Of Automatic Tray Sealing Machines?

There are several common types of Automatic tray sealing machines, each designed to handle different applications and materials.

The first type is automatic map (modified atmosphere packaging) tray sealing machine. this type of automatic tray sealing machine is used to reduce the oxygen content in the trays and extends product shelf life. It is typically used for food packaging and other products that can benefit from a modified atmosphere.

The second type is automatic vacuum tray sealing machine, which is used to remove air from the packages in order to extend product shelf life and prevent oxidation or spoilage of perishable items such as cheese, seafood, etc. This Automatic tray sealing machine is also used for medical and pharmaceutical applications.

The third type is automatic skin packaging machine, which seals the product with a thin plastic film that adheres to the tray closely. This Automatic tray sealing machine is commonly used in food packaging or other products that require a tight seal.

Finally, automatic shrink-wrapping machines are also often used for automatic tray sealing. This type of automatic tray sealing machine uses heat to shrink a plastic film around the tray, providing an extra layer of protection and tamper-proofing.

Each automatic tray sealing machine has its own unique features and benefits depending on the application. It is important to select the automatic tray sealing machine that best fits your needs. By doing so, you can ensure a quality seal and an extended shelf life for your products.

5.What Are The Applications Of An Automatic Tray Sealing Machine?

Automatic tray sealing machines have many different applications. Below are some of the common uses for these machines:

Packaging Of Food Products

Automatic tray sealing machines are especially useful for packaging food products, as they ensure that the product is efficiently and securely sealed with a durable seal that will keep the product fresh and safe from contamination.

Pharmaceuticals And Medical Products

Automatic tray sealing machines can be used to package pharmaceuticals and medical products securely, ensuring that the product is transported safely to its destination with no contamination.

Electronic Products

Automatic tray sealing machines can also be used for packing electronic parts or components, such as LED screens, circuit boards, and other sensitive items. This ensures that fragile products are securely sealed for transportation and storage.

Cosmetics

Automatic tray sealing machines are also useful for the packaging of cosmetics, from lotions and creams to makeup compacts and lipsticks. These machines can help ensure proper sealing of delicate items like these in order to protect them from contamination and damage.

Accessories and other objects

Automatic tray sealing machines can also be used to package toys and other accessories, such as jewelry, watches, keychains, and other small items. This ensures that these items are securely packaged for safe transport.

6.What Are The Advantages Of An Automatic Tray Sealing Machine?

Automatic tray sealing machines have a number of advantages over traditional manual methods.

- Speed: automatic tray sealing machines work much faster than manual methods, making them ideal for high-volume production lines and large batch sizes.

- Consistency: automatic tray sealing machines provide consistent results every time, ensuring that products are consistently sealed and of high quality.

- Versatility: automatic tray sealing machines can be used for a variety of different products, from food to pharmaceuticals, making them extremely versatile and cost-effective.

- Safety: automatic tray sealing machines are significantly safer than manual methods, as they reduce the risk of human error and are less likely to cause injury.

- Cost-effectiveness: automatic tray sealing machines reduce labor costs, as fewer workers are needed to operate the machine, and they require little maintenance, making them cost-effective over time.

- Efficiency: automatic tray sealing machines are very efficient in terms of energy consumption and production speed, further increasing their cost-effectiveness.

7.What Types Of Materials Can An Automatic Tray Sealing Machine Handle?

Polyethylene (PE): Automatic tray sealing machines can handle polyethylene film, which is a lightweight plastic that is commonly used in food packaging. It is durable and provides good moisture and oxygen barriers to keep food fresh.

Polypropylene (PP): Automatic tray sealing machines can also handle polypropylene film, which is a slightly thicker plastic that is more resistant to heat and chemicals. It provides excellent mechanical strength for longer product shelf life.

PVC: Automatic tray sealing machines can also handle PVC film, which is a heavy-duty plastic that offers superior protection against water vapor, oxygen, UV radiation and other contaminants. It also has excellent clarity for product visibility.

Aluminum: Automatic tray sealing machines can also handle aluminum film, which is a highly reflective metallic material that provides superior protection against moisture, oxygen and ultraviolet light. It also offers great flexibility and strength for increased shelf life.

Paper and Cardboard: Automatic tray sealing machines can also handle paper and cardboard, which provide excellent barrier properties against moisture, oxygen, light and other contaminates. They also offer great strength and flexibility for product packaging.

8.What Features Should You Consider When Buying An Automatic Tray Sealing Machine?

Automatic tray sealing machine Type

Automatic tray sealing machines come in a variety of types, such as semi-automatic, fully-automatic and inline machines. Depending on the volume and type of trays you need to seal, it’s important to choose an appropriate automatic tray sealing machine that will work best for you.

Tray Size

Automatic tray sealing machines vary in capacity, so you need to make sure that the tray sealing machine can accommodate the size of your trays. Check the specifications of each automatic tray sealing machine and select one with a tray size that is suitable for your needs.

Construction Materials

Automatic tray sealing machines are typically made from stainless steel or aluminum and should be of high quality to ensure that the automatic tray sealing machine can handle your demands.

Ease Of Use

Automatic tray sealing machines should be easy to operate and maintain. Look for one with clear instruction manuals, user-friendly controls, and foolproof design features.

Production Capacity

Automatic tray sealing machines should be able to handle a high volume of trays in short periods of time, so you can maximize your production capacity and efficiency.

Safety Features

Automatic tray sealing machines should have safety features such as emergency stops, automated temperature sensors, and other valuable safety measures.

Warranty

Automatic tray sealing machines should come with a warranty to protect your investment and ensure long-term use of the automatic tray sealing machine.

9.What Are The Most Common Problems Encountered When Using An Automatic Tray Sealing Machine?

The most common problems encountered when using an automatic tray sealing machine include:

Failure to Seal Properly

Automatic tray sealing machines may fail to seal the trays properly due to incorrect settings or worn-out parts. This can lead to improperly sealed trays, which increases the risk of spoilage and contamination.

Jamming

Automatic tray sealing machines can get jammed if trays are not loaded properly, if there is a packaging film or foil problem, or the pressure of the seal is wrong. This can cause significant delays in production and impacts on efficiency.

Poor Tray Handling

Automatic tray sealing machines are designed to handle lightweight trays but heavier trays can cause problems. Poor tray handling can lead to jams, incorrect seals, or trays that are not loaded onto the machine properly.

Electrical Issues

Automatic tray sealing machines rely on electricity for power and operation. If there is a problem with the electrical components of the machine, it may fail to function optimally and cause delays in production.

Wear and Tear

Automatic tray sealing machines are subjected to a lot of wear and tear due to their constant use. This can cause parts to break down or become worn out over time, leading to problems with the machine’s performance. Additionally, regular maintenance is needed to keep the machine running smoothly.

Mechanical Issues

Automatic tray sealing machines contain a number of mechanical components that can fail due to wear and tear or incorrect settings. This can lead to jams, improper seals, or other issues with the machine’s performance.

Poor Quality Seals

Automatic tray sealing machines may produce poor quality seals if the pressure is not set correctly or there is a problem with the packaging film or foil. This can lead to leaks and contamination, which should be avoided.

10.How Can An Automatic Tray Sealing Machine Be Used In Conjunction With Other Packing Machines?

1.Labelers

Automatic tray sealing machines can be used in conjunction with labelers to provide a complete, automated packaging line. Labelers allow for quick and easy labeling of products — especially useful in food production where products must be labeled quickly. Automatic tray sealing machines then seal each product onto trays that are ready to go into the packing process.

2.Packers

Automatic tray sealing machines can be used in conjunction with packers to provide a complete, automated packaging line. Packers are used to package multiple items into one container or crate for shipping and storage. Automatic tray sealing machines ensure that each individual item is safely packed within its own protective tray before being placed into the larger packing container. This creates an efficient, automated packaging line that can help businesses save time and money on their packaging operations.

3.Stackers

Automatic tray sealing machines can be used in conjunction with stackers to provide a complete, automated packaging line. Stackers are used to store large amounts of product into conveniently sized crates for easy transport and storage. It ensures that each item is properly sealed and protected before being stacked into the crate. This helps to reduce product damage and waste during storage and transport, as well as reducing downtime associated with manual stacking processes

Conclusion

The automatic tray sealing machine is an incredible technology that can be extremely beneficial for businesses looking for an efficient and cost-effective way of packaging their products.If you’re looking for a state-of-the-art solution to increase packaging performance and make your workplace more efficient, then contact Allpack today to learn more about this amazing machine. Trust us when we say that it’ll be worth the investment!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide