Capsule Filler:The Complete Buying Guide in 2025

The capsule filling machine is one of the most important pieces of machinery used in numerous industries, ranging from research and development laboratories to larger manufacturing sites. In 2025, there are more options than ever when it comes to capsule filling machines—ranging from manual models designed for basic operations to fully automated units equipped with cutting-edge features that meet even the most demanding industry requirements.

This buying guide covers everything you need to know about purchasing a capsule filler in 2025, from evaluating size and scale specifications required for your particular application to understanding encapsulation protocols before making a purchase decision. Read on as we discuss all aspects of finding the perfect capsule filling machine!

1.What Is A Capsule Filler?

A capsule filler is a machine used to help fill capsules with powders, pellets, tablets and other materials that may be needed for medical use. They are commonly used in the manufacturing of pharmaceuticals and supplements, as well as for research purposes. It has been designed to help automate the process of filling capsules quickly and accurately. The machines come in a variety of models, sizes and capacities, so you can find one that best suits your needs. They typically feature a chute-style filler system, or an automated drop-dispensing unit. Some models also have additional features such as dust extraction units, adjustable filling speeds and multiple dosing pumps.

With the right capsule filler, you can get the job done accurately and efficiently with minimum effort. So if you’re looking for a way to help speed up the process of filling capsules, consider investing in a capsule filler today. It will save you time, money and effort in the long run!

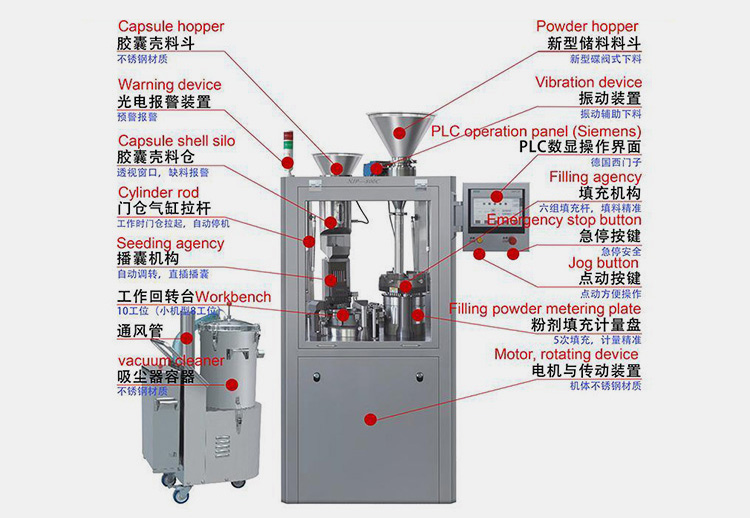

2.What Are The Different Components Of A Capsule Filler?

A capsule filler is a powerful machine that helps pharmaceutical companies, health supplement manufacturers, and other organizations to quickly and accurately fill capsules with the desired content. This machine consists of several components, each of which plays an important role in achieving efficient filling.

Capsule hopper

A capsule hopper is responsible for storing and distributing the empty capsules to the filling agency. It consists of two parts, a bottom base and an upper hopper cover. The cover has adjustable height and width settings in order to suit various sizes of capsules.

Powder hopper

This component holds the powder or other substance that will be filled into the capsules. It is composed of a cover, body and base. The base contains several grids that let the powder drop evenly into the capsule shells.

Vibration device

A vibration device is used to ensure that the powder hopper is always filled with the same amount of powder. It helps to reduce manual time and minimizes chances of human error while filling capsules.

Cylinder rod

This component is responsible for pushing the capsules into the filling agency. It is usually made of stainless steel and contains a plunger to press down on the capsules and move them forward.

Filling agency

The filling agency receives the capsules from the cylinder rod and fills them with the desired content. It can also be adjusted to fill different sizes of capsules.

PLC operation panel

The PLC (Programmable Logic Controller) operation panel is used to control the machine’s settings and operations. It also has a jog button which is helpful for making small adjustments in case of any erroneous operations, as well as an emergency stop button to quickly halt the machine in case of any emergency.

Warning device

This component is responsible for alerting operators if there are any malfunctions in the machine or in its components. It consists of a light indicator, an alarm bell, and a buzzer.

Workbench

A workbench presents a set of rotating discs which move the capsules through the filling agency. It is also responsible for ensuring that each capsule gets the same amount of powder.

Filling powder metering plate

This component is used to measure the amount of powder that will be filled into each capsule. It has adjustable settings in order to accommodate various sizes and shapes of capsules.

Vacuum cleaner

The vacuum cleaner is used to maintain the cleanliness and hygiene of the machine by removing any extra dust or debris from its components. It helps in preventing contamination during the filling operations.

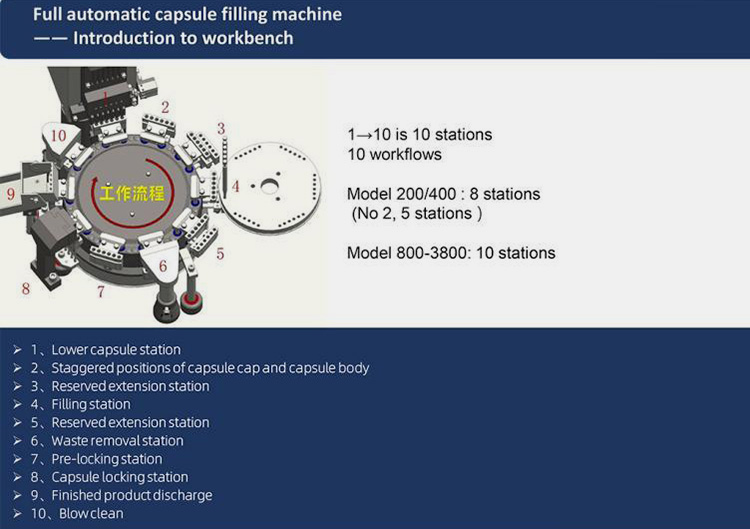

3.How Does A Capsule Filler Work?

The working principle of capsule filler is based on the electrical and mechanical coordination between different components. First, empty two-piece capsules are loaded into the capsule hopper at the top of the machine, while powders and granules are added to the powder hopper. Then, a vibrating device shakes the capsules so that they fall through the capsule shell silo into a cylinder rod.

At this point, the filling agency is then activated to fill the capsules with powders and granules to a predetermined weight. It contains rotating discs with a lower capsule station which holds the capsule cap and capsule body separately. After filling, any waste is removed and placed back to the recycle device which ensures there is no waste of content or empty powder. Finally, the capsules are locked and the finished product is ejected from the machine ready for package and delivery.

The entire process is automated and monitored by a PLC operation panel and various sensors attached to it. The working speed of the machine can also be adjusted as per requirement through this control system.

4.What Are The Applications Of A Capsule Filler?

The applications of a capsule filler are wide-ranging, from pharmaceuticals and medical products to food supplements and other dietary aids. Here are some of the main uses for a capsule filler:

Pharmaceuticals and medical products

Most pharmaceutical companies use capsule fillers to make their tablets, capsules and other products. This is because they allow them to accurately measure out exact amounts of ingredients that are needed in each dose, while also providing consistent quality control.

Food supplements and dietary aids

Capsule fillers are used to make food supplements like vitamins, minerals, herbal extracts and other natural health products. This ensures that the ingredients are accurately measured out before being encapsulated, allowing for precise doses of each ingredient in the product.

Nutraceuticals

Nutraceuticals are products that contain nutrients, vitamins or other natural substances which have proven to be beneficial to health. A capsule filler can help ensure the accurate and consistent distribution of these ingredients into capsules.

Recreational drugs

Capsule fillers are also used for the manufacture of recreational drugs like marijuana. This ensures that each dose is accurately measured out, making for a more consistent and pleasurable experience.

Cosmetic products

Capsule fillers are also used for the manufacture of cosmetic products like lipsticks and face creams. This is because they help ensure that each dose contains the right amount of each ingredient, making sure that the product works as intended.

Veterinary products

Capsule fillers are often used for the manufacture of veterinary drugs and supplements. They can help ensure that each dose is accurately filled, which helps to make sure that animals get the correct amount of medication they need.

5.What Are The Advantages Of Using A Capsule Filler?

A capsule filler can be an incredibly useful tool for any industry that deals with pills, tablets or other small items. Here are the seven advantages of using a capsule filler:

High Speed

Using a capsule filler can dramatically speed up the process of filling capsules, depending on the number of capsules that need to be filled. The machine is designed to quickly and accurately fill capsules with just the right amount of powder ingredients.

Hygiene

Since capsule filling machines use air compression to fill the capsules, there is no risk of contamination from people handling the capsules. This ensures that the capsules remain clean and free from any bacteria or other contaminants, which is essential for pharmaceutical-grade quality.

Accuracy

A capsule filler ensures accuracy when filling capsules, as it allows for precise measurements of powder. This means that you won’t have to worry about under or over-filled capsules, as the machine will make sure that each one is filled with the correct amount.

Reliability

Capsule filling machines are incredibly reliable and long-lasting. As they are designed to withstand the rigors of daily use, you can be sure that it will continue to work for years to come. This means that you won’t have to worry about replacing it anytime soon.

6.What Are The Different Types Of Capsule Fillers Available?

When it comes to capsule filling, there are several types of machines that can be used depending on the size and complexity of your capsule-filling project. Here is a look at some of the different types of capsule fillers available:

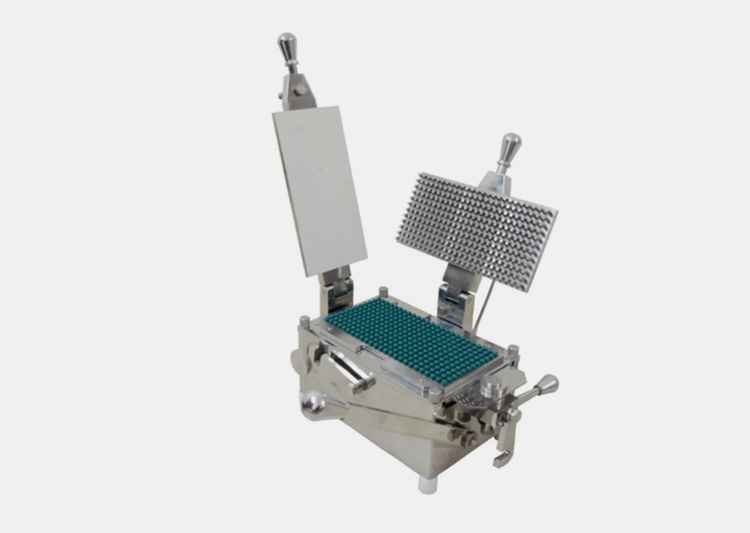

Manual Capsule Fillers

Manual capsule fillers are small and compact, making them perfect for a home user or small business. They are easy to use and require minimal training, as well as low maintenance costs. These machines require no electricity, so you can use them anywhere. The capsules are filled manually using a crank handle that moves the filling material into the capsule at a rate of up to 20 capsules per minute.

Semi-automatic Capsule Fillers

Semi-automatic capsule fillers are larger than manual models and require a bit more training to use. These machines have a higher speed capability, with the ability to fill up to 50 capsules per minute. They also require electricity and can be easily adapted for other applications, such as tablet making.

Automatic Capsule Fillers

These fillers are the most popular type of machine used in pharmaceutical companies and dietary supplement manufacturers. Automatic capsule fillers machines are larger, more complex, and require a high level of skill and experience to use. These machines can fill up to 300 capsules per minute, making them ideal for high-volume production environments. They also come with advanced features such as automatic loading/unloading systems and precision controls for accurate filling.

7.What Is The Difference Between Manual And Automatic Capsule Filler?

Manual capsule fillers and automatic capsule fillers are two types of equipment used to fill capsules with a variety of products. It is important to understand the differences between manual and automatic capsule filling machinery in order to choose the right one for your application.

The most obvious difference between manual and automatic capsule filling machines is that manual machines require manual labor to operate, while automatic ones are operated using computer-controlled systems. Manual capsule filling machines rely on the user to manipulate controls in order to adjust for size and fill rate of each individual capsule. Automatic machines use sensors and programmed algorithms to ensure accurate filling of each type of capsule.

Another difference between manual and automatic capsule fillers is the production rate. Manual machines can fill fewer capsules per hour than automatic ones, and they require more time to adjust and re-calibrate for different sizes of capsules. Automatic machines are capable of filling multiple types of capsules at a much higher rate.

In terms of cost, manual capsule filling machines are typically cheaper than automatic ones. However, automatic machines are more efficient and cost-effective in the long run due to their larger production rate and reduced labor costs.

Finally, manual capsule filling machines typically have a smaller footprint than automated ones, meaning they take up less space on your production floor. They are also often easier to set up and maintain than automated machines.

8.Are There Different Types Of Capsules That Can Be Used In a Capsule Filler?

You can use a variety of different types of capsules in a capsule filler. The type of capsule you use will depend on the condition and contents of your product. Here are some of the most common types:

Gelatin Capsules

These are made from animal collagen, which gives them their flexibility and resistance to moisture. They are available in a wide range of sizes, colors, and shapes. They are ideal for products with delicate ingredients, as they are easy to swallow without breaking down the contents.

Vegetable Cellulose Capsules

Vegetable capsules are made from vegetable cellulose and do not contain any animal products. They provide an all-natural alternative to gelatin capsules and are typically used for herbal supplements. They are also ideal for products that contain volatile ingredients, as they keep the content’s freshness intact.

HPMC (Hypromellose) Capsules

HPMC stands for hydroxypropyl methylcellulose, which is a plant derivative used to create a vegan-friendly version of the gelatin capsule. HPMC capsules are known for their superior strength and stability in various environmental conditions.They can withstand high temperatures without breaking down, making them ideal for products with heat-sensitive ingredients.

9.Which materials can you fill in capsules by the capsule filler?

Capsule fillers are used to fill a variety of materials into empty gelatin or HPMC (hydroxypropyl methylcellulose) capsules. Some common materials that can be filled into capsules include:

Powders

Powdered substances, such as vitamins, minerals, and herbs, are the most commonly filled materials in capsules. These substances are easy to measure and dispense, and they mix well with other ingredients.

Pellets

Pellets, which are small, round beads, can be made from a variety of materials, including plant extracts and synthetic compounds. Pellets are often used to provide a controlled release of the active ingredient over time.

Tablets

Tablets can also be filled into capsules if they are of a specific size or shape that is not suitable for direct consumption. This method helps to mask the taste or appearance of the tablet and makes it easier to swallow.

Granules

Granulated substances like herbs, caffeine, sugar, and salts can also be filled into capsules. These materials are typically ground into a fine powder and then filled into the capsule.

10.What quality standard should capsule filler meet with?

Good Manufacturing Practices (GMP) Compliance

Good Manufacturing Practices (GMP) are guidelines established by the International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH). According to these standards, all manufacturing and production processes must be in compliance with safety regulations and quality control protocols. This applies to capsule fillers as well, ensuring that they are built and operate correctly to ensure patient safety.

ISO 9001 Certification

International Organization for Standardization (ISO) standards provide guidance on quality management processes and procedures related to product development. They are used to ensure that products are produced in a consistent manner, meeting all relevant safety regulations and producing consistent results. For capsule fillers, the ISO standards help manufacturers make sure that their machines are reliable and produce capsules of a consistent quality and size.

FDA (Food and Drug Administration)

The Food and Drug Administration (FDA) is a regulatory body in the United States responsible for ensuring that all drugs, medical devices, food and other products sold in the US meet certain standards of safety, quality and efficacy. Capsule fillers sold in the US must comply with FDA regulations to be legally marketed.

CE (European Conformity)

Capsule fillers must also meet the standards established by the European Union’s Conformité Européenne (CE) program. This is a voluntary certification that requires manufacturers to submit their product for testing and approval before it can be put into production. The CE also sets strict requirements for electrical safety of the machine and labeling of the product. By meeting these standards, manufacturers can ensure that their capsule fillers meet all applicable safety regulations in Europe.

Conclusion

Capsule fillers make it easier for people to take their medication. With a quality Capsule Filler, you can be sure that your capsules will be filled correctly and efficiently. Allpack is a leading manufacturer of high-quality packaging machinery and we can help you choose the right machine for your needs. Contact us today to learn more about our products and how we can help you boost your business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide