Lip Balm Filling Machine: The Complete FAQ Guide In 2025

Lip Balm Filling Machine: The Complete FAQ Guide In 2025

What is your favorite product in daily skin care? Do you think lip balm is the most popular product? Have you ever known what is lip balm filling machine? Do you know the current market share of lip balm filling machine? The following blog can offer you a good understanding of what lip balm filling machine is and their uses with the detailed product features. Hope you'll like it!

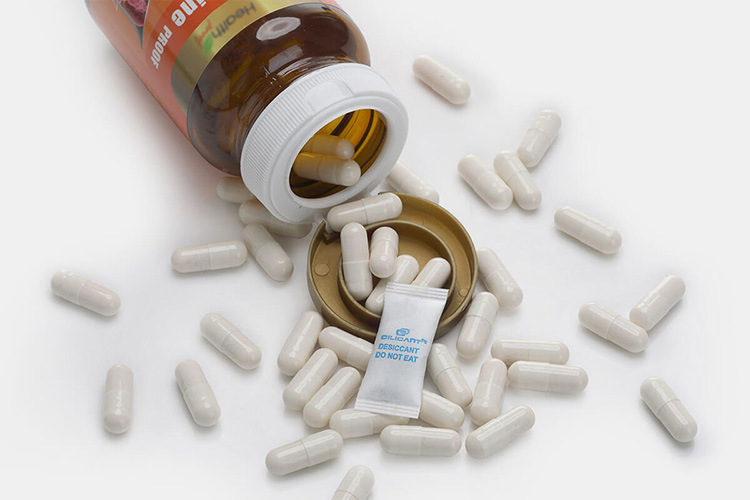

1. What Is The Lip Balm?

The lip balm is a wax-like substance inside the lip bar that is specially formulated to moisturize and hydrate the lips.

Lip balms with different ingredients serve different purposes. Most lip balms have nourishing and moisturizing functions. A small number of lip balms have medicinal functions, such as anti-inflammatory and bactericidal. Some lip balms even have the function of color development and even sun protection.

2. What Is The Lip Balm Filling Machine?

The lip balm filling machine is specially designed for filling and packaging cosmetics, liquid pastes, cream, and semi-solid products into different containers for producing lip balms, lipsticks, pen lipstick, eyebrow pencil, lip oil, lip gloss, etc.

It can produce a wide variety of products. And it contains a variety of different models, which can meet a variety of production needs. With heating, mixing, and filling functions, this machine can be applied to a series of products with multiple types.

3. What Products Can Be Applied By The Lip Balm Filling Machines?

There are plenty of products that can be made by the lip balm filling machines:

Lip Balm

Lip balm filling machines are mainly used to make and produce lip balms. It can provide a variety of lip balms production, including chap stick, lip repair, lip masks, lip wax balm, etc.

Lipsticks

Lipsticks are a type of cosmetics that are mainly used to cover up the original color of the lips and add other colors to your natural solid color. Lipsticks come in countless colors and brands and are popular with women.

Lip Gloss

Lip gloss is a product between lip balm and lipstick. It is distributed as a fluid or a soft solid product. It combines the advantages of lip balm and lip gloss. It can not only bring moisture to lips but also add your favorite color to lips.

Liquid Eyebrow Pen

The liquid eyebrow pen can be applied for eyebrow coloring with liquids. When used on brows, the liquid will gradually solidify after a few seconds of air drying.

Eyeliner

Eyeliner is mainly used in eye makeup. Likewise, it can be applied by the lip balm filling machine with high efficiency and accuracy.

Solid Glue

Solid glues are specially used for pasting paper. It belongs to a stationery product. Also can use a lip balm filling machine to complete filling and packaging.

Peppermint Balm

Peppermint balms are the kind of fast-acting products that can give you instant relief from tension, headaches, or sinus. It is a paste and is widely produced by the lip balm filling machine.

Scented Candles

Scented candles are also made with lip balm machines. The raw materials for scented candles are wax, too. So they also need the cooling system but do not need the capping system.

Face Balms

Face balms are mostly applied for cleaning, repairing, and deeply nourishing your face. They are mostly produced by lip balm machines. All the related products including body balms and hand balms are made with lip balm machines.

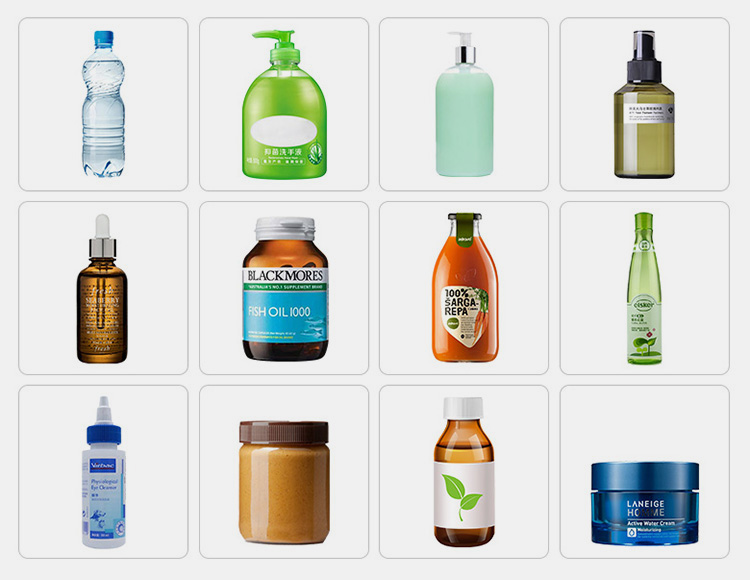

4. How Many Types Of Containers Are There For Lip Balms?

Lip balms come in a variety of packaging. The most popular packaging containers are as follows:

Twist-up Tubes

The twist-up tubes can be applied to all kinds of lip balms for easy use and clean. And it is also perfect for lotion bars and solid perfumes. The tubes can be twisted up and down for your use and protect your wax from squeezing.

Round Jars

The round jars for lip wax are mostly aluminum or plastic made. It can also be applied for packaging hand cream and lotion. The round jars are easy to carry and can pack 0.5g to 10g at one time.

Lip Gloss Tubes

The lip gloss tubes are generally long tube-shaped packaging. This packaging method can be convenient for users to take and wipe. The lip gloss tubes are mostly made with durable PETG plastic. The clear tubes make it easy to identify the product inside.

Lip Balm Sphere Containers

The lip balm sphere containers with lids are perfect for pockets, purses, wallets, handbags, backpacks, and suitcases. It can seal and open smoothly. And it can be applied to your lip perfectly.

Roll-on Gloss Lip Balms

The roll-on gloss lip balm does not require fingers to apply, and the roll-on top dispenses product directly on the lip. This not only prevents the liquid in the product from becoming contaminated but also allows for an even application to your lip.

Irregular Shape Lip Balms

The pineapple lip balms belong to the irregular shape of the packaging. There are also other shapes in the online shopping mall, such as apples, oranges, lemons, etc. This can attract the attention of more consumers, thereby increasing sales.

5. What Are The Feature And Advantages Of Lip Balm Filling Machines?

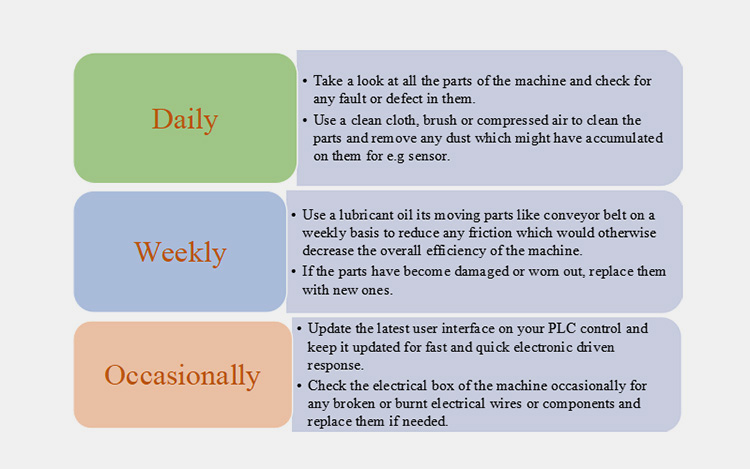

The features of the lip balm filling machines are:

High Filling Accuracy

The lip balm filling machine adopts a piston filling system to feed hot products into different containers, which can provide you with high filling accuracy and precision. The filling accuracy can be controlled within ±0.5%.

Smooth Filling

With the 150L heating and stirring tank of three layers for different materials mixing and melting, it can offer you a smooth filling for materials of different sizes and shapes.

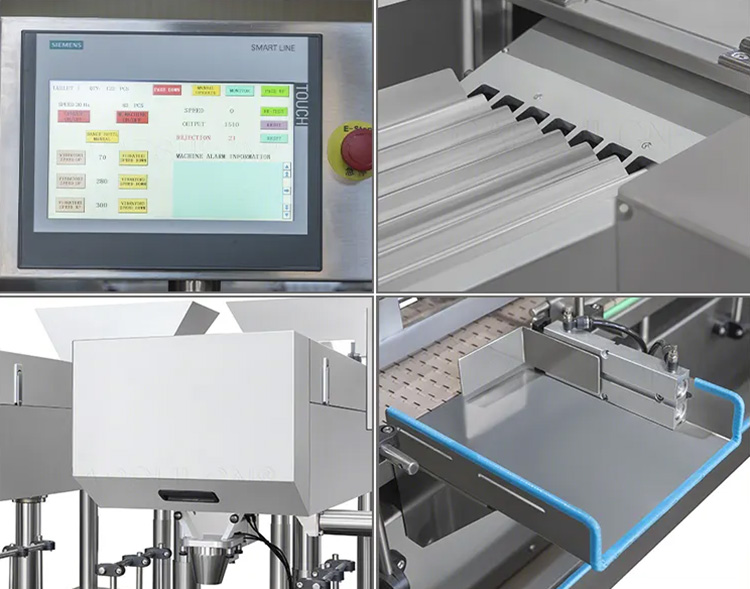

Electric Eye Sensing

Due to the electric eye sensor, it can precisely position each filling container for you. There will be no leakage, etc.

The advantages of the lip balm filling machines are:

Wide Application

In addition to common skin care products and cosmetics, the lip balm filling machine can also be applied in other industries. For example, wind oil essence ointment, peppermint ointment, scald ointment, etc. in the pharmaceutical industry. Daily chemical industry shoe polish, etc.

Easy Clean And Maintenance

All in-contact with filling materials are made of food-grade stainless steel which is durable, strong, and safe.

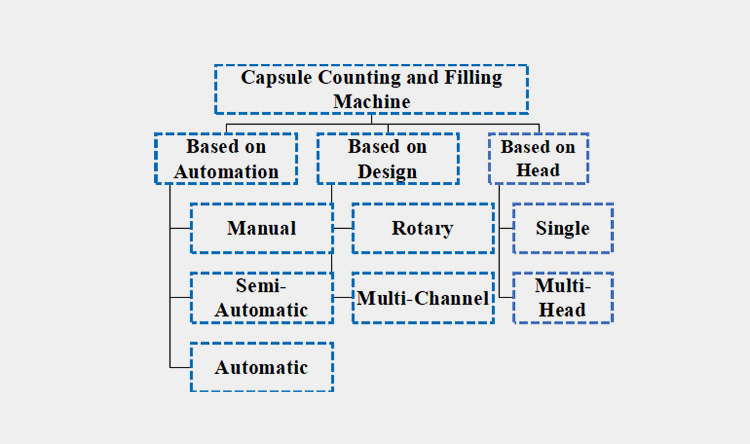

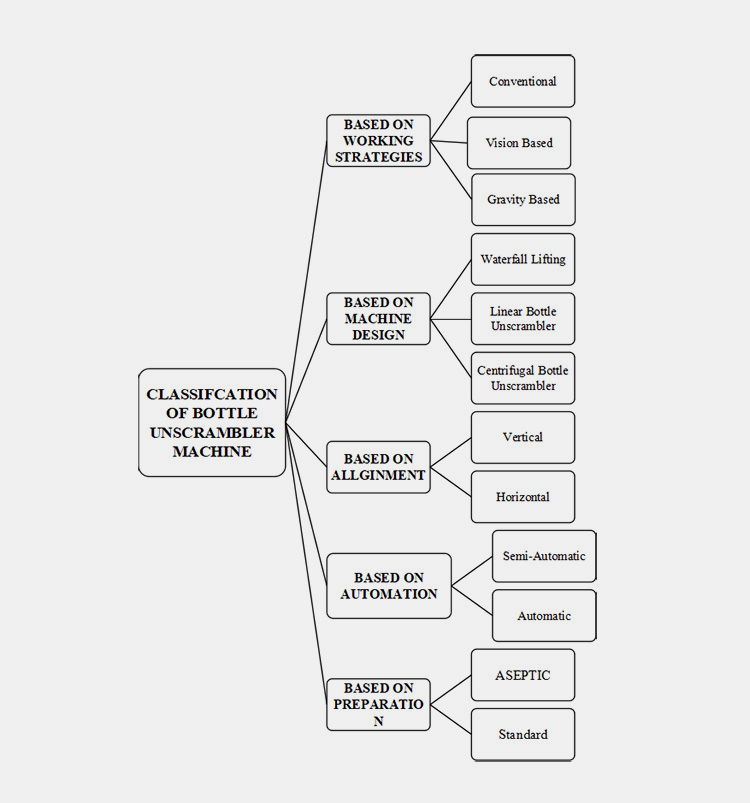

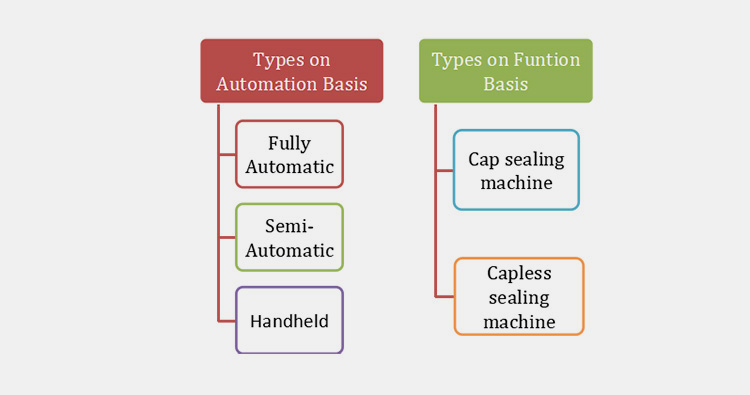

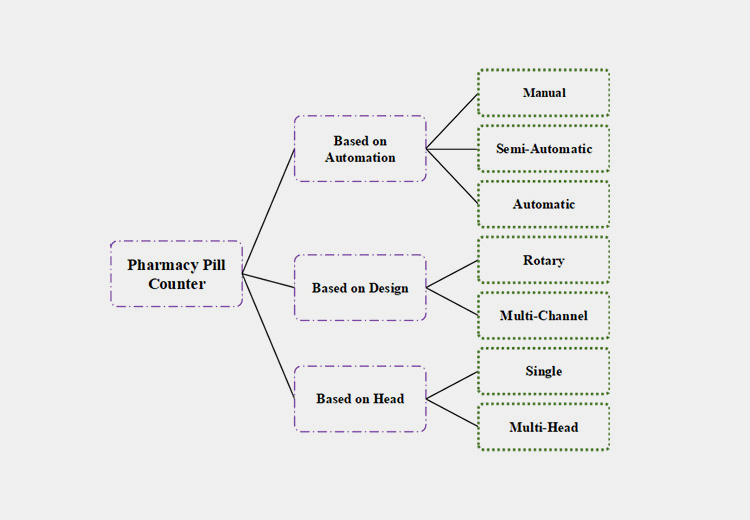

6. What Are The Types Of Lip Balm Filling Machines?

There are countless types of lip balm filling machines, the most important ones include:

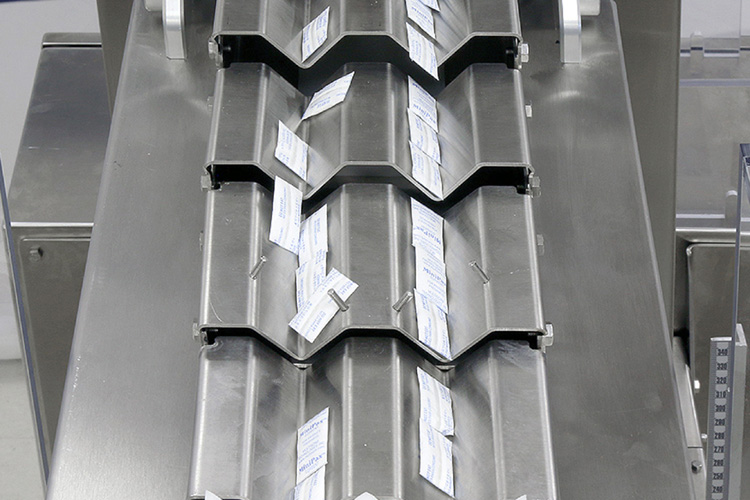

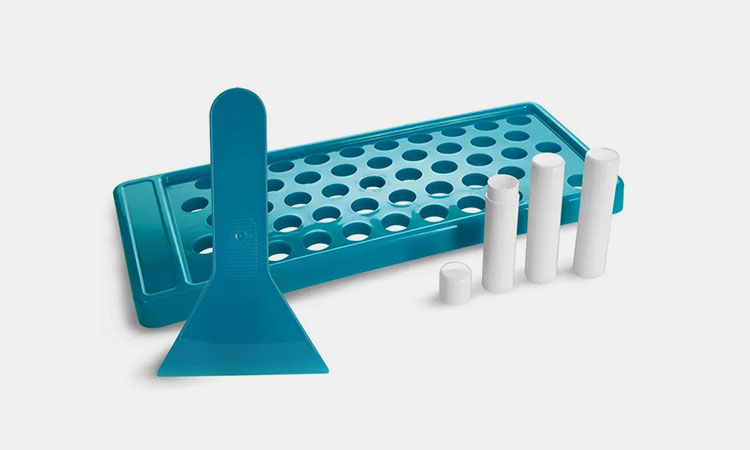

Lip Balm Filling Trays

The lip balm filling trays are specially designed for filling lip wax into tubes. It can fill up to 50 lip balm tubes at once instead of pouring them individually. All the tubes and trays are made of durable, food-grade high-density plastic materials that can ensure you good quality and long service life.

Manual Lip Balm Filling Machine

Manual Lip Balm Filling Machine -sourced: kenchi

The manual balm filling machine is suitable for filling sticky cream products after being mixed and warmed up, such as lip balms, lipsticks, liquid foundation, nail polishes, etc. It can be integrated into the filling lines for capacity needs. The individual temperature control for tanks can achieve precise and smooth filling.

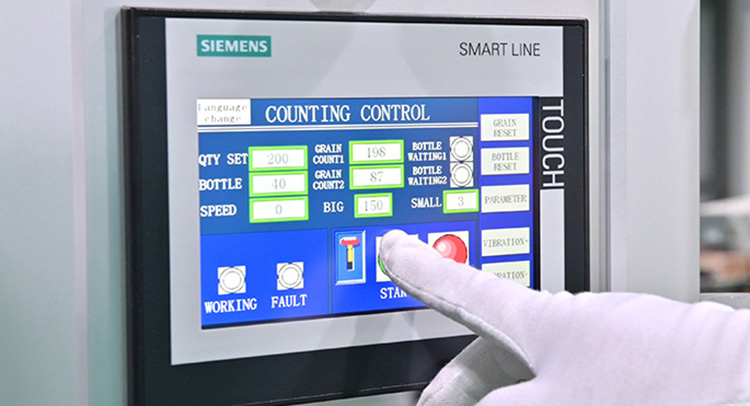

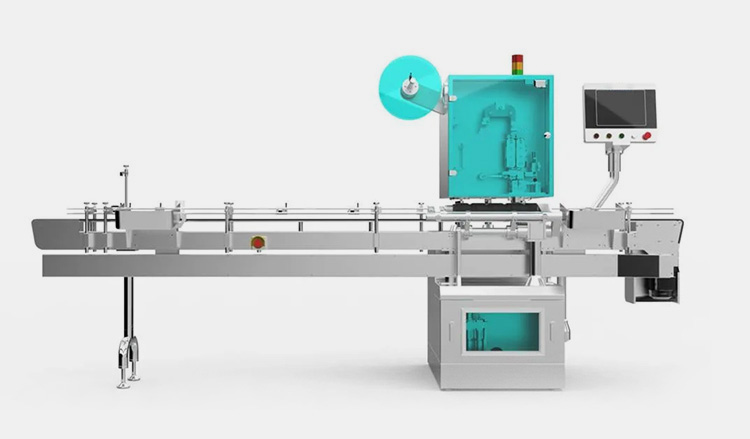

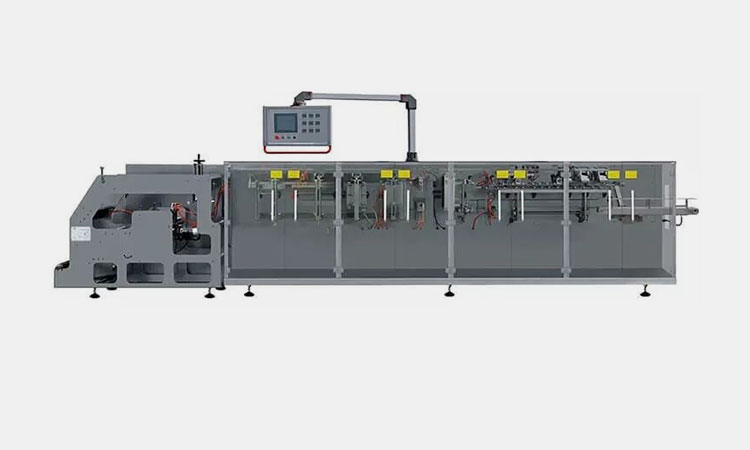

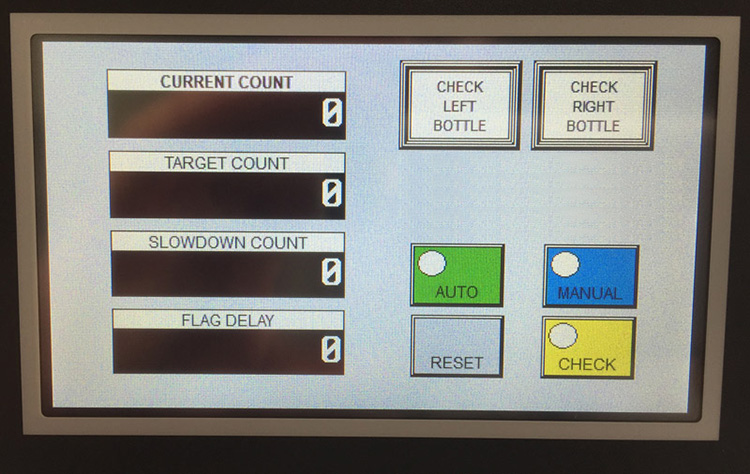

Semi-automatic Lip Balm Filling Machine

Semi-automatic Lip Balm Filling Machine -sourced: kenchi

The semi-automatic lip balm filling machine is equipped with a touch screen panel and servo motor for stable and digital control. The filling speed and filling ranges can be adjusted easily and for your different needs.

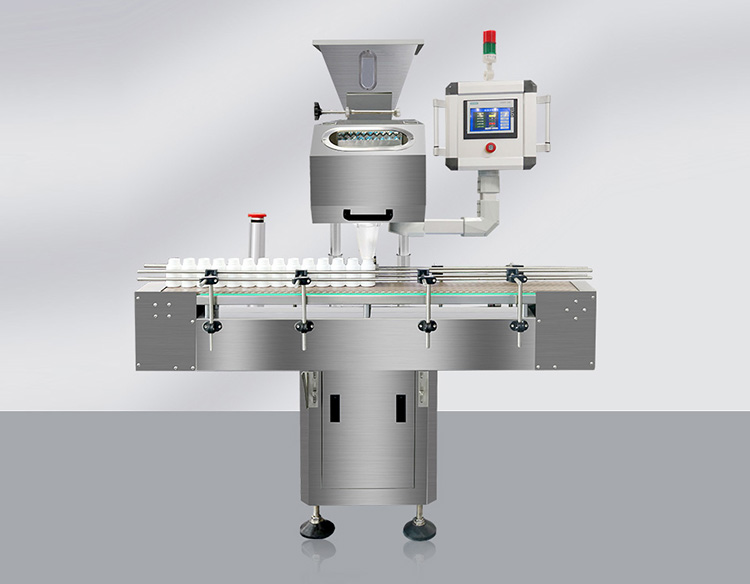

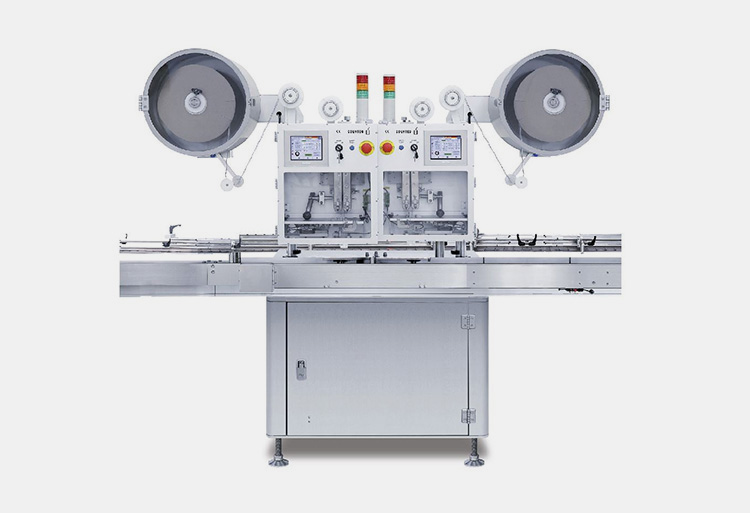

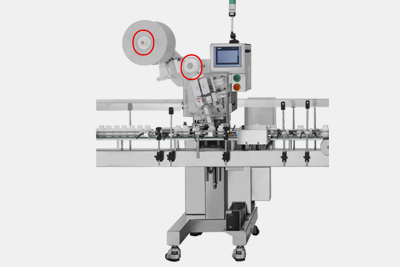

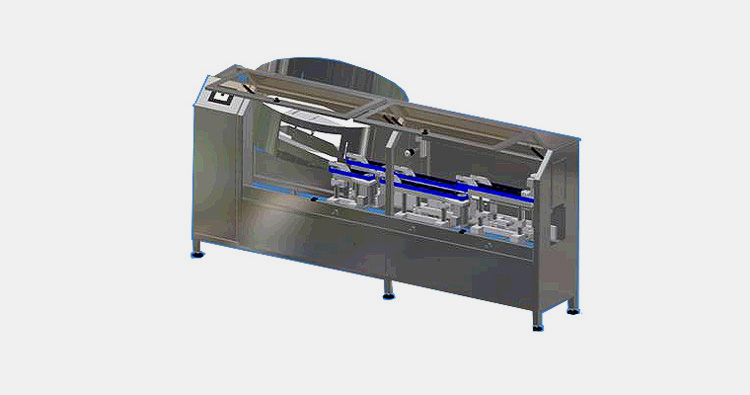

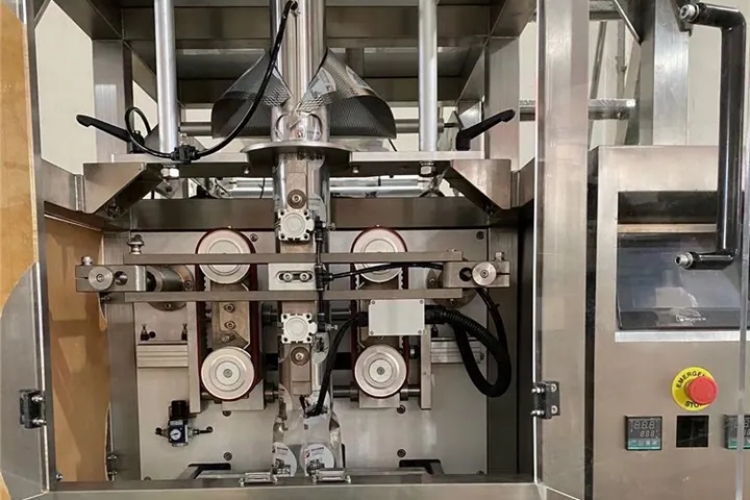

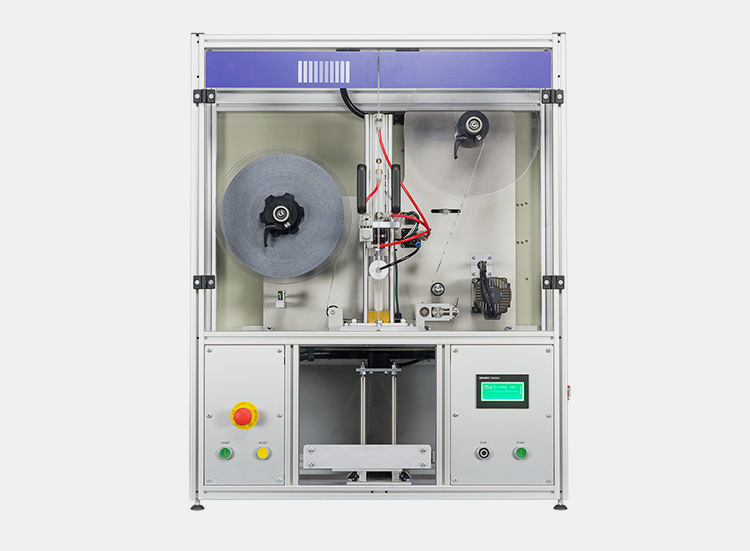

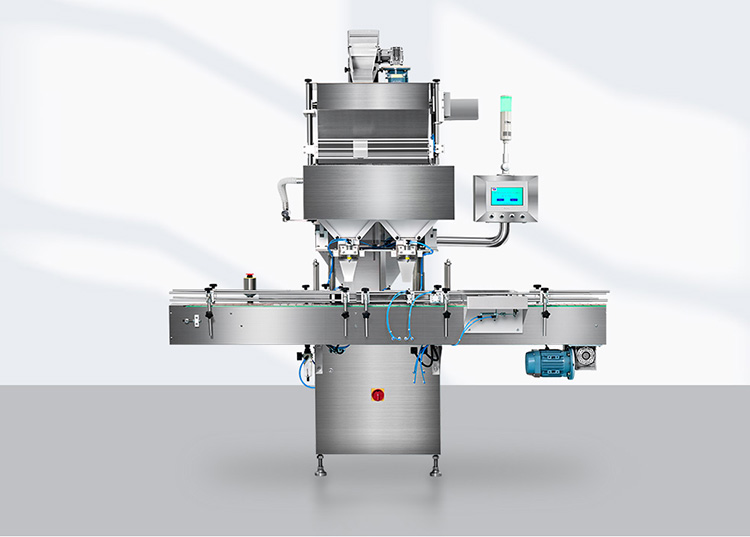

Automatic Lip Balm Filling Machine

Automatic Lip Balm Filling Machine -sourced: harsiddhengineering

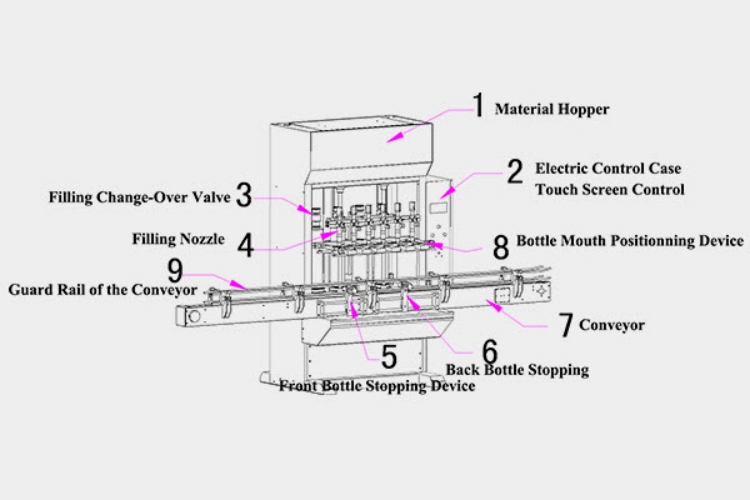

The automatic lip balm filling machines are suitable for all types of shapes and sizes container filling and packaging. Equipped with the SS conveyor, it can offer you automatic material filling. With four filling nozzles, it is used for high efficiency and capacity.

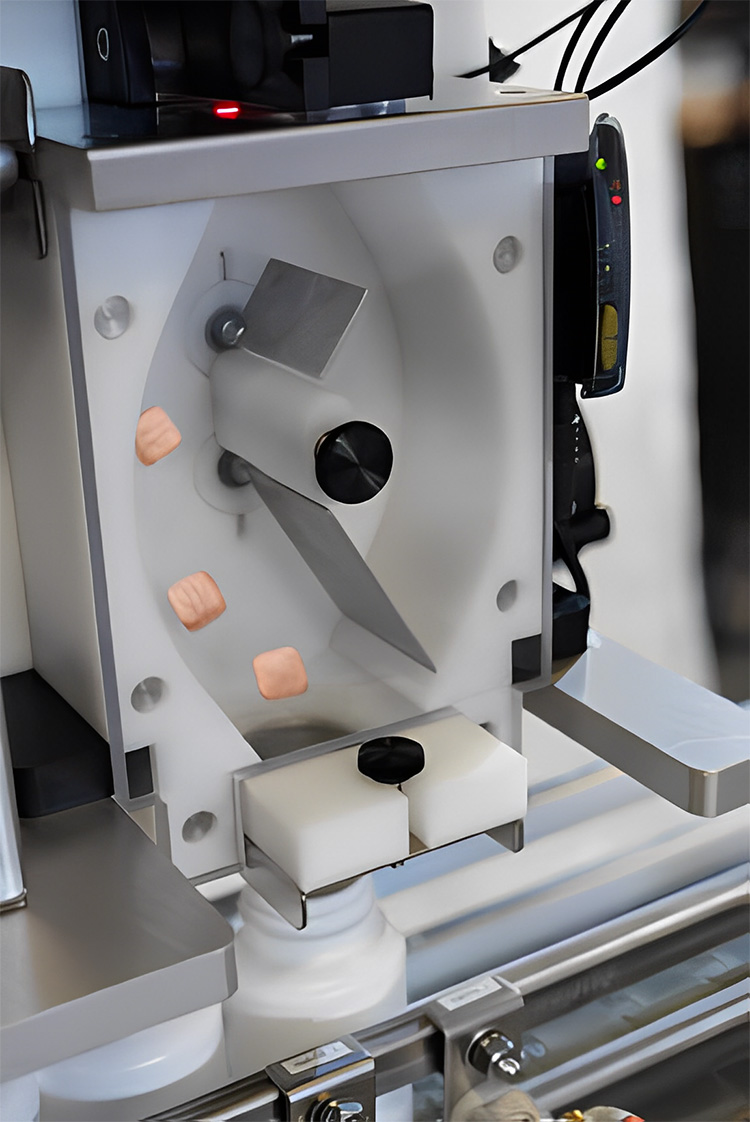

Ball Balm Filling Machine

Ball Balm Filling Machine -sourced: eugeng

The ball balm filling machine is applied for filling the hot products into ball or egg shape containers, such as lip balm, deodorant stick, balm jar, face balm, hair wax, etc. It applies the mold pre-heating system with a touch heating plate and blowing hot air from the top. This balm filling machine applies the piston-filling system for high accuracy.

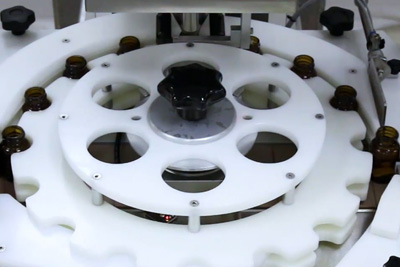

Rotary Lip Balm Filling Machine

Rotary Lip Balm Filling Machine -sourced: szhxmachine

The rotary type lip balm filling machine applies the rotary plate to control the accurate filling. With the servo motor system, it can control the pushing, feeding, and filling with high efficiency. The nozzle raising and lowering work smoothly and easily.

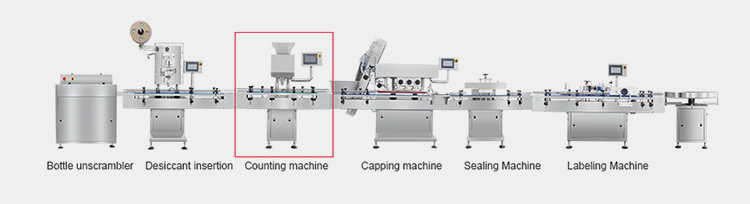

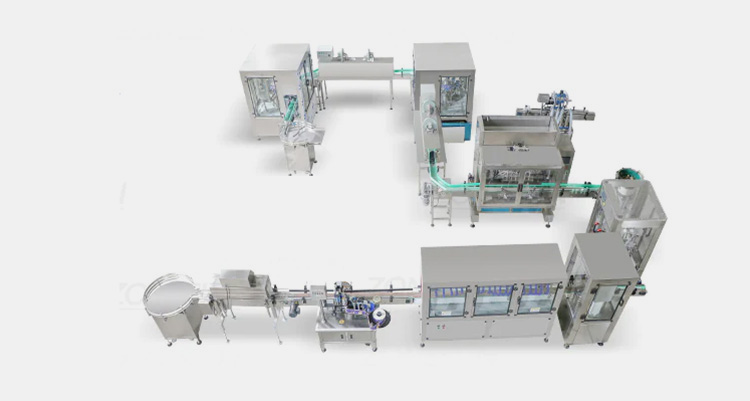

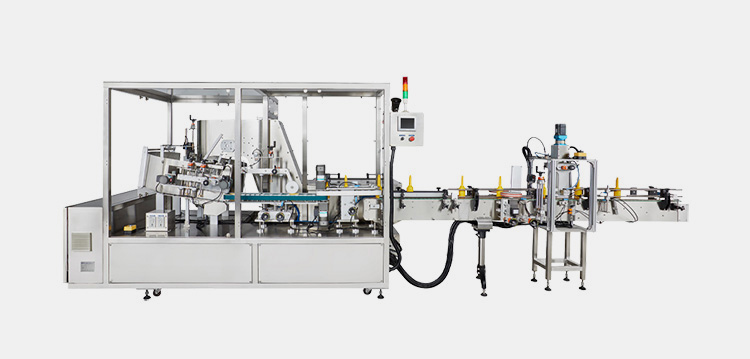

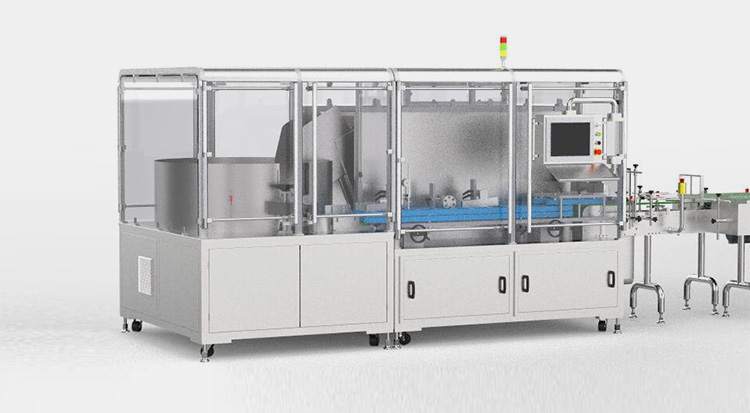

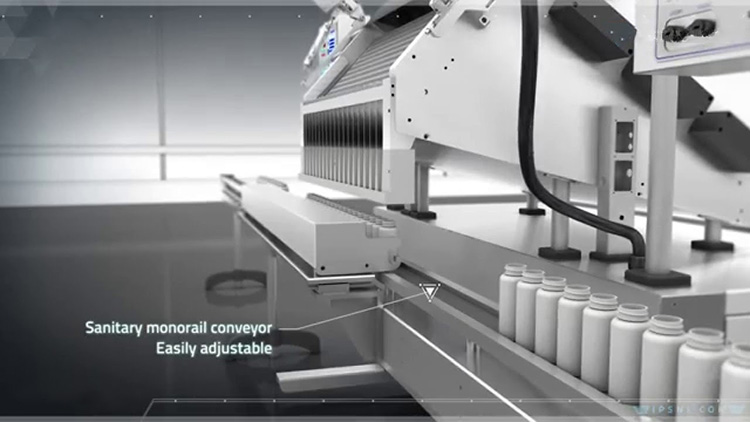

Lip Balm Filling Lines

Lip Balm Filling Lines -sourced: gieni

The lip balm filling lines can offer you the whole working process for producing lip balms without labor participation. It contains six main parts including tube uploading system, materials melting and mixing system, automatic filling system, cooling tunnel, and capping system. The lip balm filling lines is suitable for mass production of a single product.

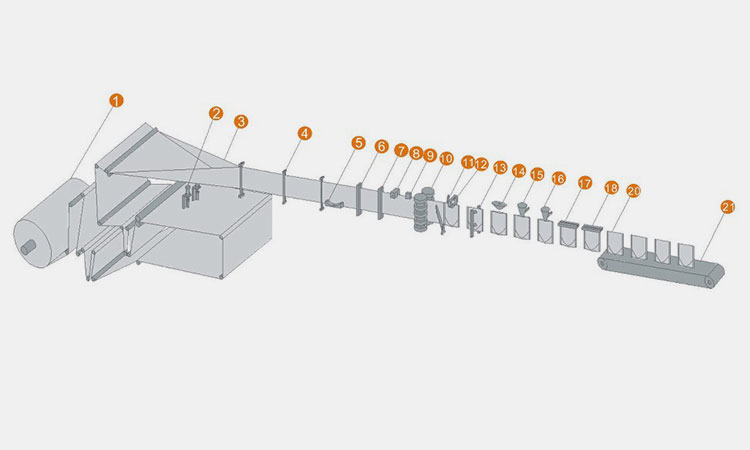

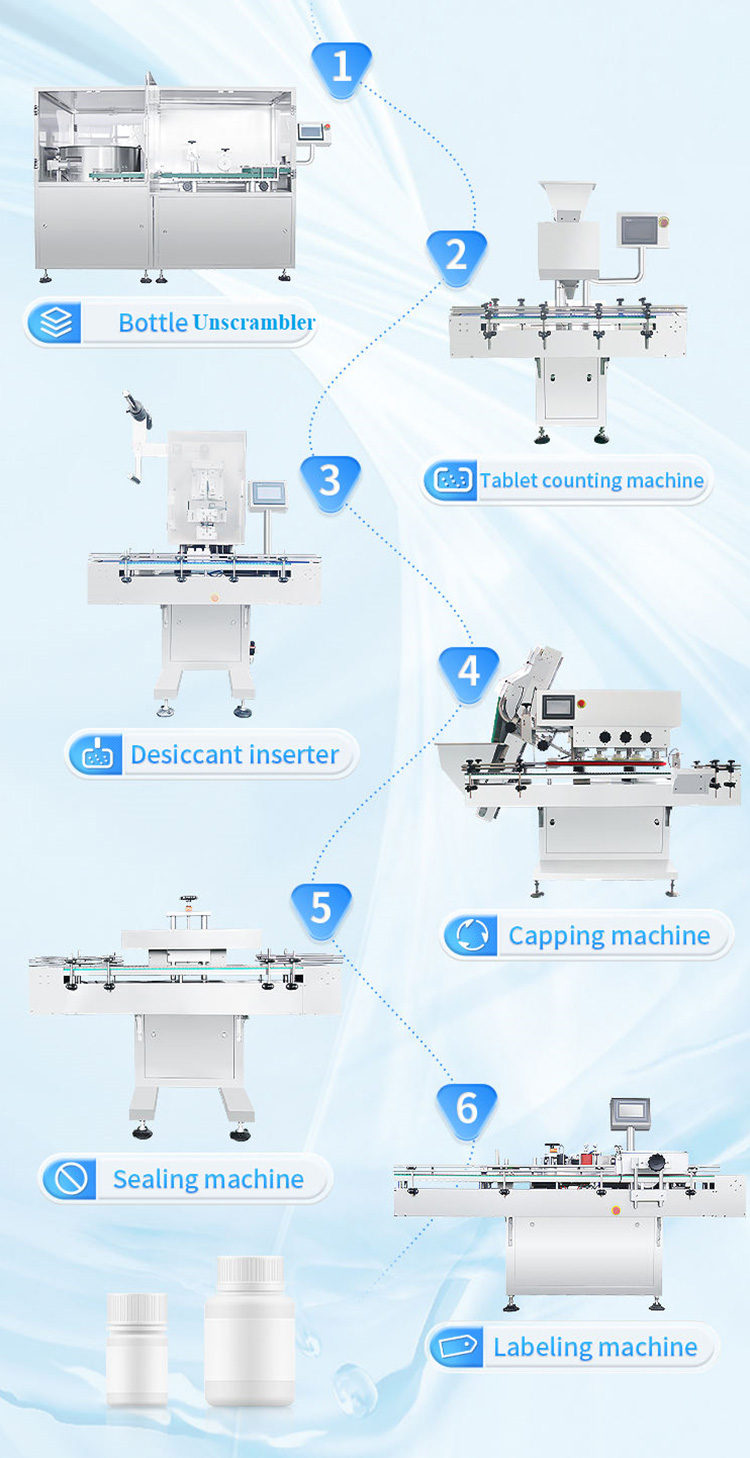

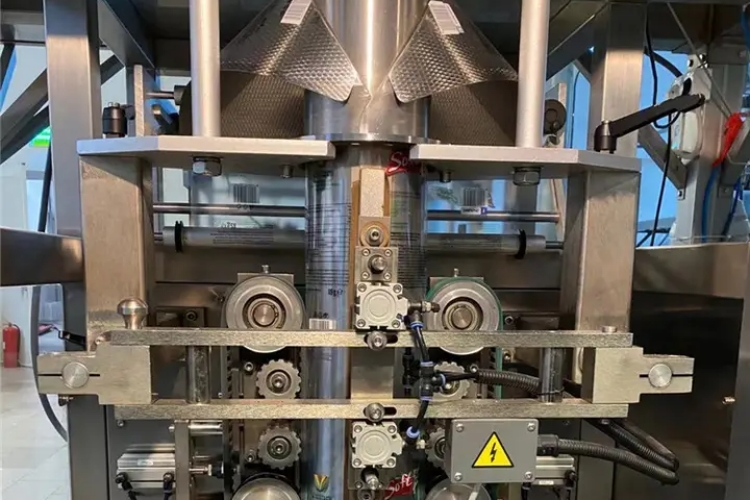

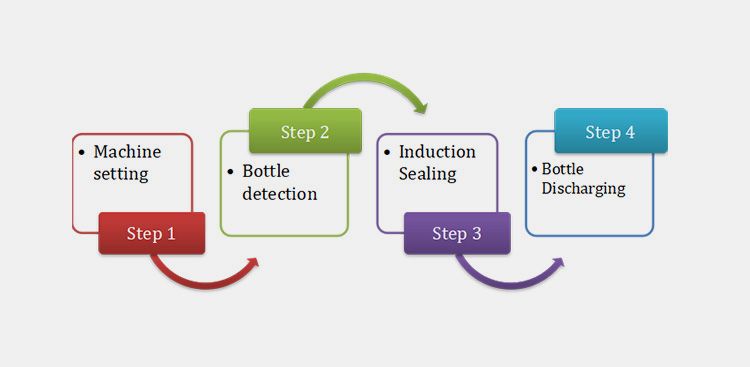

7. What Is The Working Principles Of Lip Balm Filling Machine?

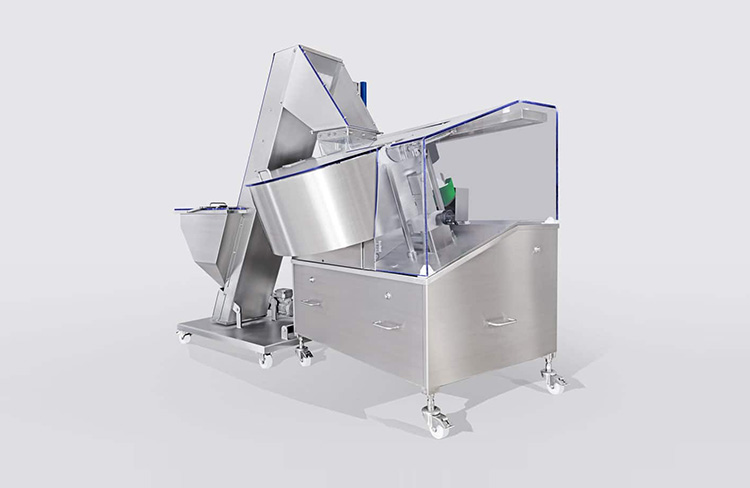

Working Principles Of Lip Balm Filling Machine - sourced: lehnen industrial service

The working principle of the lip balm filling machine follows the steps below:

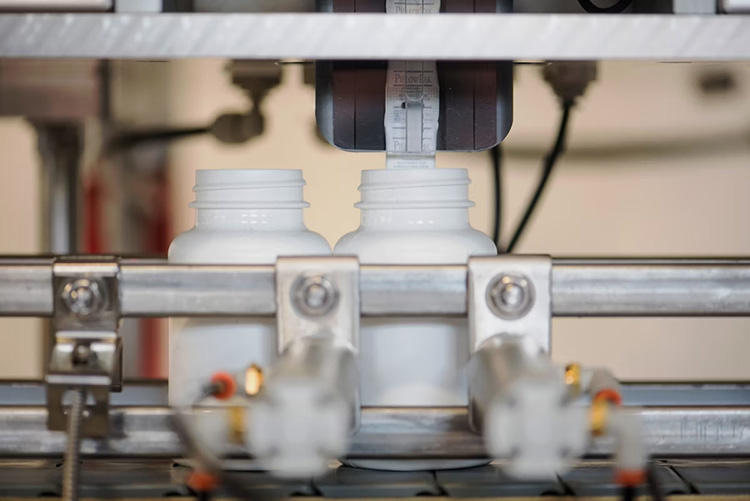

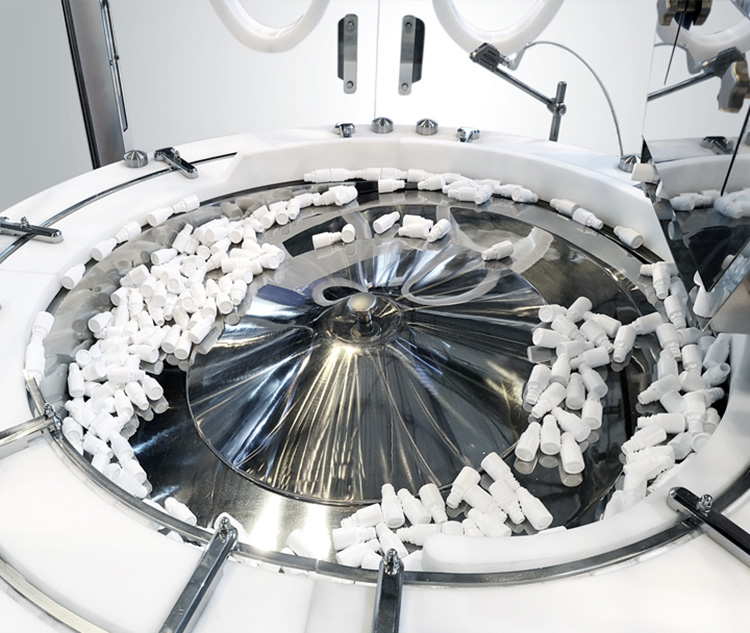

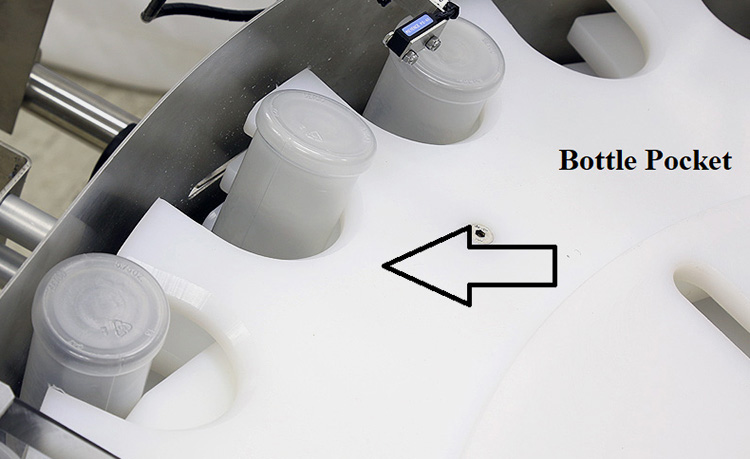

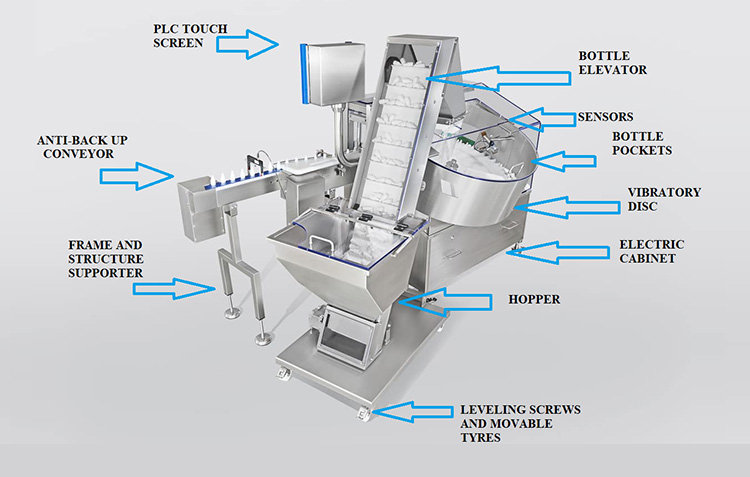

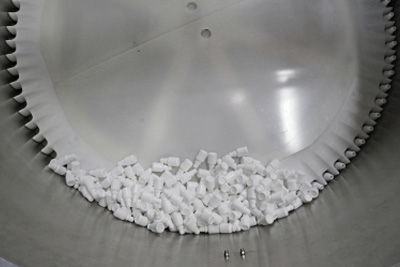

- Bulk Tube Elevator. The empty tubes that have been cleaned and sanitized will be uploaded into the bulk tube elevator. The tube elevator will be fed into the counting bowls with a vibrating system.

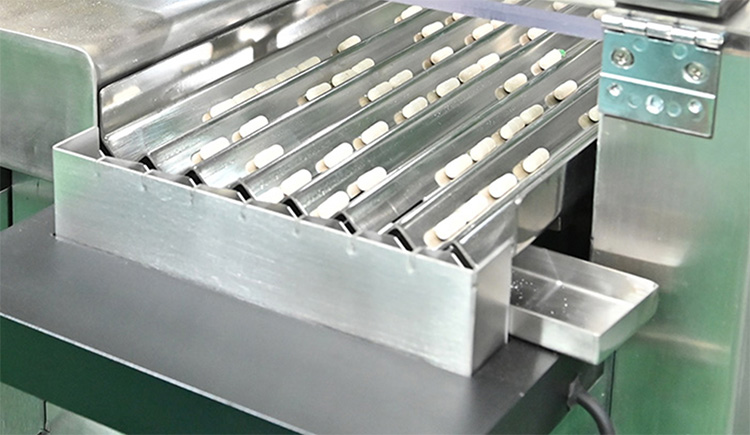

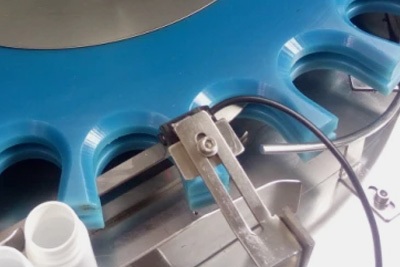

- After being counted by the vibrating bowl, all the empty tubes are now inserted into the molds with ten in a set in the conveyor belts.

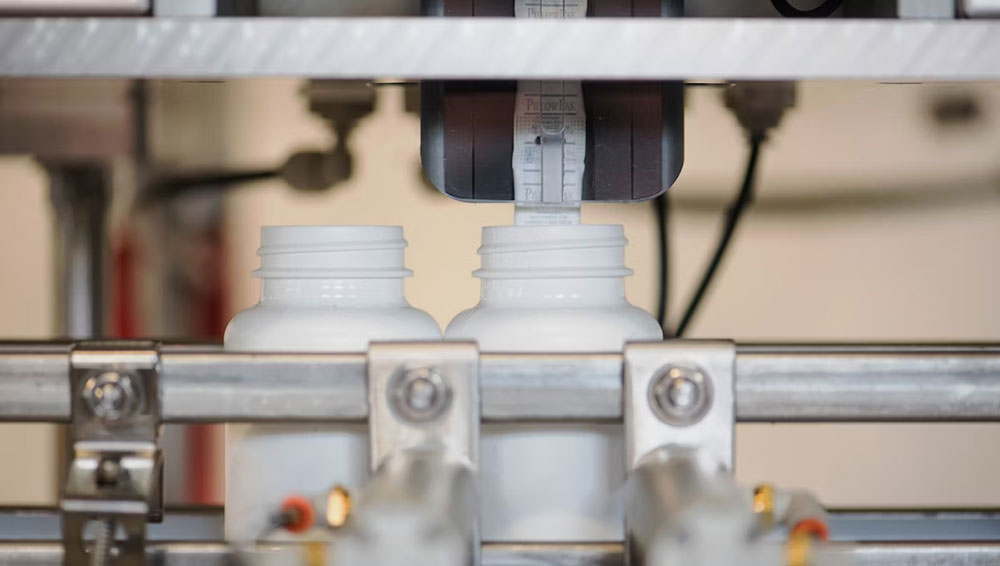

- With the automatic electric eye sensor, the set tubes will be filled with the raw materials set by set.

- After being filled with the hot products, all the filled tube sets will be pushed into the cooling system for better shaping.

- After being cooled down, the set tubes are now transferred to the melting station for re-melting to better occupying the tube packaging.

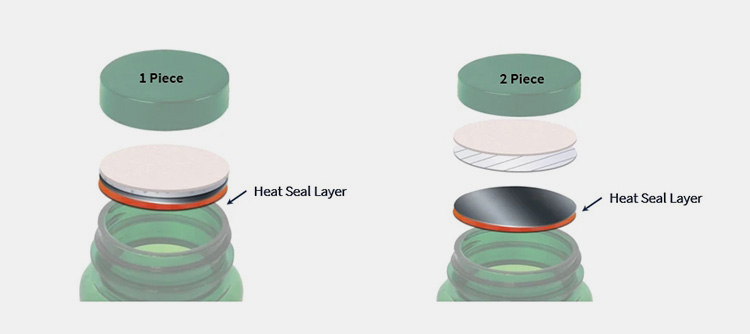

- After being re-melted, the set tubes are now carried to the cap sorting station. All the caps will be cleaned and sanitized before being uploaded into the cap sorter.

- Inside the cap sorter, all caps will be counted and ink-jet coded before being applied to the tube body.

- After being securely capped, all the tubes will be bottom-coded and film-wrapping packaged.

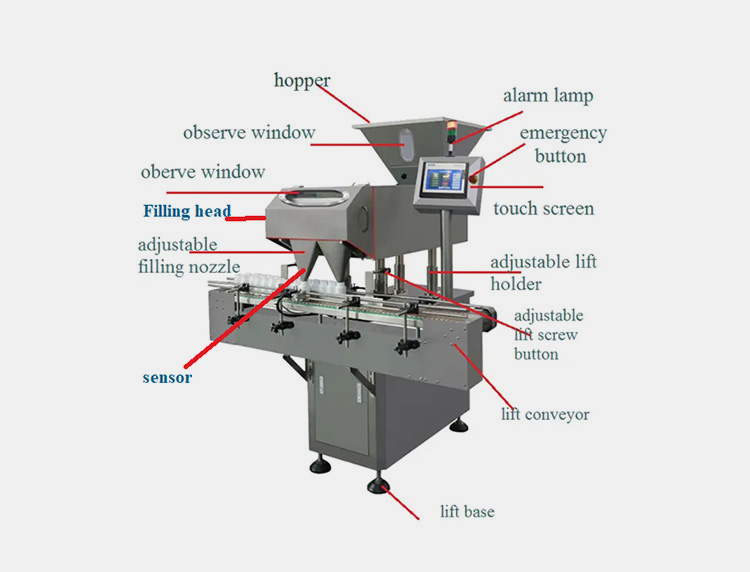

8. What Are The Main Components In The Lip Balm Filling Machine?

Main Components In The Lip Balm Filling Machine -sourced: kenchi

The lip balm filling machine mainly consists of a stirring motor, 20L heating barrel, filling range adjustment wheel, filling nozzle, pump temperature controller, barrel temperature controller, automatic/manual mode switch, and stirring speed knob.

Stirring Motor

The stirring motor mainly controls the stirring fans inside the barrel for better mixing and blending of the liquid, pastes, and cream materials. After being better mixed, they can be evenly filled.

20L Heating Barrel

The heating barrel can provide you with large-capacity material heating and stirring space. Due to the special material and simple structure, the heating barrel can be heated well without emitting harmful substances.

Filling Range Adjustment Wheel

The filling range adjustment wheel can be adjusted for your different capacity needs. The range can differ from your container volume. The adjustment range usually is from 5ml to 50ml.

Filling Nozzle

There are different volume filling nozzles for your choices. With the anti-drop function, it can precisely control each filling needs. Materials of different materials have different options for filling nozzles. For liquids, you can choose to fill nozzles thinner. For cream or pastes, you can choose slightly thicker filling nozzles.

Pump Temperature Controller

The pump temperature controller is mainly designed for controlling the pump's temperature. In order to avoid the overload of the pump and the temperature soaring during the heating of the mixing tank, which will affect the use of the machine.

Barrel Temperature Controller

During stirring, the barrel is heated to melt the materials that need to be filled. By constantly stirring and melting the materials, they can be mixed evenly, and it is convenient to fill them later.

Automatic/Manual Mode Switch

The automatic/manual mode switch can be applied for adjusting the machine's working mode. You can choose both the automatic filling and the manual filling by the foot-pedal control.

Stirring Speed Knob

The stirring speed knob is specially used to adjust the stirring speed. By judging the thickness of the material, you can manually speed up or slow down the stirring speed.

9. What Are The Dosing And Filling Process For The High Viscosity And Abrasive Pastes In The Lip Balm Filling Machines?

In the lip balm filling process, the most important part is the material dosing and filling. Especially when dealing with high viscosity and highly abrasive paste filling, how does the lip balm filling machine handle it?

Empty System And Dosing Pumps For Dosing Process

When filling abrasive pastes like washing pastes or scrub, common filling systems like gear pumps, and piston fillers usually will not work and may even cause damage to the machine. By employing a special tank emptying system and a dosing pump, it can directly start dosing highly concentrated raw materials. There is not even a need for a self-heating process.

Pressure Control System For Filling Process

When you are filling mascara, before heating the barrel and filling the nozzles, we will install a pressure control system with soft tubes for you. During the filling process, the pressure control system applies pressure to the hose, then enables the materials free flowing.

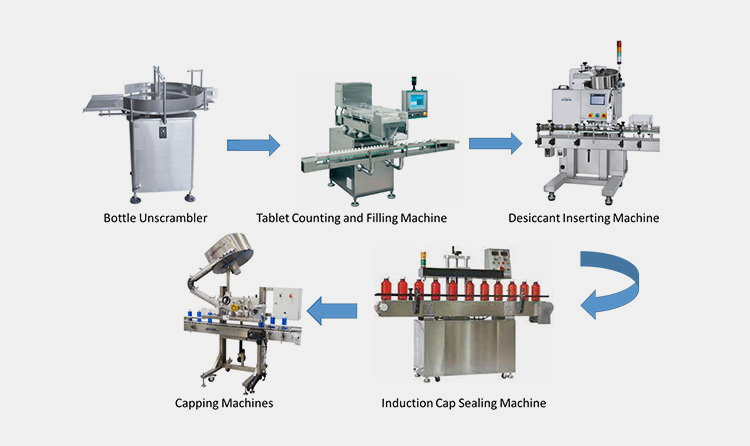

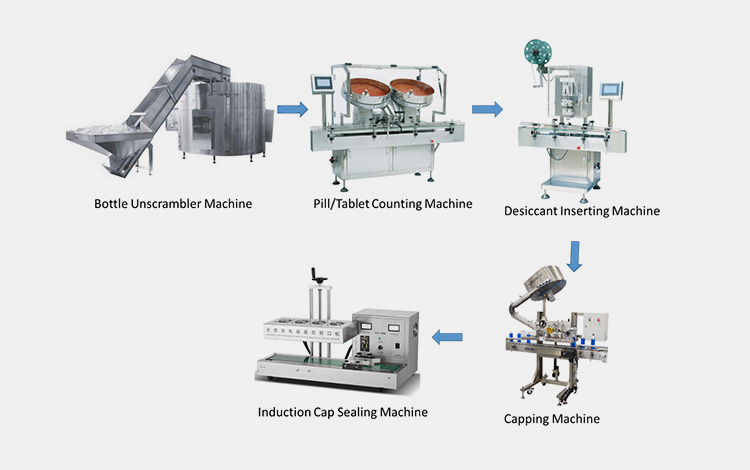

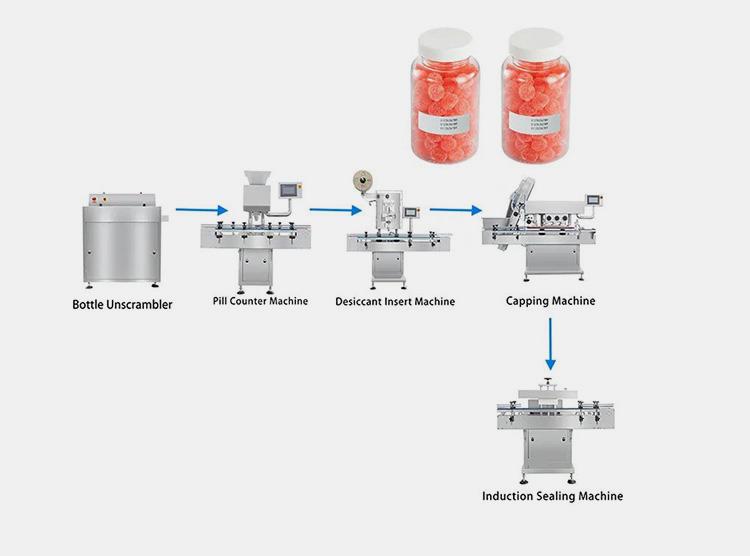

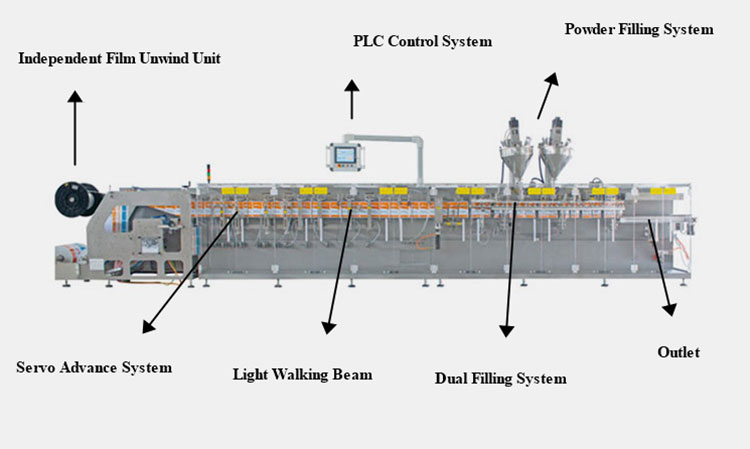

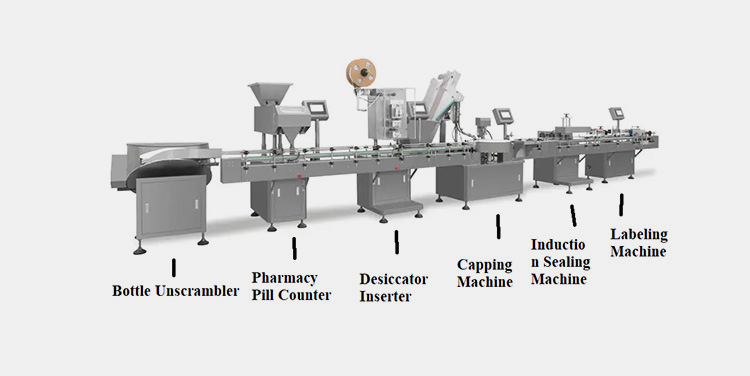

10. What Are The Auxiliary Equipment To Make The Lip Balm Filling Machine Into A Line?

Lip Balm Filling Lines -sourced: gieni

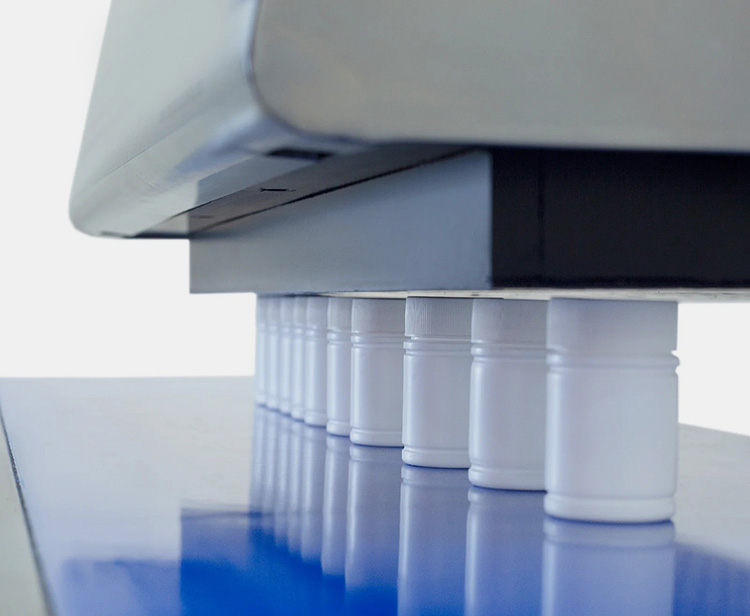

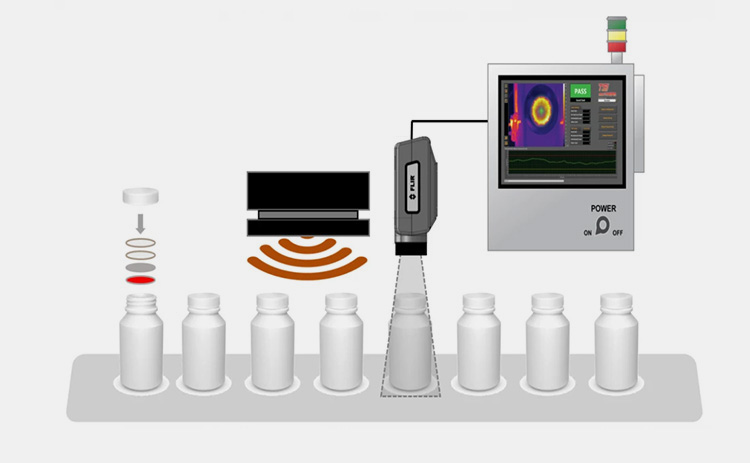

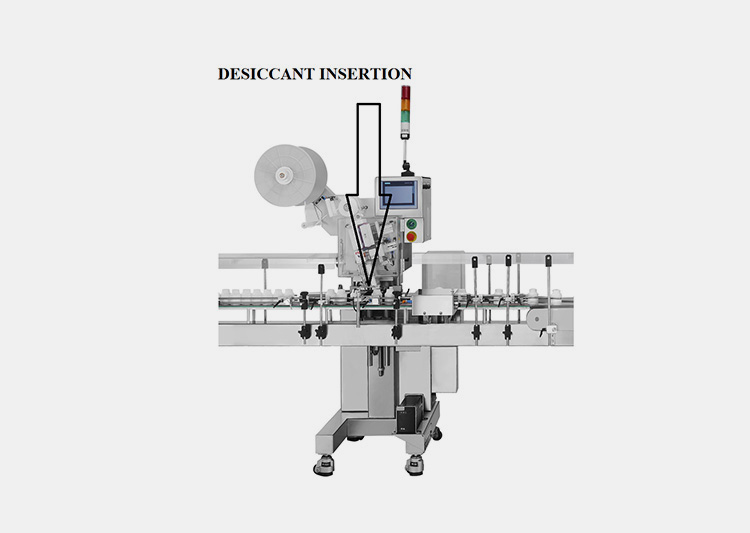

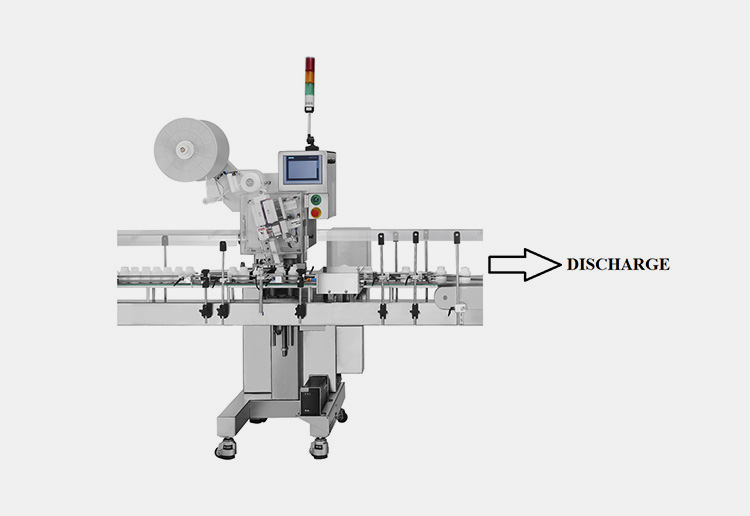

To make the lip balm filling machine into a line, you need more parts. The lip balm filling line consists of a tube uploading system, materials melting and mixing system, an automatic filling system, a cooling tunnel, and a capping system.

The whole lip balm filling line can automatically achieve the whole process of auto-filling, cooling, re-melting, second cooling, and finished product discharging.

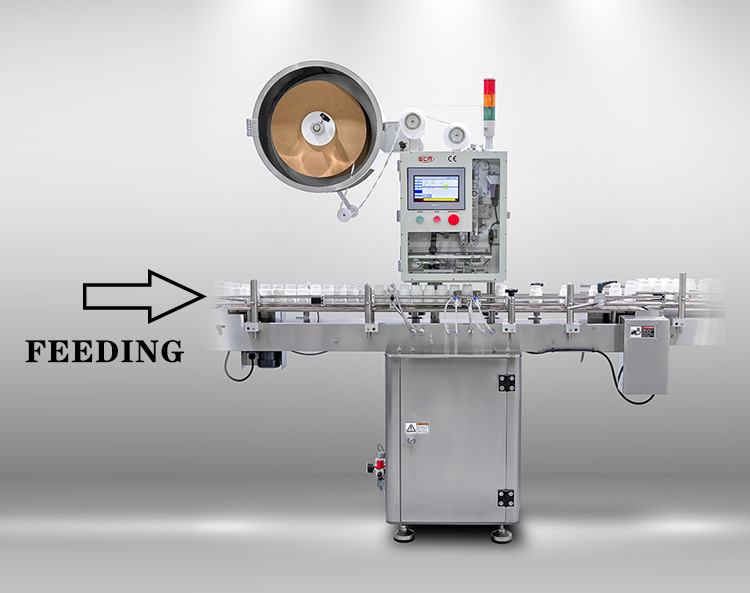

Tubes Uploading System

The tubes uploading system will upload the empty tubes to the tank melting and mixing part by the conveyor belts smoothly and securely. All the tubes will be well-cleaned and sanitized before use.

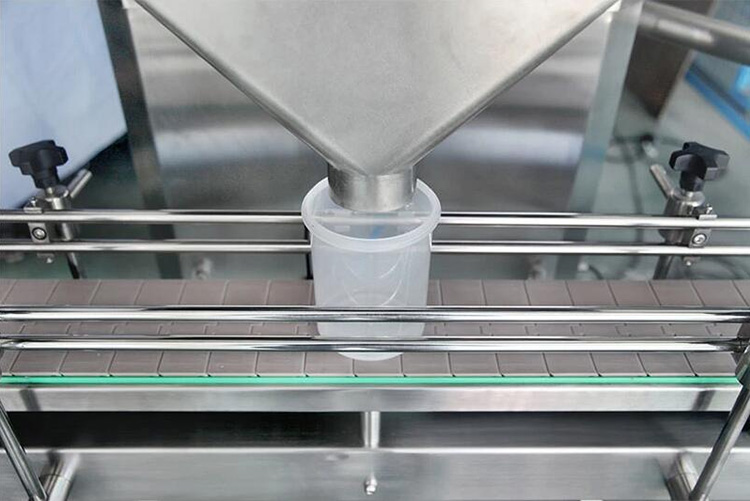

Mixing And Melting Tank

Before filling the raw materials, they need to be mixed and melted in the heating tank for better mixing. Through heating and fusion, the raw materials will be more delicate and uniform during filling and subsequent use.

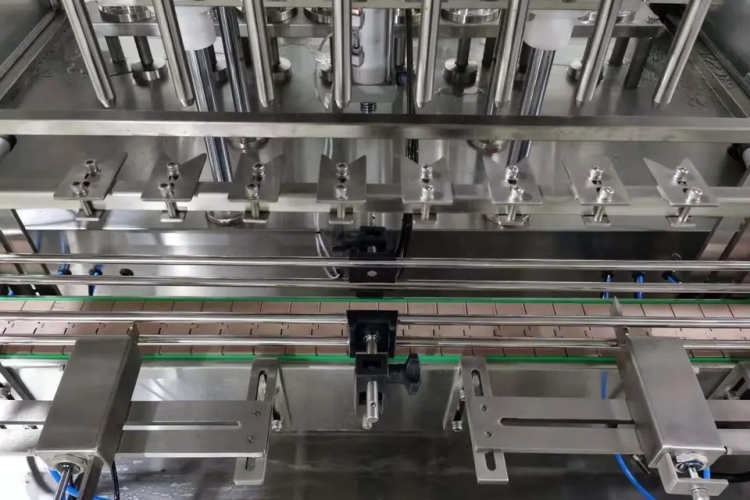

Automatic Filling System

The automatic filling system is equipped with an electric eye sensor for better positioning the empty tubes and quick & high filling. There will be no leakage with the filling system.

Cooling Tunnel

After being filled with the hot materials, all tubes will be transferred into the cooling tunnel for better shaping. During the cooling tunnel, the hot materials will be solid and not easy to leak.

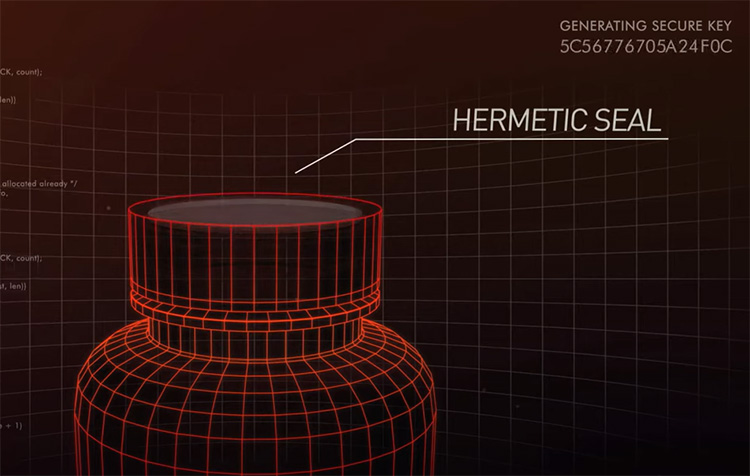

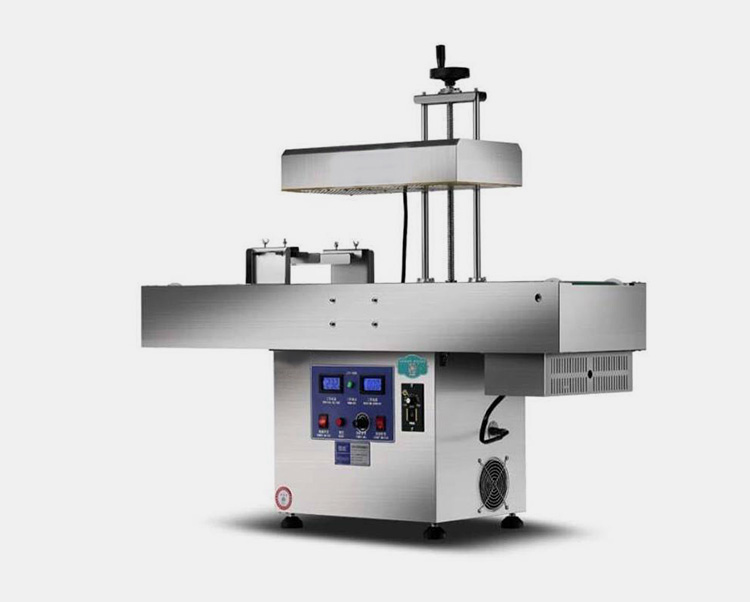

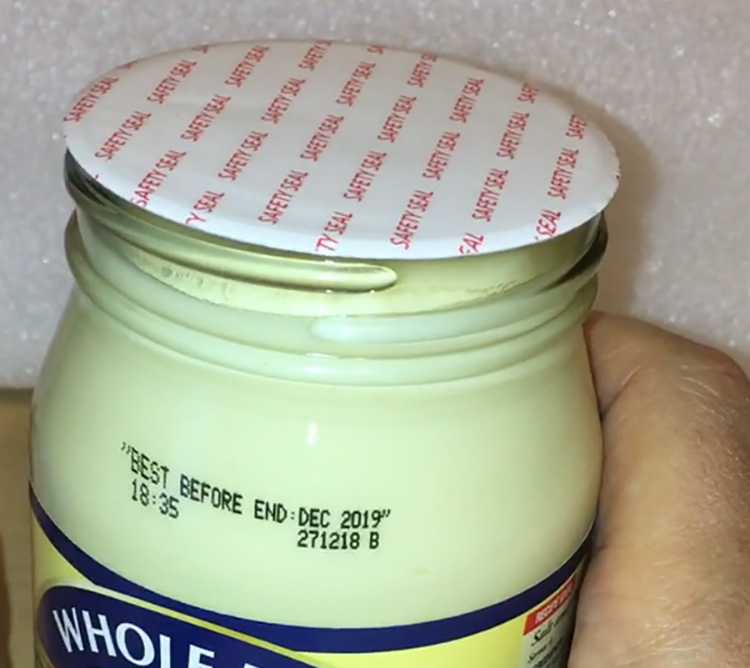

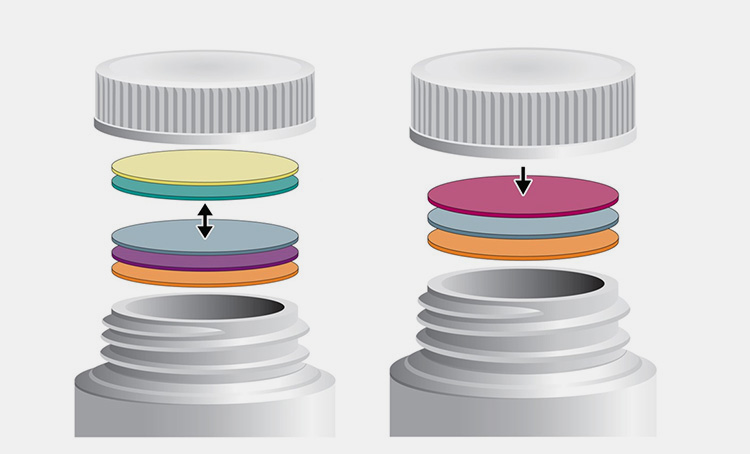

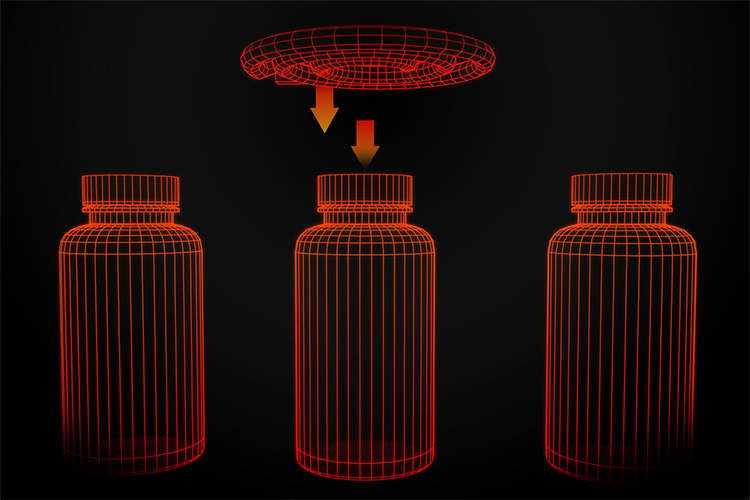

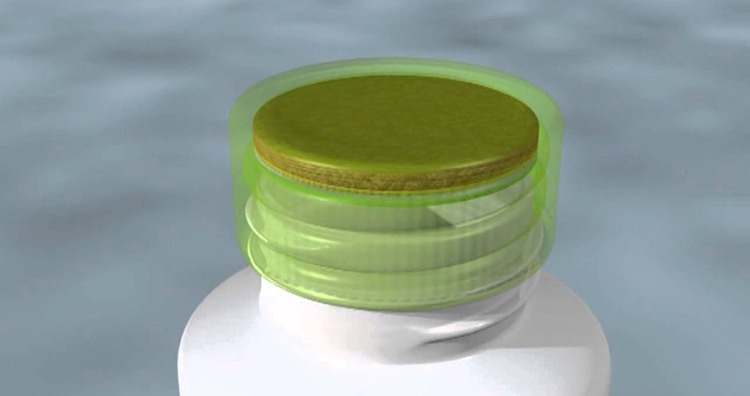

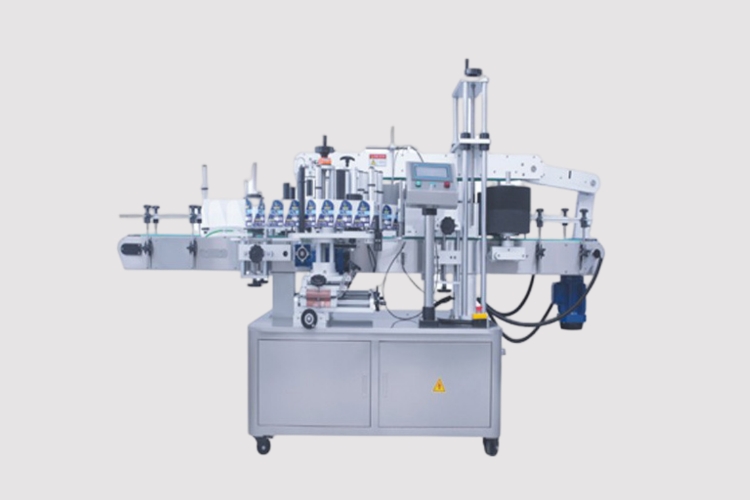

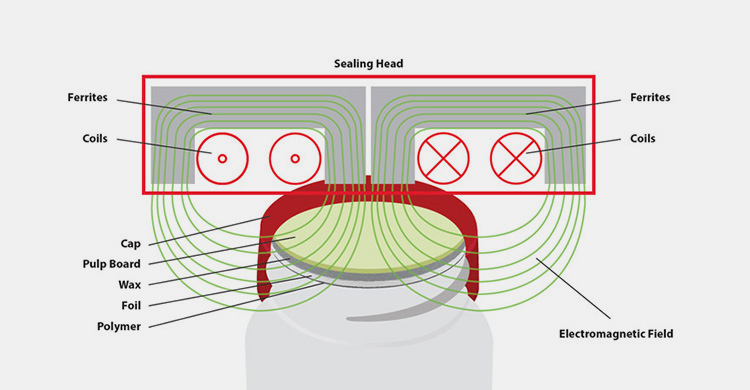

Capping System

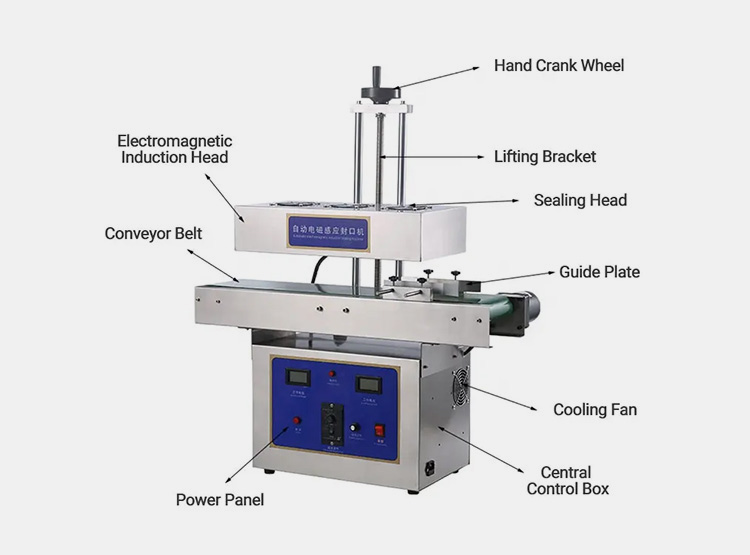

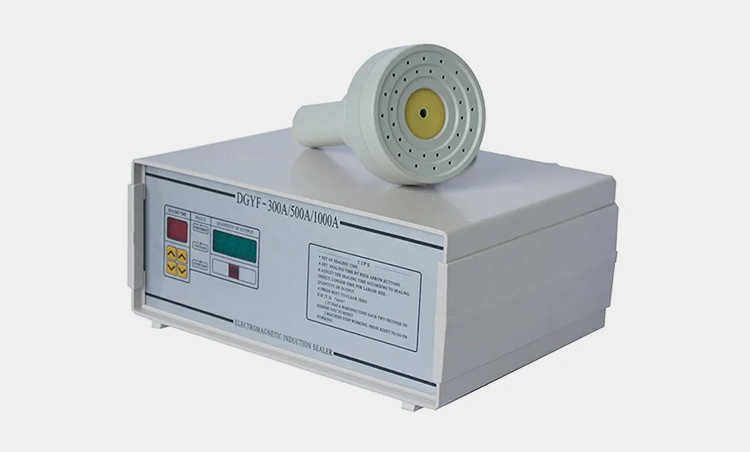

After all the hot materials have been evenly mixed & melted, and been filled into the tubes, then cooled down, and perfectly solid in the tubes, all the products will be securely and well capped and labeled.

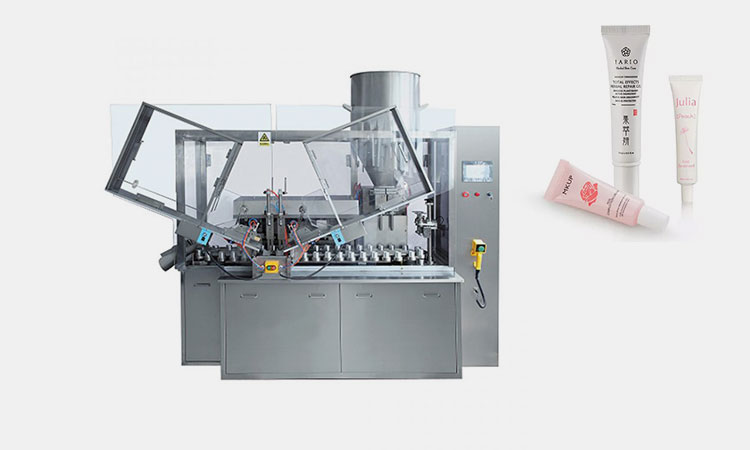

11. Lip Balm Filling Machine VS Tube Filling Machine

Lip balm filling machines and tube filling machines are similar for filling pastes and creams into different containers.

Tube Filling Machine

Tube filling machines are mainly used for filling and packaging pastes and creams of flow and viscosity into different soft tubes. They can complete the precision filling, and folding sealing at the same time with high speed and high efficiency.

| Lip Balm Filling Machine | Tube Filling Machine | |

| Machine Design |  |

|

| Product Samples |  |

|

| Main Products | Lip balm, lipstick, lip gloss, liquid eyebrow pen, eyeliner, etc. | Hand cream, lotion, hair conditioner, toothpaste, ointment, mayonnaise, etc. |

| Machine Types | Trays, manual types, semi-automatic types, automatic types, rotary types, automatic filling lines. | Semi-automatic types, automatic types, automatic filling lines. |

| Working Principles | Tubes uploading, mixing and melting, auto-filling, cooling, capping, and labeling. | Tubes uploading, mixing and blending, auto-filling, sealing, and labeling. |

| Auxiliary Equipment | Melting tank, cooling tunnel. | Vacuum emulsifier |

12. How To Select Your Best Lip Balm Filling Machine?

There are several types of lip balm filling machines you can choose from. But how to choose your best type of lip balm filling machine? There is no perfect machine, however only the most suitable machine for you.

So, the best machine must be the most suitable style for you. You can choose the model that suits you from the following criteria:

Production Capacity

Production capacity is very important to choose a suitable lip balm filling machine. Faced with different production capacity, you can choose from small-scale manual models to large-scale fully automatic series.

Labor Quantities

Manual and semi-automatic are the best options if you have a high need for manual operations. Because of the large amount of manpower invested, the use of this machine model is very extensive. It can match more molds and produce more kinds of products.

Machine Performance

If you prefer a multi-functional lip balm filling machine, then the fully automatic style is more suitable for you. Generally, automatic models will have counting, capping, or labeling functions.

Conclusion:

Lip balms and lip balm filling machines are products that are used very frequently. Does this article have solved all your doubts about lip balm filling machines? Are you interested in this product? If you want to know more or you want to inquire about related products, please contact our customer service or browse our official website directly.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Lip Balm Filling Machine: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours