Top 10 Global Vacuum Packaging Machine Manufacturers:The Ultimate Guide In 2025

Top 10 Global Vacuum Packaging Machine Manufacturers:The Ultimate Guide In 2025

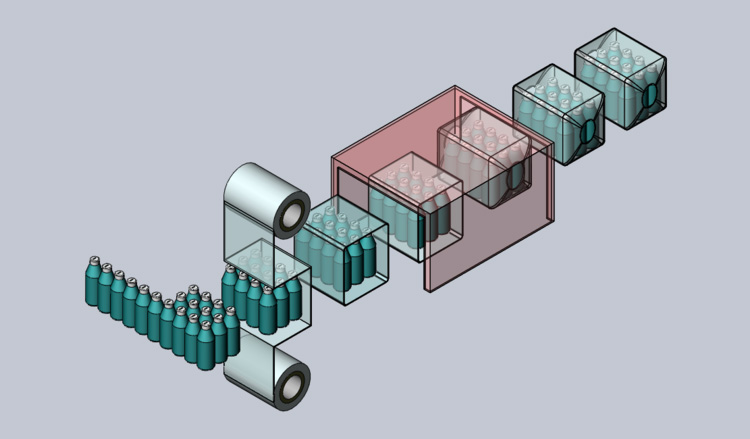

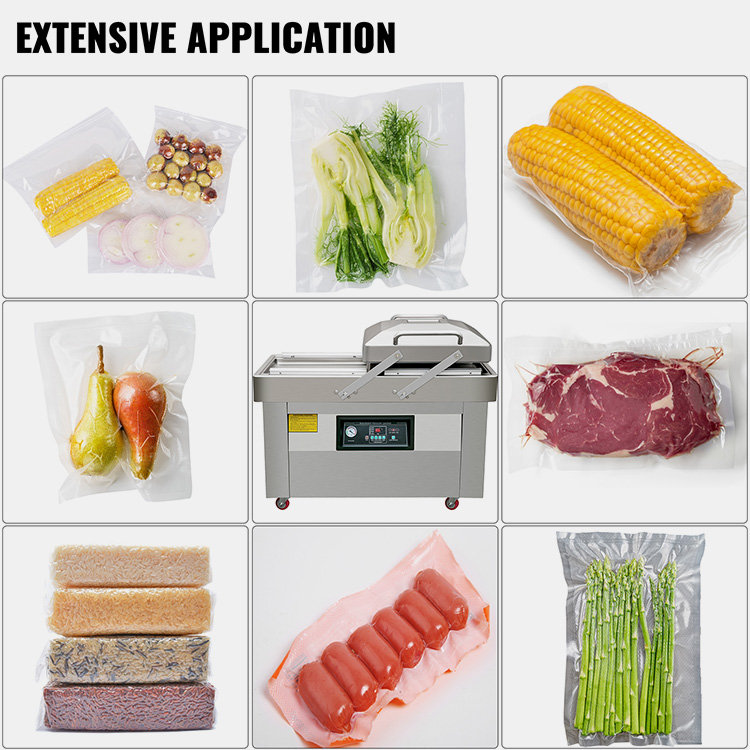

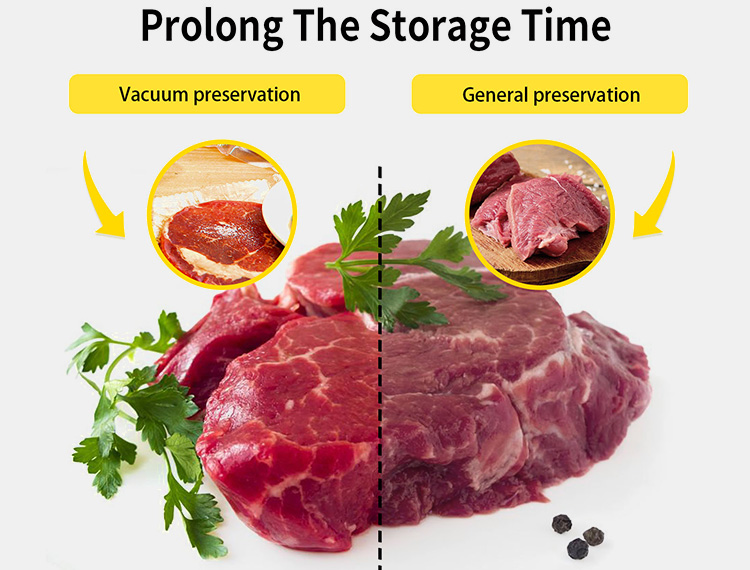

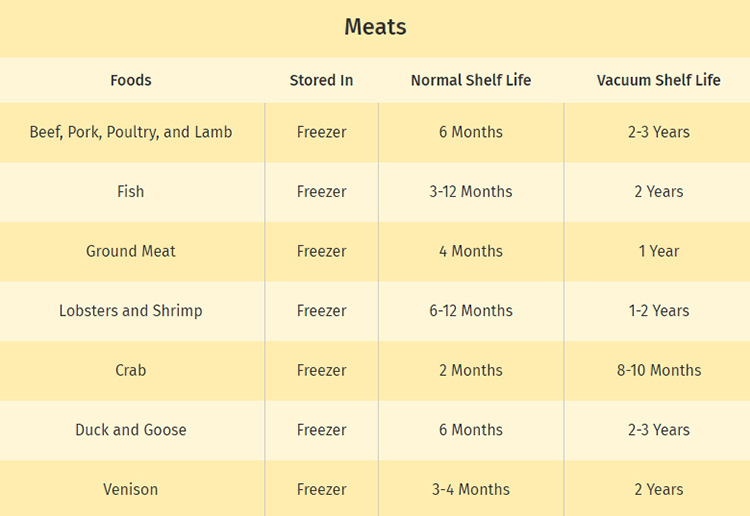

Nowadays,vacuum packaged products are more and more common in people’s daily life,to meet the growing demands,vacuum packaging machines has been widely applied in various industries,even there are some families use these machines in their houses.To be honest,there are thousands of vacuum packaging machine manufacturers all over the world,and many of them are quite famous.

With so many different manufacturers to choose,are you feel confused and don’t know which one is the best?If you have this problem,please keep on reading this blog.This blog will list the top 10 vacuum packaging machine manufacturers around the world,to introduce them in detail and tell you their advantages,help you choose your machine in all directions.

| Rank | Manufacturer | Headquarter |

| 1 | Colimatica USA | USA |

| 2 | AMAC Technologies | USA |

| 3 | MULTIVAC | USA |

| 4 | Allpack | China |

| 5 | SuperVac | Austria |

| 6 | Henkelman | Netherlands |

| 7 | Orved | Italy |

| 8 | WEBOMATIC | Germany |

| 9 | VC999 | Switzerland |

| 10 | Rema Engineers | India |

1.Colimatica

Company Background & Information

Colimatica USA is a division of Coligroup spa,this company was founded at 1998,until now it has already been 25years.The company focuses on packaging equipment for medicine field and food products,with its profession and advanced technology,the products provided by it are of top-class quality.Because of constantly providing high level machines,this company has become one of the leadership in this area.

Key Products

LG 110 Vacuum Chamber Machine

THERA 650 Thermoforming Machine

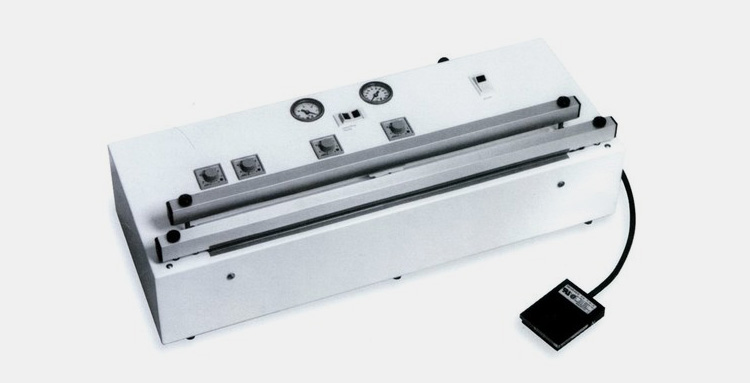

Colimatica USA vacuum packaging machines are high cost-effective,they have high efficiency,can seal food or other products in pouches within 20 seconds.Meanwhile,they are versatile,they can pack various categories of products of different sizes.And you can see from the pictures,these machines have modern and high-tech sense appearances,look pretty high end.

Recommend Reason

- The machines provided by Colimatica USAare flexible and easy to use,and the price of them are reasonable,with perfect performance,these machine can largely save your cost.

- The machine provided byColimatica USAare made of AISI 304 stainless steel,therefore,they are durable and hygiene,will be good choices for you.

- Colimatica USAprovides reliable and customized packaging solutions to customers,so you can get the most suitable packaging equipment and solutions for your industry.

- Colimatica USAhas focused on vacuum packaging machines for 25 years,its products have a patent characteristic that their size can be variable,which distinguishes them from normal machines on the market.

2. AMAC

Company Background & Information

AMAC Technologies is located in California,it has been a leadership in vacuum packaging machine manufacture filed for over 40 years.During the past 40 years,the company has accumulated much experience about vacuum packaging machines,has been developed more and more professional to give customers packaging solutions.

The products provided by AMAC Technologies has been widely applied in food,non food,pharmaceutical,electronics industries and so on.

Key Products

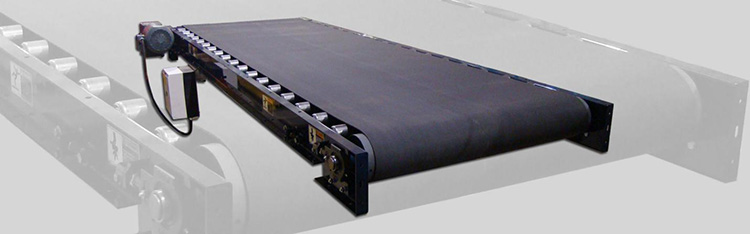

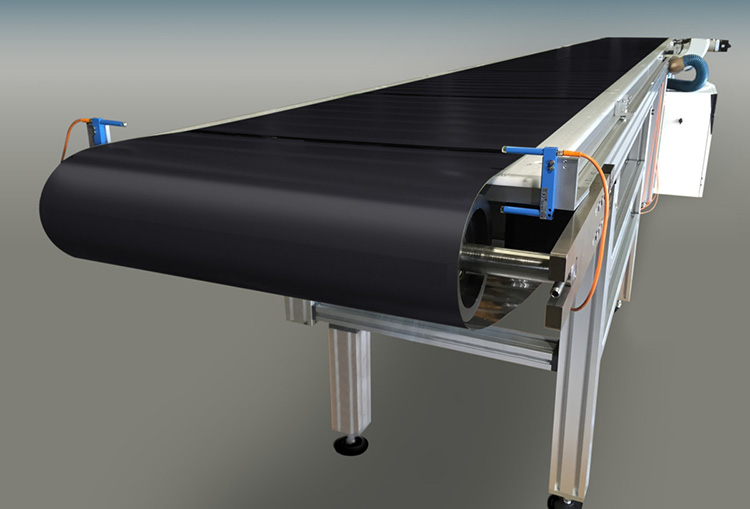

CONTINUOUS BELT VACUUM PACKING MACHINE

T-135F Tabletop Vacuum Packaging Machine

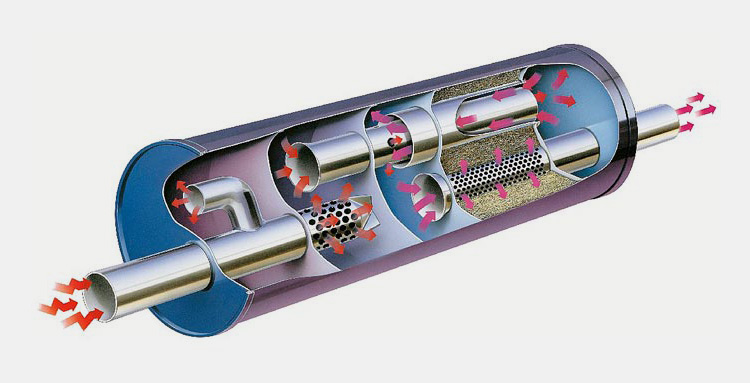

AMAC Technologies’ vacuum packaging machines are made of high level stainless steel,which makes them durable and sanitary.These machines are user friendly,very easy to operate.The vacuum packaging machine provided by this company have high capacities,can pack pouches quickly and accurately.

Recommend Reason

- AMAC Technologies provides a wide range of vacuum packaging machines,which can meet your demands for all aspects.

- AMAC Technologieshas a professional team which consists of engineers,administratorsfinance officer,have wide market resource,can provide trustworthy customer service for you.

- AMAC Technologies has abundant experience in vacuum packaging machine production area,and the company insists of constant innovation,improves the quality of machines.

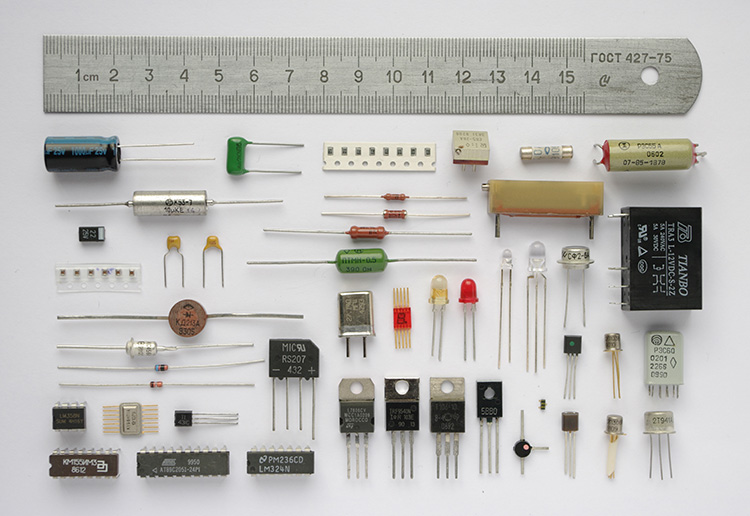

- The machine provided by AMAC Technologies are made of high quality components and technologies,to ensure good usage experience for customers.

3.MULTIVAC

Company Background & Information

MULTIVAC is a world leading packaging machine manufacturer,it was established in 1961,its machines have a large range of applications,such as food industry,life science and healthcare industry,consumer products industry and other industrial applications.This company produces packaging machines which adopt advanced technology,have high automation degree,can perfectly help you in your business.

Key Products

Tabletop Chamber Machine

Double Chamber Machine

The vacuum packaging machines produced by MULTIVAC have perfect performance ,durability and cost efficiency.These machines are easy to operate,clean and maintain,they adopt advanced technologies,can realize outstanding vacuum packaging effect,are ideal choices for buyers.

Recommend Reason

- Syntegon offers you perfect multi-shift processing machine which give you speedy production.

- Their machines have different formats for packaging.

- Their 203-E horizontal flow wrapper has multiple options for packaging such as hot or cold sealing, curved or straight sealing.

- Their machines can give you optimum result on small footprint with easy handling.

4. Allpack

Company Background & Information

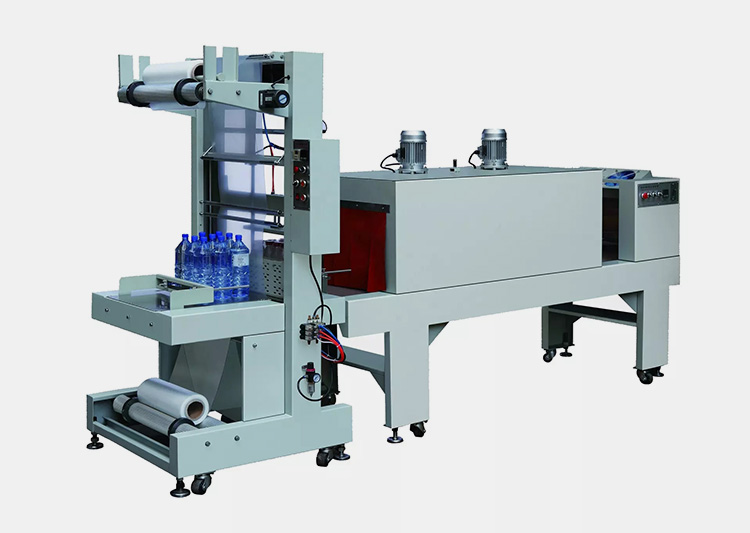

Allpack is a leading packaging machine manufacturer which have over 12 years experience in this field,it provides a large amount of packaging machines,such as vacuum packaging machine,continuous sealing machine,strapping machine,shrink packing machine,liquid filling machine and so on,the company can meet all your demands in packaging industry.

Key Products

DZ-400/T Single Chamber Vacuum Packaging Machine

HVC-410S/2A Double Chamber Vacuum Machine

Allpack provides various models of vacuum packaging machines,these machines are suitable for many industries,such as food industry,pharmaceutical industry,chemical industry,electronic components industry,etc.These machines have high production efficiency,can quickly pack products,and they are easy to use,the operator only need to click some buttons.

Recommend Reason

- The vacuum packaging machines provided by Allpack are durable and easy to maintain,they have long service life,can make high cost effective to you.

- Allpack insists of constant research and development new technology,improve the quality of its packaging machines,to provide customers good packaging solutions

- Allpack has complete infrastructure,strong technical support and strict management,to provide better service to customers.

- Allpack provides 24 hours online service,so whenever you have any problems,you can contact with the staffs of this company,they will resolve your problems as soon as possible.

- Allpack possesses a wide logistic network,it can deliver machines to you no matter where you are.

5.SuperVac

Company Background & Information

SuperVac was started at 1952,it has been founded for almost 70 years,during the past 70 years,the company has aimed at providing good packaging solutions and packaging machines to customers.The product range of this company is large,which includes vacuum packaging machines,shrink machines,cooling and dry machines,bag opener and conveyorized machines.

Key Products

GK 195 B Single Chamber Machine

GK 255 Double Chamber Machine

SuperVac vacuum packaging machines take advantages of durable stainless steel body,sanitary design,stable packaging effect and high end components.With so many advantages,the machines are quite excellent to be used,they can bring good practicability and reliability to you.

Recommend Reason

- SuperVac focus on the quality of products,so it invest much money,human labor and resources in research and development,to improve the quality of its machines.

- SuperVac will consider your demand in a long term perspective,so the company will provide you complete packaging solutions,therefore,you can trust this company and get deep cooperation with it.

- SuperVac possesses 55 representative offices around the world,so no matter where you are,if you have problems,you can contact with the company rapidly,which is very convenient for you.

- The company has a very long history of 70 years,its first vacuum packaging machine was created in 1964,until now its technology has been quite mature,the vacuum packaging machines provided by SuperVac are at world class.

6.Henkelman

Company Background & Information

Henkelman was established in 1994,the company has focused on vacuum packaging machine when it was started,now,its vacuum packaging machines are sold to over 80 countries,the sales volume is more than 15,000 a year,it s one of the most top vacuum packaging machine manufacturers in the world.

Key Products

Henkelman Aero 42XL Vacuum Packaging Machine

Henkelman Polar 2-50 Vacuum Packaging Machine

The vacuum packaging machines produced by Henkelman have beautiful appearances,they are durable,stable,efficient and accurate,which are practical device for you to pack your products.These machines are equipped with sensor control,can be easily operated,and they conform with CE and ETL certified,the quality is guaranteed.

Recommend Reason

- The company provides good customers service,it send products to you in a fast speed,and it provides a 3 year warranty,to protect your consumer rights and interests.

- Henkelman has 450 distributions all over the world,you can easily purchase its machines in your country,and the maintenance of the machine is more convenient.

- Henkelman possesses complete product line,can solve different types of packaging demands no matter your products are food or non-food.

- While guaranteeing the quality of vacuum packaging machines,the products provided by Henkelman are at a competitive price,which can save your cost.

7. Orved

Company Background & Information

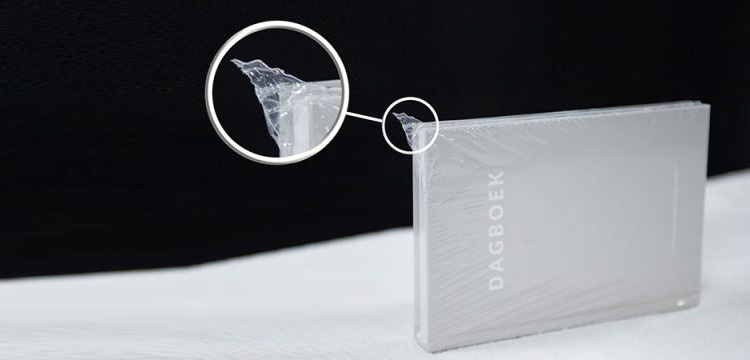

Orved was established in 1984,it is a vacuum packaging machine manufacturer comes from Italy.The company provides different models of vacuum packaging machines,these machines look modern and high level.Been founded for nearly 38 years,the company has accumulated a lot experience in this area,and keep on providing high quality machines.

Key Products

Orved Idea 32 Hi-Line Vacuum Packaging Machine

Orved Evox Hi-Line Vacuum Packaging Machine

The vacuum packaging machines offered by Orved are equipped with smart touch screen,which makes them easy to operate.In addition,they are equipped with absolute vacuum sensor,which makes the vacuum process more accurate.The chambers of these machines have smooth surface,round corners and their thickness are uniform,the chambers are very easy to be clean,make the machines more user friendly.

Recommend Reason

- Orved provides different series of vacuum packaging machines,although these machines belong to different series,they are both professional and high end.They are designed smart and adopts new technology,have absolute market competitions.

- Orved keeps on innovation,it constantly upgrade its machines,to let them more suitable for human to use,can better meet customers needs.

- Orved insists of sustainable development,its packaging machines are environmental friendly.

- The products of Orved gain many certifications,and accord with European standards and regulations,which are very strict,so the safety and quality of these machines are trustworthy.

8.WEBOMATIC

Company Background & Information

WEBOMATIC was established in 1958,it is a top class packaging machine manufacturer which comes from Germany.The company provides various kinds of vacuum packaging machines,such as table vacuum packaging machines,single chamber vacuum packaging machines,double chamber vacuum packaging machines,tray sealers,thermoforming machines,etc.WEBOMATIC has built international service network,it has many agencies around the world.

Key Products

WEBOMATIC Vacuum Packaging Machine I 30

WEBOMATIC Double Chamber Machine duoMAT 450

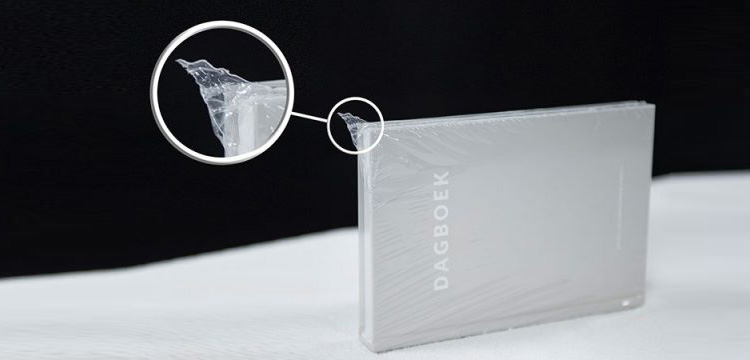

The vacuum packaging machines of WEBOMATIC are equipped with expansion compensations,which can improve the sealing effect and extend the service life of these machines,so that they can realize perfect vacuum packaging.Meanwhile,these machines take advantages of compact design,high packaging efficiency,sanitary,easy cleaning and maintenance.

Recommend Reason

- WEBOMATIC offers a variety of vacuum packaging machines which have different constructions and features,can meet different demands from customers.

- WEBOMATIC insists of customer-center principle,the company aims to provide reliable packaging solutions to its customers.

- WEBOMATIC uses top class and excellent quality materials to produce vacuum packaging machines,which makes these machines durable and stable,can help people package their products faultlessly.

- WEBOMATIC possesses many skilled and experienced engineers and technicians,they innovate and develop new technologies,to continue improving the quality of machines.

9.VC999

Company Background & Information

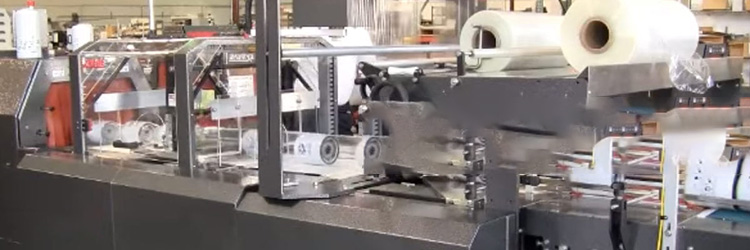

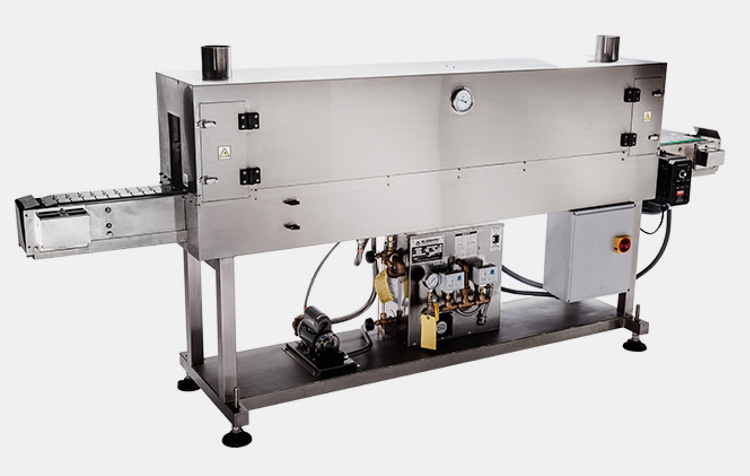

VC999 was started in 1975 in Switzerland,,this company is a leading packaging machine manufacturer.,during these years,the company has expanded its commercial layout,until now it has many branch offices in many countries,such as the USA,Austria,Germany,the UK,Canada,Colombia,Mexico,the company has over 70 representations in global.VC999 has a complete product line,from all kinds of vacuum packaging machines to shrink wrappers and dryers.

Key Products

K5S – SINGLE CHAMBER VACUUM MACHINE

K9 – BELTED SINGLE CHAMBER VACUUM MACHINE

The vacuum packaging machines produced by VC999 are designed to be user friendly,they are equipped with PLC touch screen,which make them easy to be operated.In addition,these machines are energy saving,designed hygiene,and they have perfect performance,can realize quick and safe sealing.

Recommend Reason

- The vacuum packaging machines provided by VC999 have beautiful appearance,looks high level and advanced,they conform to most people’s aesthetic appreciations.

- As is mentioned above,VC999 has established branch offices in many countries and has over 70 representations all over the world,which make them convenient to provide fast and on-time service for customers.

- VC999 possesses complete product line,it offers a large range of packaging machines,and some of them can be used in combination to form a production line,in other word,this company can meet all your demands in packaging and can give you effective packaging solutions.

10.Rema

Company Background & Information

Rema Engineers is a manufacturer and exporter of tray sealing machines and vacuum packaging machines from India,this company was founded in 2003,it has a history of almost 20 years.Rema Engineers has established cooperation with many local major industrial centers,its business has covered the whole India,it is the largest vacuum packaging machine manufacturer in India.

Key Products

Model No. TZ – 260 Heavy Duty Table Top Vacuum Packing Machine

Model No. ST-450 Heavy Duty Single Chamber Vacuum Packing Machine

The vacuum packaging machines which are offered by Rema Engineers are made of hard stainless steel so they are absolutely durable,and they are designed hygienic and intelligent,convenient for customers to use.These machines have good performance,can package food or nonfood products with high speed and high precision,they are ideal choices for customers.

Recommend Reason

- Rema Engineers has extensive customer base,the company has cooperated with many leading companies in India,therefore,it has good reputation and it is reliable,you can trust this company.

- Rema Engineers aims at providing high quality,reliable,eco-friendly and efficient packaging machines to customers,and its products are at reasonable price,they are affordable for most of people.

- Rema Engineers has advanced technologies,it constantly adopts these technologies to extend the service life of its packaging machines,to offer practical products to customers.

- Rema Engineers constantly meets new challenges and continue innovating, for the purpose to adapt to the changes of the era.

Conclusion

All these above are the top 10 global vacuum packaging machine manufacturers,each of them have their own background,core products and strengths.It is believe that you also have your own requirement for a vacuum packaging machine,and after reading this blog,hope it can help you have a more specific choice.If you still have other questions,welcome to contact us,we are 24 hours online.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Top 10 Global Vacuum Packaging Machine Manufacturers:The Ultimate Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours