Automatic Box Taper Machine: The Complete FAQ Guide in 2025

In any kind of business or in industry you always look to deliver your products in a safe way as much as possible for your customers satisfaction.

There are multiple packaging machines available from which automatic box taper machine is one of them that comes with multiple technical and supportive features.

By reading this guide you are going to learn all the important things and guidelines about the working and the usage of automatic box taper in many industries from a small business to a major one.

1.What is an automatic box taper machine?

When it comes to machines that make your packaging process easier, an automatic box taper is a must-have. This type of machine is designed to quickly and efficiently apply pressure-sensitive tape to the seams of cardboard boxes. An automatic box taper machine is a type of packaging machinery that is used to seal the corners of cartons or boxes. This process is also known as box strapping, and it is commonly used in the packaging of products such as food, beverages, and electronics.

If you’re not using an automatic box taper, you’re likely wasting time and money hand-taping boxes or using a semi-automatic machine that doesn’t provide the same level of efficiency. In this blog post, we’ll discuss the benefits of using an automatic box taper and how it can help improve your packaging process.

2.How an automatic box taper machine will be beneficial for you?

If you are looking for a machine that can help you with your packaging needs, then an automatic box taper machine is the way to go. This type of machine is designed to help you quickly and easily seal up boxes so that they are ready for shipping.

Here are just a few of the benefits that you can enjoy when you use an automatic box taper machine:

- An automatic box taper can help to increase your packaging efficiency because it can seal multiple boxes at once

- Overall, an automatic box taper machine can be a great investment for any business that ships products regularly.

- If you are looking for ways to streamline your operation, this is definitely a piece of equipment worth considering.

- By using an automatic box taper machine you will get quality touch to your products but if you do it manually your products will not look good in shape.

3.Explain the working process of an automatic box taper machine?

An automatic box taper machine is a machine that automatically measures the width of a box, and then cuts the box accordingly. The machine utilizes a sliding carriage to move the cutting blade along the length of the box. This ensures that the cut edges of the box are always consistent in shape and size.

Working Process

The working process of an automatic box taper machine begins with the user inputting the desired width of their box onto a computerized measuring system. Once the desired width is determined, the carriage moves to the beginning of the desired length and begins measuring.

If there is an error in measurement, such as when two boxes have different widths but are both measured as being within tolerance, then a warning will be issued and the cutting process will begin anew from where it was interrupted. If all measurements are accurate, then the carriage moves to one end of the desired length and begins cutting.

The blade on this end is wider than on the other end, which allows for even more precise cuts down to even millimeters in size. As each cut is made, a signal is sent to a control panel which calculates how much material needs to be removed so that there will be an even edge across all lengths of cardboard box tapers come in many shapes and sizes but at its core it is just cardboard shaped like this for example would need measurements all around it before we could start our machine so customers know everything about what they’re buying.

4.What are the different types of automatic box taper machine?

There are a few different types of automatic box taper machine, each with its own unique features and benefits. These types are as follows:

Top and bottom Box tapers

These machines are designed to seal the top and bottom of a box at the same time. This is the most common type of machine used in warehouses and distribution centers.

Top and bottom tapers are the simplest type of tapered roller bearings, with one end that is narrower than the other.

Working Principle

The working principle of a Top and bottom taper in an automatic box taping machine is to move the tape from the supply reel to the output reel by using a series of cam and claw devices. Each of these devices has two cams, one for moving the tape up and the other for moving it down.

The claws grip the tape at either end or pull it towards the middle, where it is cut off by a blade. This process allows the machine to consistently produce even-width tapes without any gaps between them.

Side Box Taper

These machines only seal the sides of a box. They are typically used for smaller boxes or for packaging delicate items.

Working

The working principle of side sealers is based on the principle of vacuum suction and air pressure. The side sealer uses a special type of tape that can be sealed by the vacuum power of the machine.

This will create an airtight seal between the two surfaces being taped together. This will ensure that any moisture or debris trapped between the two surfaces will not be able to escape and cause damage.

Inline Box tapers

These machines are designed to seal boxes as they move through a production line. Inline tapers are often used in conjunction with other types of packaging machinery, such as labelers and printers.

Working Principle

The working principle of inline tapers is based on the simple premise that when a linear motion is applied to a piece of metal, it will deform inwards. This inward deformation creates an angle between the two ends of the metal, and as the linear motion continues, this angle will continue to increase until it reaches a point where the metal has been completely deformed. At this point, the taper has been created.

Slot-head box taper

This type of machine has slots cut into its head, which enables it to produce various widths and angles in the tape while it’s feeding it through. It is often used for packaging products that require multiple shapes and sizes.

Working

The working principle of Slot-head taper is based on the use of a slot head that cuts the wire at a slot-like shape. This slot head moves along the wire and creates a gradual taper, which results in a more even tone across the entire length of the wire.

This type of automatic box taper machine is preferred for applications that require an even tone, such as harp strings or guitar strings.

Random box taper

This type of machine produces a random slope in the width of the tape as it is fed through it, resulting in a more irregularly shaped finished product. It is usually used for packaging products that do not require a specific shape or design, such as cereal boxes or bags.

Working

As the material is fed through the machine, it enters at one end and exits at the other, with each cut made progressively narrower. This gradual taper reduces the amount of needed force to make each cut, meaning less wear and tear on both your machinery and your hands.

Circular box taper

This type of machine produces a sharpened angle at the end of the tape, which gives it an attractive and professional appearance. It is often used for packaging products that require a more rigid or complete edge, such as books or boxes.

Working

The working principle of the circular taper machine is based on the principle of automatic box taper. The machine has a moving belt that evenly distributes the material it cuts, and this results in a perfectly circular cut every time. This allows for even pressure on the material as it is being cut, which in turn ensures a smooth finish and prevents any tears or jams.

5.What kind of boxes an automatic box taper machine can tape?

An automatic box taper machine can tape all kinds of boxes, from small to large. The following are the kinds of boxes that can be used by this equipment. It can also tape cardboard, paperboard, and plastic boxes.

Cardboard Boxes

The very first kind is cardboard that is used for taping purposes. With this machine, you can easily tape together several boxes to create one large, sturdy piece. Plus, since the tapes are automatically applied, there’s no need for any kind of manual dexterity.

Paperboard

The next kind you can use for taping is the paperboard boxes. Paperboard boxes are unique and engaging pieces of packaging. They’re sturdy and can be used for a variety of products, such as food or clothes. You can find a range of different designs and colors, so you can find the perfect one for your product. They’re also affordable, so you can afford to purchase a few to use in your business.

Plastic Boxes

The last kind is plastic boxes. Plastic boxes are an interesting and unique way to store your belongings. They are lightweight and durable, making them a great option for storage. They also come in a variety of colors and designs, so you’re sure to find one that suits your needs.

6.Which industries use automatic box taper machine?

There are many different types of businesses that use automatic box taper machines. Some of the most common industries include:

Food and beverage packaging

If you are in the food or beverage industry and need a machine to produce consistent, accurate cuts with even spacing, then an automatic box taper machine is perfect for you. These machines are often used in breweries, wineries, and other food-related businesses.

They work by smoothly reducing the size of a box as it is cut, which results in even spacing and accurate cuts. This prevents bonfires from forming on the top of the box and allows for uniformity of product across the batch.

Pharmaceuticals

The automatic box taper machine is a machinery used in the pharmaceutical industries for the purpose of controlling the dosage levels of drugs. The machine helps to keep the dosage levels consistent and safe for patients, while also reducing the time and cost associated with producing custom dosages.

It is a highly efficient piece of equipment that has revolutionized how pharmaceuticals are produced.

Cosmetics

The automatic box taper machine is an innovative tool that is being used increasingly in the cosmetic industry. It is a versatile machine that allows for the precise and accurate production of custom-sized boxes.

This machine helps to ensure consistent quality control, as well as accurate dosage delivery to customers. It also enhances efficiency and accuracy in the production process.

Electronics

In electronics industries, automatic box taper machine is used to produce various electronic components. It is a reliable and efficient tool that helps to reduce the time and cost required to produce various components.

The equipment cuts the parts using a series of gradual curves, which results in fewer variations and less chance of defects. As a result, it helps to improve the quality of the final product.

7.Is it possible to make a carton or box waterproof using automatic box taper machine?

Yes, it is possible to make a carton or box waterproof using an automatic box taper machine. There are a few different ways to do this, depending on the type of machine you have and the materials you are using.

Use a Water-Resistant Machine

One way to make a carton or box waterproof is to use a machine that has a water-resistant coating. This will create a barrier between the inside and outside of the box, preventing any moisture from getting in.

Use a Sealant Machine

Another way to make your box waterproof is to use a machine that has a sealant. This will seal up any gaps or cracks in the box, preventing any water from getting in.

By Settings Adjustments

If you are using an automatic box taper machine, there are usually settings that you can adjust to make your boxes more or less waterproof. By playing around with these settings, you should be able to find the perfect balance for your needs.

8.How you can troubleshoot common problems of automatic box taper machine?

If your automatic box taper machine is having trouble sealing boxes, there are a few things you can do to troubleshoot the problem.

Tape Roll is Properly Loaded

First, make sure that the tape roll is properly loaded and that the adhesive side of the tape is facing up. If the tape roll is not properly loaded, the machine will not be able to seal the box correctly.

Boxes Flaps are Properly Aligned

Next, check to see if the box flaps are properly aligned. The box flaps must be aligned in order for the machine to seal the box correctly.

Replace the Tape Roll

Finally, if the machine is still having trouble sealing boxes, you may need to replace the tape roll. A new tape roll will have fresh adhesive that will help to seal boxes more effectively.

By these things you can easily troubleshot your automatic box taping machine.

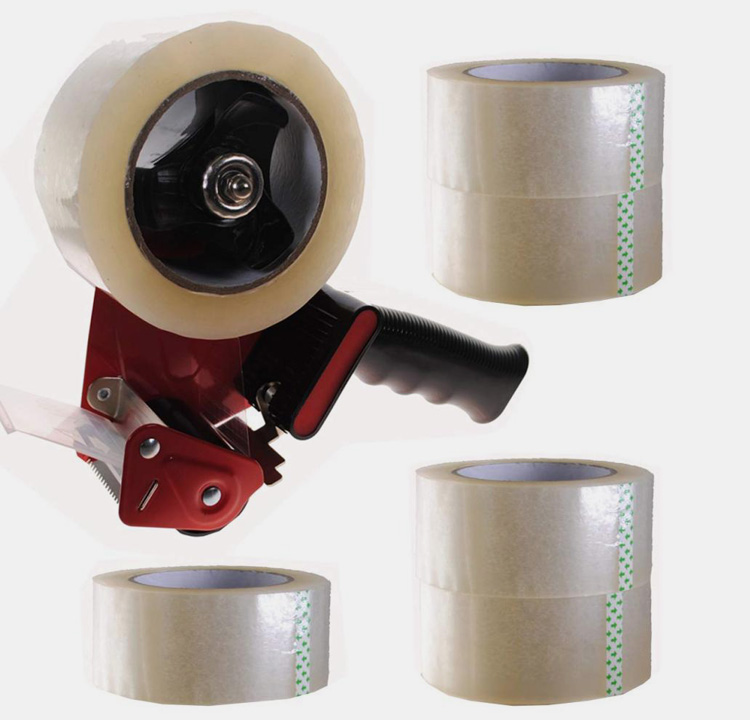

9.Which tape you should use for tapping different kinds of boxes?

Selection of the tape is a very crucial step because there are many kinds of tapes available and each one of them serves a different purpose.

While choosing the tape, you should look for the adhesiveness, thickness and tensile strength of the tape and then you should choose the best tape accordingly.

For sealing the different types of boxes, the most preferred type of tape should be the paper tape, also known as packaging tape or flatback tape.

The paper tape has excellent adhesion and it is split resistant. Therefore, it provides the much required strength and security to the boxes. Moreover, it is very easy to tear.

10.Why you should buy from us?

You know China is the global leader in terms of providing different machines and equipment and we have the best professional & technical staff.

Our staff will design and structure the machine according to the requirements that you want for your business in order to achieve best output rate.

As a professional manufacturer we provide services all around the world and our aim is to provide quality products to make our clients happy and satisfied.

Conclusion

If you are in the market for a box taper machine, we highly recommend the automatic box taper machine. It is easy to use and will save you time and money in the long run. Allpack is the best provider of automatic box taper machine. You can simply seal the boxes using this equipment. If you have any questions related to this article, you can contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide