What Is The Difference Between Shrink Sleeve Labeler And Traditional Labeling Machine

The term “labeling” refers to the attachment of particular label to any thing or material so it can be easily identified. In packaging area labeling is an inevitable part that play crucial role in every manufacturing firm because labeling is the key for their products’ recognition.

But have you ever been amazed by looking into same bottles having different lables? Did you ever try to know the reason or dissimilarity behind? If not! This detailed review article is designed to get you enable to better understand the difference between shrink sleeve labeler and traditional labeling machine. Just keep reading to know more!

1.What Is Shrink Sleeve Labeler Machine?

Shrink sleeve labeler is advanced automatic machine that applies plastic labels on the whole body of bottles so they can be protected from light and external damage. It uses heat to shrink the label on bottles and provide you an opportunity to brand your products by creating 360-degree labeling.

It is capable of processing bottles regardless of different shapes and sizes. Businessmen around the globe are utilizing this technology on broad level because it give their products’ charming look and quality recognition which grabs the attention of consumers.

2.What Is Traditional Labeling Machine?

A traditional labeling machine generally uses the old technique of labeling products with self adhesive stickers that comes in various forms. It applies pre-glued lables that are provided in stock of reel either in form of paper or film.

Unlike shrink sleeve labeler it does not provide enough space for writing much information but necessary facts are mentioned for easy accessibility. Many firms still follows this technology for their items.

3.What Is The Difference Between Shrink Sleeve Labeler And Traditional Labeling Machine?

Structure

Shrink Sleeve Labeler

Structure of shrink sleeve labeler is somehow complicated with too many parts joined together performing different tasks. Its main components include:

Label roll feeder

It is the label which has to apply on the bottles through a process. Film is stocked on reel in layers form. This is located on the top side of machine.

In feed Conveyor

This part of machine work as a road while ensuring the stable movement of products..

Sensors

Various sensors are fixed at different levels for varying purposes. They detect the registration codes, end of label and metering of products. This helps in the formulation of accurate labeling.

Cutter

It functions as a knife with smooth cut. When the labels are formed in sleeve shape the cutter cut them down in order to divide them into separate labels.

Shooter Motor

Shooter Motor along with ejector wheels precisely applies the label dispensed on bottles.

Shrink Tunnel

This is the core component of machine where exact shrinking of labeling takes place through generating heat.

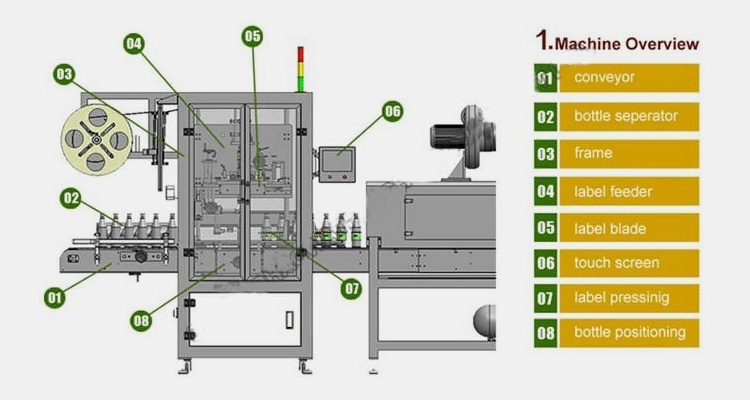

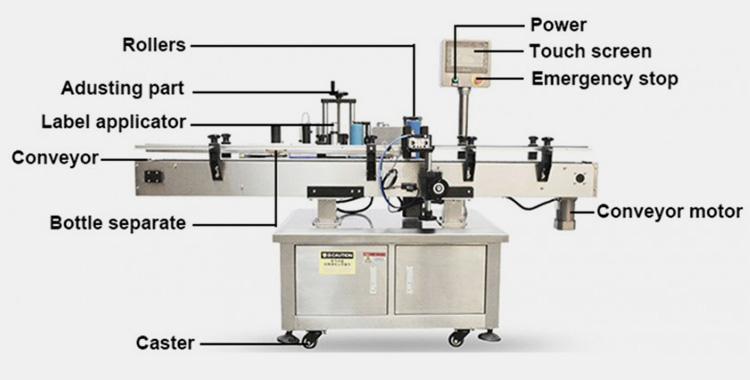

Traditional Labeling Machine

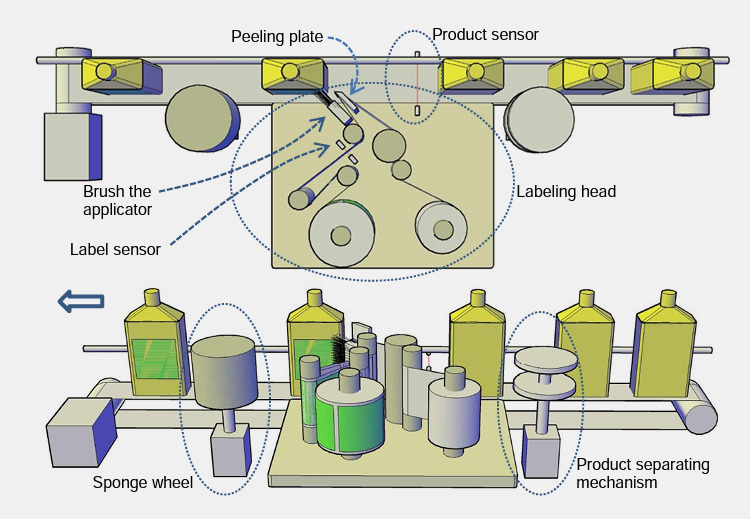

Compare to shrink sleeve labeler, traditional labeling machine is composed of fewer parts. These are:

Product Sensor

It senses the presence of containers and sent the signal to controller for preceding the process.

Controller

It counts the numbering of items and order command to release the labels accordingly.

Supply Reel

Labels are combined in unified form as a roller on supply reel.

Peel Bar

It peels the label from laminated liner and pushes it towards bottle.

Labeling Head

Parts associated with labels are located in labeling head. Labels are delivered until machine realizes the gap between containers thus stop labeling and wait for another one.

Applicator Brush

When label is peeled off by peeling plate the brush pasted it on bottle and exert some pressure to get the label stick to the bottle.

Procedure

Shrink Sleeve Labeler

The process of shrink sleeve labeling is a little bit lengthy. It starts when unlabeled containers are transported through in feed conveyor. Rotating screw feeder meters the product.

On the other side, unwinding of film from reel initiates the movement and the film is produced in form of continuous web. During this mechanism label registration sensor detect the registration code on each label after which the label is turned into round shape.

The labels are then carried out by shooter motor which accurately place it over product and the container is then passed through heat tunnel where the film shrinks and transform into the shape of bottle. Eventually the operation completes and material is discharged.

Traditional Labeling Machine

In contrast to shrink sleeve labeler, traditional labeling method is quite simple with few steps. These are:

Once machine is switched on after fixation of parameters the operation begins. Bottles kept on conveyor belt are sensed by controller and the process of labeling initiates. The controller allows the labeling reel to release labels and the blade cuts them for separate containers.

When label is applied on container a light pressure is applied due to which the label simply adheres to the surface of object.

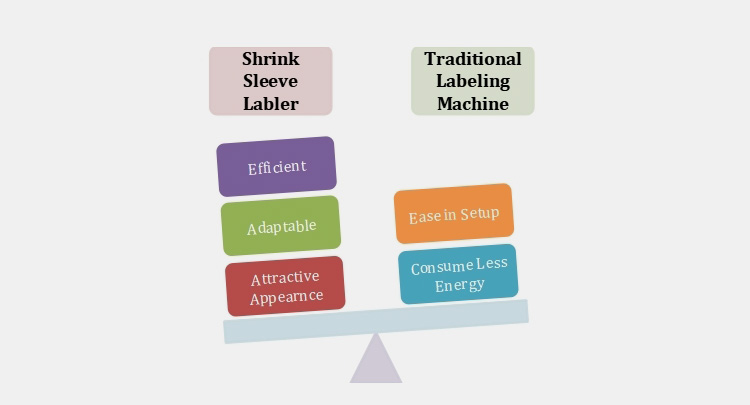

Pros

Shrink Sleeve Labeler

Efficient

The process of shrink sleeve labeling is fast as the product just passes through the heat tunnel and film itself shrinks to the shape of bottle.

Adaptable

Shrink sleeve labeler is highly flexible as it conforms to irregular shaped bottles and easily transforms the label to shape of containers. It creates perfect shrinkage without wrinkles in unusual shapes. It is also capable of labeling and decorating on complex shaped containers.

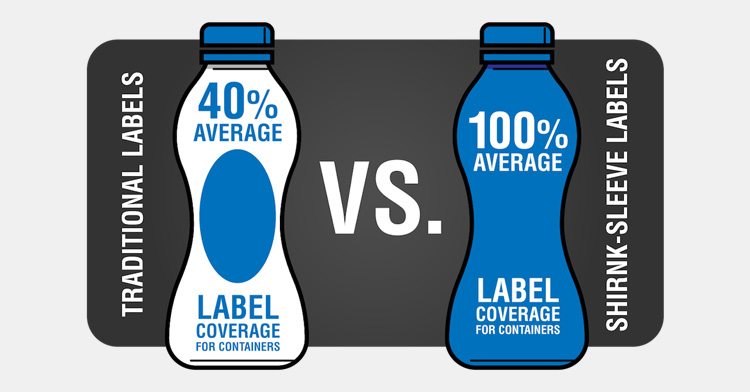

Size

Shrink sleeves are mostly of big size they cover the entire body of bottles and offer 360 degree area to print labeling content. Thus provide enough space to manufacturers for displaying the important information which they want to deliver to customers.

Attractive Appearance

Its use can benefits you in so many ways among which the prominent one is the beautiful look which it gives to your products. This ultimately catches the attention of buyers and increases their interest in such products.

Durable Seal

Shrink sleeve labeling works as anti tamper agent and provide strong rigid seal which is difficult to damage.

Traditional Labeling Machine

Ease in Setup

A traditional labeling machine provides you with easy setup that can be changed without any difficulty.

Consume Less Energy

This machine applies pressure sensitive labels which do not require much force thus consume less energy.

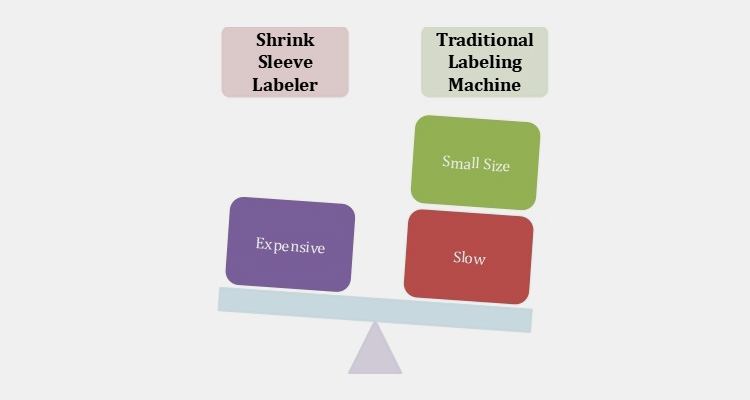

Cons

Shrink Sleeve Labeler

Expensive

Shrink sleeve labeler is expensive in nature as the machine comprised of various parts with complicated structure.

Traditional Labeling Machine

Slow

The process of traditional labeling is slow due to the peeling of labels and the gap between containers which stops the process until container is close to labeling head.

Small Size

Traditional labels are often small in size due to which only product or company names can be printed.

4.Composition Of Shrink Sleeve Labeler Vs Traditional Labeling Machine?

There is huge difference between shrink sleeve labeling and traditional labeling on the basis of their composition. Material from which these two are made is described below separately:

Shrink Sleeve Labeling

Plastic

Shrink sleeve labeling is always made from strong plastic because the film has to pass through the heat which other material cannot endure. Plastic used in such labeling is durable, tamper resistant and 100% recyclable. As plastic is more flexible compare to paper, it can be transformed into any type of bottle shape covering it from top to bottom.

Traditional Labeling Machine

Paper

Compare to shrink sleeve labelling, traditional labeling is mostly produced from paper, cards or rarely from light plastic. Although it cannot be recycled due to deterioration caused by moisture but its fast decomposition makes it environmental friendly.

5.Which Machine Is More Cost Effective-Shrink Sleeve Labeler OR Traditional Labeling Machine?

How the cost of shrink sleeve labeler and traditional labeling machine differs one from another is what we have explained below:

Shrink Sleeve Labeler

Shrink sleeve labeler is 25% more costly than traditional labeling machine. The reasons are; use of strong plastic to endure the heat pressure, the large amount of films as whole body of containers are to be covered and complex components of machine which are expensive.

Traditional Labeling Machine

Traditional labeling machine is less expensive than shrink sleeve labeler because of the less parts requirement and its use of paper labels which are relatively cheaper than plastic. Thus it is more economical and suitable for processing number of products.

6.Which Labeling Machine Is Popularly Used Between Shrink Sleeve Labeler Machine And Traditional Labeling Machine?

Shrink Sleeve Labeler

Large scale industries with huge production level usually use the shrink sleeve labeler. These are:

Food Products Industry

This machine is mostly used for bottles having food products like ketchup, pickles, coffee, candies, cooking oil, snacks etc. Their main motive behind labeling the bottles is to better inform customers about ingredients present in prepared items.

Beverage Industry

The foremost industry which assume shrink sleeve labeler as obligatory part of its business is the beverage industry. Variety of juices, cold drinks and even water bottles are wrapped in shrink sleeve labels.

Wine Industry

Shrink sleeve labeling is used in wine factories to create eye catching designs on wine bottles. Along with that it also helps producers to introduce their brands with new ideas which too trigger the cost.

Dairy Industry

This machine is also used for shrink sleeving the bottles of products made from milk like butter, cheese, milk shake etc.

Chemical Industry

Different types of chemicals and various other toxic substances are frequently found in bottles having shrink sleeve covers. It is basically done to better assure the safety of users by mentioning the complete usage method and necessary precautions on attached labels.

Pharmaceutical Industry

Another industry which is taking the services of this machine on large scale is obviously pharmaceutical that deals with the packaging of thousands of medicines every day. To make them well identified a shrink sleeve labeler is always admired for doing the task accurately.

Cosmetics Industry

Large number of cosmetics products such as lotion, shampoo, face wash and creams are shrink sealed with sleeve labels to better assist the customers in knowing brand names, used ingredients and steps of usage etc.

Condiment Industry

Condiments and spices are of various types. It becomes difficult to identify each of them if their is no proper label available on bottle. In this way, shrink sleeve labeling is widely used in condiment industries where beautiful pictures of each product is printed on labels for easy identification and safe packaging.

Traditional Labeling Machine

Small scale manufacturing firms with low and ordinary production volume are keen to incorporate traditional labeling technology into their business sphere: They are:

Medical Industry

For labeling variety of bottles containing injection medicine, tablets and syrups traditional labeling machine is usually preferred as their is no such need of additional information necessary to mention.

Traditional Industries

Industries which have traditional business or their origin of manufacturing are far historical, use such type of labels and feel proud to take their customs with them.

Food Industries

Factories that produce different types of food like dry fruits, sweets or other items look for easy identification method so they find traditional labeling machine suitable to their economic condition as well.

Conclusion

Demand for labeling is growing day by day as most of the markets even does not accept the products without proper label. In such circumstances it is a matter of significance to look for best labeling machinery that better compliment your needs. Allpack is always there for providing standard quality equipment. For availing this opportunity contact us by clicking into our link given here.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide