Dog Food Packaging: The Complete FAQ Guide In 2025

Dog Food Packaging: The Complete FAQ Guide In 2025

Are you aware of how dog food packaging can unlock the horizon of profitability and skyrocket the business? Today, you’ll explore how dog food packaging isn’t just a way to provide quality, safety, and freshness but it can give a strong identification to your brand and growth. How to utilize this state of art technique? What packaging type is suitable for your product? How can you achieve the right machine on a compact budget? Is it easy to do dog food packaging? so on. To design effective dog food packaging, you must have innumerable questions in mind. We know how to answer these questions, without further ado let’s begin the effective topic.

1.What Is Dog Food Packaging?

Dog food packaging is a compliant, convenient, and functional way of storing and offering food products. This is a great solution for busy lives and chaotic work routines, where pet owner always strives to get a reliable solution for taking care of their lovely dogs. The dog food packaging is easy to open, providing fresh food, which is featured with resealable technologies, smooth handling, and less space.

2.Why Do You Need Dog Food Packaging?

Dog food packaging is beneficial for preserving and storing food due to the following reasons:

Freshness

The dog food packaging offers you an optimum solution to maintain and extend the shelf life of the food product. The packaging material have the ability to obstruct the interference of physical factors such as light, humidity, UV radiation heat to damage the product due to possessing high barrier properties perfect for the product.

Convenience

Dog food packaging is commonly available in flexible pack sizes that are ideal to grab for your pet with easy opening and closing features. This is considered an ideal property by global food packaging brands who implement it in their packaging.

Sustainability

Due to environmental awareness, dog food packaging is composed of recyclable material which is recognized as valuable entity for your products and boosts brand’s value.

Easy to Store and Transport

You can carry the dog food packaging everywhere because they’re accessible and easy to use. The packaging is done in such a way that allows end users to access, transport, and store without worrying about degradation.

Offering Broad Range Sizes

As dog food packaging is needed for a longer time, packagers provide various size ranges that hold the food in an optimum quantity. Too much tight or airy packaging is not suitable in any way. Perfect packaging must the one that can preserve flavors and freshness with easy-to-real properties.

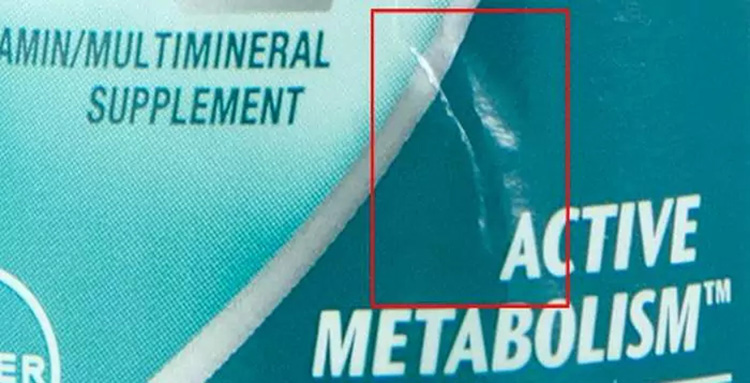

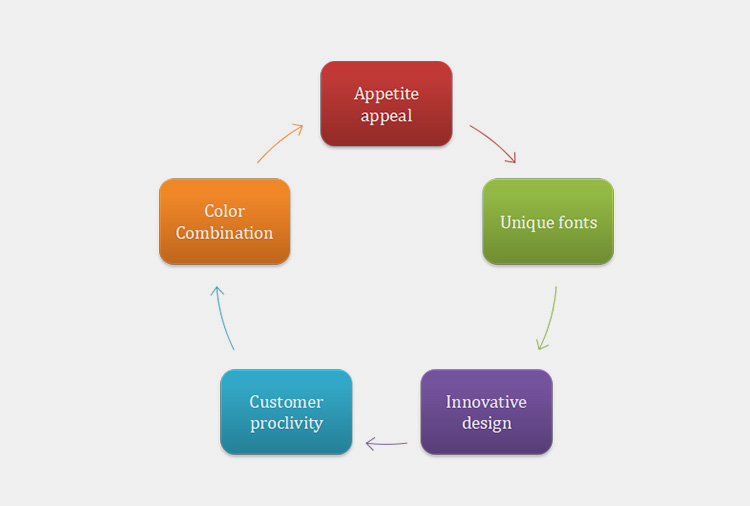

Interactive Illustrations and Graphics

The primary goal of every manufacturer is to make their product prominent and attractive to customers; this can be achieved by illustrations and graphics on the packaging that gain the attention of specifically millennial customers.

Informational Packaging

The key to success in dog food packaging is to include things on labels such as brand, dates, usage method, storage guidelines, etc., moreover, talk about ingredients and their benefits so consumers can understand about products and find them more appealing.

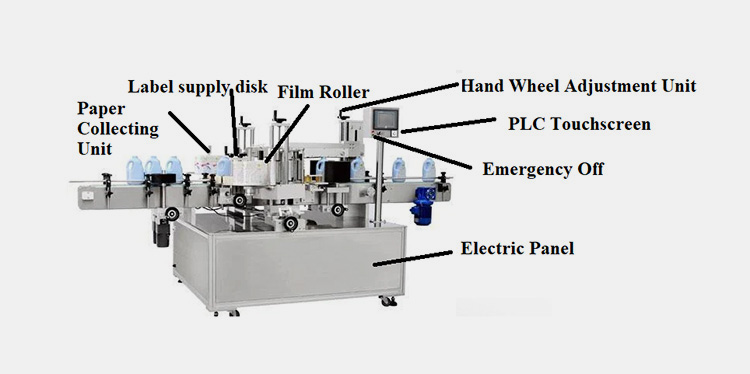

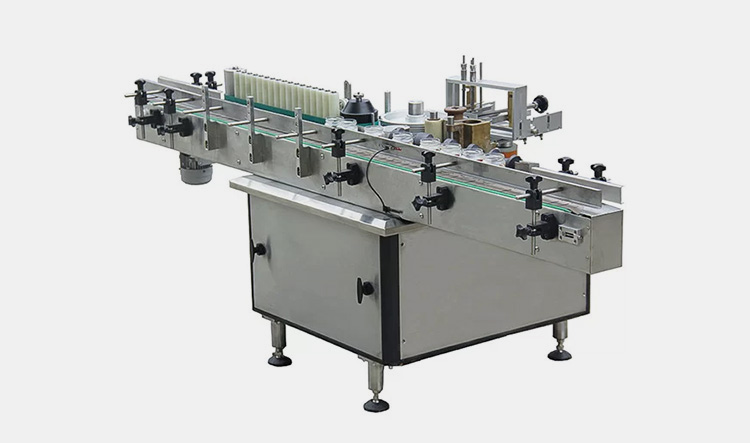

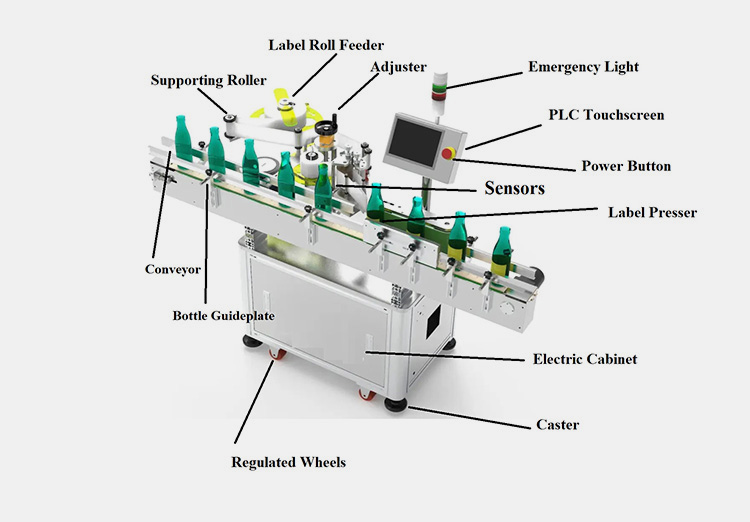

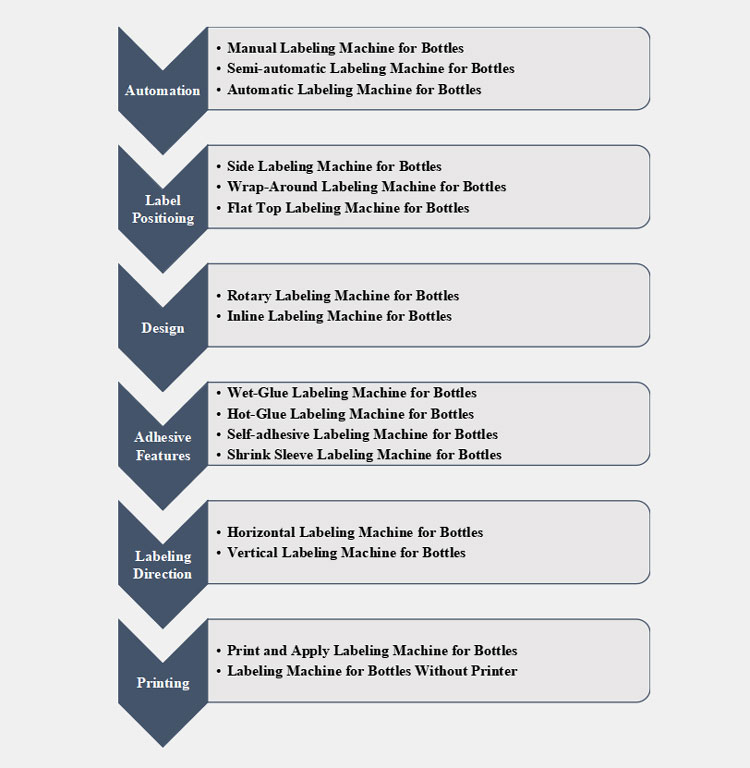

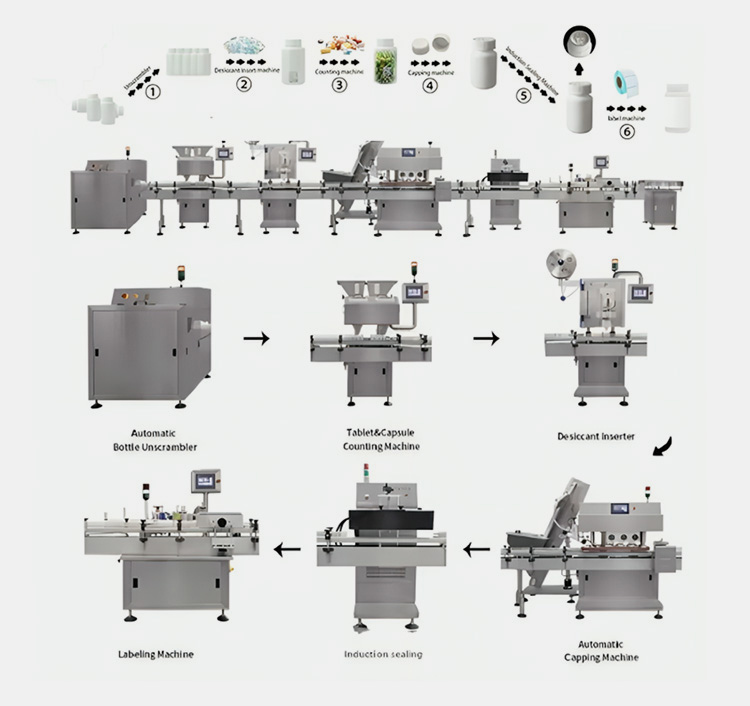

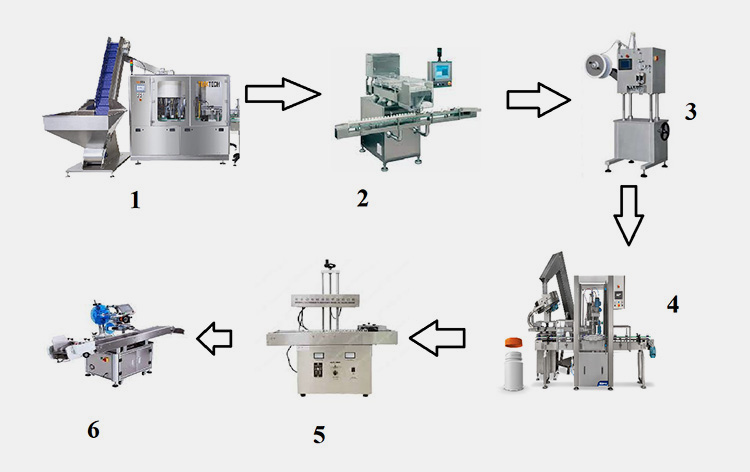

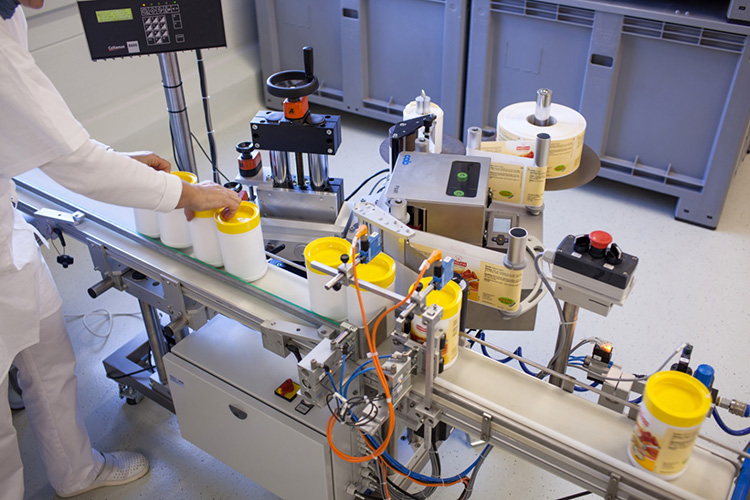

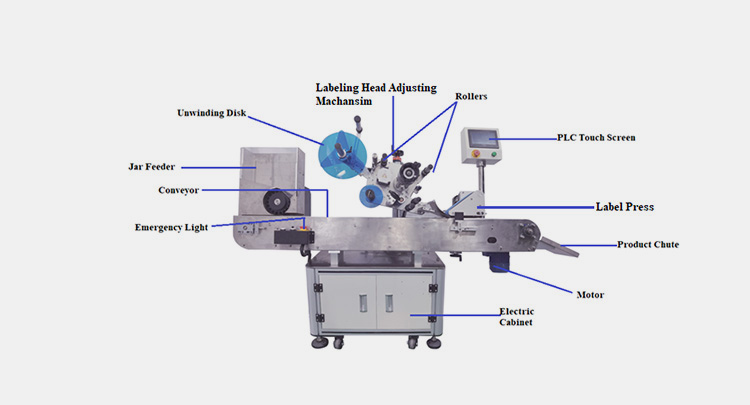

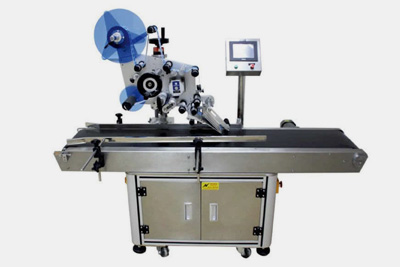

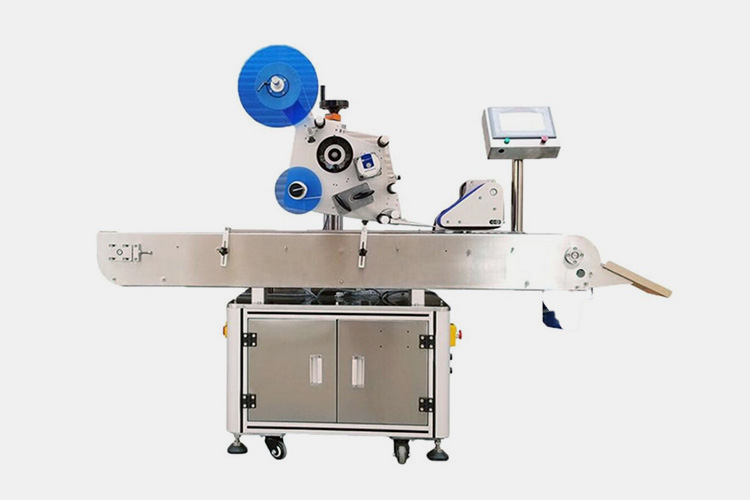

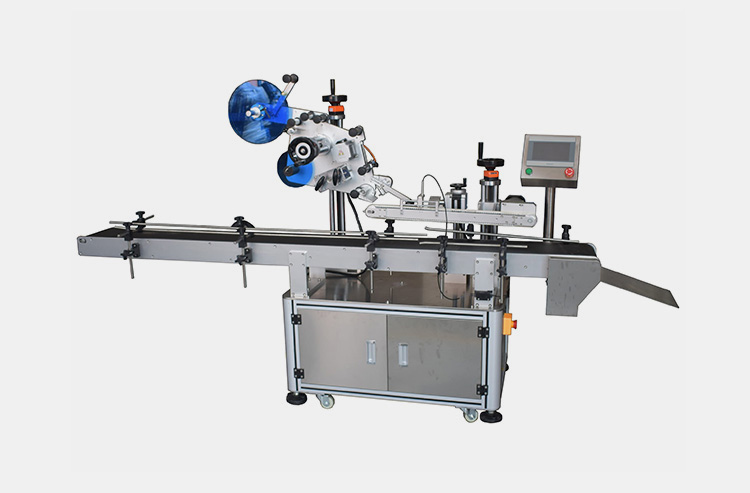

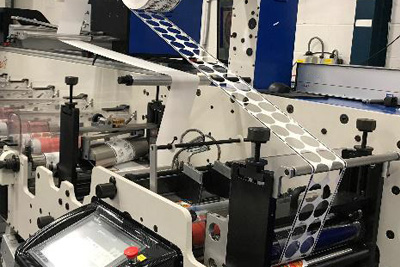

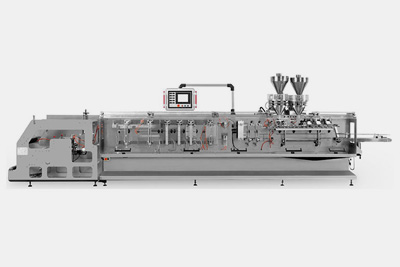

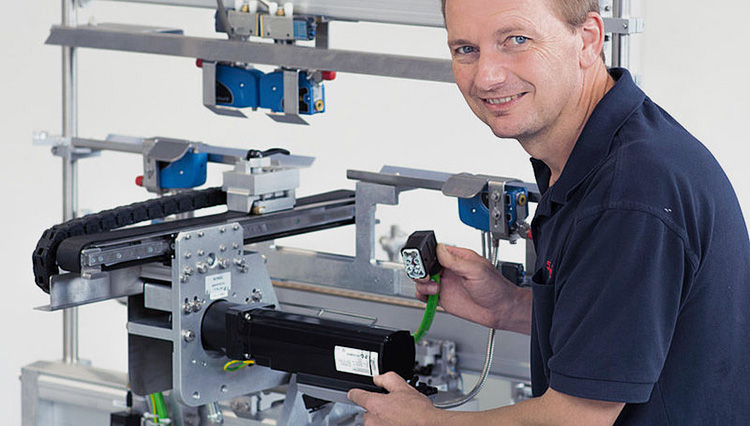

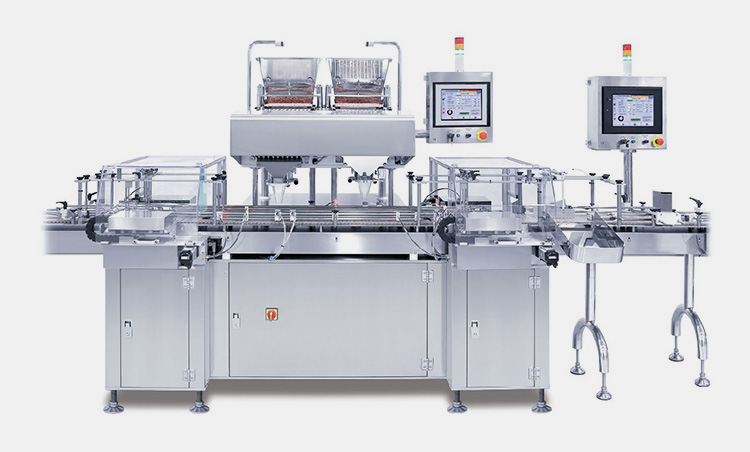

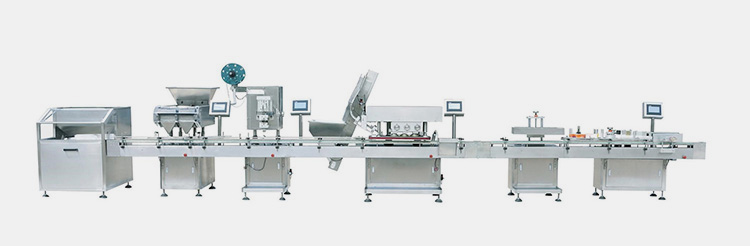

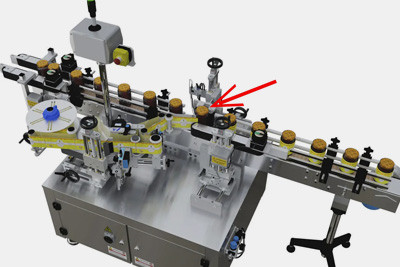

A huge Packaging Line offering Dog Food Packaging

Picture Courtesy: BW Packaging

Dog food packaging features, designs, and labeling to make packaging visually attractive. There are various packaging lines to offer a huge formatting for dog food packaging.

Highlighting the Pros & Cons of Dog Food Packaging

Picture Courtesy: Habitat pet supply

Aluminum

| Pros | Cons |

| This is highly safe corrosion resistant, humidity resistant, and gas resistant (oxygen). | You cannot weld aluminum packaging |

| A highly lightweight and durable form of dog food packaging material | Less strength |

| For sure, this is a recyclable material | It offers limited shapes. |

| This is an expensive form of packaging material |

Paper

| Pros | Cons |

| Paper dog food packaging is made from natural sources. | As compared to other packaging materials, this is poor and resistant to moisture and light. |

| This is highly safe and biodegradable. | Paper dog food packaging can be easily torn or can’t resist pressure. |

| This is a very light and inexpensive form of packaging |

Tin Plate

| Pros | Cons |

| This type of dog food packaging is water and light resistant. | This is heavier than aluminum. |

| This is considered as the most durable form of packaging. | Tin plate needs can opener to open them. |

| As compared to aluminum, this is cheaper. | This is prone to corrosion. |

| This is easily recyclable. | The tin plate cannot be weld. |

Plastic

| Pros | Cons |

| This is the most traditional packaging material which is strong in nature. | The packaging is threatful and may exert environmental effects. |

| The packaging is ideal for hot filling of the product with excellent barrier quality. | |

| Plastic dog food packaging gives excellent clarity. | |

| This packaging is highly tear-resistant. |

3.What are the Types of Dog Food Packaging?

The types of dog food packaging are divided into the following categories:

According to Types of Dog Food

There are basically three types of dog food that need different packaging. Certainly yes, all of them need to be packed differently.

Dry Dog Food Packaging

You can also term it kibble, which hold low-moisture content in it. Common examples of kibble are grains, and vegetables, that are produced by drying or evaporating water content to extend their life. The dry dog food packaging is mostly done in bags, pouches, and boxes and they should be kept in an air-dry and cool place to sustain their quality, taste, and freshness.

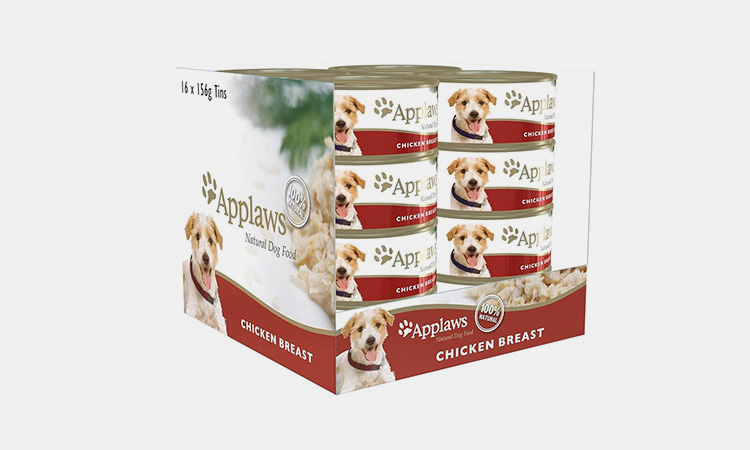

Wet Dog Food Packaging

Picture Courtesy: Woonona

This is also known as canned food. The wet food mostly holds 70 to 80% of the liquid in the product that is fixed and sealed firmly to preserve the freshness and taste of the food. For example, vitamins, protein, milk, beef, chicken, etc. The packaging material used in can are commonly metals tin, or steel. You can store wet dog food packs at room temperature if unopened but after unsealing it is recommended to use the refrigerator or controlled temperature.

Semi- Liquid Dog Food Packaging

Picture Courtesy: My Dog

The semi-liquid dog food is mostly packed in pouches, tubs, trays for single serving only. These foods are mostly prepared with mixed liquid and have chew texture and soft consistency. After packaging it is recommended in cool and dry place but after unsealing it is suggested to use a controlled temperature. The commonly foods include in semi-liquid include meat of different animals or grains, or fiber.

According to Types of Formats

There are various kinds available for dog food packaging that we believe all comes with specific requirement about the products. Whether bag or pouch; all of the packaging types are ideal for every portion of food you want to pack. Let see the available options one by one.

Pouches

Picture Courtesy: Habitate

Flat bottom, stand up, zip-lock, or pre-made pouches and others aptly represents the functionality of packaging which is suitable and appeal to the product display and its storage property. For the dog food packaging manufacturer commonly select pouches as it offers a large volume of storage with stability. The pouches are lightweight, and durable and perfectly pack the products with easy packaging production line.

There are various types of pouch formats:

Lay-flat Pouch

Picture courtesy: Fiverr

Lay-flat or pillow pouches are made flexible to adapt incorporating a small quantity of dog food inside using less material. The pouch is made with sealed top and bottom with a back fin seal to preserve food freshness. This type of dog food packaging serves as an easy to go option for dog owners.

Stand up Pouch

Picture courtesy: Stan Branding

Stand-up pouches have bottom gusseted design to attract customers due to their displayable nature on a shelf. They are featured with food grade material packaging which ensures that the dog food is protected from environmental moisture and oxygen. These pouches have both easy to tear and ziplock features for convenience and compliance.

Quad seal pouch

Picture Courtesy: Sante

Quad seal pouches are also known as block bottom , flat bottom, or gusseted bags having up to 4-5 panels which allows excellent display of brand message and this packaging has the capacity to fill more volume of dog food. Due to its multilayer protection of packaging material, it ensures that the dog food is protected inside from humidity or high temperature.

Fin seal pouch

Picture courtesy: Hezcy packaging

These pouches are also known as fold over seam bags or T-seal pouches, which have two interior sides of the packet sealed together and the fin is folded over. Fin pouches are produced for high volume products filling such as dog food.

Lap seal pouch

Lap seal pouches are also known as overlap seam bags where the outside packaging film is folded over the inside packaging film. If the packaging is filled vertically, it can be good for smaller dog food products whereas if filled horizontally it can contain both wet and dry pet food.

Zip lock pouch

Picture courtesy: Chegos pl

Ziplock pouches are made with a reclosable sealing feature that is applied to a stand-up pouch or gusseted bags. They provide a moisture free environment for the dog food to lock it’s freshness and are available in many formats. This bag is good for filling large quantities of dog dry food.

Bags

Picture Courtesy: Gripster

This type of packaging is similar to pouches. This is the smartest, and optimized form of packaging that offers sturdy designs and excellent volume for storing dog food for a longer period. This type of packaging is accompanied by gussets on each side that expand and provide a larger volume area to the product. This is typically designed with a fin seal at the back side with an opened top for the filling of the product. Upon filling the bottom of the bag becomes flattened at the base. Moreover, the bag is designed with additional areas that ensure the manufacturer mentions information and promotional content about the brand.

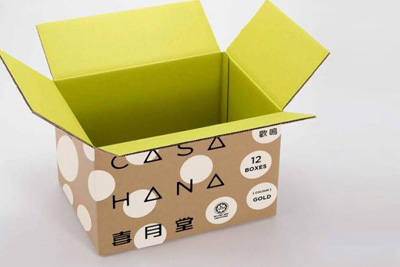

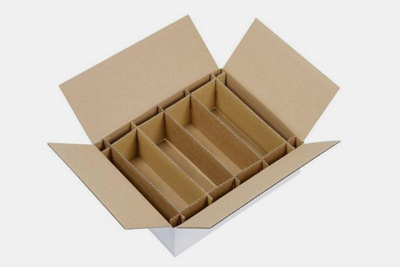

Cartons

Picture Courtesy: Pet Food Process

They’re made up of cardboard that offers premium quality for dog food packaging. When you open each carton, they’re packed with various individual packets of dog food that can be useful as a single serving or with re-sealable pouches or sachets. The purpose of carton packaging is to offer additional benefits to dog food during transportation and display information about the brands as well as the product.

Cans

Picture Courtesy: Newrby Produce

Metal or steel cans are preferred as a dog food packaging material that can be opened by pulling a can seal and finding the food. Can dog food are mostly available as ready to eat product under highly controlled storage conditions to present fresh product. Cans are available in various sizes and used as a single serving.

Cans are of two types:

Disposable Can

Canned tin packaging of dog food has been increasingly popular as it is convenient for use and can hold wet dog food. They provide airtight safety to the food inside preventing moisture from spoiling it.

Reclosable Can

Reclosable cans are those that can be utilized by pet owners for storage purposes again or which can be reused again as a sustainable option. These cans have a closure lid made up of metal or plastic which is sealed to preserve dog food freshness.

Tubs

Picture Courtesy: Purina

The resealable tubs are commonly used for wet dog food packaging. They are designed with an induction sealed lid. Upon pulling the lid and unsealing the tub, food is obtained and can be re-sealed after usage. This type of packaging is suitable for single or multiple time serving.

Containers

Picture Courtesy: Whole Dog Journal

Whether bulk food or single serving, a container is suitable for dispensing dog food in large quantities. The containers are available in the form of plastic as well as metals, which is considered a great source of presenting dog food packaging in large amount.

Trays

Picture Courtesy: ADVANCE

These are individual servings that are made up of aluminum or plastic material offering an easy way to present food to your dogs. The tray is provided with a lid that helps in securing and protecting the food against the external environment. Once the tray dog food packaging is opened and used, it should be disposed of.

According to Packaging Materials

What is an ideal dog food packaging material? This is the most frequent question that every manufacturer asks to enhance the sustainability of their packaging. Nearly, all kibbles come in biodegradable packaging that is 100% made up of recycled material. The materials that are conventionally used in dog food packaging include:

Plastic

Picture Courtesy: Phud

This is the most common and traditional material that offers huge benefits in terms of aesthetics, temperature barrier, extending shelf life, as well as environmental footprints. This packaging is used to preserve aroma and freshness of the dog food product and due to its lightweight property, it is easy to transport and handle offering low shipment cost.

Paper

Picture Courtesy: PaperWise

This is a highly growing form of packaging that has taken attention due to its health and environment safety properties. The food grade paper are used for dog food packaging that has basic four types such as kraft, coated, cardboard, and offset paper. These papers are tough in nature that present aesthetic and smooth texture and enhance brand identification and market. The paper food dog packaging is suitable for dry dog foods packaging such as cereal, nuts, rice, or other relevant grains, etc.,

Tin

The tin dog food packaging is the common packaging method where cylindrical, square, or rectangular cans of various shapes and size pack dog food for the long term. The packaging offers high safety and prevention against progression of microbial growth. The packaging is divided into two types two-piece tin and three piece tin dog food packaging. This is a soft metallic packaging which is non-corrosive and safe from product contamination.

Aluminum

Picture courtesy: sustain

This is highly flexible and light dog food packaging material which is easy to handle and recyclable. The aluminum packaging is hygienic and non-toxic in nature keeping fragrance, and taste of dog food for longer period. Plus, it offers protection against external unwanted environmental factors such as oxygen, UV light, microbial contamination, etc.,

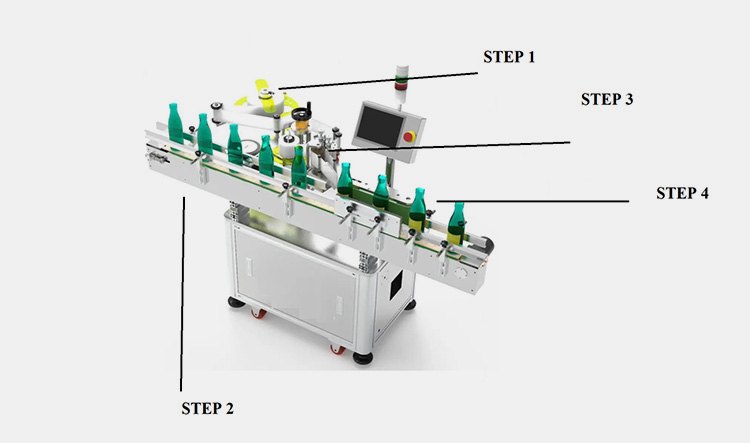

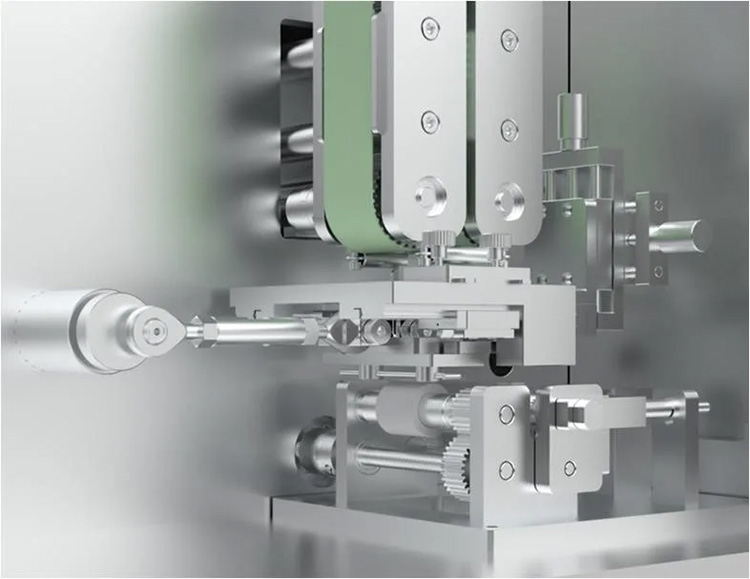

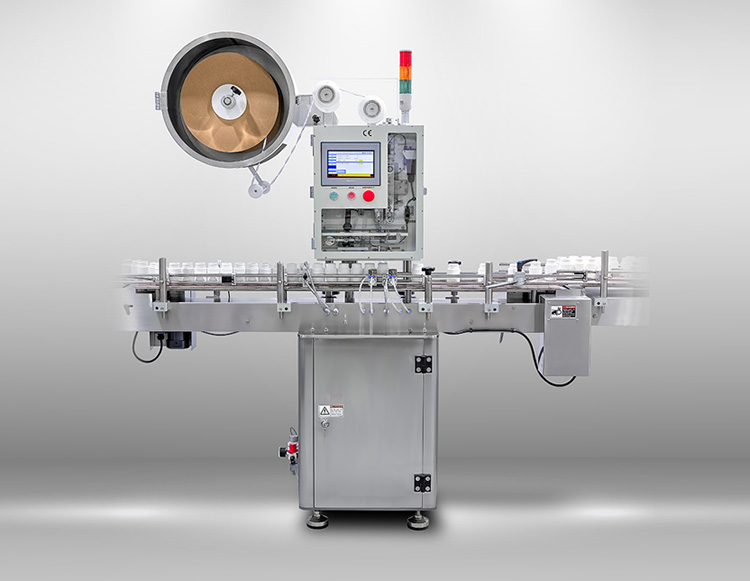

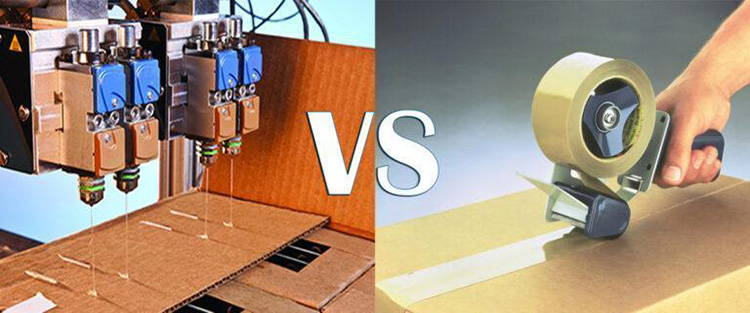

4.What is the Kind of equipment for dog food packaging?

Dog food packaging has a significant role in boosting the growth of the animal food industry for offering premium food. For the packaging of dry dog food packaging bagging machines and various film forming machines are used. Discussed below is the list of packaging machines that is based on product type and capacity.

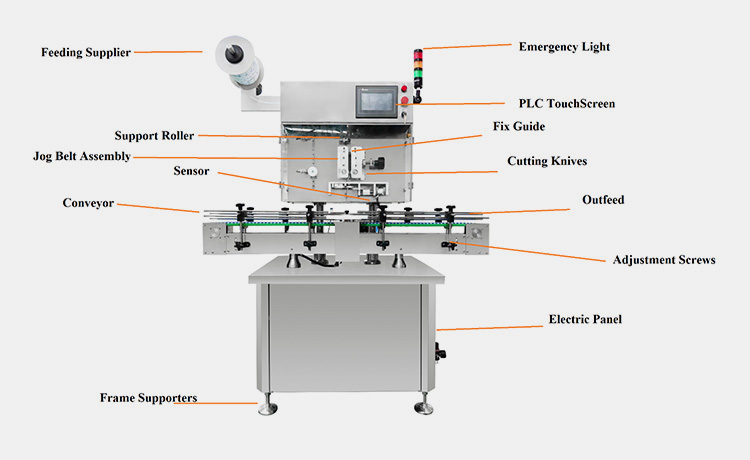

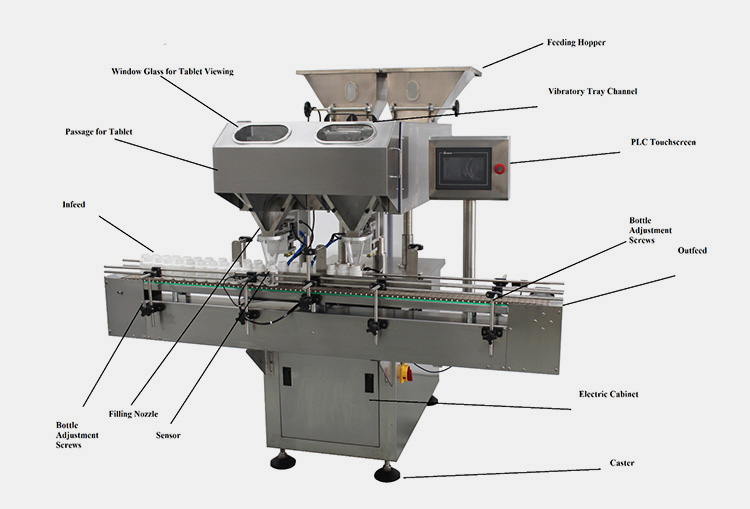

VFFS (Vertical Form Fill and Seal) Dog Food Packaging Machine

VFFS Machine- Picture Courtesy: Lenis

The machine is used for filling and packaging a wide variety of dog feed including dry or wet slurries or grains or seeds. The machine works on the basis on gravitational force that allows the falling or transferring of product from hopper to packaging material in a smooth flow. The VFFS machine is featured with a PLC touchscreen and sensors that ensures a consistent and reliable packaging.

Working Principle

The film roll which is fixed in the unwinder helps in the uncoiling of the sheet. An opened film forms a narrow shaped bag with the help of a roller equipped in the forming unit. The presence of vertical sealers that are heated jaws that seal the bag at each side and the bottom. The filling of dog food takes place with the help of gravitation force; once the bag is filled it is sealed firmly using horizontal sealers. The cutting knives separate the bag by cutting the edges of the bag.

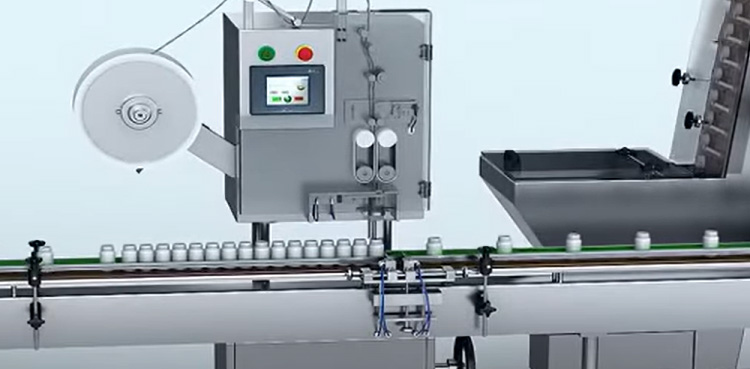

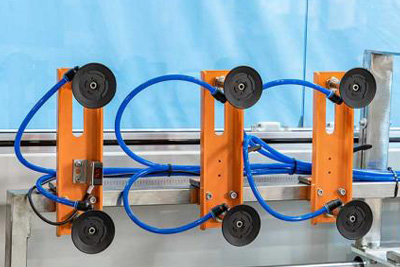

HFFS (Horizontal Form Fill and Sealing) Dog Food Packaging Machine

HFFS Machine

This is a highly economical way of dog food packaging that allows large stand up pouches or gusseted bags to form. Like VFFS, HFFS machines are also widely used devices that are accompanied by broad packaging applications following similar working principles except dimension of filling.

Working Principle

The HFFS machine works by unwinding the film roll around the dancer's arms. The opened film turns around the forming unit to form a design as needed. The formed bag is opened by a pair of inflators or openers that help in the expansion of the bag’s edges. This process either takes place linearly or in rotational manner. The opened bags reach the filling station where a predetermined amount of feed is transferred into each bag. Upon filling, the horizontal sealer pressed them and firmly sealed them one by one. The finished pack product is discharged through the outfeed. With the help of a conveyor, the filled and packed material is transferred to the next machine for final transportation.

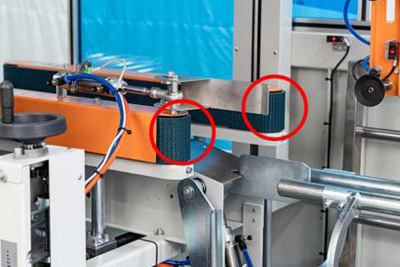

Flow Wrapping Machine

Flow- Wrapping machine

This machine is used for dog food packaging for large quantities of products that need to be packed in an individual form. This is an ideal machine preferred for other different food industries that seals the products by wrapping film or envelopes of plastic or foiled material. The purpose of the flow wrapping machine is to achieve safety and extend the product’s shelf life.

Working Principle

The machine working is very simple where the packaging product is moved on a conveyor toward the forming zone. A thin film is wrapped and forms a bag or pouch with the help of a forming tube, at this point, the food product is positioned and with the help of heating sealers and cutters, the pouch is sealed and cut into individual wraps. The finished product exits the machine and leaves for further packaging steps.

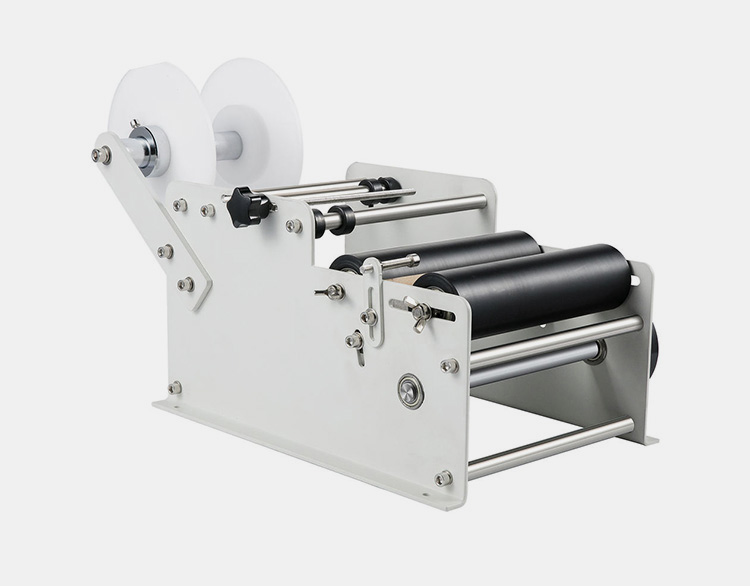

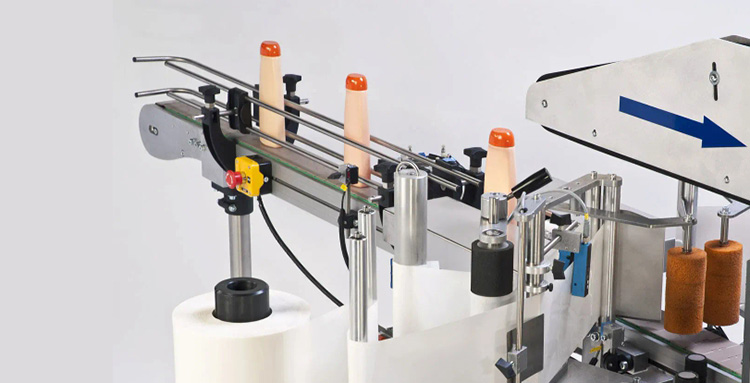

Premade Pouch Dog Food Packaging Machine

Premade Pouch Dog Food Packaging Machine- Picture Courtesy: Perfect Automation

The machine is convenient for dog food packaging of various states and tastes with predetermined sizes or volumes. The machine is recommended for dealing with large production packaging where multiple formats of premade pouch bagging can be handled easily.

Working Principle

A set of premade bags are loaded in the magazine of the machine where grippers pick them one by one and bring them towards the filling unit of the machine. The help of highly compressed blowers allows bags to inflate by the entrance of air. Once the bags are opened the dog food materials are transferred into a bag with the help of either auger or volumetric fillers. Once the process is finished final sealing is done by horizontal sealers.

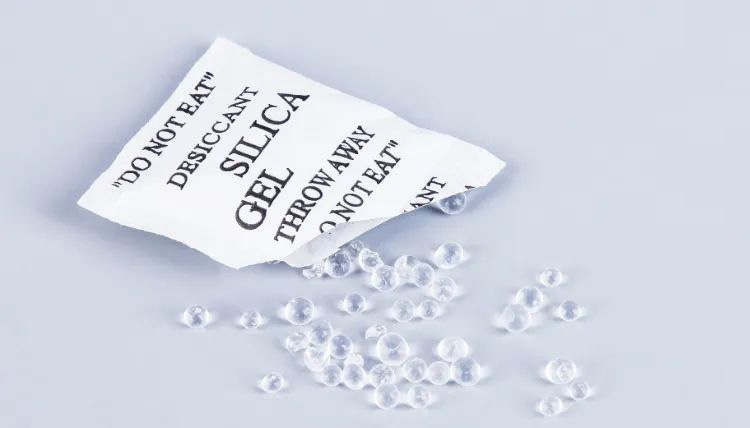

Vacuum Packaging Machine

Vacuum Packaging Machine

Along with packaging material, using the vacuum packaging method can also offer top hygiene to dog food and provide finished kibble fresh and flavourful for a longer time. A vacuum dog food packaging machine is a compact solution that replaces oxygen molecules inside the pouch/bag with nitrogen gas. Nitrogen is an inert gas that do not harm the food or not exert any unwanted health effect improves the shelf life of the product and preserve them for a long.

Working Principle

The vacuum dog food packaging performs its action by vacuuming and sealing simultaneously. The air inside the bag is removed with the help of a nozzle. The product is positioned inside the bag via a hopper. With the help of clippers, the mouth of the bag is closed. The bag is vacuumed and then sealed with the help of an impulse system known as a vacuum sealing chamber. The machine uses about 0.5 to 8 torr degree of vacuuming. Also, the machine is highly efficient and deals with dozens of product at the same time.

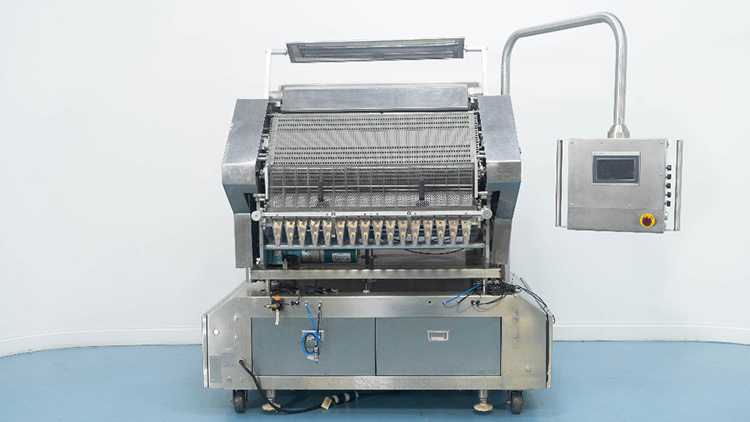

Can Dog Food Packaging Machine

Can Dog Food Packaging Machine- Picture Courtesy: IC filler

Can dog food packaging is the most conventional way of storing and transporting goods across the globe. Today, a can dog food packaging machine is still considered as an advanced machine that can carry large volumes packaging in a precise and accurate way.

Working Principle

The cans are loaded into the machine hopper where guiding chutes or grippers handle them without risk of falling. The process begins when can reaches to the filling station and the product is transferred via auger, volumetric, cup or piston filler. The sealing process is done by airtight and tamper evident induction sealing of the lid, in the case of bottles or jars, capping is done prior to induction sealing.

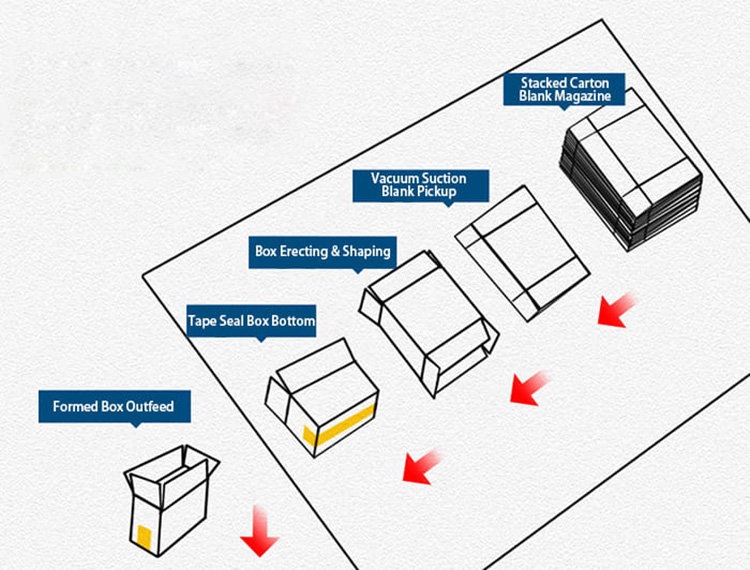

Carton Dog Food Packaging Machine

Carton Dog Food Packaging Machine- Picture Courtesy: Kingvictor

This is also known as a cartoner or box machine which is used to make cartons of various shapes and sizes., such as rectangular, square, small, or large, etc., the carton dog food packaging machine is also one of the traditional packaging machines that effectively protects the good inside the packaging and considered as a suitable way to transport and market the product with the best recyclability.

Working Principle

The set of cartons is positioned on the guide rail where an activated push plate mechanism opens the carton and send it toward the folding area. In this unit, the folding of the carton take place simultaneously on the left and right side in rotating motion. The carton tongue seals the front cover and secures the packaging. The dog food is introduced into the case and lid is pushed to lock it securely.

5.What Is Shelf Life of Dog Food Packaging?

Picture courtesy: IAMS

As a pet owner, it is surely mandatory that you check out your dog food’s expiration date before stocking up in bulk or planning to do so. The shelf life of dog food packaging is equally important as that of human food, i.e., if you want to ensure your dog stays healthy and eats safe quality food.

Dry dog food can last up to 12-18 months, while some might even stay good for two years. However, once the pack is opened it is suggested to be fed to your pet within 4-6 weeks for best taste and quality. But the shelf life can also be increased for about a month if stored properly. Frozen raw dog food lasts for about 6-12 months if kept in a freezer ideally but after being opened it can last for only few days. While unopened freeze dried food might last for two years and after being opened it may degrade soon, so it is better to feed your dogs within a period of 7 days.

6.What Is the Standard Dog Food Packaging Bag Size?

Picture Courtesy: BAOLAI

Dog food packaging manufacturers have brought about various options for the food bag’s specific weight and size. You can also customize and change the specification according to the type of food, brand and quantity you deliver.

However, there is no such generalized size for a dog’s food packaging bag. They vary from small bags which can carry as little as 100 grams to bags which can hold bulk quantity up to 5 kilograms or more. Commonly used packaging bag sizes for dog’s food ranges according to product weight (5lbs to 40lbs). One can package their dog food in bag sizes ranging from 80×155 mm to 300×370 mm or it can be personalized as per your requirement. Those who buy small portions for trial food or maybe for their small dogs may get small packets of food packaging and those willing to purchase in bulk quantity may get larger bags for their big dogs.

7.Can You Reuse Dog Food Packaging?

Picture courtesy: Meals for Mutt

You can use your dog food bag again to store some dog food and make sure it is sealed properly. Canned packaging can be washed thoroughly and used as containers for holding different things around the house.

But first, it is necessary to ensure that the food packaging material has not worn off and has no holes or tears on its surface. It should be avoided to hold human food as it may pose the risk of contamination and health risks as some particles might leave their odor and chemicals in the bag. Plastic bags for dog food is usually not recyclable so it must be carefully disposed of if cannot be reused for storage purposes again. As a pet owner, it is prominent how environmentally friendly you think by reusing your dog food packaging bag for refilling its food again.

8.What is the average profit margin for dog food packaging?

Dog food manufacturers have been facing a wide diversity of trends that help them to increase their chances of profit earning.

Key factors like premiumization in pet food quality such as those free from preservatives make customers willing to pay more. Similarly, dog foods that are consciously designed and customized specific to their health conditions and keep sustainability in mind, also make pet owners readily buy such dog foods.

Now seeing the average profit margin, according to Trade India dog food industry has chances of 40-50% revenue generation in 2023. Adding more, Sandler research had reported a global forecast in the pet care market to have grown by 4.72% in the period of 2016-2020. The Pet Food market industry is assumed to skyrocket from USD 101.74 Billion in 2023 to USD 145.15 billion by 2030.

Conclusion

Dog food packaging is the fastest-growing sector that brings high marketing trends. Therefore, the packaging pattern must be aligned with good functional property according to the buyer’s values. For manufacturers, meeting suitable dog food packaging demands must not be compromised. We have discussed a guide that will help you in deciding convenient and compliant packaging factors such as selecting the right machine, the right material, and the right packaging type. Use them all to boost your production. Allpack is the hub of offering amazing dog food packaging machines with excellent customer service. Message us now to open the horizon of a skyrocketing dog food packaging business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Dog Food Packaging: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours