Pickle Packing: The Complete FAQ Guide In August 2025

Pickle Packing: The Complete FAQ Guide In August 2025

You must be familiar with watching glass jar and a tight metallic lid over it when finding the pick packing, the prime reason behind this standard packing is an ideal partnership of pickles, metals, and glass. But with time you can see other important ways of pickle packing as well!

This guideline is important if you want to get familiar with pickle packing and its behind the process.We will assist you to know about types, machines, do and don’t & much more. So, it is ideal to stay with us to expand the horizon of pickle tartness.

1.What is a pickle? What to know about Pickle Packing?

You must taste a savory mixture of fruit and vegetables that are mostly preserved for a certain period of time to improve fermentation.

That’s known as pickles. They are offering you various health benefits as well as enhancing your food taste. You can prepare pickles by reducing its pH and by addition of salts and condiments.

You can find various methods to prepare them like by either fermentation of vegetables by lactic acid or by preservation of vegetable with acetic acid i.e., vinegar and pickles in oil.

Despite of high preservation abilities and its action against antimicrobial contamination; the quality and taste of pickle deteriorate if not packed properly. It is the process of storing the pickle in order to retain its taste and aroma intact.

Moreover, it offer you 99.99% protection against the effects of light and moisture with pickle content and making excellent sealing and aesthetic appearance to pickles.

2.Why Pickle Packing is Popular?

Before going to discuss it, you must know the basic reasons behind its need and popularity worldwide.

Pickle Packing Extends Shelf Life

Good Storage extends the shelf life- Picture Courtesy: Thrillist Australia

Pickles are hygroscopic in nature which is prone to react with nature such as moisture, air, light and other factors. The proper one is ensuring you that your product is airtight and safe against external factors hence it improves shelf life of the pickles in the term of taste, flavors, aroma, and quality.

Pickle Packing Preserves Originality of the Pickles

Freshness of pickle preserves with pickle packing- Picture Courtesy: Global Growers

The material is inert in nature which doesn’t react with ingredients of pickles and meet quality standards to help in the maintain integrity of pickles. Thus, it will give health benefits with original taste as ripened from garden.

Pickle Packing Ensuring Promising Health Benefits

Right Pickle Packing, Right Wellbeing

As mentioned above the reaction of pickles with oxygen induce rancidity of the product via progression of microorganisms and spoilage via breeding.

Right packing is a good protector against these issues hence offering you brilliant health benefits.

Pickle Packing Makes Product Look Attractive and Premium

Mouthwatering pickle packing

A manufacturer with premium and good packing can directly grasp the attention of consumers and compel them to grab the product. The packing not only saves the product but makes them eye catching and more visible.

Pickle Packing Make Easy Transportation and Sale

Easy Transportation with Correct Pickle Packing- Picture Courtesy: The Spruce Eat

You can smoothly distribute the packs at every corner of the world if they’re packed correctly with premium materials. For product marketing they’re also available and packed in individual packed samples, similarly for branding and distribution, you can find standard packing that offers easy shipment all over the world.

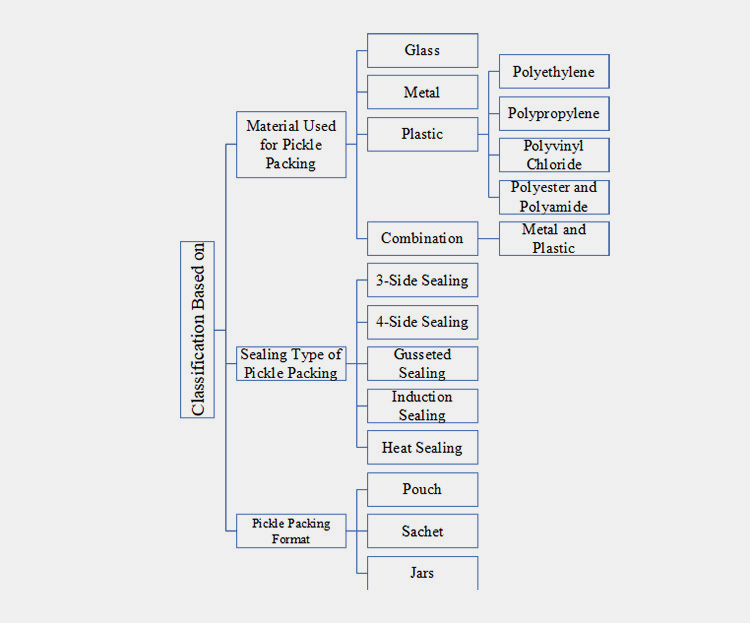

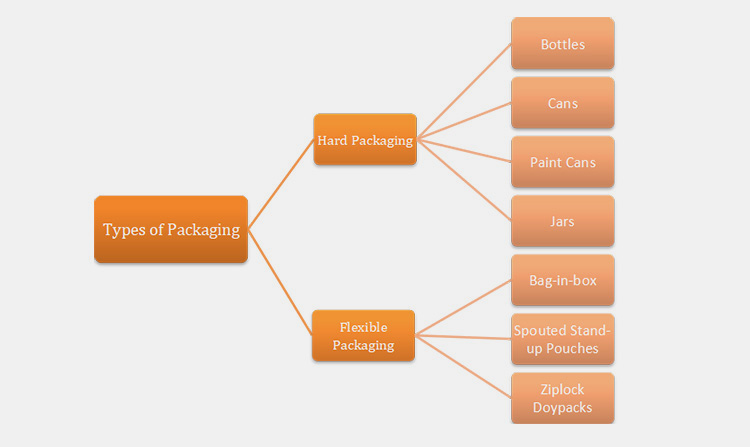

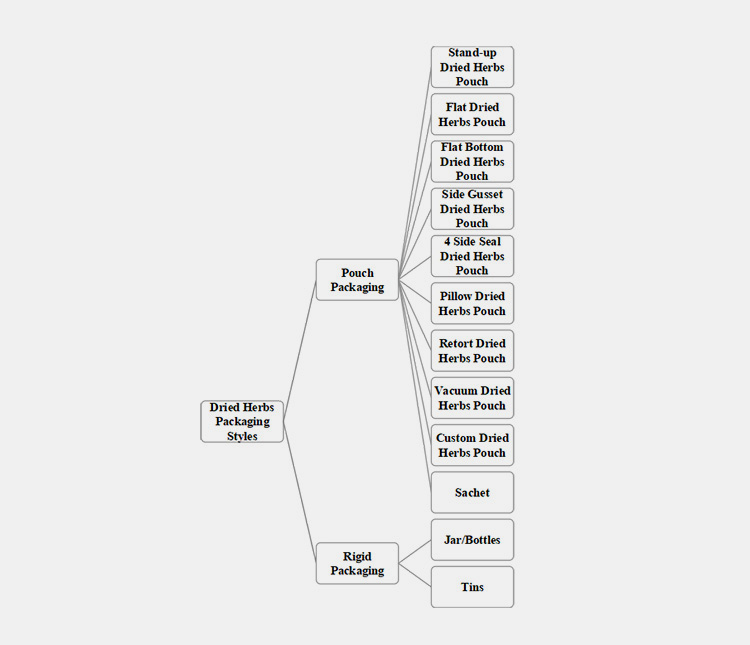

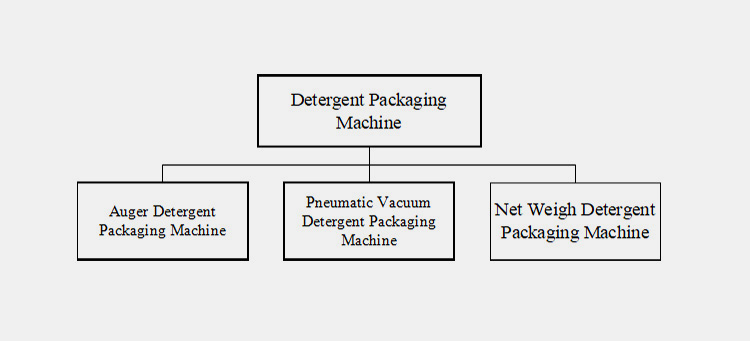

3.How to Classify Pickle Packing?

Different types of pickle packing

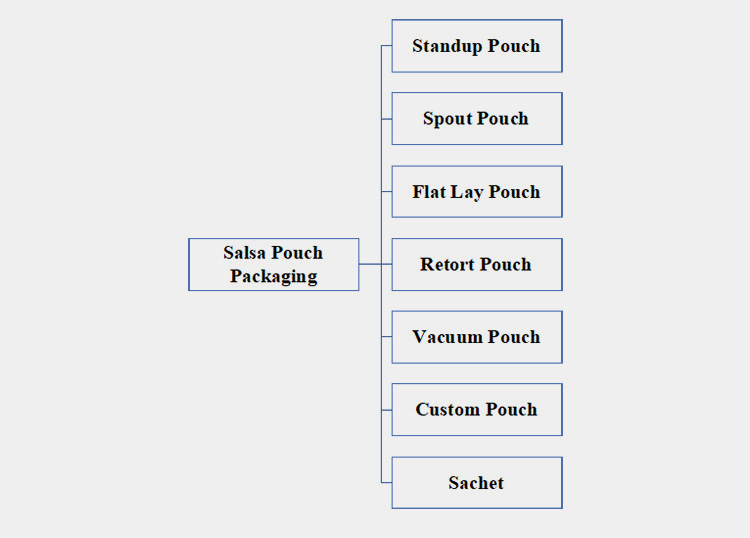

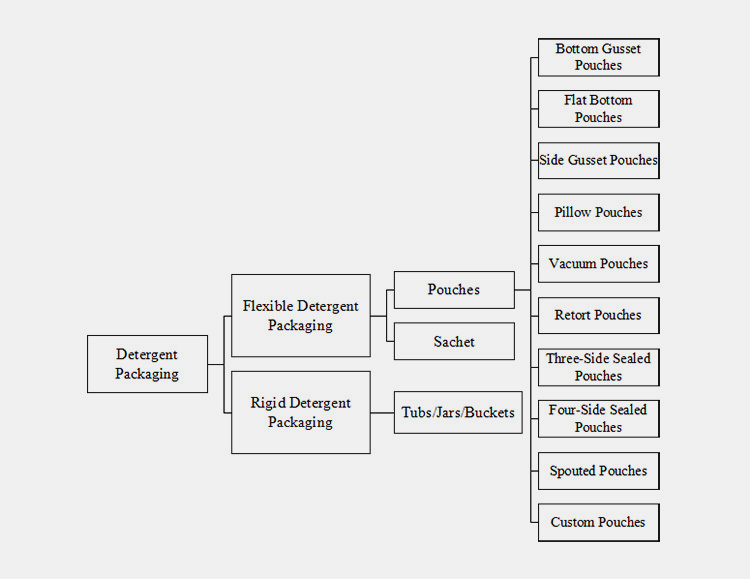

To pack, a variety of packing materials are available which are classified into two main categories such as: Flexible and Hard packing which is further categorized as.

Flexible Pickle Packing

Flexible Pickle Packing- Picture Courtesy: Lolli4U

Flexible packing is a great choice for holding pickles, it can be prepared with zipper-seal packing which helps to use easily. Plastic pouches, Pillow bags, Sachet pickle packed, and re-closeable zipper bags are examples of flexible packing.

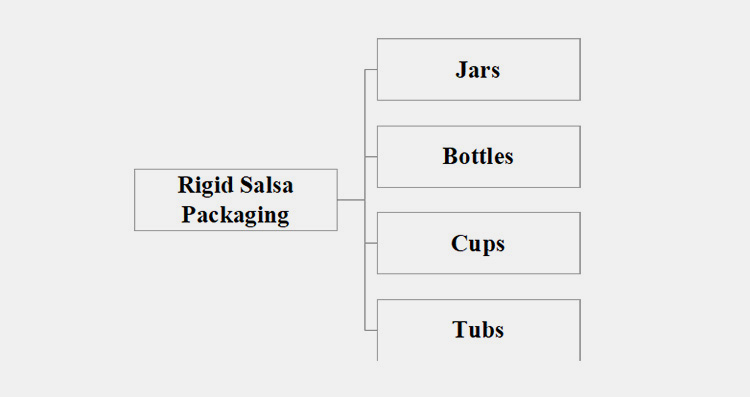

Rigid Pickle Packing

Rigid Pickle Packing- Picture Courtesy: Epicurious

Rigid packing is hard and difficult to move from one place to another due to its heavy weight. Glass jars, plastic containers, and cans are examples of rigid pickle packing.

Both types of flexible and rigid packing sub-classified based on the materials used and the type of sealing method. Such as.

Overall classification of pickle packing

Pickle Packing- Based on Types of Packing Materials

Glass Pickle Packing

Glass Pickle Packing- Picture Courtesy: ABC

Glass pickle jar packing has been a popular choice for the last decades, and it is found in numerous colors and styles. It is non-porous which protects pickles from dust, and it can be easily cleaned. Pickles in the glass jar remain fresh for a long time compared to plastic packing.

Metal Pickle Packing

Metal Pickle Packing- Picture Courtesy: Onegreen

The metal jar is also a popular choice to store pickles. The pickle can be easily stored and moved from one place to another due to metal packing.

Plastic Pickle Packing

Plastic Pickle Packing- Picture Courtesy: Sweetiemail

Good quality plastic bags must be used for packing pickles on plastic bottles/jars. Different types of plastic materials are available to store pickles, such as polyethylene, polypropylene, polyvinyl chloride, polyester, and polyamide-based plastic packing.

Various Plastic based pickle packing- Picture Courtesy: ID8

| Polyethylene-based Plastic Pickle Packing | Polyethylene is considered to be the backbone packaging film as it protects the pickles from moisture. These films are free from plasticizers and other additives. |

| Polypropylene-based Plastic Pickle Packing | Polypropylene-based plastic packing is more stuff and has better clarity than polyethylene-based pickle packing. |

| Polyvinyl Chloride-based Plastic Pickle Packing | Polyvinyl Chloride film has a low gas transmission rate and can be a transparent, rigid film. It is heat-sealable, and used to wrap pickles. |

| Polyester and Polyamide-based Plastic Pickle Packing | It is stiffer than the other plastic-based packing. It protects pickles from the dust and gases. |

Pickle Packing- Based on Types of Sealing

3-Side Sealing Pickle Packing

3-side Sealing Pickle Packing

In this sealing method, the packed that is usually a pouch is sealed with three sides and one side remains open for filling pickles inside the pouch. Then the fourth side is also sealed after filling.

4-Side Sealing Pickle Packing

4-Side Pickle Packing

In this type of packing all four sides become sealed which provides the shape of the packing. It is commonly used for sachet and small pouches.

Gusseted Pickle Packing

Gusseted Pickle Packing

The gusseted packing has two sides gussets that provide space for pickle storage. The lower portion of the pouch is first sealed then the above portion of the pouch is used to add pickles inside the pouch.

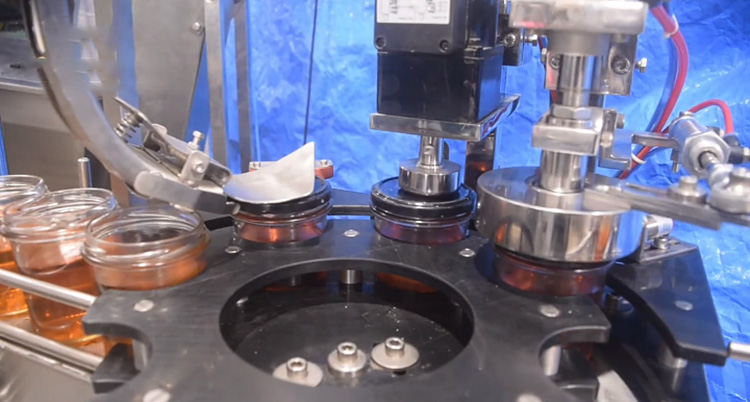

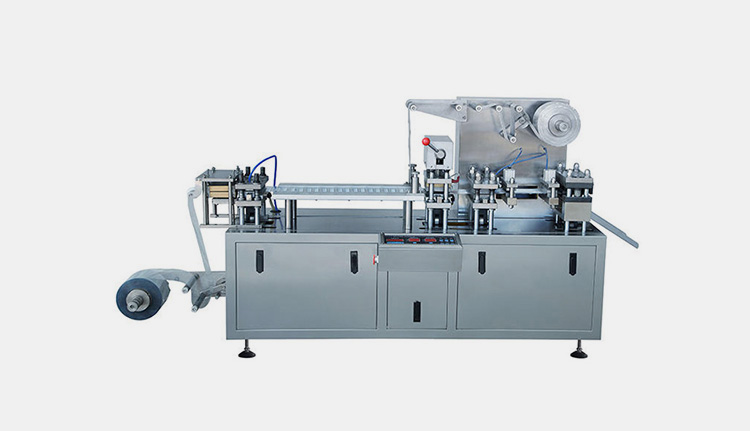

Induction Pickle Packing

Induction Pickle Packing

It is convenient pickle packing, Initially, the pickles are added to the jar and then it is sealed with the help of a machine.

Heat Sealing Pickle Packing

Heat Sealing Pickle Packing

In the heat-sealed packing, the pickle becomes sealed in the pouch or jar with heat. It is used to protect and seal pickles.

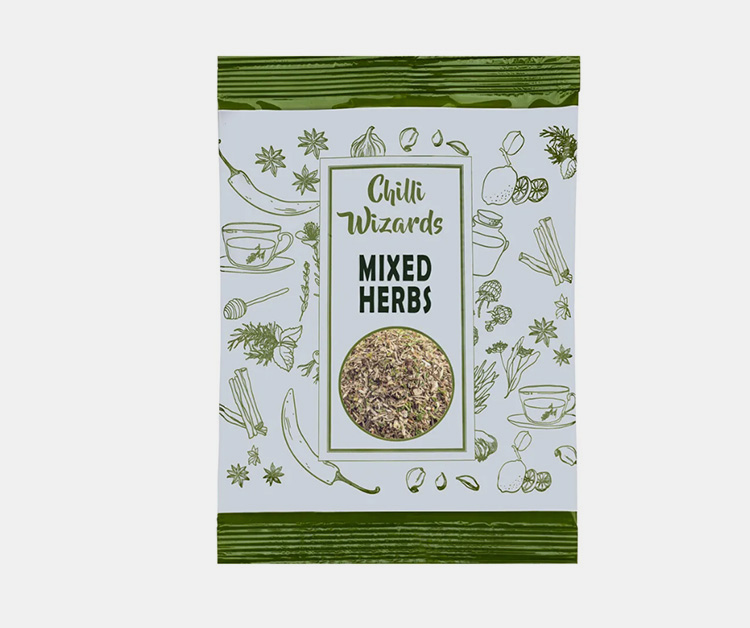

Pickle Packing- Based on Formats Pouch

Pickle Packing Pouches

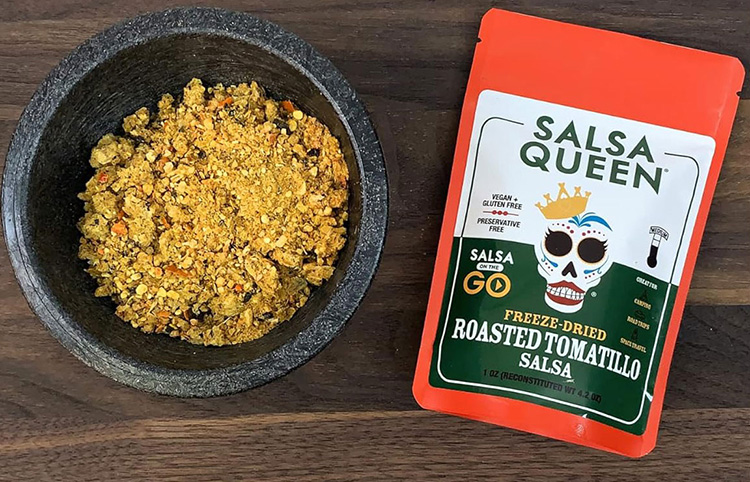

This is modern way of storing and transporting pickle where pack are commonly made of multi-layer plastic material with high levels of flexibility. The pouches are easy to carry without worrying for breakage like glass. You can find pouches of various shapes and sizes hence more user compliant and cost-effective.

Sachet

Pickle Packing Sachet

Sachet is used for packing where you need single serving and limited storage space. They are preferred for branding and testing purposes that is ideal if product has to deliver or used for short life span.

Jars

Pickle Packing Jars- Picture Courtesy: Trillian Food Australia

This is the most conventional and popular way of packing that allows you to see inside the pickles. jars are commonly made up of glass that is entirely inert and offers a strong barrier against external factors to react with pickle and ensures promising quality.

Cans

Pickle Packing Jars

It offers you a reliable way of packing which is impermeable to external physical factors hence making product with longer shelf life. Cans are suitable for long-distance shipment but due to high-temperature sealing or packaging; it is not preferred by some companies.

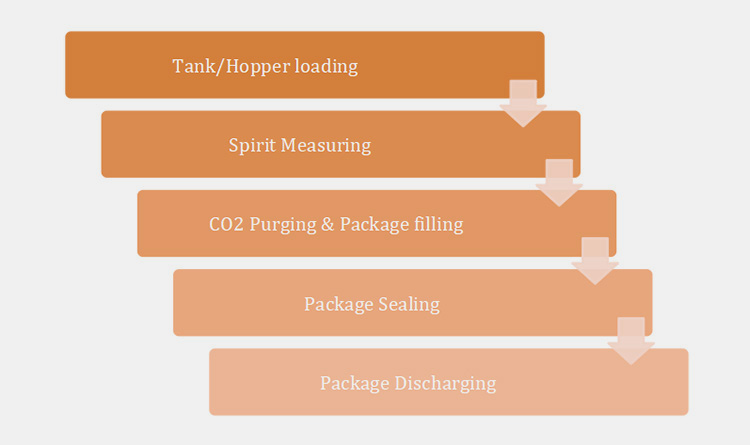

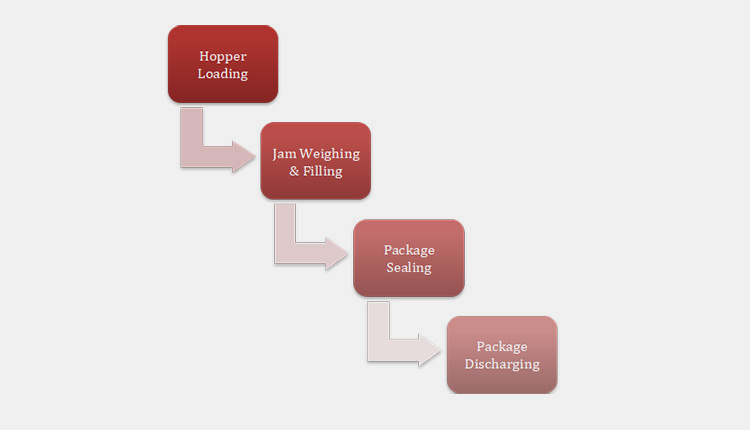

4.How to begin Pickle Packing? What is Pickle Packing Machines?

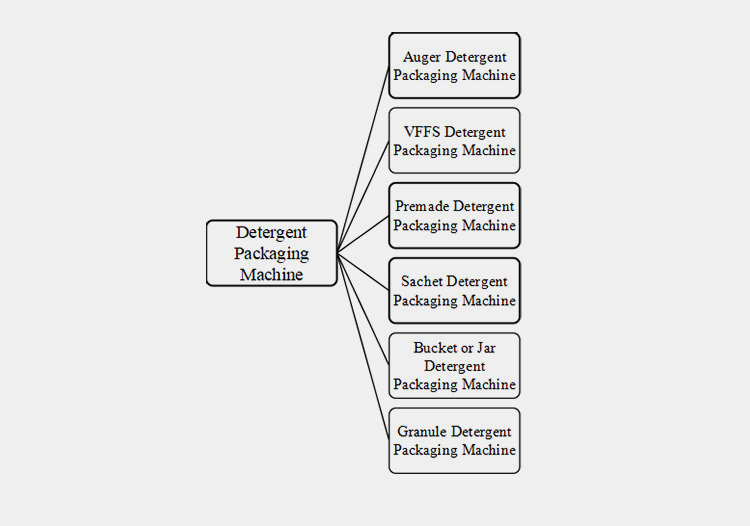

Pickle Packing is the process for packaging the pickled products in an efficient manner. The machines are the equipment designed for the packing of pickled products. These packing machines are used in food industries to increase the efficiency and quality of products.

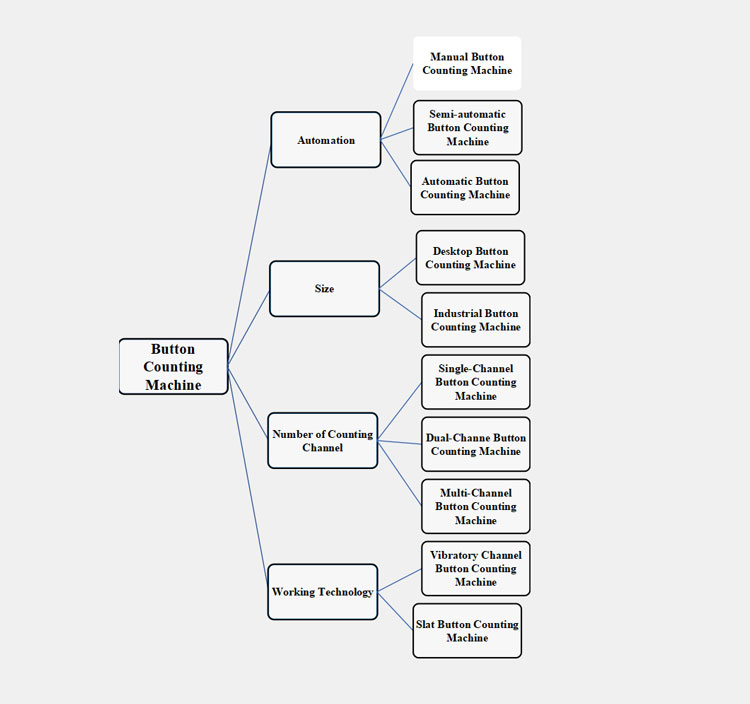

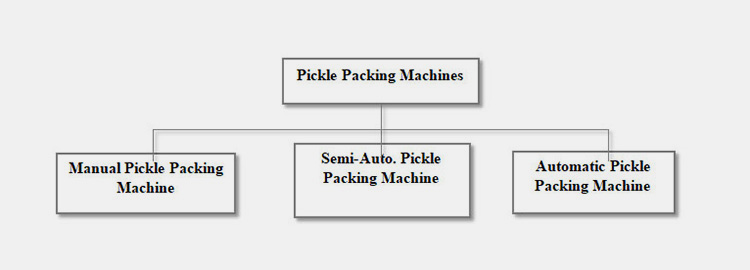

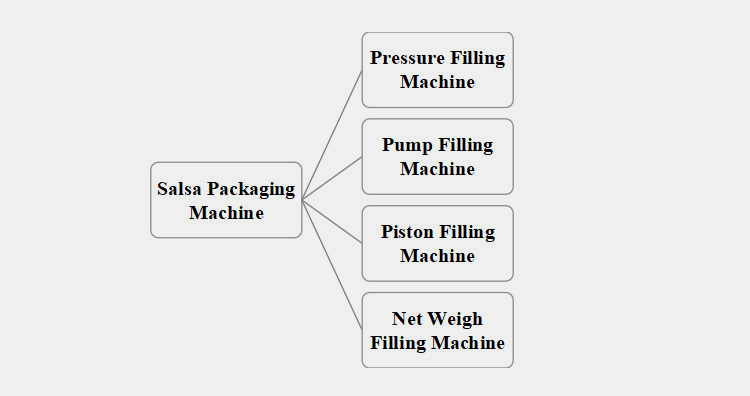

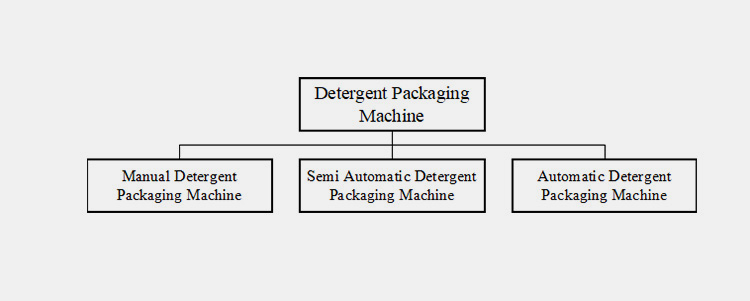

According to Automation

Manual Pickle Packing Machine

Manual Pickle Packing Machine

This machine works on manual operations. In this machine, you have to place containers for filling the product. An optimized or pre-determined amount of pickle are transferred into each packaging material via pressing the pedal or hand operated handle. Once it is filled, you need to remove it manually.

Semi-Automatic Pickle Packing Machine

Semi-Automatic Pickle Packing Machine

This machine is based on advanced technology except for feeding of packaging material.

The filling material is placed under the filling nozzle, the operator must adjust the parameters to transfer pickles into each container. Once packaging material filled, they are conveyed to the sealing station for sealing and labelling process.

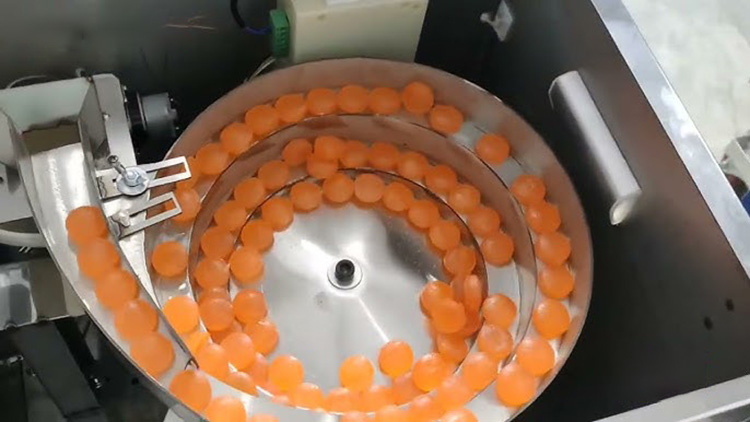

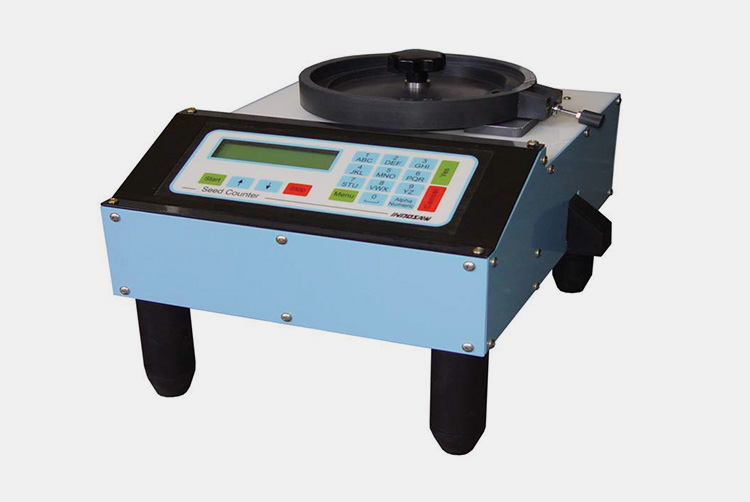

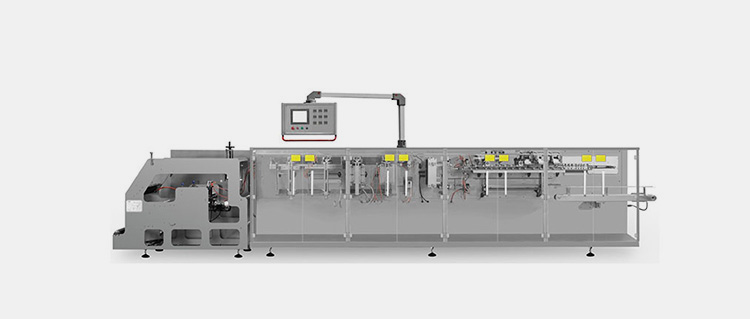

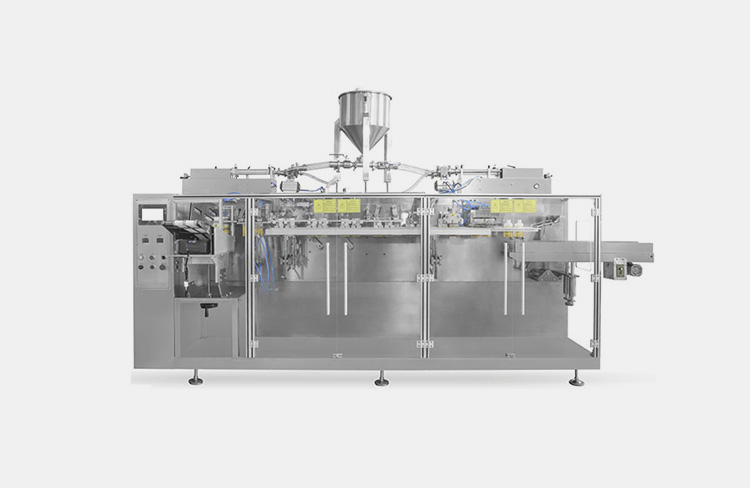

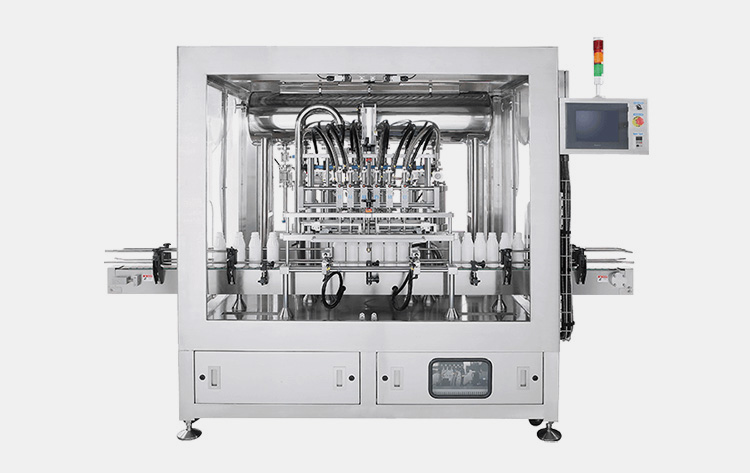

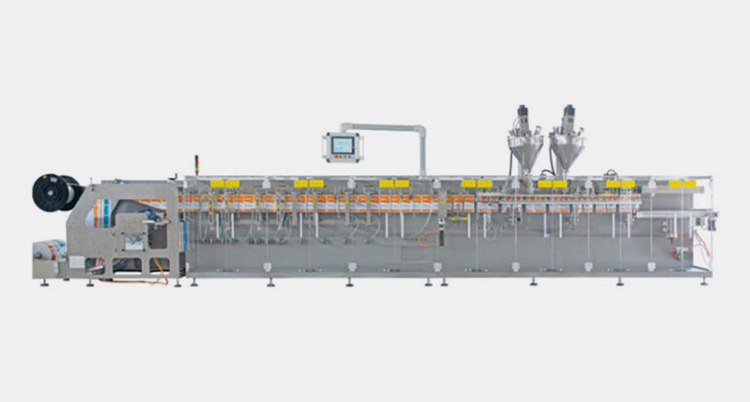

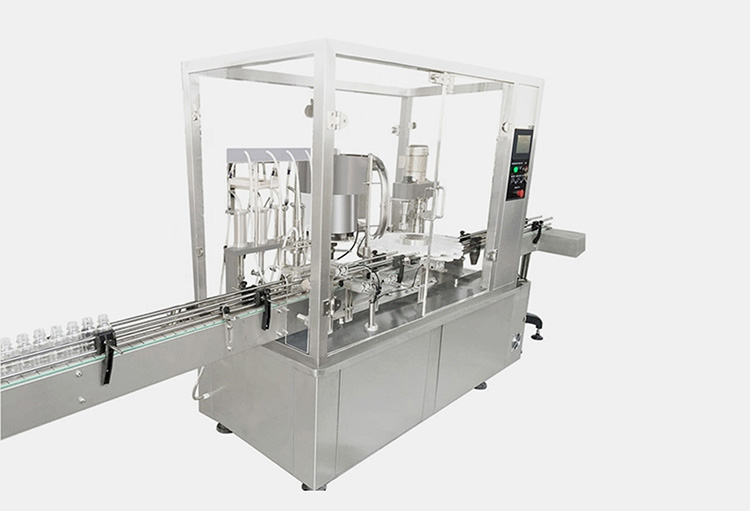

Automatic Pickle Packing Machine

Automatic Pickle Packing Machine Picture Courtesy: Allpack

This machine is used for the quick and accurate packing of solid or semi-solid products into jars and cans of different sizes. It can be operated easily because of its simple interface.

It offers automatic and quick filling of the products. The empty jars are loaded and then forwarded to the filling station for precise filling of jars. It contains a built-in weighting machine which adjusts the weight for jar. These filling parameters can be set by the machine operator. This machine helps to improve the efficiency and consistency of packaging.

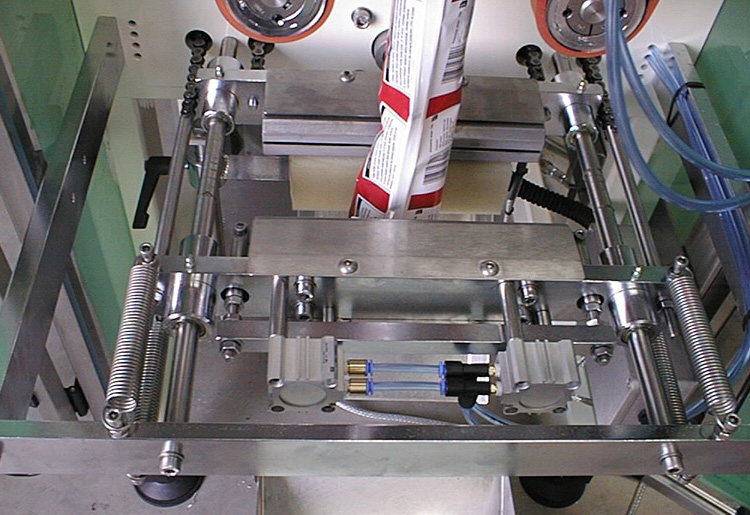

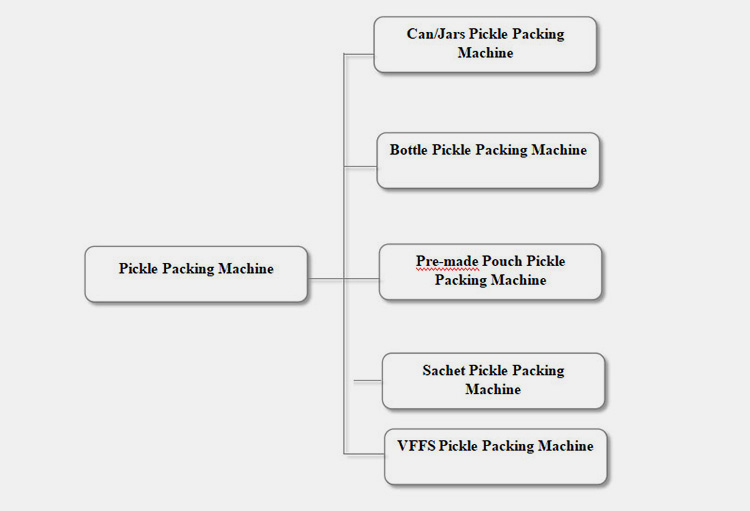

According to Packing Formats

Can/Jars Pickle Packing Machine

Can Pickle Packing Machine Picture Courtesy: Techno pack Corp

In can packing machine the empty cans are placed in conveyer system and are forwarded to filling system and for lid placing, followed by sealing process to for final sealing of cans. Its automated process reduces the number of operators and works continuously. This machine also reduces the labour costs and gives efficient productivity.

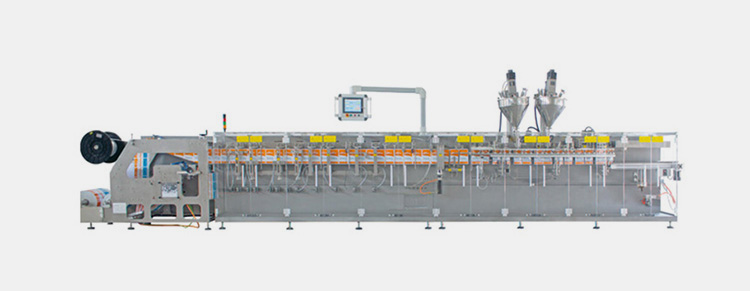

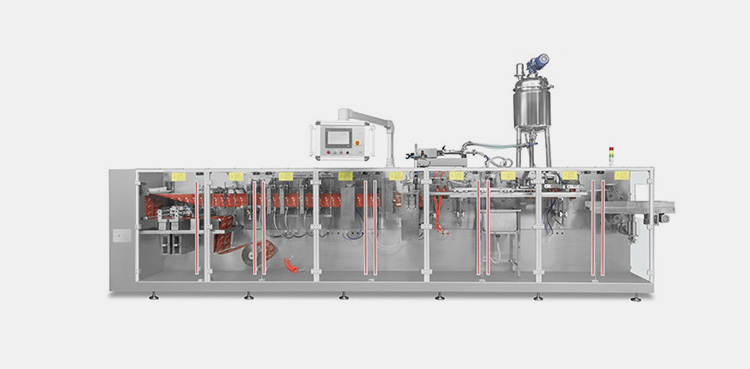

Premade- Pouch Pickle Packing Machine

Pouch Pickle Packing Machine Picture Courtesy: Allpack

This machine involves the precise filling and finishing of pouches of almost any size.

In this machine premade pouches are loaded on the machine, then these pouches are picked by gripper for conveying to filling stations. It also contains a dosing and sealing system which controls the filling and sealing of pouches.

Sachet Pickle Packing Machine

Sachet Pickle Packing Machine- Picture Courtesy: Allpack

This machine can automatically measure and fill the product into bags, also used for cutting and sealing the bags.

The working principle of the machine includes the making of sachets. Then the product is filled accurately in the sachets, by following the pipelining the sachet is forwarded for sealing and printing process. Here in this machine the sachets are made and filled with product automatically by machine.

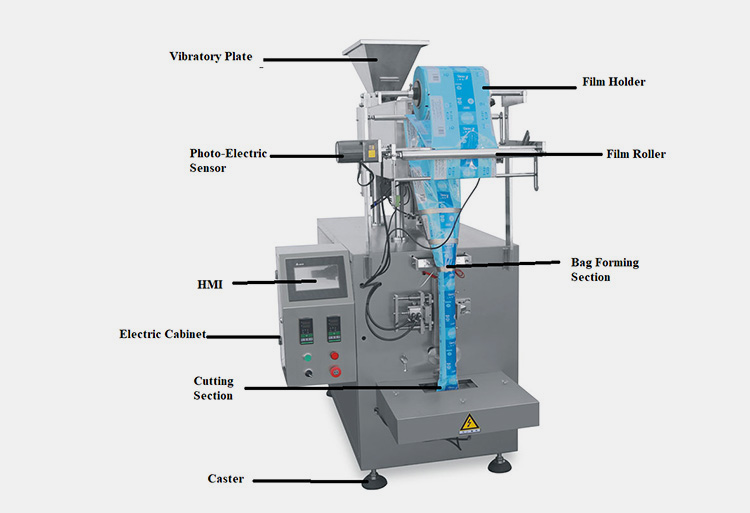

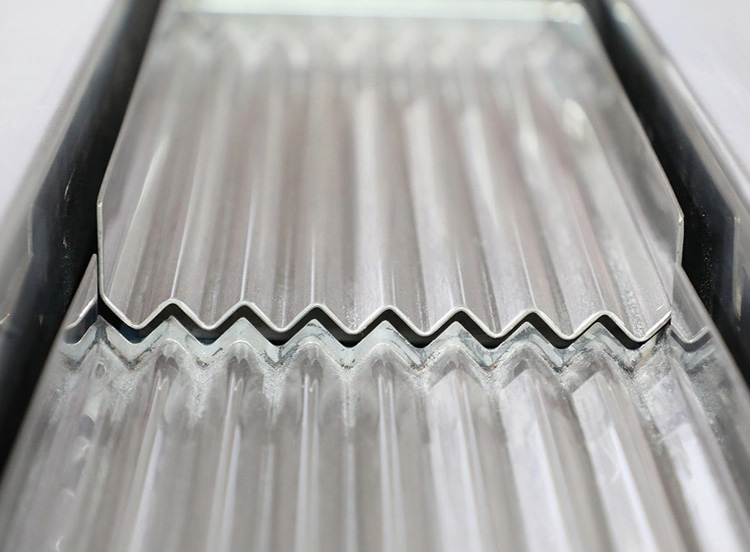

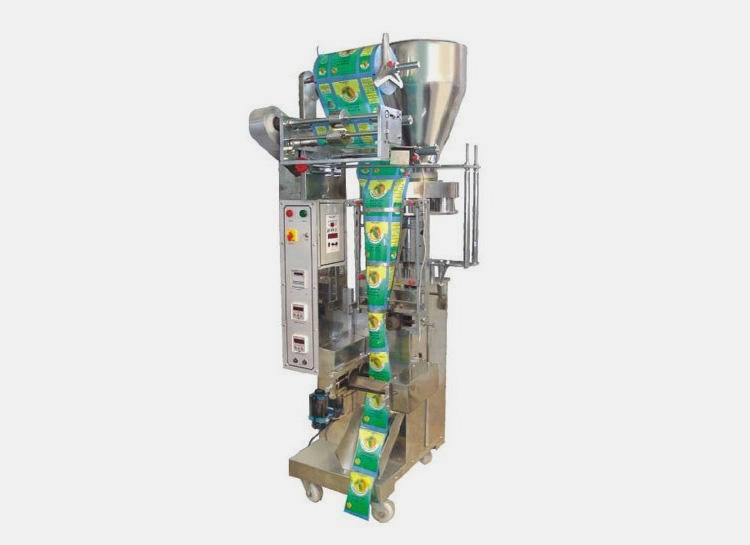

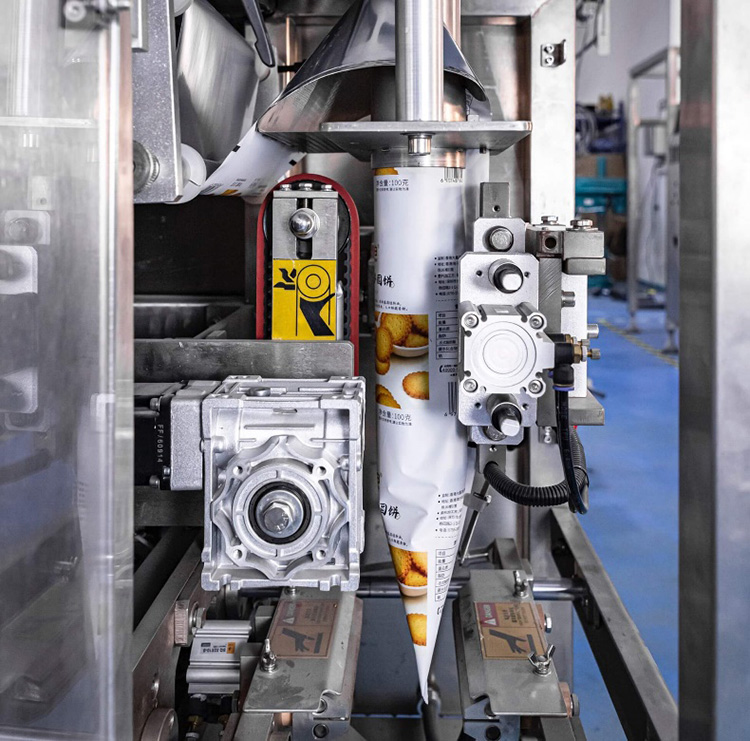

VFFS Pickle Packing Machine

VFFS Pickle Packing Machine Picture Courtesy: Allpack

This machine is mainly used for the packaging of Pickles. From the formation of bag to filling and sealing all the process is completed in vertical fashion.

The working process of VFFS packing machine starts with the creation of vertical bag by using packaging films and then the product is dispensed in the bag. The final process of machine involves the sealing and cutting of each pack.

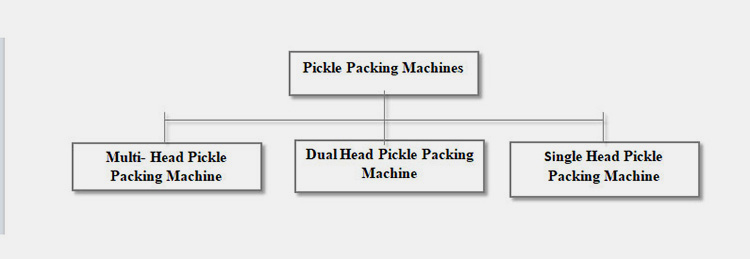

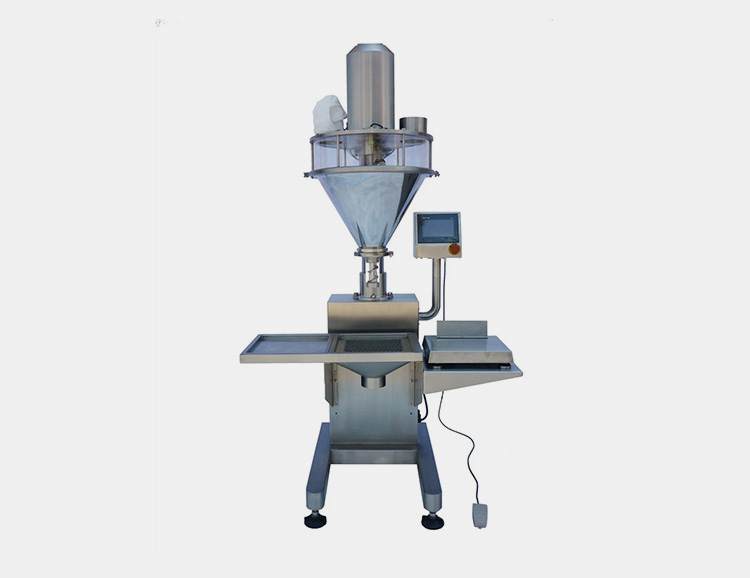

Based on Heads

Single Head Pickle Packing Machine

Single Head Pickle Packing Machine Picture Courtesy: Allpack

This machine is used for specialized packaging of small accurate and efficient pickle packs. The filling process of machine is operated by using single head for dispensing the product into packs. The additional feature of the machine involves the sealing and labelling of packs. This machine is suitable for production on a small scale.

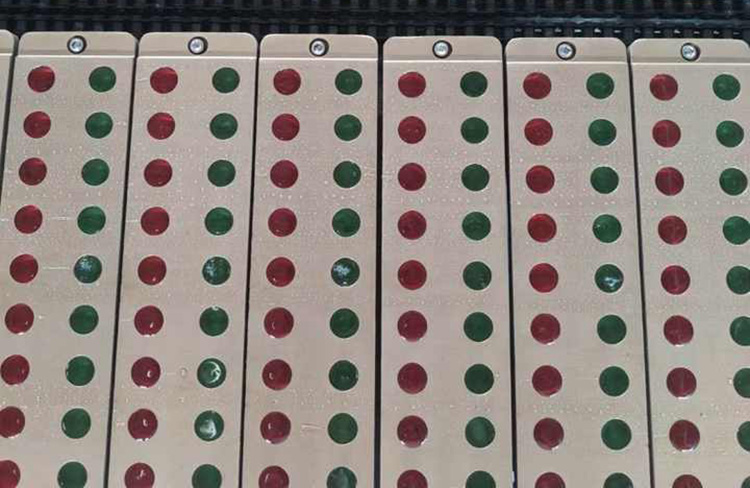

Dual Head Pickle Packing Machine

Dual Head Pickle Packing Machine Picture Courtesy: kenwei

Dual head packing machine is more efficient and quicker than the single head for the packaging of products because of dual heads working simultaneously. It can easily handle the packaging of two packs at same time.

Multi- Head Pickle Packing Machine

Multi- Head Pickle Packing Machine

This machine is designed to enhance the productivity of packing. It is much more efficient and faster than single and dual head packing machines. Each head dispenses the precise amount of product into the packets. Following the pipeline process, the packs are forwarded for the sealing and labeling process. Multiple heads of the machine make it suitable for the production on large scale.

Based on Storage

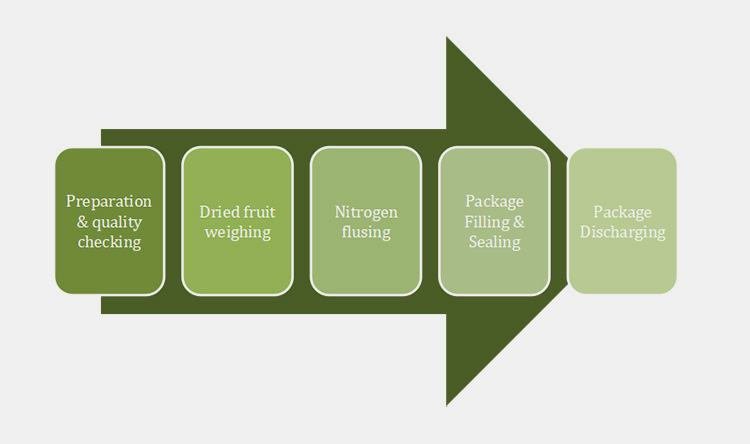

Nitrogen Flush Pickle Packing Machine

Nitrogen Flush Pickle Packing Machine Picture Courtesy: paxiom Group

Nitrogen flush packing machine is used for the removal of oxygen from packs with the help of nitrogen to maintain the taste and freshness of the product. The containers filled with the pickles are moved for nitrogen flushing and final sealing.

Vacuum Pickle Packing Machine

Vacuum Pickle Packing Machine Picture Courtesy:Allpack

Vacuum packing machine is used for the packing of pickles to preserve their freshness and quality by removing the air from the packs.

In this machine empty bags are loaded on machine and then these bags are filled with product. After filling them they are forwarded to vacuum station for the removal of air. Then these bags are moved for the final sealing.

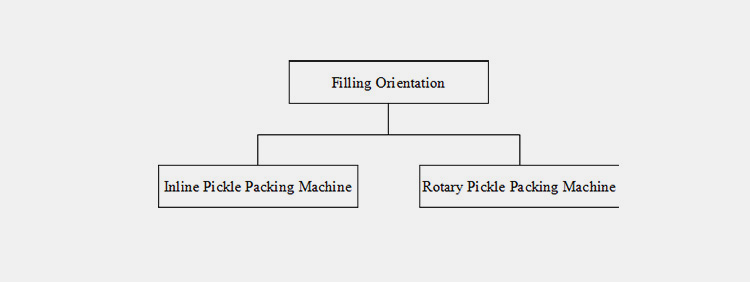

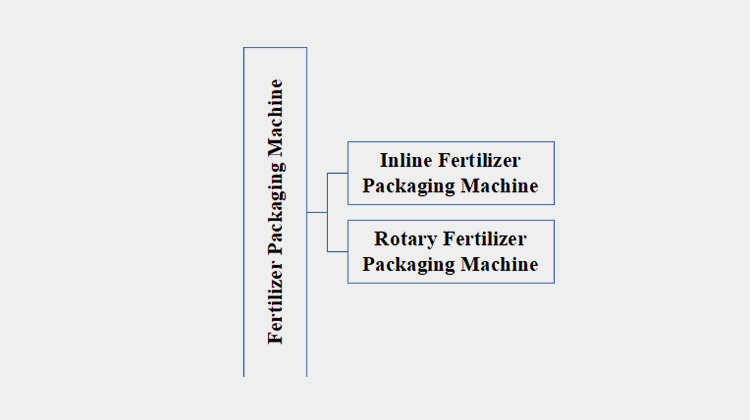

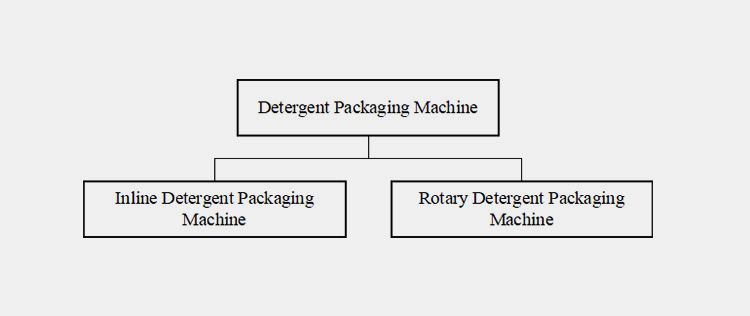

Pickle Packing Machine- Based on Filling Orientation

Inline Pickle Packing Machine

Inline Pickle Packing Machine

This is a subtle and linear configured packing machine where you can observe the working pattern carried out in a direct and inline manner. For example, entrance, filling, and discharging steps take place in a direct sequence.

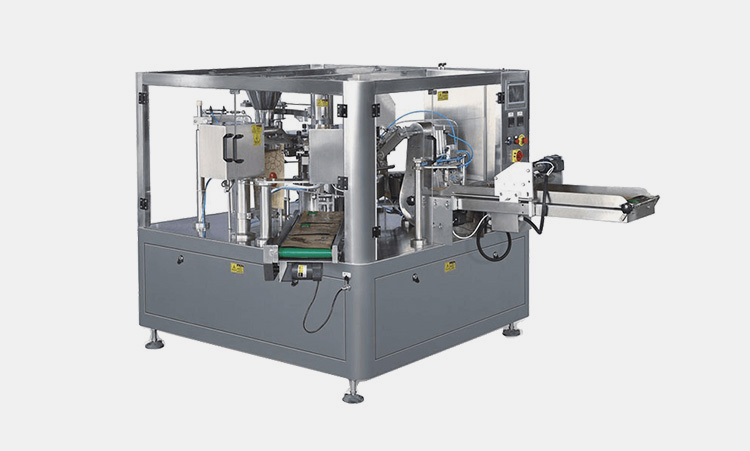

Rotary Pickle Packing Machine

Rotary Pickle Packing Machine- Picture Courtesy: Allpack

In this design, the packing procedure is carried out in a rotational manner where subjected products are fed into the machine, filled, and discharged via rotational fashion. This machine is preferred when you need to obtain high production capacity as it works in gives you high output in a shorter time.

5.What is the Difference between Nitrogen Flush and Vacuum Pickle Packing?

Many of you might be thinking of nitrogen or vacuum pickle packing as the same. But there is a huge difference between these entities.

Perhaps, the purpose of implementing these methods is to achieve quality packing.

Oxygen is the biggest culprit of pickle or foods which induce contamination and spoil your food very quickly. Therefore, nitrogen flushing pickle packing and vacuum packing is appreciated.

|

Description |

Nitrogen Flush Pickle Packing | Vacuum Pickle Packing |

| Nitrogen is the element used for preservation. It has the quality to keep food products in a stable condition. If you’re worried about its side effect, then you’ll be surprised to know that it is harmless.

The nitrogen is odorless and tasteless which keep pickles long lasting. That’s why nitrogen flush is used which is a modified atmosphere packaging (MAP) that displaces oxygen inside the packing and reserved the process of pickles or food decaying by overcoming progression of microbial growth. |

Vacuumpacking is simply involved with procedure including the suction of oxygen and other elements that are presented inside the packing prior to fixed sealing.

However, there is an optimum level of oxygen still presented inside the pack that is insufficient to induce contamination or microbial growth. |

|

|

Concentration |

The concentration of nitrogen used for the preservation of pickle are 99.0%. This is the safest and an economical way of food packing where sometimes concentration of nitrogen is depending upon brand to brand and various types of pickles. | As in your atmosphere, the concentration of oxygen is 21%; in this process the level drops down to 2.1%. For example, from 1000 millibar atm to 100 millibar. |

|

Inside Packaging

|

Pickle packing with nitrogen inside | Pickle packing with a vacuum inside. |

| Safe | This is the safest packing. | This is also the safest mode of packing. |

6.How Long is Pickle Packing Good for You?

You can Extends the Quality of Pickle Packing

Pickles are considered as the most highest shelf life food but still has an expiry date. Pickle packing shelf life is ideally based on how accurate and correctly production process has taken place and number of leakage or any cracks.

This includes types of pickle packing material, pickle packing machine, sanitary, and internal condition of the packing. For example, how tightly sealed it is, whether it is packed under vacuum or used nitrogen flush; similarly, how airtight packaging would be and so much more.

Ideally, industrialists prefer packaging time stability till the next season of pickle vegetable or fruit arrives.

In the same context, the pickle packing shelf life mostly based around six to 12 months unopened. Once you open the pickle pack, the shelf life could be maintained if kept under low temperature that do not favors microbial growth.

That’s the reason you mostly keep pickle packing refrigerated to enjoy fresh and crispy pickles as freshly prepared from farms.

In this regard, choosing the right material and the right packaging material for pickles assumes great significance.

7.How Do You Tell if Pickle Packing Goes Bad?

Pickles can go Wrong if Not Stored Properly- Picture Courtesy: Portland Monthly

Well, it is pretty easy for you to notice abnormality in pickle packing and determining that your pickles are no more perfect to consume.

You can find it by observing the color, odor, texture, and of course by pickles taste.

The presence of whitish growth over the top surface of the pickles is the first indicator to stop you and discard the pack. This whitish matter is indeed a growth, or you can call it a mold which is a positive sign of spoilage.

Remember, avoid eating soft or slimy pickles as a progression of yeast can be a factor behind this problem.

Scientifically, you can follow the rule of thumb, that narrates to discard pickle packing if its jar is bulging. Also, if you see the tiny bubbles or watery broth; stay safe and consider the pack as no longer okay for consumption.

Always remember that the fermentation can also form cloudy brine, in this case, assess the indication of spoilage, white spots, or mold.

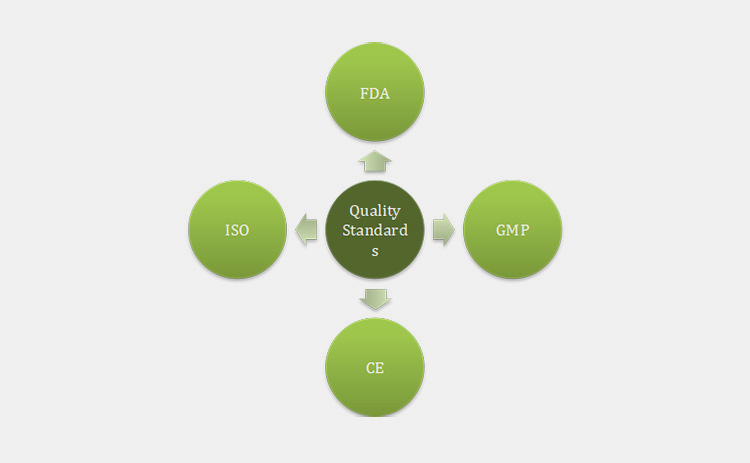

8.What is Quality Testing for Pickle Packing?

Pickles always offers you a bundle of health benefits if prepared and packed correctly.

That’s the reason, top industries always concern about your health first. For this purpose, pickle packing can reach to you after passing through various quality testings.

The purpose of these testing is to assure the packaging is best fit for transportation, without worried for leakage or contamination.

Thus, good pickle packing can improve high business. Let’s see worldwide used quality standard testing.

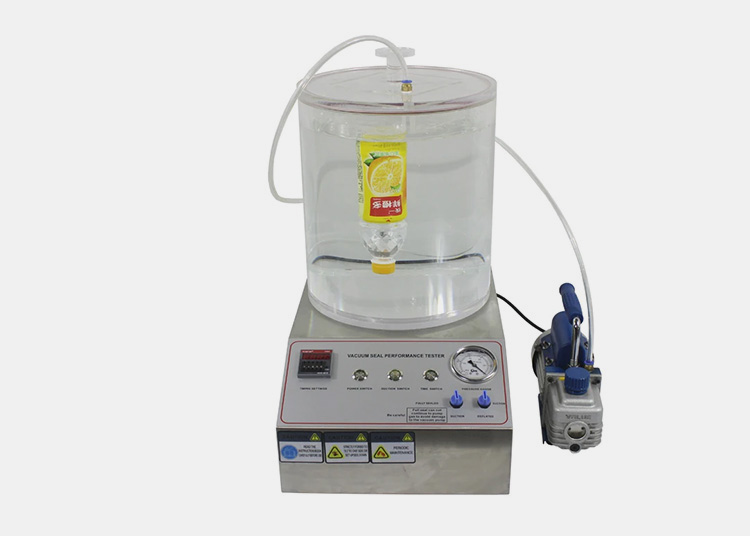

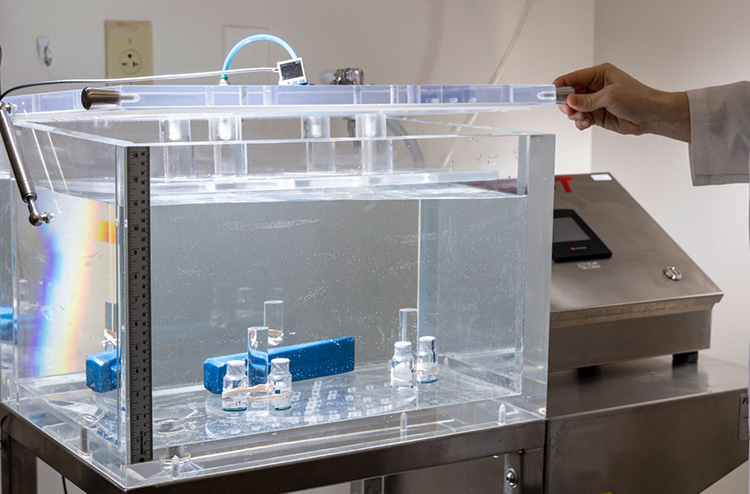

Bath Leak Testing

Bath Leak Test- Picture Courtesy: Sealtick

This is the most efficient method to assess the correctness of the pickle packing.

Once the pickle packing is finalised the final testing is done by submerging the pickle pack into an enclosed tank which is filled with water.

This system is well controlled, under vacuum and with transparent walls you can easily observe the emergence of tiny bubbles in the water which indicates the presence of hole or leakage in the pickle pack.

This is very promising method and can be carried out in a cost effective manner that help to tell you number and area of leakage.

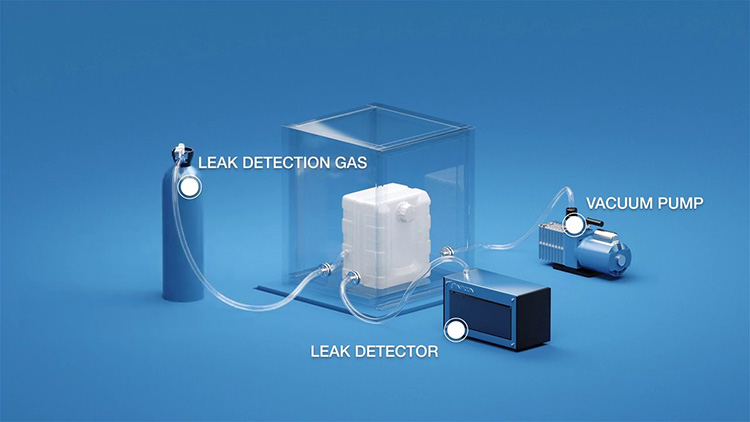

Pressure Decay Testing

Pressure decay testing

This is a widely used method to determine pickle packing quality packaging.

The test is taken and placed under reduced controlled environment.

Here, the pickle pack is subjected to a chamber where you can induce pressure over the packing material. A tester is used to measure the amount of pressure applied over the packaging. If the time taken to reach the optimum is more than expected, it simply considered as the presence of leakage. Conversely, if the time to build pressure is optimum then it assure the packing is ok for final step.

Optical Laser-Based detection system

Seal Leakage Detection Test- Picture Courtesy: MoveTherm

With the advent of modern technology, advanced machines and various innovative tools, you can also offer with Optical-based laser based detector system to detect pickle packing leakage or packing problem.

This is an effective way where the wavelength is responsible to identify the leaking of pickle packing.

By using CO2 gas with a narrow beam of IR where the absorption CO2 is helpful in displaying the signal. If you get the demonstrated wavelength as specified location it will be considered as leakage presence.

9.What are pickle packing problems and what should be the solution?

Some common problems during pickle packing can be solved- Picture Courtesy: Designerpeople

Working with the packing process with modern and advanced machines are now much easier than conventional packaging. Anyhow, there are still some common problems that everyone faces even today. We have enlisted those issues with technical troubleshooting below:

Problem 1: pickles stuck in the machine

Reset the Operating Options can correct Pickle Jamming

This problem is accompanied with difficulty in the flow of pickles toward the packaging material which could be due to either incorrect installation of the hopper or material blockage.

To solve this problem, our expert recommends resetting the hopper setting that allows an easy flow of pickles following a force of gravity.

By use of hopper featuring stirrer can ease the dropping of Pickles faster with more precision and accuracy.

Problem 2: Inaccurate Pickle Packing

Machine must be accurate in pickle packing

The machine mostly offers 99.99% precision in order to offer promising filling but sometimes due to incorrect selection of filler type the machine could result in inaccuracies.

For instance, you can’t select auger filler for pickle filling. Similarly, it is recommended to use piston filler when it comes to attaining accurate pickle filling that works on a volumetric pneumatic way.

Problem 3: Foaming in Pickle Packing

Pickle Packing Must be Cleared and Aesthetically Pleasant- Picture Courtesy: KAHAN int.

The packing is a finished and refined method that allows not only accurate filling but a cleared one as well. Sometimes you notice foaming on the upper level of the pickles which is undesirable for the final packaging.

To avoid this problem, it is recommended to use diving Nozzle Mechanism which is specialized way to overcome the formation of foams or bubbles and giving you finest packing without spillage.

Problem 4: Leakage Of Pouch Pickle Packing

Pickle Packing Must Be Leakproof For Easy And Durable Shipment

Sometimes you may face undesirable issues when pouch filled with pickles starts leaking. It could not only waste your valuable product, precious time but side by side it can mess working surroundings.

The problem caused by a little malfunctioning or error in heat sealers.

To correct please correct the setting of heat sealer up to the edges of the pouch to be sealed. Fix the temperature of heat sealers.

Last but not least, go through settings calibrate the process using PLC and run a test to determine the process before running the final.

Conclusion

Pickles are just fun treat for craving and salty moment where freshness, crunchiness and freshness stimulate your happy hormones. But right pickle packing and excellent pickle packing machine are the well-deserving partners who cares your happiness! If you want to be among those trustworthy producers- Just choose our machines that will give promising throughput. Allpack is an ideal place that offers one-stop-solution for pickle packing in your budget. Please contact us to begin new journey of success now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Pickle Packing: The Complete FAQ Guide In August 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours